Professional Documents

Culture Documents

Dynasep Peach Depth Cartridge

Uploaded by

cartarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynasep Peach Depth Cartridge

Uploaded by

cartarCopyright:

Available Formats

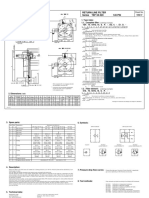

P E R RY E QUI P ME NT COR P OR AT I ON

Series PCHG Gas Filtration Products

USA Patent No. 5827430 and 5893856 (International Patents Granted)

E N G I N E E R E D F I L T R A T I O N T E C H N O L O G I E S

The PEACH

Conical Helix

Structure

yields high flow

and maximum

efficiency.

THE PEACH

The PEACH

consists of several

lateral sections of PEM formed into a

conical helix pattern. Each section

consists of multiple helicaly wrapped

layers. Through thermal bonding,

these spiral layers are applied to

conform and overlap the previous

layer, forming a conethe conical

helix structure. This structure results

in a graded density pattern that yields

high contaminant loading, structural

strength, maximum

efficiency, and excellent reproducibility.

GRADED DENSI TY

Each layer of the PEACH

filter

performs a particular function.

While all layers are designed to a

specific micron rating, each lateral

section removes contaminants. The

outer layer typically removes the

bulk solids. As contaminants move

through the depth of the cone,

the filter densities increase to meet

the required micron rating. The

inner layers of the filter provide

structural strength.

Peach Media 150X

SEM Photo by Southwest Research Institute

PEACH

FI LTRATI ON TECHNOLOGY

A performance engineered cartridge

Predictable performance

Performance assured from start-up

No unloading

High dirt holding capacity

No media migration

ENVI RONMENTAL FEATURES

100% synthetic

Incinerable (CO

2

+ Water) Trace ash & no plastic residue

Ease of disposal: crush, shred, chop, etc.

Coreless, no metal parts

No fiberglass media

PECO

ENGINEERED MEDIA

PEM, specifically designed for filtration

coalescing, is the key component in

the production of the PEACH

gas

element. The PEM is designed with

an assigned micron rating and

efficiency. Raw fibers of various

denier are weighed, blended and

thermally bonded, then formed into

a compressed filter media sheet.

Various layers of PEM are then used

in the manufacture of the PEACH

gas element.

PECO

ENGINEERED APPLIED

CONICAL HELIX TECHNOLOGY

PEACH

is the manufacturing

process incorporating PEM to

form an element into a conical

helix. This innovative patented

process makes possible a graded

density pattern which yields

outstanding filtration.

PEACH

FI LTRATI ON TECHNOLOGY

gives you consistent, predictable performance,

high contaminant loading, and high efficiency.

PEACH

- an innovative gas filtering/coalescing technology.

CONSTRUCTI ON

Media Polyester or Polypropylene

Gaskets/End Cap Integral thermally bonded

polyester or polypropylene.

Optional buna-n or viton with

metal end caps.

Core None in standard construction.

If required louvered,

carbon steel.

OPERATI ONAL DATA

Recommended Element Change Out:

12 - 14 PSID / .83 - .97 bar.

See chart below for collapse strengths

Maximum Operating Temp:

Polyester 240 F / 116 C

Polypropylene 180 F / 82 C

Note: Temps from 200 - 240F require a core

for 4.5 & 5.5 O.D. filters.

Micron Ratings:

0.5, 1, 5, 10 SCW=0.3

Recommended Torque to Seal Filters: 5-10 ft-lbs

NOTE: This Torque should not be exceeded.

PRODUCT ADVANTAGES

PEACH

element has a high density tube

with tolerances of +/- 5%, as compared

to fiber glass tubes with tolerances of

+/- 15%

Integral end cap serves as gasket =

60 Durometer

Long shelf life on elements without cores

Resistant to erosion at high velocities

Direct replacement to standard Fiberglass

element

Cylindrical elasticity eliminates collapsing

on element carrier

Multiple bonded layers for strength and

rigidity

Graded density for higher dirt loading

and coalescing efficiencies

Hydrophilic and oliophilic materials

means greater coalescing efficiencies at

higher rates

No binders or glues for more direct

chemical compatibility

I SO 9001 CERTI FI CATI ON

PECO

Filtration Elements are manufactured under

a quality management system certified to ISO 9001.

This assures that each PECO

Filter is engineered and

manufactured to the highest level of quality

standards therefore assuring you consistent

tolerances and qualityfilter after filter!

CORE COLLAPSE STRENGTHS: PSI D

Size

3

4.5

5.5

Temp F

100

150

200

100

150

200

100

150

200

No Core

40

35

20

30

25

N/R

N/A

N/A

N/A

STD Core

N/A

N/A

N/A

50

50

50

35

35

35

High Pressure

Core

N/A

N/A

N/A

145

145

145

N/A

N/A

N/A

N/R = Not Recommended

N/A = Not Applicable

Notes:

1. Polypropylene is recommended in filter/separators which are

downstream of an amine processing plant due to possible contact

with carryover amine fluids.

2. It is recommended that a core be used in the PCHG elements when

retrofitting into some vessels other than PECO

. PECO

vessels

incorporate a full length element z-bar carrier to support the element

and therefore do not require a core in the standard 4.5 O.D. filters.

3. Refer to Core Reference Chart on back page to determine if cores

are available as standard.

PEACH

GAS ELEMENTS

W/Core

Standard

Standard

Standard

W/O Core

N/A

N/A

N/A

Style

All KPCHG

All PPCHG

All BPCHC (S)

B

END CONFIGURATION

No Symbol = No Gasket

G = Thick Buna-N Gasket

V = Standard Viton

B = Standard Buna-N Gasket

EXT = Extension

E = Extension

CE = Closed Endcap w/bolt hole

5

MICRON

No Symbol = 1 Micron

SCW = 0.3 Iron Sulfide Barrier

A = 0.5 Micron

5 = 5 Micron

10 = 10 Micron

336

DIMENSIONS

O.D. X LENGTH

12 = 3.0" X 12''

24 = 3.0'' X 24"

36 = 3.0'' X 36"

72 = 3.0'' X 72"

312 = 4.5'' X 12"

324 = 4.5'' X 24"

336 = 4.5'' X 36"

372 = 4.5'' X 72"

536 = 5.5'' X 36"

572 = 5.5'' X 72"

PCHG

PRODUCT LINE

PCHG

PECO Conical Helix Gas

PPCHG

Peerless PECO Conical Helix Gas

KPCHG

King Tool PECO Conical Helix Gas

BPCHC(S)

BS&B PECO Conical Helix

Closed (Spring)

C

CORE TYPE

No Symbol = No Core

C = Carbon Steel Core

MATERIAL

None = Polyester

PP = Polypropylene

PCHG NOMENCLATURE CHART

AVAI LABLE MODELS The PCHG is a direct replacement to the PECO

FG gas element. *Comparisons illustrated for 1 Micron Elements

Length

(in/mm)

12/304

24/609

36/914

72/1828

12/304

24/609

36/914

72/1828

36/914

72/1828

OD

(in/mm)

3/76

3/76

3/76

3/76

4.5/114

4.5/114

4.5/114

4.5/114

5.5/139

5.5/139

ID

(in/mm)

2.08/53

2.08/53

2.08/53

2.08/53

3.125/79.38

3.125/79.38

3.125/79.38

3.125/79.38

4.25/108

4.25/108

Model

PCHG-12

PCHG-24

PCHG-36

PCHG-72

PCHG-312

PCHG-324

PCHG-336

PCHG-372

PCHG-536

PCHG-572

PCHG Dirt Loading

(lbs/gms)

.71/323

1.50/684

2.24/1021

4.43/2020

1.17/533

2.33/1062

3.50/1596

7.00/3192

4.27/1947

8.11/3698

FG Dirt Loading

(lbs/gms)

.70/319

1.45/661

2.2/1003

4.4/2006

1.05/478

2.09/953

3.14/1431

6.28/2863

3.83/1748

7.67/3496

* *

*See core reference chart as applicable.

*

CORE REFERENCE CHART

W/Core

N/A

N/A

Optional

Standard

Standard

Standard

Standard

Standard

W/O Core

Standard

Standard

Standard

N/A

N/A

N/A

N/A

N/A

Style

PCHG 3 O.D.

PCHG SCW 3 O.D.

PCHG 4.5 O.D.

PCHG 4.5 O.D., 5 & 10

PCHG 5.5 O.D., 5 & 10

PCHG 5.5 O.D.

PCHG SCW 4.5 & 5.5 O.D.

PCHG A 3, 4.5 & 5.5 O.D.

N/A = Not Applicable

Printed in USA Please refer to www.perryequipment.com for most current literature edition.

Corporate Offices &Plant

PERRY EQUIPMENT CORPORATION

Wolters Industrial Park

P.O. Box 640

Mineral Wells, Texas 76068

Telephone: 940-325-2575

800-877-PECO

Telefax: 940-325-4622

e-mail: mwsales@perryequipment.com

Houston Branch Office

1758 West Sam Houston Parkway N.

Houston, Texas 77043-3115

Telephone: 713-973-2575

Telefax: 713-467-0475

e-mail: houstonsales@perryequipment.com

Perry Equipment

Italiana S.R.L.

via Camozzi, 106

24121 Bergamo (BG)

Italy

Telephone: 3903-523-6340

Telefax: 3903-523-6380

e-mail: italysales@perryequipment.com

Perry Equipment De Mxico

Parque Industrial Benito Jurez

Acceso III, 4-A

Quertaro, Quertaro, Mxico C.P. 76120

Telephone: 52-42-10-34-89

Telefax: 52-42-10-90-39

Parque Industrial Quertaro

Calle Cerrada La Noria #108

Santa Rosa Jaurequi

Quertaro, Quertaro, Mxico C.P. 76220

e-mail: mexicosales@perryequipment.com

Perry Equipment

Corporation

S.E. ASIA REGIONAL OFFICE

35-4 Jalan SP2/1

Taman Serdang Perdana, Seksyen2,

43300 Seri Kembangan

Selangor D.E., Malaysia

Telephone: 603-8941-2366

Telefax: 603-8941-1366

e-mail: asiasales@perryequipment.com

Peco Filters, Ltd.

1351 Hastings Crescent S.E.

Calgary, Alberta

Canada T2G-4C8

Telephone: 403-243-6700

Telefax: 403-287-9304

e-mail: canadasales@perryequipment.com

European Offices

PERRY EQUIPMENT LTD.

Brunel Business Court

Brunel Way, Thetford

Norfolk 1P24 1HP

England

Telephone: 01842 821000

Telefax: 01842 821050

e-mail: uksales@perryequipment.com

www.perry-equipment.co.uk

e-mail:

elements@perryequipment.com

web site:

www.perryequipment.com

EL-PCHG-SL-01 (LHA 1/04))

Your l ocal di st ri but or :

*Above results are based on standard PECO

testing protocol.

You might also like

- General Products Oil and Gas PDFDocument16 pagesGeneral Products Oil and Gas PDFAlcides Llanque Choque100% (1)

- Peco Filter General Products BrochureDocument16 pagesPeco Filter General Products BrochureAiman Hilmi Aiman HilmiNo ratings yet

- Eco Micron FitDocument4 pagesEco Micron FitNicholas Jeffrey DaviesNo ratings yet

- PECO Filters PDFDocument12 pagesPECO Filters PDFmishraengg100% (3)

- Gas Vessel PecoDocument16 pagesGas Vessel PecopsycopaulNo ratings yet

- PECO Filters PDFDocument12 pagesPECO Filters PDFG.SWAMI100% (1)

- Facet Fg24 Peco FiltroDocument2 pagesFacet Fg24 Peco FiltroPilar TorquemadaNo ratings yet

- GDS134Document4 pagesGDS134Saurabh VermaNo ratings yet

- PCC Technova: Series "CPL" Cylindrical ValvesDocument5 pagesPCC Technova: Series "CPL" Cylindrical ValvesAnju VijayanNo ratings yet

- Chem Pure CatalogDocument20 pagesChem Pure CatalogfazyroshanNo ratings yet

- KWH Wehogas BrochureDocument8 pagesKWH Wehogas BrochureDanny D.No ratings yet

- Chapter-8 Quality Control Quality AssuranceDocument35 pagesChapter-8 Quality Control Quality AssuranceMei YeeNo ratings yet

- Dynasep Peach Depth CartridgeDocument4 pagesDynasep Peach Depth CartridgesanjayNo ratings yet

- TF4 Mar 20 06Document6 pagesTF4 Mar 20 06DANIZACHNo ratings yet

- HDPE GuideDocument78 pagesHDPE GuideCarlos Herrera100% (1)

- PE Pipe Design and Engineering Guide (Polypipe)Document78 pagesPE Pipe Design and Engineering Guide (Polypipe)QYTREWPOIUDNo ratings yet

- Fibrceptor FFP: Depth Microglass Coalescers With Integral Pre-FilterDocument2 pagesFibrceptor FFP: Depth Microglass Coalescers With Integral Pre-Filtermatteo2009No ratings yet

- Filtro Peco HorizontalDocument4 pagesFiltro Peco HorizontalEdgar CanelasNo ratings yet

- Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PasteDocument4 pagesSolder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PastebehzadNo ratings yet

- Cat 4190 HBMDocument7 pagesCat 4190 HBMSrta IncognitaNo ratings yet

- Pleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsDocument4 pagesPleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsWarlexNo ratings yet

- 12CS/50CS Series: Coreless Medium Pressure FiltersDocument11 pages12CS/50CS Series: Coreless Medium Pressure FiltersPartsGopher.comNo ratings yet

- LMI Series G Metering Pump Datasheet PDFDocument6 pagesLMI Series G Metering Pump Datasheet PDFVkita MolinaNo ratings yet

- Tricosal KatalogasDocument32 pagesTricosal KatalogaschaubeyskcNo ratings yet

- (P) SRFDocument6 pages(P) SRFYing Kei ChanNo ratings yet

- Filtros Retorno ParkerDocument8 pagesFiltros Retorno ParkerBilly ZununNo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- 8&9. Ds-Og-Trugard-Psfg-191118Document2 pages8&9. Ds-Og-Trugard-Psfg-191118Reza PramataNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- TM CatalogDocument58 pagesTM CataloghacenescribdNo ratings yet

- Nesl Training ManualDocument91 pagesNesl Training ManualSOUMYA DEEP CHATTERJEENo ratings yet

- PT Series: Tank Top FiltersDocument14 pagesPT Series: Tank Top FiltersPartsGopher.comNo ratings yet

- PET Processing V4 - 1Document48 pagesPET Processing V4 - 1Somasundaram Yamaraja100% (5)

- B 4600Document6 pagesB 4600sergioarrayaNo ratings yet

- PE Pipe Design and Engineering Guide (Polypipe)Document78 pagesPE Pipe Design and Engineering Guide (Polypipe)1zorro1100% (1)

- El FF TD 01Document2 pagesEl FF TD 01Masood Alam FarooquiNo ratings yet

- Bulletin 114 IOM Manual GP Steam DsfilterDocument4 pagesBulletin 114 IOM Manual GP Steam DsfiltervextersNo ratings yet

- Doneldson Air Breather FilterDocument14 pagesDoneldson Air Breather FilterParinpa KetarNo ratings yet

- Cuno ZPC Zeta Plus Sanitary HousingDocument4 pagesCuno ZPC Zeta Plus Sanitary Housinggeorgadam1983No ratings yet

- Petro-Klean Cartridge Filter Systems For Oil and Gas Processing Petro-Klean Cartridge Filter Systems For Oil and Gas ProcessingDocument9 pagesPetro-Klean Cartridge Filter Systems For Oil and Gas Processing Petro-Klean Cartridge Filter Systems For Oil and Gas ProcessingsalahalhabashyNo ratings yet

- p1500 Org Adv Pls Eom 05Document23 pagesp1500 Org Adv Pls Eom 05diego contrerasNo ratings yet

- PeDocument55 pagesPeمنير أحمدNo ratings yet

- Compair Line FiltersDocument8 pagesCompair Line FiltersmuppetscrapNo ratings yet

- Snap Trap HankisonDocument8 pagesSnap Trap HankisonSaku-Jessy CamposNo ratings yet

- 362kVGas Circuit Breaker Catalog English Feb2008 HyosungDocument6 pages362kVGas Circuit Breaker Catalog English Feb2008 HyosungbyjuvcNo ratings yet

- Design and Development of Blow Molding DieDocument15 pagesDesign and Development of Blow Molding DieRahul VatsNo ratings yet

- Black Eagle Hose BE 4466-UKDocument44 pagesBlack Eagle Hose BE 4466-UKmhollowayNo ratings yet

- DS Og Trugard PSFG 191118Document2 pagesDS Og Trugard PSFG 191118Friday gamingNo ratings yet

- MANUAL DezumidificatorDocument98 pagesMANUAL DezumidificatorcivodulNo ratings yet

- PW Series Wafer Check ValvesDocument2 pagesPW Series Wafer Check ValvesroadiewebNo ratings yet

- Trugrid Structural Final DraftDocument27 pagesTrugrid Structural Final DraftrogerngcyNo ratings yet

- Pigging Valves PDFDocument8 pagesPigging Valves PDFmarkobilo100% (1)

- Laminova Intercoolers Laminova Intercoolers Laminova Intercoolers Laminova Intercoolers Laminova IntercoolersDocument8 pagesLaminova Intercoolers Laminova Intercoolers Laminova Intercoolers Laminova Intercoolers Laminova IntercoolersAnonymous dEfIaUNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Datasheet Hi Cart Meter SpecDocument4 pagesDatasheet Hi Cart Meter SpeccartarNo ratings yet

- Manual Hi Cart Meter ManualDocument24 pagesManual Hi Cart Meter ManualcartarNo ratings yet

- InstallationDocument32 pagesInstallationcartarNo ratings yet

- Brochure - Delta en WebDocument12 pagesBrochure - Delta en WebcartarNo ratings yet

- b3hpc 3m1480 DataDocument2 pagesb3hpc 3m1480 DatacartarNo ratings yet

- ROOTS Meters & Instruments: Series B3-Hpc: 11M1480 Roots MeterDocument2 pagesROOTS Meters & Instruments: Series B3-Hpc: 11M1480 Roots MetercartarNo ratings yet

- P 192.629 Purging of Pipeline RevisionsDocument7 pagesP 192.629 Purging of Pipeline RevisionscartarNo ratings yet

- Appendix D Suggestions For Additions or RevisionsDocument4 pagesAppendix D Suggestions For Additions or RevisionscartarNo ratings yet

- Purging PaulCabot PDFDocument43 pagesPurging PaulCabot PDFcartarNo ratings yet

- GasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFDocument320 pagesGasPipelineSafetyOIR Plea WildGoose 20130628 280481 PDFcartarNo ratings yet

- Chapter 2 Why O&M? : Operations and Maintenance Are The Decisions and Actions Regarding The Control and Upkeep ofDocument6 pagesChapter 2 Why O&M? : Operations and Maintenance Are The Decisions and Actions Regarding The Control and Upkeep ofcartarNo ratings yet

- Chapter 11 Ten Steps To Operational Efficiency: Monitoring EquipmentDocument2 pagesChapter 11 Ten Steps To Operational Efficiency: Monitoring EquipmentcartarNo ratings yet

- Triple Tap Line Stop Fitting 2 2014 PDFDocument4 pagesTriple Tap Line Stop Fitting 2 2014 PDFcartarNo ratings yet

- McQuay Fan Coils Sales BrochureDocument20 pagesMcQuay Fan Coils Sales BrochureRoger AklNo ratings yet

- Protein Preci PT at I On PlateDocument2 pagesProtein Preci PT at I On PlatesrichainuluNo ratings yet

- First Periodical Test in ScienceDocument6 pagesFirst Periodical Test in ScienceGrace GaraldeNo ratings yet

- USP Monographs Sulfamethoxazole and Trimethoprim TabletsDocument2 pagesUSP Monographs Sulfamethoxazole and Trimethoprim TabletshmtlionNo ratings yet

- Filtration ControlDocument8 pagesFiltration ControlapsekarNo ratings yet

- Inorganic Chemistry Volume 50 Issue 20 2011Document12 pagesInorganic Chemistry Volume 50 Issue 20 2011Lee ToulouseNo ratings yet

- AmericanSurvivalGuide-August2018, Gear GuideDocument124 pagesAmericanSurvivalGuide-August2018, Gear Guideknsb100% (1)

- 30-36 Filter ManualDocument10 pages30-36 Filter ManualDavid RodriguezNo ratings yet

- Filter PaperDocument4 pagesFilter PaperMuhammad Bilal TahirNo ratings yet

- Return Line Filter Series TEF 55-320 145 PSI: Sheet NoDocument2 pagesReturn Line Filter Series TEF 55-320 145 PSI: Sheet NoRonaldNo ratings yet

- Assessment Report of Potential FSM LaboratoriesDocument79 pagesAssessment Report of Potential FSM LaboratoriesDr. Engr. Md Mahmudur RahmanNo ratings yet

- Chalk LabDocument2 pagesChalk LabHope GemidaNo ratings yet

- Research BookDocument174 pagesResearch BookGeraldine BermundoNo ratings yet

- Industrial Water Treatment-Ufc 3 240 13fnDocument262 pagesIndustrial Water Treatment-Ufc 3 240 13fnh5n1watcherNo ratings yet

- Chemistry Matters Textbook Answers Chapter 3Document3 pagesChemistry Matters Textbook Answers Chapter 3MahamIsmail93% (15)

- Lubrication Systems For Turbomachinery by Fredrick B. WilcoxDocument4 pagesLubrication Systems For Turbomachinery by Fredrick B. Wilcoxkamal arabNo ratings yet

- 1996 Chou Refining Quality of Raw SugarDocument9 pages1996 Chou Refining Quality of Raw SugarnghiNo ratings yet

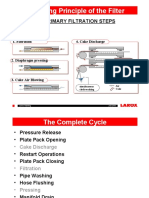

- Operating Principle of The Filter: Primary Filtration StepsDocument7 pagesOperating Principle of The Filter: Primary Filtration StepsTawanda Nyambiya100% (1)

- Filter Press Lab ReportDocument16 pagesFilter Press Lab Reporthinman714No ratings yet

- Filter Media Cleaning An Alternative To Media Replacement: Brian JobbDocument2 pagesFilter Media Cleaning An Alternative To Media Replacement: Brian JobbKanchanNo ratings yet

- Hydraulic Filtration DonaldsonDocument196 pagesHydraulic Filtration DonaldsonTowerNo ratings yet

- Interview Questions With AnswersDocument4 pagesInterview Questions With AnswersMohamed HashemNo ratings yet

- The Extraction of Melanin From SkinDocument5 pagesThe Extraction of Melanin From Skineatmeup3000No ratings yet

- VSP Operations Manual 2018-508 PDFDocument291 pagesVSP Operations Manual 2018-508 PDFFabio SidriNo ratings yet

- Use of Clay in Drilling Fluids: B Y Delmar H - LarsenDocument13 pagesUse of Clay in Drilling Fluids: B Y Delmar H - LarsenValerio Cruz CoraguaNo ratings yet

- Orion Ice Dryer&FilterDocument8 pagesOrion Ice Dryer&FilterCanh LuongtienNo ratings yet

- Heldon Catalogue Edition 69 CompressDocument158 pagesHeldon Catalogue Edition 69 CompressPaniti DitsarintripadaNo ratings yet

- Essay FiltrationDocument4 pagesEssay FiltrationAbraham Sandoya LaraNo ratings yet

- Chemistry PracticalDocument14 pagesChemistry PracticalIt IsNo ratings yet