Professional Documents

Culture Documents

Cdna10040enc 001

Uploaded by

Sachin PayyanadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cdna10040enc 001

Uploaded by

Sachin PayyanadCopyright:

Available Formats

Commission of the European Communities

physical s c i e n c e s

ADVANCED STEAM TURBINE POWER

PLANT TECHNOLOGIES

AND THE MATERIALS IMPLICATIONS

Commission of the European Communities

physical s c i e n c e s

ADVANCED STEAM TURBINE POWER

PLANT TECHNOLOGIES

AND THE MATERIALS IMPLICATIONS

P.R. Sahm, E. Fiender

Foundry-Institute

Aachen Institute of Technology

DG XII JRC, Petten Establishment

Directorate-General

Science, Research and Development

1985 EUR 10040 EN

Publ i s h e d by th e

COMMISSION OF THE EUROPEAN COMMUNITIES

Di reet o ra te -G e n e ra I

In forma ti on Ma rke t a n d In n ova ti on

Bti me n t Je a n Mon n e t

LUXEMBOURG

LEGAL NOTICE

N either the Commission of the European Communities nor any person

acting on behalf of the Commission is responsible for the use which might

be made of the following information

Cataloguing data can be found at the end of this publication

Luxembourg, Office for Official Publications of the European Communities, 1985

ISBN 92-825-5549-6 Catalogue number:

ECSC-EEC-EAEC, Brussels Luxembourg, 1985

Printed in the Netherlands

CONTENTS

SUMMARY

1. DEFINITIONS ANS SCOPE OF THE STUDY

1.1 SUBJECT OVERVIEW

1.2 OUTLINE OF SCOPE

2. STATE OF THE ART TRENDS

2.1 THE POWER CONVERSION SYSTEMS

2.2 PLANTS AND EFFICIENCIES

2.3 NATIONAL EFFORTS

2.4 MATERIALS TECHNOLOGIES

3. FUTURE R&D

3.1 ECONOMY OF STEAM POWER PLANT

3.2 TURBINE DESIGN AND ENGINEERING

3.3 MATERIALS AND COMPONENT MANUFACTURE TECHNOLOGIES

3.4 TECHNOLOGY MIX (R & D IN MATERIALS PROCESSING)

4. CONCLUSIONS

5. REFERENCES

PREFACE

The Joint Research Centre of the Commission of the European Communities, Petten Establishment,

is executing a High Temperature Materials Programme. It provides a scietific service to European

industry, being concerned with materials information, data handling and direct research projects

for relevant areas in energy and industry, including power generation and utilisation, which

require materials for long term service in high temperature aggressive environments. The

programme, through its Information Centre project promotes, coordinates and conducts studies

to evaluate materials behaviour in critical areas of industrial processes.

During the past half century, European power producing industries have made a large investment

in materials research to improve the efficiency and reliability of steam turbine plant. However

many problems remain which will be intensified by the continuing drive towards these twin

objectives. The present study was therfore commissioned as part of a data gathering exercise for

the planned further review of the technological requirements for high temperature materials

R&D. Its aim was to evaluate the potential for improving the effiency of steam power plant by

operating with higher steam inlet temperatures, to assess the associated technical problems and

to identify R&D requirements. Specific objectives were to:

- examine the current status of knowledge on the thermodynamic and engineering concepts for

a high effiency steam turbine to operate at 700C or higher, probably with supercritical steam

at ca. 30 MPa,

- assess the incentive for an Advanced Steam Turbine, for instance in respect of the cost

benefits which would arise from the succesful use of these conditions,

- identify the problem areas where critical material R&D is needed to enable the target

conditions to be used reliably and safety for a design life of 250 000 h.

The HTM programme acknowledges the scientific input made by the authors and wishes to take

this opportunity to express its grateful thanks to them for the conscientious and industrious

manner in which they tackled the study and responded positively to the objectives.

M. Van de Voorde

Programme Manager

J.B. Marriott

Technical Coordinator for the study

Commission of the European Communities

Joint Research Centre

Petten Establishment

CEC Contract No. 320046

This report was prepared by Prof. P.R. Sahm and Mr. E. Fiender, R.W.T.H., Aachen, Germany,

under contract to the Commission of the European Communities (Joint Research Centre, Petten).

Copyright remains exclusively with the Commission of the European Communities.

No extracts from this report may be reproduced without the prior written consent of the Director

of the Petten Establishment of the Commission of the European Communities.

The source must be Acknowledged.

SUMMARY

Assuming the background of a relatively conventional scenario of

steadily rising energy costs and increasing environmental constraints

steam turbine cycles employing primary and reheat temperatures in the range of

750 to 800C at pressures of 500 to 600 bar appear to be reasonable to thrive

for as thermal efficiency gains of at least 5% may be realized. In terms of

feasible cost increases of plant both with respect to invested per kWh and

tolerance limits for R & D money expendable over a period of about 10 years,

R & D towards this goal seems interesting.

Befor: starting out on a conscious effort in "materials and technologies for

post-next-step steam power plant" (the "next step" is currently well underway

on a national effort basis at least in two economic world regions: USA and

J apan) , another 3 year period of more detailed preparatory studies seems appro-

piate.

The "next.step-steam-power-plant", underway within US and Japanese national

efforts, does not lean on substantial technological breakthrough (except possibly

for the steam raising process in J apan) . It thrives for temperature and pressure

ranges about 560C and 240 bar, but not more than 650C and 350 bar) that have

been utilized for a number of years in smaller, industrial type power plants.

While the problems here may be characterized by

transfer of experiences with medium size units (50 to 150 MW)

to large units (800 to 1300 MW)

the problems of "post-next-step-steam-power-plants" are

entering fully a class of materials, i.e. austenitic steels, with

which little or no large scale experience has been collected so far.

Simultaneously, this may mean entering looking for new materials technologies

or switching from one to another class of materials processing or, in effect,

taking on new processing sequences ("technology mix") not heretofore practiced.

The advent of CAD-CAM makes computer simulation and modelling an important

partner of this R & D effort.

1. DEFINITIONS AND SCOPE OF THE STUDY

Consumer preference for electricity as a clean, versatile energy source has

been clearly demonstrated in recent years, and increased electrification of

industry is inevitable. Electricity has unequalled ability to speed automa-

tion and increase productivity, and new microprocessor technology will increase

that ability further. The competitiveness of industry will thus depend in

some measure on the price of electric power. Whilst a number of ways of

raising steam are available, e.g. by burning coal or oil, by the fissioning

of uranium in reactors cooled by water or COp the steam turbine/generator

remains the most widely used vehicle for turning heat into electricity.

Efficient steam turbines are therefore a cornerstone of prosperous economies.

1.1 SUBJECT OVERVIEW

Figure 1.1 a indicates the importance of the steam turbine in terms of conver-

ting the world's energy resources into electricity. It illustrates its unique

significance for both the entire earth's and the individual nations' economies.

Because coal appears to be particularly suitable as a fossil fuel source for

the steam plant energy conversion process, Western Europe as one of the world's

four coal rich regions, figure 1.1 b , must be concerned with more efficient

future technologies.

In simplest terms, figures 1.2 a to 1.2 d present the water steam cycle of a

steam turbine power plant including an overall view of the entire process with

auxiliaries in figure 1.2 d. The theoretical basis for this energy conversion

process was laid down by Carnot in 1824. It yields a theoretical efficiency which,

in practice, can only be asymptotically approached due to various losses along

the technical process loop and the non-useable heat content of the liquid. Fi-

gures 1.3 a to 1.3 c illustrate these loops and simultaneously indicate the

essential terminology utilized in the description of the technical process.

Figure 1.4 expands on the definition of the Carnot efficiency.

... quoted from COST statement, 1981

Distribution of coal resources

Western

Europe

Middle East

/ 8

NDrth Atnco

Japan

SouthAfncaf

production consumption

^ ^

Energy production and consumption

U. Renz 1982

2:

5i 100

BC

6 G

0

20).

O water

O coal

O lignite

+ mi neral oil

gas

nuclear

V y

0

; >

* * $

$ ^

$

o o

o o o o o o

o o o o O

i i a Q a Q o o o o Q o o Q Q n o o o a n O n n o o o p ) ! ;

1 1 1 1 1 1 1 1 1 1 r 1 J' >

o

* .

C

B c

E*

a m

Ha

/

1950 1954 1958 1962

year

1966 1970 1974

c

'

3

Th. Bhm et al. 1977

100

so

20

10 -

st-nm turbine

gas turbine

hydroelectric

11%

13%

all other

_l

1 %

1960 1965 1970

year

1975 1980

USA electric power generation

installed capacity

W G . Steltz 1980

Figure 1.1: In terms of

energy conversion pro-

cesses the steam turbine

power plant is based

mostly on coal combustion

( a ) ; for countries having

to import most of the ener-

gy resources ( b) high

efficiency processes are

particularly relevant; for

countries well equipped with

coal resources high effi-

ciencies are mandatory due

to cost comparison with other

energy conversion forms.

generator

S tedin rai s ing uni t

(SIW)

(a)

Schroeder

1962

y/7777 V///' 777? electrostatic '//// '

J

'/////

coal yard pul veri zers preci pi t at or i . d. fans SO2 absorbers

stack

>)//// R.I. Jaffee

1979

Figure 1.2: The principle of a steam turbine electricity generating plant

stems from the ability of superheated water vapor to perform work. The steam

cycle, illustrated in (a) and (b) requires a series of engineering designs and

materials (c) that have to cope with extreme mechanical stresses and environ-

mental attack (e.g. corrosion) while being exposed to elevated temperatures,

but also, in turn, burdening the environment (atmosphere and water) with non-

natural emanations like NO and SO, see also figure 1.2 d.

Figure 1.2 d: T he flow chart of the lignite steam power plant at Miederau en of RWE illustrates complex ities

of interconnections.

8

condensate

pump

5.000 1.250

. 5 ..ooo

c

Q)

-

r>

cr

-3. 000

Q.

1/1

"

C

ZJ

.

- 2. 000

=3

1/1

1/1

CX

1.000

=51.000

:

c

-

-C

11

&

)

CD

1

CU

-J

a

a

E

Q'

-*-

750

500

250

reheater

1 el ectri c

Lrtfi generator

i

boiler feed

pump

1

I

low

pressure condenser

turbi ne

1.000

W. Hossli 1969

Figure 1.3 a: Steam temperature, pressure and volume are the critical factors

in the design of a steam power plant. The curves show how these three factors

vary throughout a typical system. Pressure is highest at the exit of the feed-

water pump leading to the boiler. At the entrance to the-high-pressure turbine

the pressure has dropped somewhat to around 2,400 lbs/in in this example. There-

after it falls rapidly as it passes through the turbine cascade. The steam

temperature is raised to 1,000 F in the superheater and again in the reheater,

finally plunging to about 80 F as it leaves the low pressure-turbine. The spe-

cific volume of the steam varies over the greatest range and is therefore plot-

ted on a logarithmic scale. At eh inlet to the high-pressure turbine one pound

of steam occupies about 0.3 cubic foot. When the steam leaves the turbine cas-

cade, it occupies about 300 cubic feet.

Iff g? g

O 1 3 L 5 6 7

s . kJ/ kg K

q.j heat into economizer

q2 heat into vaporizer

q3 latent heatot evaporation

into vaporizer

q, superheat into superheater

(b)

3 L 5 6 7

s. kJ/kg K

q

T

usable energy

q non usable heat content

of liquid

Figure 1.3 b and c: T he steam turbine cycle delivers energy by an efficiency which

is determined by that amount of heat which is being cycled above ambient tempera-

ture T

a

( b ) . T he sk etch in ( c) indicates the various heat inputs and outputs along

the cycle.

10

\

\ \

0

QT

* = constant

\V\

"12 = VX} ,

^ \V3

\

^ \ " ^ J i = const.

\

S

O \ q 3 4 = 0 ^

/ J V .. _ Ju = const.

qjl at Tu = const\

T)th,

g l

q

nl

l^ i i l

1 2 compress, adiabatically (q

12

= 0) from p, to p

2

temperature rises from T

TT

to T

T

2 ^ 3 expand, isothermally (Tj = const) from p~ to p

3

;

heat qjis added

3 ^ 4 expand, adiabatically (q

34

= 0) from p

3

to p.

temperature decreases from T, to Try

4 compress, isothermally (TJ T = const) from p, to p,

heat qrj is extracted

1.4: The pV diagram illustrates the theoretical Carnot effi

to be arrived at from comparing heat input and output by

ng through a cycle of pressure and volume changes (Carnot

Figure

ciency

fol lowi

cycle).

The history of steam plant electricity through its approximately 80 years of

existence, figures 1.5 a and b, reflects a relatively steady rise in tempera

tures and pressures of the working fluid. It is particularly noteworthy that

much of the progress made with respect to rising efficicencies was closely

linked to improved materials and their technologies. Figure 1.6 exemplifies

the development of alloyed steels for turbine parts, in particular blades,

rotors, and casings.

11

K

During t hi s period European power producing i ndustri es have made a large i n-

vestment i n materials research to improve the ef f i ci ency and r el i abi l i t y of

steam turbi ne pl ant . However, many problems remain. Some of these are associated

wi t h the steady growth i n uni t size of turbines which, f or example, leads to

requirements f or l arger forgings and castings wi th associated problems of

qual i t y and properti es. Furthermore, the use of high output uni ts leads t o

very high costs of outages (pl ant shut-down) which resul ts from unplanned re-

pairs when component f ai l ur e occurs. For the same reason there i s pressure

from the u t i l i t i e s to increase times between scheduled maintenance periods.

The need to minimise losses due to outages has led to increased ef f or t s t o

improve component r el i abi l i t y and thereby to reduce di rect operating costs.

Other problems ari se as a consequence of the changing circumstances i n which

the el ect r i ci t y generating i ndustri es i n many i ndust ri al i sed countries now

operate. For example, el derl y pl ant or i gi nal l y designed f or base-load operation

has frequentl y to be used f or peak-lopping wi th rapid st art -up and shut-down

which can be hi ghl y damaging to cr i t i cal components. The l i f et i me of pl ant

working i n t hi s way cannot readi l y be estimated. Al so, benefi ts i n increased

ef f i ci ency resul t i ng from higher operating temperatures, par t i cul ar l y i n the

smaller i ndust r i al t urbi nes, place new demands on t r adi t i onal materials and

provide the i ncenti ve f or the development of improved al l oys*

Besides such a strai ghtforward house-keeping act i vi t i es ( r el i abi l i t y , remnant

l i f e , maintai nance) f ut ure R&D has to center on improving today's technical

status both on the level of the

simple evolutionary scale ( i . e. improvements made on l ocal and small scale)

and, i f at al l possi bl e, even more so on the

more-than-evolutionary scal e, i . e. preparing f or the next generation(s)

of steam turbi ne el ect r i ci t y production.

* quoted from COST 505-statement, 1981

12

% C bar

r

300

rcast

iron

250 h

600

550

40I500

30

20r

3 5 0

101300

h i gh l y al l oyed steels

p

pioneer pl ant s '

average"pTats

'y.

thermal ef f i ci ency

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

year

^adopt ed and extrapol ated from data by K. Sch roeder 1962 and K.J. Irvi ne 1975

Figure 1.5 a: Since steam turbines came i nt o use around 1900 a rapid development

of higher power and ef f i ci ency uni ts took place. When 1300 MW uni ts were i nt r o

duced ef f i ci ency was less emphasized f or the sake of keeping components under

bearable operating condi t i ons, i ncl udi ng the low temperature steam nuclear

power pl ant s.

13

IM

cx

U 3

t.

.

C

L. -

. e

tu c

<-

<>

3 5

01 C

Ol o

'a:

WO ]SX

mo mo ;;:

\ ^ 1 au s ten i tes

= l ow a l l o y ^ s ^

j creep

ow al l oy s t e e l ^ ^ s i s u n ^

chemical softening

chemical prepuri fi cati on xj ei oni sat i on

and evaporation

v

^

V

N

V

radi ant t ype ?^

\

b O l e r

t

f lo w b o i le r

f

,, . v ve r t i c a l t u b e

full s i z e \ b o i le r s

b o i le r

s

piston steam engine

^

number of turbine cyl i nder: one . , ,

t w0 t 0

three

t hree t o four

i.

Ol u kW/m

5

mo mo

s o o t

: : : : .

__ hard coal.

brown

__ coal

hard coal , high _ oi l ,

_ash content __Z

ga s ,

1910

m

y..

nx

'.: ,.;

: .

. Sc hr o e de r 1962

Fi gu r e 1.5 b : The de ve lo pme nt of steam t u r b i ne po w e r plant resulted i n an

i nterplay of va r i o u s e le me nt s such as s ys t e ms , c o ns t r u c t i o n, ma t e r i a l, feed

w a t e r qu a li t y and steam rai si ng u ni t s .

14

heat resistant steel high temperature

resistant steels

I

C

o

o

o

o

o

400 500 600 700

temperature, C

1.CoCr20Ni20W

2: X40CoCrN2120

3:GX8CrNiNb1613

800

(NI

E

E

eh

_*

a

D

".

O

-

.

ai

(_

_c

50

40

30

20

10

^^

O "

^ ^ ~ -

. ^ +

^

o

rj i

u

>. O

D

C

3

^-

>

o

. i . rvi

^ t _

M

550C

K. Roesch and K.Zimmermann 1966

Fi gure 1.6: An i nt er est i ng example of th e sequent i al improvement of low

al l oy st eel s' creep r upt ur e beh avi or f or el evat ed temperature use i n

steam t ur bi nes has been gi ven by K. Roesch and K. Zimmermann. Higher

temperatures r equi r e h i gh er al l oyed st eel s.

bearings

r ot or s AEG Publ i cat i on 1963

Fi gur e 1.7 a: T h i s "opened machine" view present s t h e main t ur bi ne components

of concern i n t h i s st udy.

15

It a p p e a r s a s if, p r e s e n t l y , b o t h t h e p o l it ic a l a n d e c o n o m ic s c e n a r io s h a v e

s e t t h e s t a g e fo r a n e x t m o r e - t h a n - e v o l u t io n a r y s t e p ( s e e s e c t io n 2 . 1) .

1.2 OUTLINE OF SCOPE

In the l i ght of the aforesai d, an overal l obj ecti ve f or f ut ure R&D should be

to improve the ef f i ci ency and r el i abi l i t y of steam turbines by better knowledge

of materials behavior i n conditions relevant f or servi ce. The speci f i c technical

objectives should then be:

- to improve the ef f i ci ency by better or new desiqns \ ,

3

future

of turbi ne components \

\ o r ie n t e d

- to e n s u r e t h a t m a t e r ia l s w it h a de q u a t e p e r fo r m a n c e { . . ^.

\ o b je c t iv e s !

a r e a v a il a b l e to m e e t n e w de m a n ds J

- t o p r o v ide an im p r o v e d b a s is fo r t h e e s t im a t io n o f r e m a in in g \ h o u s e

l ife in c o n s e r v a t iv e l y de s ig n e d t u r b in e e q u ip m e n t * > k e e p in g

' o b je c t iv e s

In p a r t ic u l a r , t h e fu t u r e o r ie n t e d o b je c t iv e s de m a n d t h a t t h e s t u dy is a im e d t o -

w a r ds e v a l u a t in g t h e p o t e n t ia l fo r im p r o v in g t h e e ffic ie n c y o f s t e a m p o w e r p l a n t

by o p e r a t in g a t h ig h e r s t e a m in l e t t e m p e r a t u r e s a n d p r e s s u r e s a n d t o w a r ds a s s e s -

s in g t h e a s s o c ia t e d t e c h n ic a l p r o b l e m s fo r t h e s a k e o f ide n t ify in g R & D r e q u ir e -

m e n t s . S p e c ific o b je c t iv e s a r e t o :

- e x a m in e t h e c u r r e n t s t a t u s o f k n o w l e dg e o n t h e t h e r m o dy n a m ic a n d

e n g in e e r in g c o n c e p t s fo r a h ig h e ffic ie n c y s t e a m t u r b in e t o o p e r a t e

a t > 6 50 C w it h s u p e r c r it ic a l s t e a m a t ^ 2 4 MPa ,

- a s s e s s t h e in c e n t iv e fo r a n " a dv a n c e d s t e a m t u r b in e " , fo r in s t a n c e

w it h r e s p e c t t o t h e c o s t b e n e fit s ,

- ide n t ify t h e p r o b l e m a r e a s w h e r e c r it ic a l m a t e r ia l t e c h n o l o g y R & D

is n e e de d t o e n a b l e t h e t a r g e t c o n dit io n s t o b e u s e d r e l ia b l y a n d

s a fe l y fo r a de s ig n l ife o f > 2 50 0 0 0 h .

T h e s t u dy is c o n c e r n e d w it h all im p o r t a n t a r e a s c o n n e c t e d w it h t h e t u r b in e c o m -

p o n e n t s in t h e s t e a m p a t h , fig u r e 1.7 a . T h e s e in c l u de m a in p ip in g a n d v a l v e s ,

c y l in de r c a s in g s a n d r o t o r s , m o v in g a n d s t a t ic b l a de s , s e a l s . T h e c o n de n s o r ,

a da p t e d fr o m C O S T 50 5- s t a t e m e n t , 1981

16

feed heaters and the like have been excluded from detailed consideration, as

has the generator. The steam raising unit (SRU) may be a conventional pul-

verised fuel boiler (PFB) , a fluidised bed combustor (FBC) , or an integral

coal gasifier (ICG ) , figure 1.7 c. In all cases coal derived fuels are used.

The study will also refer to the combined gas/steam cycle, where it appears

to be relevant to the steam inlet conditions given for the "advanced stage".

The SRU itself, figure 1.7 b, is not being considered, although attention will

be paid to superheater areas, both on the fire side and the steam side.

2. ST AT E OF T HE ART T RE NDS

The present state of development in steam turbine power conversion systems is

rather diversified depending on the local (national, political, economic etc.)

scenario. The fundamentals of the steam power-electricity cycle have been pre-

sented in chapter 1.1. Here, a short comparison of different national scenes

will be given in order to gain a "3-dimensional" viewpoint. Before this, however,

a more generalised look at the various power conversion systems, in the final

consequence all relying on the steam turbine process, appears to be in order.

2.1 THE POWER CONVERSION SYSTEMS

Taking into account that for high overall efficiencies, see figure 1.3, the

absolute temperature difference must be as high as possible, numerous non-

conventional schemes have been proposed. Figure 2.1 indicates the wide varia-

bility of efficiency-to-cost interactions. A detailed evaluation of the data

of figure 2.1 is claimed to suggest the following systems worthy of further

R & D-pursuit (L.H.Th. Rietjens 1982) :

- combined gas turbine - steam turbine cycle,

- magnetohydrodynamic steam cycle,

- liquid metal Rankine cycle,

- high temperature fuel cells.

Presently these processes show relatively high costs - due to the early stage of

their development. Costs are likely to be lowered with progressive stages of R & D.

Further cycles worthy of consideration are the

- high temperature reactor (see figure 2.2)

17

RWE p u b l i c at i on 1967

1 ec onom i z er

y ev ap orat or

3 J II

4 HP s u p erheat er

5 wall s u p erheat er II

6 wall s u p erheat er III

7 b u l k head

8 final s u p erheat er

9

10J

reheat er

I

II

11 L j u ng s t r m air p reheat er

F i g u re 1.7 b : T hi s cut t hrou g h a p res ent s t at e of the art p u l v eri s ed fuel

" onc e- t hrou g h- b oi l er" ( system Su l z e r ) i nd i c at es m ai n c om p one nt s . T he p i p i ng

of c onc ern in this s t u d y has b een s p ec i fi c al l y narked by .

18

C o nve nt i o na l

St e a m R a i s i ng

U ni t ( SR U )

Flu i di z e d Bed

C o mb u s t i o n SRU

for Atmospheric

Pressure

Flu i di z e d Bed

C o mb u s t i o n SRU

f o r 16 b a r

Figure 1.7 c: The t ot al size of

the steam rai si ng uni t decreases

subst ant i al l y wi th more modern

processes of coal energi zati on.

Therefore, improvements i n the

process are h i gh l y desi rabl e.

The example presupposes a 660

MW uni t .

K.H. Krieb and W. Ratzeburg 1978

50m

90

80

70

60

50

40 7i

- ^ N Supercritical CO, V \ / h / s .

\ (LBTU integrated

S

V f S\ \

30

2 0

Lowtemperat ure

fuel cells (HBTU fuel)

I ^^LMMHD/ st eam

r* (coal fired)

I

I

I

I

^v ^Supercritical CO,

I \ (coal AFB)

I \

I . CCMHD steam

7 (coal firedl

--' 7\

\ i v

' I CCMHD/steam

SRC luel

LMR steam (coal fired (AFBI)

I

\ !

\

j \ (Lb integrated

* gasifierl \ f . I

V / High-temperature \ '

"* fuel cells

1

(LBTU) V

CGT (HBTU fuel) N I J.

N. ,- \ ^

' 7~i

"GT (coal fired (AFB)) ( , \

Low t emperat ure, ""^^/ " / *1

A V

CCMHD/steam

v ' (coal fired)

\

\

V. OCMHO/steam

l_ / . (coal and SRC fuel)

./ ;

fuel cells

(hydrogen fuel) I

\

V

Pressurized

s \ combustor

LMR/steam (coal fired (PEB))

^CGT/organic

f ^^l coal lired(AFB))

N \ > ' / f ^ l c o a l lired(AFBI)

\ \ ) * 1 _ ~ / / Advanced steam (coal fired)

' _ If ' V - - . ' I t rr

(HBTU fuell / >

/

OGT/organic

T'

I

I

10

Combined cycle

(clean fuels)

LMR/5Ieam (coal (PFB) and

LBTU integrated gasifier

350Opsl/1O00F/10OO'

Steam system (conven-

tional furnace)

Combined cycle

(LBTU integrated

gasifier)

10 20 30 40

Overall energy efficiency

(a) General Electric results.

50 60

241 bar

537C

Figure 2. 1: A summary

of resul t s obtained from

ECAS- study shows a large

vari et y of power conver-

sion systems to be consi -

dered when designing f u-

t ure scenarios.

L. H. Th. Rietjens 1982

19

and, of course, the

- high temperature conventional boiler steam turbine,

obj ect of this study. In most of these cases the very high temperature steam

can be procured. Due to the different steam raising methods involved, the ma-

terials technology problems also require different approaches. Although in this

study only the conventional, coal-based techniques are being considered, the

other possibilities must be k ept in mind for future assessments. Schematic over-

views of these steam turbine cycles be they already utilized or still in deve-

lopment have been put together in figure 2 .2 . T o the greatest ex tent the systems

considered in figure 2.1 rely on steam turbines to convert the heat into elec-

trical energy, thus emphasizing once more the central significance of the steam

turbine.

E x amining figure 2 .1, it has been pointed out that the various scenarios are

quite different in their approach, particularly with respect to which k ind of

energy sources are to be harnassed. T hu s , for ex ample, the rather technical

question, whether the future will include the use of higher temperatures or

not, will also depend to some ex tent on the political scenario, particularly

where democratic processes of opinion formation are involved. Figures 2.3 a to c

present a possible sequence of arguments concerning this point. In this connec-

tion special mention must be made of modern day constraints being introduced by

environmental considerations, figure 2.3 c. T he removal of SO^ waste g as , for

ex ample, being evolved when burning coal in the steam raising unit, has had a

decisive impact on the increase in energy cost - over and above the oil crisis.

2.2 PLANTS AND EFFICIENCIES

besides questions such as : " which large, overall direction will have to be tak en

in the future" , detailed differences within the more conventional approach may

already yield sizeable efficiency gains. Referring back to figure 1.2 there are

several areas within the entire plant cycle which appear worthy of further opti-

mization. T he two most promising items are the steam raising unit and the steam

turbine. L ik ely SRU systems to be considered are presently

- conventional pulverized fuel combustion,

- Integrated gasification combined cycle ( ICG CC) ,

- pressurized fluidized bed combined cycle ( P F B CC) .

20

PRESSURIZED I

COAL GASFICATION I COUPLING

PLANT LINK

ga s i fi e r s te a m

I ga s i fi e r a i r

>r a i r I ?

mr

r i Mt t

I

COMBINED

CYCLE PLANT

20 ba r 320C

c oa l

combined cycle plant

a i r th rottl e

va l vt

s te a m

turbi n e

condensor

K.H. Krieb et al 1979

nuclear reactor

steam power plant

exhaust

waste . nuclear

heat | | material

teed

heater

electrical sfr

energy

tJr

waste

heal

G. Di be l i us 1974

MHD

seed, generator

cyclic

heat-

exchangers

compressor

c l os e d c y c l e

seed

MHD

generator

compressor steam

generator

op e n c y c l e

MHD-s te a m p owe r p l a n t s L.H.Th. Ri etjens

1982

Figure 2.2: While the "combined cycle" (gas and steam turbine) is presently

already being used (smaller units) , both the high temperature reactor and

the MHD systems are yet under development.

21

l'Mll

Enl wie It lung.

Konstruktion

1

1981

S

Material

beschaffung Fertigung

Mort ige

Inbetriebnahme

Eriahrungs

ruchtauf

198?

D=^0^^>

1983

1964

0

"WS

I

*

I

1

! 1

1986 1987

5

1988

Blau I.andtj^allien Rot: Bufklr<M|;\wjMrn

>

1989

(a)

Einwellen-

Sattdampfturbosatz 1300 MW

Uran (Weltvorrate 15600Mrd t SKE bei Nutzung durch Bruter)

nC

B Einvvellen

Z wischenuberhitz ungs

Damp fturbosatz 800 MW

Vergasung

' ' T \-\\ I M . ^ m Gasturbosatz 2 200 MW

pnHCUl

Kohle ( W eltvorr te 550Mr d t SKE)

I f IJJ

II \ . n II \ . I mit Gasturbosatz 2x200MW

g - -,

Erdgas (Weltvorrate 9 0 Mr d t SKE)

Gas- und Dampt -

( GUD- ) Proze

mi t Ga s turbos a t

Da mp ttui bos a tz 2O0MW

Ga s - un d Da mp l -

( GUD- ) Proze

mi t Ga s turbos a t

Da mp fturbos a tz 200 MW

rfW-l -n

rOJ

x r ~r r

TS0"

Erdl (We l tvorra te 1 40Mrd t SKE)

Kombi n i e rte r Proz e

mi t Ga s turbos a tz 1 00 MW

Zwi s c n e n ube rh ttz un gs -

Da mp fturbos a tz 700 MW

Figures 2.3 a to c:

T he diagram in ( a)

above illustrates,

how, for ex ample, in

Germany a new techni-

cal concept of energy

conversion, from the

inception to finali-

zation, may tak e as

long as two election

periods - indicating

possible political

difficulties for its

realization; due to

the various possible

choices of energy

sources ( uranium, c oal ,

gas, oil) there is,

figure 2.3 ( b ) , un-

fortunately, no clear-

cut singular optimal

concept for energy

conversion, and there-

fore it remains, to a

certain ex tent, open

to opinionated decisions;

(b)

22

PULVERIZED COAL

COMBUSTION WITHOUT

DESULFERIZATION

PULVERIZED COAL

COMBUSTION WITH

DESULFERIZATION 90%

PRESSURIZED COAL

G ASIFICATION; NO

DESULFERIZATION

COAL CONVERSION

BY "GUD" PROCESS

COAL GASIFICATION

WITH HIGH TEMPERATURE

REACTOR

188.6! Schwefeldioxid

53t Schwefeldioxid

19.4t Schwefeldioxid 191 Schwefeldioxid

,r

1000 MW

r

1000 MW

fe *.

372,2t Gips : CaSO^

Kohle-

vergasungs-

anlage

92t Schwefel : S

I Kohle-

I I vergasungs-

\ 7 anlge

621 Schwefel : S

E HTR If

1000 MW

84t Schweleil :. S I

(c)

Figure 2.3 a to c, continued: the l at t er poi nt becomes par t i cul ar l y relevant when

discussing ef f ect s of waste products on the environment: f i gur e 2.3 ( c) ; adopted

from W. T ral , 1980.

best nuclear units

best f ossi l uni t s

source: FPC/N RC

I I

1940 1950 1960

year

1970 1980

W.G. Steltz 1980

Figure 2. 4: Heat rate

trends i n US-American

steam power pl ant have

l evel l ed out at around

8000 BTU/kWhr f or the

best f ossi l uni t s. For

f urt her improvement

considerable steam tem-

perature and pressure

increases would be

requi red.

23

T hey represent essential efforts in their own right and are not subj ect of this

study. T he steam turbine appears to be the other most rewarding area of endea-

vors, i.e. improving the steam turbine efficiency through raising steam tempera-

tures and pressures. T he trend of improving heat rate, figure 2 .4 , could thus

obtain another j ump downwards.

Of considerable importance in the power industry is the price of electrical

energy supplied to the consumer. In the USA the price per k Wh has steadily

decreased over the forty year period from 193 0 to 1970, figure 2 .5, both in

current dollars and relative dollars considering 1972 as a base. T his trend

dramatically changed in the early 1970's as fuel prices and inflation rates

escalated. Thermal efficiency has progressively assumed greater importance

both to the consumer and to the utilities. P enalty clauses dependent on

achieved heat rates versus contractual values are commonplace, dollar value

penalties of % 50,000 to % 100,000 can be imposed on the manufacturer for

every Btu/ k Wh if his equipment is proven deficient. T he utility also places

enormous value on vendors' quoted heat rates, evaluating them at rates of up

to % 2 50,000 per Btu/ k Wh on new equipment. T he message is clear, thermal

efficiency is of paramount importance in the design of steam turbines and

related equipment. Statistical and potential values are given in figure 2 .6.

The rate of improvement of turbine cycle thermal efficiency is obviously

decreasing - increases in blading efficiency, reduction of ducting losses,

etc., are becoming more and more difficult to achieve. P ower plant and

machinery designers are work ing hard to achieve small improvements - con-

sidering the worth of energy. What then are our options leading to thermal

performance improvements and the management of our energy and financial

resources? Are ex otic processes the answer - MHD, solar power, the breeder

reactor, fusion? - Or perhaps the use of alternate fluid sub-posed cycles,

combined gas and steam turbine cycles, or even increases in steam conditions

of steam power plants, see figures2 .1 and 2 .2 . Significant changes will be

required in the future and the trade-off parameters will be the energy source

and cost.

2.3 NATIONAL EFFORTS

In the following a look at several national efforts may help to gain better in-

sight into the present state of " future think ing" .

quoted from W . G . Steltz 1980

24

()

10

8

6

If

* 3

CL

2

i b)

pr oj ect ed

h i stori cal

00 r

300

200

construction period

i nterest

environmental

protection

current dol l ars

I I I

source: EEI/BLS

J Li

1930 1940 1950 1960 1970 1980 1990

year

W.G. Steltz 1980

const ruct i on

ti me

45years

KTrenkler 1978

Figure 2.5: The constantly dropping price of electricity in the US has picked

up since the oil crisis 1973 and requires more attention on efficiency of the

energy conversion process (a). Costs for everything, in particular, investment,

environmental protection, and mortgages for :the duration of construction have

risen dramatically (b).

(a) (b)

unit si ze trends

steam plant additions

C

3

average si ze

of addi ti ons

1950 1960 1970 1980

year

W.G. Steltz 1980

(c)

18000r

1 16000

* 14000

e 12000

_ 10000

8000

,2.5 MW

net heat rate

tf =520C

t =520C

without reheat

wi th reheat

10 20 50 100 200 300 500

inlet pressure, bar

Krieb and W. Ratzeburg 1978

55 60 65 70 75

year

H. Trenkler1978

Figure 2.6: While the maxi

mal unit size has reached

1300 MW the average size

adjusts to between 600 and

800 MW units (a). Actual

heat rates are located

around 2350 kcal/kWh

(^9200 btu/kWh ^9700

kJ/kWh) the layout heat

rates being about 10%

lower (b). For present

day parameters (520C,

300 bar) the optimally

economic heat rate is

not much better than

9500 kJ/kWh (c).

25

USA I A recent study conducted by EP RI on " Improving T hermal E fficiency of Con-

ventional Steam E lectric P ower P lants" nay serve to set the scenery for further

enquiries ( see D.V. Giovanni and A. F . Armor 1 9 8 1 ) .

T he " best average" plant, referred to as BASE plant, characterizes the present

(" best average" ) status in the USA, figure 2.7 a. T he studies were set up to

ex amine the case for better efficiency with pulverised fuel fired boilers which

would then be an evolutionary improvement rather than the stepwise change needed

with Integrated Gasification Combined Cycle, i.e. gas and steam ( IGCC) and

P ressurized Fluidized Bed Combined Cycle ( P F B CC) .

It is said that most conventional steam plants with coal-fired drum boilers have

a net thermal efficiency of 3 3 -3 4 % . T hose in the 3 00-800 MW range have an inlet

steam temperature of 53 bC ( with reheating of the steam to this temperature be-

tween high pressure ( HP ) and intermediate pressure ( IP ) u ni t s ) . T he next stage

of the study presents the preferred high efficiency design that is commercially

available today. It uses proven materials at a performance level that is well

established by field ex perience. Statistics are presented to show that contrary

to general opinion, ex perience over the past ten years with " once-through" -

supercritical boilers shows that they are as reliable as the drum boilers of the

more conventional plant related to above.

T he operating conditions of this " base plant" are 24 MP a pressure, 53 8 C inlet

steam temperature with 2 reheats to 5b0C and 56C. T he net thermal efficiency

is 3 7. T hese improvements in the " base plants relate to better design, control,

inspection etc. ano more confident material selection" , figure 2.7 a.

An ADVANCE D P L ANT is then proposed, figure 2.7 b. It does not presuppose " tech-

nological break -throughs" .

T he two studies have different approathes. T he higher efficiency of the Westing-

house design does not seem to be directly due to materials. It appears that they

have a more serious materials problem in the very high pressure turbine than

General E lectric. T hey allow for this " to concentrate any metallurgical and me-

chanical problems due to higher temperatures at the HP end where components sizes

are smaller" . It is said that " the technology is limited by the metallurgical

properties of critical components" . T he concepts require previously unproven mate-

rials, material applications at larger component sizes than previously tried, mo-

dified designs of components.

26

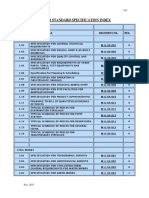

BASE Pl ant General Sp e c i f i c a t i o n s

Gross Ra t i n g , MW

A u x i l i a r y Power, MW

NET RATING, MW

A u x i l i a r y Power, % of Gross

T ur bi ne Heat Rat e, Btu/kWh

NET HEAT RATE, Btu/kWh

NET THERMAL EFFICIENCY, %

T h r o t t l e Pr essur e, psi g (MPa)

T h r o t t l e T emper at ur e, F (C)

T h r o t t l e Fl ow, Ml b/ hr

1st Reh eat T emper at ur e, F ( C)

2nd Reh eat T emper at ur e, F (C)

Fi nal Feedwat er T emper at ur e, F (C)

Number Feedwat er Heat er s ( i n c l . deae at or )

Condenser Backpr essur e, i n . Hg

T ur bi ne l a s t st age l e n g t h , i n . (cm)

Gener at or E f f i c i e n c y ,

B o i l e r T h ermal E f f i c i e n c y , %

Excess Combust i on Ai r , %

A i r Pr eh eat er E x i t Gas Temp, F (C)

FGD Ex i t Gas T emper at ur e, F (C)

St ack Gas T emper at ur e, F C O

General E l e c t r i c , Westi ngh ouse,

BSW Team C Team

725

53

672

7. 3

765S

9350

3 6 , 5

35oo (2 1)

1 o o o ( 5 3 8 )

4. 7

1025 ( 552 )

1050 ( 566)

553 (2 90 )

9

1. 5

33. 5 (85)

98. 7

89. 5

17

300 (149)

120 (49)

170 (75)

742

4S

697

6. 1

7530

9190

37,1

35oo (2 4)

l o o o ( 5 3 8 )

4. 5

1025 ( 552 )

1050 ( 566)

550 (2 88)

8

2 . 5

31 (79)

98. 65

88. 5

22

290 (143)

120 (49)

170 (76)

T h ermodynami c cycl es f or th e BASE pl ant s

1050 F

r r

1025 F from

. bot e

3500_p3i

1000 F

1st RH

2ndRH

Westi ngh ouse base pl ant

boiler

1025 F 1050 F

taa

'TO?

GE base pl ant

Figure 2.7 a: Base

plant speci f i cat i ons

i ndi cate present

steam turbi ne con

di t i ons as seen by

two main US turbine

manufacturers.

27

Advanced Pl ant General Sp eci f i cat i ons

General El e c t r i c , W esti nghouse,

B4W Team C Team

Gross Rat i ng, MW

Auxi l f ary Power, KW

NET RATING, MW

Auxi l i ar y Power, i of Gross

Turbine Heat Rate, BtuAWh

NET HEAT RAIE. Btu/kWh

NET THERMAL EFFICIENCY, i

Tnr ot t l e Pressure, p sig (MPa)

Thr ot t l e Temp erature, *F C O

Thr ot t l e Fl ow, Ml b/ hr

1st Reheat Temp erature, *F C O

2nd Reheat Temp erature, *F C O

Fi nal Feedwater Temp erature, *F C O

Nu'noer Feedwater Heaters ( i n c l . deaerat or)

Condenser Backp ressure, i n. Hg.

Turbi ne Last Stage Length, i n. (cm)

Generator Ef f i ci ency, 1

Boi l er Thermal Ef f i ci ency,

Excess Combustion Ai r ,

Ai r Preheater Exi t Gas Temp, *F C O

FGO I nl e t Gas Temp erature. *F C O

FGO Exi t Gas Temp erature, *F C O

Stack Gas Tenp erat ure, ' F C O

725

824

'.

674

1.0

7300

8875

38,5

4500 ( i n

1050 (566)

4.4

1075 (579)

1100 (513)

580

9

1.5

33.5 (85)

98.7

89.5

300 (149)

235 (113)

120 (49)

170 (76)

51

73

5.2

7180

8330

41

4 5 0 0

( 3 1 )

1100 (593)

5.1

1050 (566)

1050 (566)

604

9

2.5

31 (79)

99.1

89.3

15

270 (132)

220 (104)

120 (49)

170 (76)

Thermodynamic cycle schematic for the ADVANCED plants

1050 F

60F

Westinghouse advanced plant

IQ5F ! 100 F

BFP

GE advanced plant

Fi gu r e 2.7 b : Ad

va nc e d pla nt s pe c i

f i c a t i o ns i ndi c a t e

a next po s s i b le

de ve lo pme nt a l step

as s e e n by two ma i n

U S t u r b i ne oanufac

t u r e r s .

28

It is claimed that, * under various scenarios, present worth lifetime savings

from $ 58,000,000 to over $ 145,000,000 are achievable, depending on the eco-

nomic scenario and the type of utility (public or investor) owned. The most

probable econimic scenarios, in which fuel inflation exceeds general inflation

by 1 to 2%, show 1ifetime .savings ranging from $ 70,000,000 to $ 100,000,000.

Thus, the savings for the first such plant would offset the development cost by

approximately five times . Figure 2.8 sums up the technical and economic con-

clusions of this study.

EUR] The present status in Europe has not been summarized in a way comparable

to the EPRI-sponsored study. The European status is mul ti level led according to

the multiplicity of national scenes. Despite the resulting divergent national

attitudes an attempt has been made here to generalize the European situation.

An approximate present state of the art may be sensed from data compiled in

figure 2.9. On the one hand, nuclear power has, despite the large sizes involved,

called for a rather conventional design (due to low steam temperatures available),

on the other, remarkable steps into the higher temperature regimes have been taken

with the small industrial type steam turbines, figure 2.9. The latter permits the

extrapolation of possible "advanced type" power system;

According to experiences gained with small units, figure 2.9, it may be rather

safely extrapolated that a temperature range of 550C and pressures up to 350 bar

may be built today. Designs for these machines are available since tbe 1950's

(H. Haas et al. 1982). In central Europe the small high - or p-niachines, figure

2.10, were mostly used as topping turbines by the chemical industry. ' Such units

typically in the range 10-60 MW, are also being employed to drive equipment such

as compressors, ships and the like. Here, there is an interest to move to higher

temperatures, motivated by efficiency and saving of space and for capital costs.

A typical advanced unit could be 20 MW with turbine stop valve (TSV) at 750 C

and 104 bar, giving ca. 50% turbine cycle efficiency. In coal fired ship propul-

sion this would equal the efficiency of diesels with cheaper fuels .

The philosophy of "centralizing" technological data in a way indicated below,

see at SU, is pursued by individual companies of the industrialized western

countries in that they all have introduced or are introducing "the piecing

together" of plants with the help of standardized modules, similar to what

will be shown below for the SU as a whole.

adapted from D.V. Giovanni and A.F. Armor 1981

** ...** adapted from J.B. Mariotte 1981: GEC statements

29

C O NC LUS I O NS

1. There Is no stati sti cal difference between the avai l abi l i t i es of operating

supercritical and subcHtlcal pressure power plants. High avai l abi l i t y and

high thermal efficiency are not mutually exclusive.

2. The optimal, commercial ly available coal -fi red steam-electric plant is

characterized by steam conditions of 3500 psig, 1000*F/102S*F/10SO*F (24 MPA,

538 / 552 / 56. The typical heat rate for this 3ASE plant Is 9250 BtuAWh

( I . e . , 37J thermal efficiency) Including FGO, a wet cooling tower, and other

cormion environmental controls.

3. An approximate IOS reduction 1n heat rate ( i . e . , heat rates below 8500 Btu/kWh

and over 401 thermal efficiency) 1s technically feasible and economically

worthwhile. The ADVANCED plant 1s similar to the BASE plant and is

characterized by steam conditions of 4500 psig (31 MPa) and temperatures to

1100'F (59 3' C). In addition, heat rate reductions are achieved by the

ut i l i zat i on of waste heat within the plant, Improved component effi ci enci es,

and optimized system design. The optimum size plant is approximately 750 MW.

4. The ADVANCED plant is cost effective rel ati ve to the BASE plant, and much more

beneficial when compared to the subcritical plants commonly being purchased

today. For the economic premises used In the EPRI studies, the overall

l i feti me savings for the ADVANCED design were typically $100,000,000 for one

uni t.

5, An evolutionary-type research and development program to realize the economic

benefits of the ADVANCED plant would cost approximately $25,000,000 and

require approximately 5 to 7 years. No technological "breakthroughs" are

required.

6. The operational versat i l i t y .of the ADVANCED plant is comparable to that of

fossil plants in operation today in terms of turndown capabi l i ty, permissible

rates of load change, startup procedures and times, and load shedding

capabi l i ty.

7. The BASE and ADVANCED plants retain their high thermal efficiency at reduced

loads and are rel ati vel y insensitive to variations in ambient temperature. In

contrast, the performance of combi ned-cycle type power generation options

characteristically varies to a larger degree with ambient conditions.

8. The BASE and ADVANCED plants are economically and technically competitive with

other power generation options when equipped with environmental controls for

S0

2

, particulate matter, N0

X

, thermal discharge, solid waste disposal, and

l i qui d effluent discharges.

9 . The ADVANCED plant Is comparable 1n terms of thermal efficiency with IGCC and

PFB. I t has a unique advantage weetngarveaototionaryImprovement".

10. The development of ADVANCED p lant technology 1s warranted at this t i e.

Fi gu r e 2.8: C o nc lu s i o ns of the

EPR Is t u dy a r e t ha t , w i t h a r e

lati vely low R & D capi tal i n

ve s t me nt , a la r ge e f f e c t ma y be

a c hi e ve d i n e f f i c i e nc y i mpr o ve

ment at li ttle techni cal r i s k.

EPR I

. I U t h l W * Irr lCll%l t> t . ^ >

Siw tacine fun ruw

D** V. fiiff>ft*i

*0 F, Uv

C t e me fcM feu; U m u t i

. *. . ;

U U " t H I C O w l * t S f A B C H N S i T U T t

- - L M I I ;-?;

30

No.

1

2

I

4

S

I

7

t

9

10

11

12

13

14

IS

16

17

I t

IB

20

21

22

23

24

25

2

27

26

2S

30

Fin

Oper

ation

1951

1955

1956

1956

1957

1957

1957

1957

1957

1957

1957

1957

1956

1959

1959

1959

1960

1960

I960

1962

1963

1963

1964

1964

1965

1966

1966

1966

1967

1967

Unit

Bayer Leverkusen 42

Bayer Leverkusen 43

Chemische Werke Huele

Fuldmuehio Reisholz

Feldmuehle Arnsberg

BASF Ludwigshaien 1

BASF Ludwigshafen 42

Power Plant Neuhof 44

Power Plant Herren

hausen 46

Power Plant Bremen

Haien 1

Power Plant Bremen

Haien 42

Bayer Leverkusen 45

Bayer Dormagen 44

Power Plant Hartingen 43

Power Plant Hartingen 4

Forges de la Providence

Bayer Uerdingen 41

Erdoelchemie 41

PoWer Plant Tocopilla

Bayer Leverkusen 47

Bayer Uerdingen 42

Erdoelchemie 43

Erdoelchemie 5

Bayer Dormagen 45

Bayer Flittard 41

Bayer Flittard 43

Power Plant Schelle 42

Power Plant Schelle 43

Erdoelchemie 47

Bayer Uerdingen 43

Main/

Reheat

Steam

Temp.

F/ T

1112/

1184

1112/

1112/

1112/

1112/

1112/

1112/968

1040/977

1040/968

1040/968

1164/

1184/

1112/977

1112/977

1040/

977/

1022/

1058/1004

1184/

917/

1036/

10367

1112/

1036/

1036/

1022/1040

1022/1040

1036/

977/

Maln

S leem

Press.

psig

2120

2100

4230

2100

2100

2190

2320

2540

2540

2540

2540

2100

2100

3330

3330

1420

4160

2810

1740

2100

4160

2810

2810

2120

2810

2810

2540

2540

2610

4160

Rating

kW

11OO0

14000

17000

11000

7000

29000

29000

B10O0

51000

84000

64000

14000

21000

107000

107000

10000

9000

18000

50000

14000

9000

17000

17000

21000

17000

17000

125000

125000

33000

15000

(a)

Year

Commissioned

1947

1950

1955

1957

1959

1962

*1966

1966

1973

Steam Condi

Unit Size I ni t i al

MW Pressure

psi

30 600

60 900

100 1500

120 1500

200 2350

300 2350

375 3500

500 2350

660 2350

t i ons

Temp.

454

483

565

538

565

565

593

565

565

Reheat

Temp.

C

538

538

565

565

565

565

* Su pe r c r i t i c a l Bo i le r

POWER PLANT DEVELOPMENT IN U K SINC E 1947, C OU R TESY C EGB

INDUSTRIAL

H. Haas et al 1982

(b)

Variante

Frischdampf"

Druck bai

Temperatur C

1. ZwischeriUburhiizer"

Druck bai

emp i'iatur

U

C.

2. ZwtschenUberhitzer"

Duick bai

Temperatur C

spez. Warmeverbr. (Rechg.)

(Jahresmittel wert)

Differenz bzw. Veibesserung W

Brennsloffeinsparung %

Vorwrmtemperatur normal 260C

bei Variante 287

U

C

3a. 4a 280C

kcal/kW h

0

186

635

43.6

535

2153

2266

1

245

565

69

568

2080

2190

7 6

3,35

Alle Da

2

3 0 0

5 2 5

95

5 3 5

24

5 6 5

2074

2183

83

3.65

3

3 0 0

570

95

5 4 5

24

5 4 5

2052

2163

103

4.52

mpfdaten beziehen sich

3 B

2047

2154

112

4.93

4

300

610

114

570

27.5

570

2022

2128

138

6,08

auf Einlrittszustand vor

A.

Schnei

4n

26

570

20T2

2119

147

6,47

Turbine.

der

Figure 2.9: I ndust ri al turbines and power pl ant t urbi nes, when compared i n t h ei r

r at i ngs, give an approximate pi ct ure of present day steam turbi ne technology:

advanced f or the f i r s t , conservative f or the l at t er ( a) . Extrapol ati ng from the

f i r s t t o use wi th the l at t er i ndi cates possible heat rate improvements and fuel

savings (b).

31

^

(a)

+.J

H. Haas et al 1982

(b)

\ I . W V H . M M I l ' I R H O H . no hei n* Imiti l* Hr. n, .t.. . . . , i h. iKe Meas, trae* ^ . e t i i i a l l * i nro, h tartu ne ' d'

H .s* < t i . I l l be i W l i r i f l nit in operation heti il i* deli red t lerenl . i t e* lor ateei OM I dt f errai k* h < *>ee | * arfceana fc larari.

lik T VA i 1*71. I l .Ir, f i r . l * . t.. aapoan umi. . T W tinS*rt i l l ran on 4 aeJajrfd h* Sant i ni ( f.*11 (atei.

W. Hossli 1969

Fi gu r e 2.10: The small i ndustri al type steam t u r b i ne uni t (a) ma y de li ve r

essenti al kno w ho w by w hi c h next ge ne r a t i o ns of large power plant steam

t u r b i ne s , such as i llustrated i n ( b ) , ma y be de s i gne d, possi bly a c c o r di ng

to c o nc e pt s i ndi cated by the EPR Is t u dy (see a b o ve )

32

JAP Japan, one of the outstanding energy consuming countries in the world, is

also confronted with the necessity of saving energy. To meet this challenge,

developments are underway towands an ultra high performance fossil fuel plant,

both coal gasification combined cycle power and "ultra supercritical" PFB plants,

The Electric Power Development Co., Ltd. (EPDC) is to undertake R & D in utili

zing coal for power generation in Japan. Having started 1981 technologies on

"ultra super critical steam condition" (U.S.C.) are to be developed. It is

aimed at performance improvement and efficiency increase by advanced steam

conditions in conventional coal fired power generation systems.

It is being expected that the U.S.C, technology will be commercialized in the

near future with an equivalent performance capability in coal gasification

combined cycle plant. In addition, adoption of lower consumption equipment

and high performance air preheater as well as others, will result in even

higher efficiency coal fired thermal power stations.

Figure 2.11 compiles data for both typical conventional as well as U.S.C.

type power plant. One may gather that design goals are comparable to the

generally accepted term of "... advanced conventional ..." type steam turbine

power plant.

SU 1 Last not least, a certain lead for the development in the communist block

countries may be obtained from examining the data given in figure 2.12 a and b.

Electrical energy in the SU is based to about 85% on heat power stations. Al

9

together, approximately 150010 kWh are being produced presently. 3 basic types

of systems:

fossil fuel fired condensation turbines for power stations WKW

power stations for heating purposes (back pressure turbine) HKW

nuclear power steam turbines KKW

Specialties of Russian steam turbine development, design, and operation are

summarized as follows

standardization of steam parameters is being attempted; both WKW and HKW

operate only with = 12.8 or 23.5 MPa; rated main and reheat temperatures

are strictly 540 to 565 C;

most WKW and KKW are being driven down to rather low vacua: 34 to 39 mbar.

An "advanced type plant" is said (B.M. Trojanowski 1980) to have been operated

for several years with the ratings 100 MW, 29.4 MPa, = 630 to 650C and

reheat temperatures to 565 C. This may be taken as being symptomatic for the

next developmental step to be taken in the SU.

33

COMPARISON BETWEEN CONVENTIONAL TYPE PLANT AND USC PLANT

C o m p a r i s o n I t

C o n ve n t i o n a l t ype

3.b O O ps l

1.O 0O /1,O SO 'F

U SC t ype

4 .SO O psi

l.iso/i,oo/i,

1. De s i g n C o n d i t i o n

R a t e d o u t p u t

S t e a m c o n d i t i o n (at t u r b i ne i nle t t

M a i n s t e a m p r e s s u r e

M a i n s t e a m t e m p e r a t u r e

R e he a t s t e a m t e m p e r a t u r e

O p e r a t i o n s y s t e m

M i ni m u m o p e r a t i o n p r e s s u r e

Ki nd o f c o a l

Th e r m a l e f f i c i e nc y tat g e ne r a t o r

e n d )

Bo i le r e f f i c i e n c y

Tu r b i n e t h e r m a l e f f i c i e n c y

2. Bo i le r

typ

Bo i le r e va p o r a t i o n at M C R

M a i n s t e a m p r e s s u r e (at SH

o u t l e t )

S t e a m t e m p e r a t u r e

M a i n s t e a m

Reheat steam

Feed water temperature

Mat uri al of bo i 1

Hu;h temjieratur spct i un

! Hushi ng SH tube

Fini. hiriv; Rll tube

ing SII o ut l e t header

m. , HMovn l. t header

1,000 MW

24 6 k g/c m

SJS'C

ibb'C

C o ns t a nt pr e s s u r e

a i t u m i n u o u s ,

Au s t r a l i a . C h i n e s e .

Am e r i c a n , So u t h

Af r i c a n C o a l s .

4 1.79

89.561

4 6.8 9*

I 1er,

radi ant , si ng l e :

ne

. or. .

3,ISO T/H

S4 3' C

S69C

287. S' C

320 kg /cm

620C

595C/S9SC

Sl i di ng pressure

80 kg/ cm

Blt u mi nu o u s *.

Au s t r a li a , C h i n e s e ,

Am e r i c a n . So u t h

Af r i c a n C o a l s .

4 3.92*

89.46

4 9.34

SU S34 7KTB

MITI SUS347HTB

JIS STFA24

(AST* A'3S P22 Equi v. )

JIS STPA24

iASTM A33S t22 Equi v. )

Monotubt bo i l e r ,

radi ant , do

. ssarf

. on.

2, 800 T/ H

330 kg / cr

625'C

S98/S98*C

316C

Modified ASTM13

7i 347H/ Hodl fl cd 1714CUMC

M ITI S U S 34 7HTB

JI S SU SJ16HTP

( ASTM A312TP 316H )

JI S SU S316HTP

( ASTM A312TP 316H )

1. Tu r b i n e

L e ng t h o f last s t a g e b la d e

N u mb e r o f c a s i ng

Ex ha u s t p r e s s u r e

Tr i ne i p*l pa r t o f M <

qu a li t y

C r o s s c o m p o u nd , 4 f lo w

e x h a u s t , r e g e ne r a t i v,

.t, c o n d e n s

i no

4 t yll

MgVac .

C r o s s c o m p o u nd , 4 f lo w

e x h a u s t , r e g e n e r a t i ve ,

d o u b le r e h e a t , c o n d e n s

i ng

4 4 i r.

.i nder

722 m n H g V a c .

t e e l o r N i C r m o

Au s t e ni t i c s t e e l

Au s t e ni t i c s t e e l

Figure 2 . 11: Japan proposes a short term plan for an ad

vanced type ( i . e . "ul t ra supercri t i cal ") steam power plant;

T. Suzuki 1981

Type and Size

Producer

Year of Producti on of

the f i r s t Aggregate

Nominal and

Maximal Power

Rotati onal Vel oci t y

I n i t i a l Pressure

I n i t i a l Temperature

MW

MW

l l

MPl

c

K.210

130

LMS

1959"

210

215

BO

12.76

540

b

K. 300240

ChTGS

1980"

300

320

50

23.54

540

b. 50

LMS

I 9 6 0 "

300

3 30

50

2 3.64

540

b 585

K500

240

ChTGS

1984"

500

535

50

23.54

540

K 800

240

LMS

1970"

BOO

635

50

23 54

540

K I 2 0 0

240"

LMS

1977

1200

1380

50

23 54

540

K500

130

LMS

1980

500

50

13,75

510

PT

60/ 100

130/ 13

LMS

1973

BO

' 00

50

12.75

555

R100

130/ 15

UTMS

1968

100

107

50

12.75

555

b 565

M I O

/no

no

UTMS

1961"

1 10

120

50

12 75

555

PT135

/ 1B5

130/ 15

UTMS

1973

135

165

50

12.76

555

T175

30

UTMS

1978

175

310

50

12.75

540

b 565

MBO

/ 210-

130

LMS

1979

180

210

50

12.75

540

b 565

T-250

/ 300-

240

UTMS

1971

250

300

50

23.54

TSO"

K-220-

44

ChTGS

19 89 "

225

240

50

4.3 1

TSO

K-500-

65

ChTGS

19 70

500

64!

50

37

TSD

K-500-

50

ChTGS

I S75

500

25

6 i l

TSO

K 750

Bi

ChTGS

19 80

750

50

B 37

TSD

K 1000

80

ChTGS

U l l

1030

2!

6 i l

TSO

K I0OO

80

LMS

I H 1

1000

BO

i.ia

b ! 7

TSD

Intermediate Super-

heat Pressure

Intermediate Super-

heat Temperature

Pressure in the

Adjustable Tapping

Heat Rate

Feedwater Temprature

Final Pressure

Number of Steam Paths

in LPStages

Typed Process Control

Length of Last

Stage Blades

MP 2.3 3.B

C 640 640

b 686 b 665

GJ/ h

C 240 266

fi 3.46 3.43

2" 3

DGB" OGR

mm 765 1060

640 640

b 586

285 270

3 4 3 3.63

274

3 4 3

3 4 6

OGR DGR OGR

274

3 58

6

0

1

230

5

4

DU

1.3

b 0.2 5

419

240

1200 960

OGR

665

234

1470

b

0. 245

770

2 3!

2

DGR

b 2.06 bit

und bil 0.3

0. 245

2090 1170

1 2

DGR DGR

bi l

0 2

1090

250

5

2

DGR

756

840

540

b 565

bi l

02

1360

253

6.0

2

DGR

0.33 034 l i t OBI 1.19 0 1 7

243 383 260 2B3 350 250

b 2 80

226 166 225 190 222 200

b 220

3 53 3 92 6 18 4 41 3 93 ' u l l

4

DR

B 2

on DR

B

O.

4 I

0 1 DB

862u 862 1450 1030 1450 1200

1030

Legend:

TSD

DGR

DR

LMS

modernised t urbi ne

wi t h Baumann stage

i i i onorotati onal

= satuated dry steam

= steam entrance valve cont rol

= t h r ot t l e cont r ol

= Leningrad Metal Works

ChTGS = Charkow Turbi ne Works

UTMS = Ural Turbi ne Machinery Metal Works

The f ol l owi ng desi gnati ons are common i n the SU:

Let t er s desi gnate type of t ur bi ne:

K: condensation t ur bi ne, R: back pressure t ur bi ne, T: heat

tappi ng t ur bi ne, P: i ndust r i al steam tappi ng t ur bi ne

Fi r s t d i g i t : nominal power i n MW ( f or tappi ng t ur bi nes:

numerator = nominal power, denominator = peak power f or

operat i on i n condensing mold) second d i g i t : i n i t i a l

pressure i n kp/cm

2

. Next number: modi f i cat i on and f or

Ptyped t ur bi nes: pressure i n the upper tappi ng posi t i on

i n kp/cm', f or Rtyped t ur bi nes: back pressure i n th e

denominator.

B.M. Trojanowskij 1980

Figure 2.12 a: The date indicate the state of the art in steam turbine power plant in the Soviet

Union.

35

lu r b i ne pr o du c e d by C hTG S, t ype K50024 02; po w e r 500 MW, i ni ti al pr e s s u r e = 23,5 M Pa , n = 50/s

IT .L

?

1 L 1

lu r b i ne pr o du c e d by L M S , t ype k30024 03; po w e r 800 MW, i ni ti al pr e s s u r e = 23,5 M Pa , n = 50/s

t u r b i ne pr o du c e d by L M S . t ype K120024 0; po w e r 1200 MW (maxi mal po w e r 13a0 M W ) ,

i ni ti al pr e s s u r e 23,5 M P a , 50/s

B.M. Tr o ja no w s ki j 1980

Fi gu r e 2.12 b : The s e typi cal steam t u r b i ne power plant de s i gns c ha r a c t e r i z e three

si ze ranges of r a t i ngs : 500, 800 and 1200 MW.

36

2.4 MATERIALS TECHNOLOGIES

In this section a short review on materials utilized in the critical steam

power plant components and present-day technologies leading to these materials

will be presented. The components are, see figure 1.7:

- turbine rotors;

- turbines blades and discs, seals;

- casings (turbine/valves) / housings, seals;

- steam ducts (main piping) and superheater;

- bolts.

Figure 2.13 a to c contains an overview of general property requirements for

the components of interest. The figures delineate clearly the three broad re-

gimes of requirements: both room and elevated temperature mechanical proper-

ties and stability against environmental media (corrosion). Better and more

non-destructive testing methods would help substantially in eyery respect. If

one looks at the materials presently available, then roughly three groups may

be distinguished, figure 2.13 b. Figure 2.13 c adds a short description for

each of the steel-families. These figures should only be consulted in "zeroth

order" comparative fashion.

Obviously, the austenitic steels, being located at the higher temperature end,

presently appear to be very suitable materials for future developments. Because

austenitic steels require high quality - high cost alloying elements this de-

velopment must, among other aspects, also be vitally concerned with improved,

though cheaper, materials and technologies. The difficultly of combinining

austenitic and ferritive components in one turbine cylinder, due to a large

difference in expansion coefficients, represents a problem area in its own

sight.

Rotors I Three basically different rotor designs are known in present steam

turbines, the "monolitically"-cast and forged, the welded, and the shrunk-on

type, figure 2.14. The large rotors required for modern steam power plants are

machined from forged ingots that can weigh from 200 to 400 tons. Not all manu-

facturers agree to the need of a centerline bore hole, figure 2.14 a. In the

case of welding together discs or shrinking them on a smaller size shaft ob-

viously the ingot size to be started with requires less critical metallurgical

engineering than in the case of the fully forged rotor.

37

^ ^ ^ comp onent s

requi r e me n t s ^ ^ ^

HP andl LP rotors i HP and nP and

I P and IP I P LP

rotors LP discs casings blades blades

HP andtttP and'

I P IP" 'valve

piping |bolts i nt eri ors:

compenjcondensor

sators i piping

mechanical room temperature

st at i c stress

toughness

fracture toughness

LCF

HCF

crack propagation

st at i c

crack propagation

cyclic

X

X

X

( x)

( x)

( )

X

X

X

X

X

X X

X X

X

x x

X X

( X) X

( )

X

X

I

i

I

,

!

mechanical elevated temperature

creep rupture

toughness

fracture toughness

LCF

HCF

crack propagation

stati c

crack propagation

cycl i c

x x x x !

x x x x '

X

X X

X

X

X

X

X X

X X

X

X X

X

:

1

( )

( )

X

, ,

environmental

gasmetalreactivity

( HTcorrosion)

corrosion local

corrosion SCC

x

i

1

( x)

X

corrosion cyclic SCC

erosive corrosion

erosive wear

f r i ct i on rear

NOT

1

X

X

:

X

1 *

X X

1

X X

( X)

I

I X

X X

X X

X

i

x

X

X

( x)

X

X

,<*)

! x

:

; !

Fi gu r e 2.13 a: Cri ti cal r e qu i r e me nt s for steam t u r b i ne c o mpo ne nt s a r e compi led

he r e and show that me c ha ni c a l t o u ghne s s and s t a b i li t y a ga i ns t c o r r o s i o n a r e the

mo s t ge ne r a lly pe r va di ng pr o pe r t y r e qu i r e me nt s . Be t t e r no nde s t r u c t i ve testi ng

me t ho ds ( NDT) i f a va i la b le , would b e pa r t i c u la r ly useful to mo ni t o r the s t a t e

o f de f e c t s and thus help pr e di c t o u t a ge s and li fe e xpe c t a nc y. ( ) s i gni f i e s a

lower level of ne e d.

38

Q.

-if

30

KM 25

E

E

20

i:

o

15

o

o

10 -

5 -

-

-

I

a\

i

tN

I

I

f

I

C^ ^

I

I

I

-

-

500 525 550 575

T, C

Fi gure 2. 13 b, c: Three main

groups of st eel s may be di s-

t i ngui shed i n steam t ur bi ne

product i on the essent i al

design pr oper t y bei ng creep

r upt ur e st r engt h (here 10

hr s! ) - ( b ) ; both proper-

t i es f or operat i on as wel l

as those necessary i n pro-

duct i on have t o be taken

i nt o account ( c ) ; AEG

publ i cat i on 1963.

600 625 650 (b)

a: low t o medium al l oy :

f e r r i t i c - T < 550

0

b: f e r r i t i c - martens i t i c

T = 550 t o 610C

c: aust eni t i c: T > 600C

creep strength

pri ce rel ati on.

cast abi l i t y

f or geabi l i t y

wel dabi l i t y

thermal shock cracking

sensi t i vi t y in l arge

t hi ck walled castings

oxide scal e- st abi l i t y

up to about, C

cut t i ng worxabil i t y

St abi l i t y gainst

erosion

chemical surface

stabi 1 i Ly (corrosi on)

f r i c t i on Jim wear at

high temera tu re s

stress and st r ai n

rel axat i on behavior

thermal expansion .

coef f i ci ent m K~

10-

b

at bCCC

thermal ;oniiuctivity

sensi t i vi t y against

thermal stresses

group a

low al l oy - steel s

see f i gur e 2. 13 b

1

good

good

good, i n some cases prehea-

t i ng and stress r el i ef

annealing necessary

low; f or crack t est i ng remo-

val of cast i ng ski n necessary

i n speci f i c l ocat i ons

560

normal

normal

bad

normal

normal

14,5 (normal)

0,09 (normal)

normal

group b

high al l oy f er r i t i c- mar t ensi t i c

steel s

f i gure 2.13 b'

3

sat i sf act or y

good