Professional Documents

Culture Documents

Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder Paste

Uploaded by

behzadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder Paste

Uploaded by

behzadCopyright:

Available Formats

Solder Paste LP 5707

No-clean, halide free, lead-free solder paste

Description LP 5707 is a no-clean, halide free and lead-free solder paste that has been developed for soldering without nitrogen and long, high reflow profiles. Additionally the solder paste exhibits extremely low tendency towards solder ball formation. The absolutely halogen free soldering chemistry, used in LP 5707 prevents dewetting when submitted to high temperatures or long profiles, also when soldering without nitrogen. Furthermore, the chemistry of LP 5707 has been designed to minimize void formation. LP 5707 is classified as RO L0 according IPC and EN standards.

INTERFLUX ELECTRONICS N.V.

Technical data LP 5707 Ver. 3.0 29-05-13

Page 1

More information:

Reflow profile P. 2

Profile recommenda- P. 2 tions Product handling Test results P. 3 P. 3

Operating parameter P. 4 recommendations

Key advantages: The solder paste keeps its rheological properties on the stencil for a long time, even under high or low humidity conditions. High and long profile resistant without nitrogen Prevents dewetting High stability on the stencil, also under more extreme atmospheric conditions Low solder ball formation tendency metal content

printing: 88,5%

Availability

alloy

Sn98,5Ag1Cu0,5 Sn96,5Ag3Cu0,5 Sn95,5Ag3,8Cu0,7 Sn95,5Ag4Cu0,5 Sn99Ag0,3Cu0,7 Sn96,5Ag3,5 Sn95,8Ag4,2 Sn99,3Cu0,7 dispensing: 85% Standard type 3 (25 45) Type 4 and type 5 available for certain alloys 500g jar 1kg1,2kg1,3kg in 12 Oz. cartridge 5cc 10cc 30cc syringe Other packaging upon request

powder size

packaging

Low voiding Low transparent residue after reflow Absolutely halogen free

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

www.interflux.com

Page 2

Technical data LP 5707

Reflow profile for SAC, SnCu and SnAg alloys

General LP 5707 is designed to withstand long and high reflow profiles, also under atmospheric conditions without nitrogen. Both soak and ramp profiles are possible. Soak profiles may be used when temperature differences across a board, due to a high mix of components or large board sizes, need to be levelled out or when voids, if present, need to be decreased. In practice the reflow profile will be mainly determined by the thermal demand and physical properties/ limitations of the components and PCB. It is advisable to always consult the technical specifications of the components and PCB. A correct profile measurement is also important. To get a good thermal mapping of the board it is advised to use thermocouples and a thermal measuring tool. Measure on small outline, big outline and temperature sensitive components. Measure on the board side near the conveyor chain, in the middle of the board and close to, or on heat sinks.

Profile recommendations

LP 5707 has a wide process window in reflow with few limitations. Below are a few examples of profiles that can be used. It is advisable to limit peak T to 260C and keep total profile length (from room to peak T) below 8 minutes.

(SnAgCu, SnCu and SnAg type alloys) 0-120sec. Reflow Peak temperature is limited by component and board specifications. Minimum 10C over alloy melting point is advised to get sufficient wetting. In general between 235C and 250C. The time over melting point of the alloy is usually between 45 seconds and 90 seconds. Cooling Cooling rate below 4C/sec because of differences in thermal expansion of the used materials.

Preheat From room temperature it is advisable to keep heating rate below 3C/seconds. Higher heating rates could result in component cracking due to absorbed moisture. Soak Usually between 180C200C and

Temperature C

Time (sec)

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

www.interflux.com

Page 3

Technical data LP 5707

Handling

Storage Store the solder paste in the original packaging, tightly sealed at a preferred temperature of 3 to 7C. Handling Let the solder paste reach room T prior to opening the packaging. Stir well before use. Printing Assure good sealing between PCB and stencil. Apply no more than enough squeegee pressure to get a clean stencil. Apply enough solder paste to the stencil to allow smooth rolling during printing. Regular replenish fresh solder paste. Maintenance Set an under stencil clean interval which provides continuous printing quality. This interval will depend on the PCB, the stencil and the atmospheric conditions. ISC8020 is recommended as cleaning agent in pre saturated wipes and USC liquid. Reuse Store used paste in a separate closed jar at room T in a container with water absorbing material. Before reuse, test the solder paste. When storing for a longer time, press the inner lid firmly on the paste, so that no air is enclosed, clean off paste residues, put on the outer lid and put back into refrigeration. Before reuse, let the solder paste reach room temperature prior to opening and test the solder paste.

Test results

conform IPC J-STD-004A/J-STD-005

Property Chemical qualitative copper mirror halide content silver chromate (Cl, Br) flux classification Environmental SIR test pass none pass RO L0 pass

J-STD-004A IPC-TM-650 2.3.32 J-STD-004A IPC-TM-650 2.3.28.1 J-STD-004A IPC-TM-650 2.3.33 J-STD-004A J-STD-004A IPC-TM-650 2.6.3.3

Result

Method

Property Mechanical solder ball test after 15min after 4h wetting test slump test

after 15min at 25C after 10min at 150C

Result

Method

pass pass pass pass pass

J-STD-005 IPC-TM-650 2.4.43 J-STD-005 IPC-TM-650 2.4.43 J-STD-005 IPC-TM-650 2.4.45 J-STD-005 IPC-TM-650 2.4.35 J-STD-005 IPC-TM-650 2.4.35

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

www.interflux.com

Page 4

Technical data LP 5707

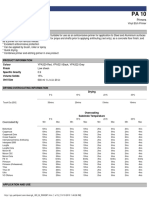

Operating parameter recommendations

Printing speed: 20150 mm/sec squeegee pressure: 250g350g/cm length preferred temperature range: 15 to 25C preferred humidity range: 25 % to 90% r.H. Mounting tack time: I.C.T flying probe testable pin-bed testable

>8

hours

Trade name : LP 5707 No-Clean, Halide Free, Lead-Free Solder Paste

Because Interflux Electronics N.V. cannot anticipate or control the many different conditions under which this information and our products may be used, we do not guarantee the applicability or the accuracy of this information or the suitability of our products in any given situation. Users of our products should make their own test to determine the suitability of each such product for their particular purposes. The product discussed is sold without such warranty, either express or implied.

Copyright: INTERFLUX ELECTRONICS

Please consult the latest version of this document on: www.interflux.com This document in another language?: www.interflux.com

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

www.interflux.com

You might also like

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- TD WSP 2006 PDFDocument5 pagesTD WSP 2006 PDFbehzadNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- TD If 9009ltDocument4 pagesTD If 9009ltbehzadNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Corrosion Protection Solutions For Oil, Gas and Water Transmission PipelinesDocument6 pagesCorrosion Protection Solutions For Oil, Gas and Water Transmission PipelinesGustavo FuentesNo ratings yet

- Rework Procedura e CurveDocument6 pagesRework Procedura e CurveMarco ZeldNo ratings yet

- PE Water AbsorbtionDocument16 pagesPE Water AbsorbtionMohamed ElarabiNo ratings yet

- NF372 TB GlobalDocument2 pagesNF372 TB GlobalFuzail AhmadNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- Nesl Training ManualDocument91 pagesNesl Training ManualSOUMYA DEEP CHATTERJEENo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- Repair WeldingDocument33 pagesRepair WeldingAkhilesh Kumar100% (1)

- Trampa Socket WeldDocument2 pagesTrampa Socket WeldOscar Nieves ZamoraNo ratings yet

- 04 044 052 Spiroflex Spiral Wound GasketsDocument9 pages04 044 052 Spiroflex Spiral Wound Gasketsgazwang478No ratings yet

- Altera Reflow GuideDocument10 pagesAltera Reflow GuideDUNCAN0420No ratings yet

- My Con Pds Sikafloor 220 W ConductiveDocument7 pagesMy Con Pds Sikafloor 220 W ConductivelaurenjiaNo ratings yet

- Fire Fighting Approved EquipmentDocument34 pagesFire Fighting Approved EquipmentAbdul RaoofNo ratings yet

- WP PPR - Thermopipe SubmittalDocument36 pagesWP PPR - Thermopipe SubmittalMohammad Rashad BarakatNo ratings yet

- K267 - PDS - en - GBDocument2 pagesK267 - PDS - en - GBJennifer BradleyNo ratings yet

- Arctic Insulation Saddle FusionDocument13 pagesArctic Insulation Saddle FusionAnand KPNo ratings yet

- HTLP Heat Shrinkable SleeveDocument2 pagesHTLP Heat Shrinkable SleeveGanesh EshwarNo ratings yet

- Sikafloor 220 W ConductiveDocument5 pagesSikafloor 220 W Conductivethe pilotNo ratings yet

- Guide to installing polypropylene pipes using butt fusion weldingDocument6 pagesGuide to installing polypropylene pipes using butt fusion weldingcrys suryo prayogoNo ratings yet

- Trampa Termodinamica PDFDocument2 pagesTrampa Termodinamica PDFriquelme0788No ratings yet

- Alpha: No-Clean Solder Paste (9098T)Document3 pagesAlpha: No-Clean Solder Paste (9098T)behzadNo ratings yet

- Om 340Document3 pagesOm 340RNo ratings yet

- Lead Free GuideDocument2 pagesLead Free Guidebeach_lover_1970No ratings yet

- Solder Paste SC 170: Physical PropertiesDocument2 pagesSolder Paste SC 170: Physical PropertiesluismcmcNo ratings yet

- Installation Instructions For Platinum Resistance Thermometers.Document4 pagesInstallation Instructions For Platinum Resistance Thermometers.username3015No ratings yet

- Amtech - RMA-223 Rev 0510Document2 pagesAmtech - RMA-223 Rev 0510Mohammed AbbariNo ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- Lead-Free Solder Paste for Ultra Fine FeaturesDocument3 pagesLead-Free Solder Paste for Ultra Fine Featuresnormans00No ratings yet

- DP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTDocument6 pagesDP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTNavneet SinghNo ratings yet

- Jedec Industry Standard Classifications and Peak Solder TemperatureDocument8 pagesJedec Industry Standard Classifications and Peak Solder TemperatureGuillermo VillarNo ratings yet

- Loctite Ea 9309.3naDocument5 pagesLoctite Ea 9309.3naechobravo1No ratings yet

- Foxboro RTDDocument12 pagesFoxboro RTDJonathanGonzalezDiazNo ratings yet

- Sigmacover 522Document4 pagesSigmacover 522Asela BollegalaNo ratings yet

- ElectroFusion Installation Manual (European Version)Document44 pagesElectroFusion Installation Manual (European Version)Jorge BaronNo ratings yet

- PPG-Hi-Temp 1027 - PdsDocument6 pagesPPG-Hi-Temp 1027 - PdsqaNo ratings yet

- Manual Soldering and De-Soldering For Spice Package-VerA PDFDocument6 pagesManual Soldering and De-Soldering For Spice Package-VerA PDFVivek SuranaNo ratings yet

- WPW Issue5 May 2022 WEB PDFDocument12 pagesWPW Issue5 May 2022 WEB PDFKadry Nabil HegazyNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeAgniva DuttaNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Amtech: LF-4300 Lead-Free Water Washable No-Clean Solder PasteDocument2 pagesAmtech: LF-4300 Lead-Free Water Washable No-Clean Solder PastebehzadNo ratings yet

- E Rogers 4350b HF WWW - Multi Circuit Boards - EuDocument4 pagesE Rogers 4350b HF WWW - Multi Circuit Boards - EuSaad MohsinNo ratings yet

- Sensirion Humidity SHTC1 Application GuideDocument4 pagesSensirion Humidity SHTC1 Application GuidesugneshhirparaNo ratings yet

- Sellos para Vacio Criterio de DiseñoDocument8 pagesSellos para Vacio Criterio de Diseñogabinho755416No ratings yet

- en-US_P091Document8 pagesen-US_P091Cris gomezNo ratings yet

- Secador SchulzDocument16 pagesSecador SchulzSantiagoAlpala100% (1)

- ThermPanManufactureInst 05Document1 pageThermPanManufactureInst 05imeqingenieriaNo ratings yet

- Fosroc Conbextra EP 0211Document4 pagesFosroc Conbextra EP 0211Tri SuhartantoNo ratings yet

- Tar ProductsDocument14 pagesTar ProductsShaival JhaNo ratings yet

- Rolon Dry Gas SealsDocument39 pagesRolon Dry Gas Sealsnarayan rajuNo ratings yet

- MS 01 91Document6 pagesMS 01 91RritalLNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- DWV Chip Capacitors: Electrical DetailsDocument7 pagesDWV Chip Capacitors: Electrical DetailsmofiwNo ratings yet

- 308Document4 pages308lacsmm982No ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158JORGEALEXERNo ratings yet

- Low ESR polymer capacitors application guideDocument31 pagesLow ESR polymer capacitors application guidebehzadNo ratings yet

- Ijarece Vol 3 Issue 3 347 350 PDFDocument4 pagesIjarece Vol 3 Issue 3 347 350 PDFbehzadNo ratings yet

- Farsi FATEk PDFDocument147 pagesFarsi FATEk PDFbehzadNo ratings yet

- Miniature magnetic field sensor FLC 100Document2 pagesMiniature magnetic field sensor FLC 100behzadNo ratings yet

- Fravahar 2Document16 pagesFravahar 2behzadNo ratings yet

- Miniature Size: 7Mml 85, Standard CDocument1 pageMiniature Size: 7Mml 85, Standard CbehzadNo ratings yet

- Large Capacitance Aluminum Electrolytic Capacitors: S I EsDocument2 pagesLarge Capacitance Aluminum Electrolytic Capacitors: S I EsbehzadNo ratings yet

- FravaharDocument11 pagesFravaharbehzadNo ratings yet

- فرهنگ چیستDocument15 pagesفرهنگ چیستJonbeshEnghelabiNo ratings yet

- Chopper Regulator, DC DC Converter and Motor Drive ApplicationsDocument6 pagesChopper Regulator, DC DC Converter and Motor Drive ApplicationsbehzadNo ratings yet

- EXR series capacitors for switching power suppliesDocument2 pagesEXR series capacitors for switching power suppliesbehzadNo ratings yet

- EMRLDocument1 pageEMRLbehzadNo ratings yet

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadNo ratings yet

- 1N5817Document3 pages1N5817Gallego OrtizNo ratings yet

- CDocument14 pagesCbehzadNo ratings yet

- SGH13N60UFDDocument8 pagesSGH13N60UFDbehzadNo ratings yet

- High Current MOSFET Polarity Switch: 126 Ridge Road - P.O. Box 187 - Lansing, NY 14882Document1 pageHigh Current MOSFET Polarity Switch: 126 Ridge Road - P.O. Box 187 - Lansing, NY 14882behzadNo ratings yet

- Robot3 PDFDocument8 pagesRobot3 PDFbehzadNo ratings yet

- Installation Instructions SL417U Model SeriesDocument2 pagesInstallation Instructions SL417U Model SeriesbehzadNo ratings yet

- Fuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesDocument1 pageFuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesbehzadNo ratings yet

- 99812028Document1 page99812028behzadNo ratings yet

- Summary - Directional Antennas Dual-Band 800/900 - 1800/2000Document30 pagesSummary - Directional Antennas Dual-Band 800/900 - 1800/2000behzadNo ratings yet

- High Power Resistors for Industrial ApplicationsDocument3 pagesHigh Power Resistors for Industrial ApplicationsbehzadNo ratings yet

- Fuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesDocument1 pageFuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesbehzadNo ratings yet

- How To Solder 0902e PDFDocument26 pagesHow To Solder 0902e PDFbehzad100% (1)

- cp3505 Error Messages PDFDocument24 pagescp3505 Error Messages PDFbehzadNo ratings yet

- Tweezer Style Passive Component R/C SMD: One-Hand OperationDocument1 pageTweezer Style Passive Component R/C SMD: One-Hand OperationbehzadNo ratings yet

- Remanufacturing Instructions: HP Color Laserjet 3000/3600/3800Document9 pagesRemanufacturing Instructions: HP Color Laserjet 3000/3600/3800behzadNo ratings yet

- Avr Family PDFDocument6 pagesAvr Family PDFbehzadNo ratings yet

- Smart Tweezers Manual ST5 PDFDocument16 pagesSmart Tweezers Manual ST5 PDFbehzadNo ratings yet

- Installation Module: Xarios RangeDocument20 pagesInstallation Module: Xarios Rangefaza1111No ratings yet

- Chilled Beam Systems As A New HVAC PossibilityDocument35 pagesChilled Beam Systems As A New HVAC PossibilityParul SharmaNo ratings yet

- FAA Hazardous Materials Carried by Passengers and CrewDocument16 pagesFAA Hazardous Materials Carried by Passengers and Crewabelardo219No ratings yet

- Life Prediction ConcreteDocument79 pagesLife Prediction Concrete100livNo ratings yet

- Simple Heat Engine Question PaperDocument4 pagesSimple Heat Engine Question PaperDesmond KaiNo ratings yet

- Cmos AnswersDocument8 pagesCmos AnswersOnu SamNo ratings yet

- Development of High Strength Construction RebarsDocument13 pagesDevelopment of High Strength Construction Rebarsosman recai100% (3)

- Automated HPTLC for Sophisticated Chromatographic AnalysisDocument25 pagesAutomated HPTLC for Sophisticated Chromatographic AnalysisIshfaq AhmadNo ratings yet

- Cat Needle Valve11Document13 pagesCat Needle Valve11Nilesh MistryNo ratings yet

- Brick Vs Concrete BlockDocument13 pagesBrick Vs Concrete BlockPriyamvada BijuNo ratings yet

- Tachometers: Balmaceda, Chris Francisco, MilfrenDocument15 pagesTachometers: Balmaceda, Chris Francisco, Milfrenjude100% (1)

- Practical 7: Determination of Ash Date of Experiment: 15 June 2020 Laboratory Group: TuesdayDocument10 pagesPractical 7: Determination of Ash Date of Experiment: 15 June 2020 Laboratory Group: TuesdayNadhirah Hamzah100% (1)

- Genersys 1850Document2 pagesGenersys 1850Villalobos EduardoNo ratings yet

- Installation of Utility Piping Systems StandardsDocument2 pagesInstallation of Utility Piping Systems StandardsNaushad AlamNo ratings yet

- AAR - Manual-Of-Standards-And-Recommended-PracticesDocument18 pagesAAR - Manual-Of-Standards-And-Recommended-PracticesAndres SalcedoNo ratings yet

- Ch02 - Manufacturing OperationsDocument55 pagesCh02 - Manufacturing OperationsHassan MughalNo ratings yet

- Coating Process of Melamine - 18092012Document2 pagesCoating Process of Melamine - 18092012Dillibabu RamanujamNo ratings yet

- 2016 Torch and Consumables Catalog: For Mechanized Plasma SystemsDocument52 pages2016 Torch and Consumables Catalog: For Mechanized Plasma Systemsrusf123No ratings yet

- Best Out of WasteDocument7 pagesBest Out of WasteGopichandu MaguluriNo ratings yet

- DB SPECIFICATIONSDocument2 pagesDB SPECIFICATIONSEr Jc Ajay ThakulNo ratings yet

- One-Component Waterproofing System by Crystallisation For The Protection of Concrete Against Water PenetrationDocument2 pagesOne-Component Waterproofing System by Crystallisation For The Protection of Concrete Against Water PenetrationLe Tuan VietNo ratings yet

- Technical ManualDocument11 pagesTechnical ManualGeLoRa66No ratings yet

- Professional: The Environmental Impact of DentistryDocument6 pagesProfessional: The Environmental Impact of DentistryAlexandru Codrin-IonutNo ratings yet

- HAAS CNC MAGAZINE 1998 Issue 4 - Winter PDFDocument19 pagesHAAS CNC MAGAZINE 1998 Issue 4 - Winter PDFguytr2No ratings yet

- Diametral Compression TestDocument11 pagesDiametral Compression TestCesar Rodolfo Angulo DelgadoNo ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- SCS Completion Tool CatalogDocument118 pagesSCS Completion Tool CatalogBAGHFAY16100% (1)

- AIR CONDITIONER SYSTEM OPERATION AND MAINTENANCE GUIDEDocument158 pagesAIR CONDITIONER SYSTEM OPERATION AND MAINTENANCE GUIDEAgus YulfizarNo ratings yet

- DSMTS-0010.6 ZN WireDocument4 pagesDSMTS-0010.6 ZN WireMario Cortes FariasNo ratings yet

- Ergonomics & Aesthetic Tool Design of Portable Drilling MachineDocument5 pagesErgonomics & Aesthetic Tool Design of Portable Drilling MachinePranav DahisarkarNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Chemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastFrom EverandChemistry at Home - A Collection of Experiments and Formulas for the Chemistry EnthusiastNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Stuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldFrom EverandStuff Matters: Exploring the Marvelous Materials That Shape Our Man-Made WorldRating: 4 out of 5 stars4/5 (289)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeRating: 4 out of 5 stars4/5 (9)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)