Professional Documents

Culture Documents

PPG-Hi-Temp 1027 - Pds

Uploaded by

qaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PPG-Hi-Temp 1027 - Pds

Uploaded by

qaCopyright:

Available Formats

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

DESCRIPTION

One-component, high-build heat-resistant inert multipolymeric matrix coating to prevent corrosion under insulation (CUI) of

carbon and stainless steel to temperatures ranging up to 650°C (1200°F) and for cryogenic service on stainless steel from -185°C

to 538°C (-300°F to 1000°F). Also to be used as a primer on non-insulated steel in a system with PPG HI-TEMP topcoats.

PRINCIPAL CHARACTERISTICS

• Formulated to prevent chloride induced stress corrosion cracking of stainless steel and has been tested by an independent

laboratory for low leachable chlorides, sulfides and halides. It helps protect against chlorides from the atmosphere and by-

products of process operations, which may be incorporated in the insulation from coming in contact with stainless steel

• Can be hot applied direct to substrates with a temperature up to 316°C (600°F) eliminating the need for costly shutdown

during maintenance

• Can be topcoated with a full range of heat resistant PPG HI-TEMP topcoats

• Resistant to thermal shock and thermal cycling in intermittent (wet, steam, dry) service

• Can be applied to tightly adhering rust in maintenance and repair situations

• Protects cryogenic equipment in continuous or cyclic operation from –185°C (–300°F) to 538°C (1000°F)

• Provides an UV-resistant, chalking-free film with no maximum recoat interval, regardless of operating temperature, as long

as the surface to be recoated is clean and free of all contaminants

COLOR AND GLOSS LEVEL

• Black, gray and light gray

• Flat

Note: Minor color change may occur in exposed service, but corrosion protection will not be compromised

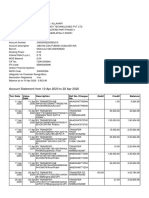

BASIC DATA AT 20°C (68°F)

Data for product

Number of components One

Mass density 1.9 kg/l (16.0 lb/US gal)

Volume solids 65 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 210.0 g/kg

max. 420.0 g/l (approx. 3.5 lb/US gal)

Temperature resistance (Continous) To 650°C (1200°F)

Temperature resistance (Intermittent) To 760°C (1400°F)

Cryogenic service -185°C (-300°F) to 538°C (1000°F)

Recommended dry film thickness 125 - 150 µm (5.0 - 6.0 mils) per coat

Theoretical spreading rate 5.2 m²/l for 125 µm (208 ft²/US gal for 5.0 mils)

Dry to overcoat/topcoat 6 hours

Dry to handle/ship 24 hours

Ref. P012 Page 1/6

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

Data for product

Shelf life At least 24 months when stored cool and dry

Note: See ADDITIONAL DATA – Spreading rate and film thickness

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Carbon steel

• All surfaces to be coated with PPG HI-TEMP 1027 must be free of all weld splatter, oil, dirt, grease, and all other

contaminants, especially salts. Round off all rough welds and sharp edges

• In maintenance and repair situations, PPG HI-TEMP 1027 can be applied over a surface in which tightly adhering rust is still

present; remove all rust scale and loosely adhering rust until glints of bright metal are visible. The remaining rust must be

tightly adherent and not easily removed by lightly wiping with a cloth

• PPG HI-TEMP 1027 should only be used to overcoat inorganic zinc or itself. When overcoating aged inorganic zinc, prepare

a small test patch and check for adhesion. If previously applied coatings other than inorganic zinc or PPG HI-TEMP 1027

are not fully removed by the method of surface preparation utilized, feather the edges of any remaining old coating, and use

PPG HI-TEMP 1027 to spot prime only the areas where the substrate is exposed

Non-insulated surfaces

• Recommended is dry abrasive blast cleaning to SSPC-SP 6, “Commercial Blast” (ISO-Sa 2) with a 25 to 50 μm (1.0 to 2.0

mils) profile

• When abrasive blast cleaning is not an option, the following methods are acceptable: (1) SSPC-SP 15 “Commercial Grade

Power Tool Cleaning”, with a minimum 25 μm (1.0 mil) profile; (2) SSPC-SP 12, “Surface Preparation by Water-jetting Prior

to Recoating” to meet the visual definition of WJ-3, “Thorough Cleaning.” Use potable water; (3) SSPC-SP3, “Power Tool

Cleaning” (ISO-St 3) or SSPC-SP 2, “Hand Tool Cleaning” (ISO-St 2)

Insulated surfaces

• Recommended is dry abrasive blast cleaning to SSPC-SP 6, “Commercial Blast” (ISO-Sa 2) with a 25 to 50 μm (1.0 to 2.0

mils) profile

• When abrasive blast cleaning is not an option, the following methods are acceptable: (1) SSPC-SP 15 “Commercial Grade

Power Tool Cleaning”, with a minimum 25 μm (1.0 mil) profile; (2) SSPC-SP 12, “Surface Preparation by Water-jetting Prior

to Recoating” to meet the visual definition of WJ-3, “Thorough Cleaning.” Use potable water. All existing coating must be

removed except for aged inorganic zinc or existing PPG HI-TEMP 1027; (3) Power or hand tool cleaning to remove all

existing coating except for aged inorganic zinc or existing PPG HI-TEMP 1027

Stainless steel

• All surfaces to be coated with PPG HI-TEMP 1027 shall be free of all weld splatter, oil, dirt, grease, and all other

contaminants, especially salts. Round off all rough welds and sharp edges

Note: Do not use chlorinated solvents on stainless steel surfaces

Ref. P012 Page 2/6

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

Non-insulated and insulated surfaces

• Small surfaces may be cleaned with a chlorinated-free solvent. Large surfaces may be cleaned utilizing a high- or low-

pressure wash or steam cleaning with an alkaline detergent, followed by a freshwater rinse. Water used should be potable

grade or better and should be checked to assure minimal salt content. Do not use any chemical additives in the rinse water

• An anchor profile is not mandatory for adhesion of PPG HI-TEMP 1027 on stainless steel surfaces. As an option, following

cleaning, a light abrasive sweep blast using an appropriate chloride-free abrasive may be performed. After completion of

this mechanical surface preparation, rinse the surface with potable grade water or better. Always allow rinsed surfaces to

dry before coating

Substrate temperature

• Substrate temperature during application should be between 10°C (50°F) and 66°C (151°F)

• Substrate temperature during application should be at least 3°C (5°F) above dew point

• Application to hot substrate: should be above 66°C (151°F) and below 316°C (600°F)

Note: For application to substrates over 260°C (500°F) to 316°C (600°F) a PPG representative needs to be consulted

SYSTEM SPECIFICATION

Insulated and non-insulated service: applied direct to ambient or hot carbon or stainless steel

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT

Notes:

- Third layer optional at 125 to 150 μm (5.0 to 6.0 mils) DFT; Total 375 to 450 μm (15.0 to 18.0 mils) DFT

- For insulated service, apply PPG HI-TEMP 1027 to achieve a minimum of 250 μm (10.0 mils) DFT

Primer/topcoat system – non-insulated service: applied direct to ambient or hot carbon and stainless steel

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT

• PPG HI-TEMP topcoats ambient apply: PPG HI-TEMP 500 VS or PPG HI-TEMP 1000 VS, hot apply: PPG HI-TEMP 500 VHA

or PPG HI-TEMP 1000 VHA

Cryogenic – insulated and non-insulated service: ambient stainless steel with service temperature range of Cryogenic –

insulated and non-insulated service: ambient stainless steel with service temperature range of –73°C to 204°C (–100°F to

400°F)

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT; Total 250 to 300 μm (10.0 to 12.0 mils) DFT

Cryogenic – insulated and non-insulated service: ambient stainless steel with service temperature range of -185°C to

538°C (-300°F to 1000°F)

• PPG HI-TEMP 1027: 125 to 150 μm (5.0 to 6.0 mils) DFT

Note: Do not exceed 200 μm (8.0 mils) total DFT

Ref. P012 Page 3/6

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

INSTRUCTIONS FOR USE

• PPG HI-TEMP 1027 is a heavy bodied material; use mechanical agitation for mixing immediately before application and as

needed during application. Be sure any settled solids are incorporated during mixing. If thinning is needed, thin only with

PPG thinners and in accordance with applicable regulations. Agitate as needed during application.

• For ambient application, surface temperature should be a minimum of 3°C (5°F) above dew point. Do not apply to surface

temperatures below 10°C (50°F)

• Do not exceed recommended maximum dry film thicknesses for the appropriate service type and temperatures

• It is essential to apply multiple thin passes of PPG HI-TEMP 1027 during application to hot steel. This process, similar to

mist coating, prevents blistering and also allows solvent to escape without leaving pinholes

• When applying to hot steel, use of a solvent other than THINNER 21-25 or PPG HI-TEMP #5 could produce a fire hazard,

and dry spray and poor film characteristics may also result. If blisters are observed in PPG HI-TEMP 1027 applied to hot

surfaces, immediately brush out the blisters before they set, using a wood-handled China bristle brush.

• For best results, do not apply PPG HI-TEMP 1027-00 black or PPG HI-TEMP 1027-90 gray over PPG HI-TEMP 1027-9003

light gray.

Air spray

Recommended thinner - application to ambient substrate below 66°C (150°F)

• THINNER 21-06 (PPG HI-TEMP THINNER 11/AMERCOAT 65)

• THINNER 91-10 or PPG HI-TEMP THINNER 10 (VOC compliant)

Recommended thinner - application to hot substrate at 66°C (150°F) up to 260°C (500°F)

• THINNER 21-25 or PPG HI-TEMP THINNER 5

Volume of thinner

0 - 5%, depending on required thickness and application conditions

Nozzle orifice

1.8 – 2.2 mm (approx. 0.070 – 0.087 in)

Nozzle pressure

0.4 - 0.6 MPa (approx. 4 - 6 bar; 58 - 87 p.s.i.)

Ref. P012 Page 4/6

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

Airless spray

Recommended thinner - application to ambient substrate below 66°C (150°F)

• THINNER 21-06 (PPG HI-TEMP THINNER 11/AMERCOAT 65)

• THINNER 91-10 or PPG HI-TEMP THINNER 10 (VOC compliant)

Recommended thinner - application to hot substrate at 66°C (150°F) up to 260°C (500°F)

• THINNER 21-25 or PPG HI-TEMP THINNER 5

Volume of thinner

0 - 5%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.48 – 0.53 mm (0.019 – 0.021 in)

Nozzle pressure

13.8 MPa (approx. 138 bar; 2002 p.s.i.)

Brush/roller

Recommended thinner - application to ambient substrate below 66°C (150°F)

• THINNER 21-06 (PPG HI-TEMP THINNER 11/AMERCOAT 65)

• THINNER 91-10 or PPG HI-TEMP THINNER 10 (VOC compliant)

Recommended thinner - application to hot substrate at 66°C (150°F) up to 260°C (500°F)

• THINNER 21-25 or PPG HI-TEMP THINNER 5

Volume of thinner

Up to 5% THINNER can be added if desired

Note: Spray application is recommended but when spray painting is not possible, brush or roller may be used. The coating should

be applied with a suitable brush or short nap roller. Brushing and rolling only in one direction may aid in building film thickness.

For more specific instructions, refer to the PPG HI-TEMP application guidelines.

Cleaning solvent

• THINNER 21-06 (PPG HI-TEMP THINNER 11/AMERCOAT 65)

• THINNER 91-10 or PPG HI-TEMP THINNER 10 (VOC compliant)

• THINNER 21-25 or PPG HI-TEMP THINNER 5

ADDITIONAL DATA

Spreading rate and film thickness – Black and colors

DFT Theoretical spreading rate

125 µm (5.0 mils) 5.2 m²/l (208 ft²/US gal)

150 µm (6.0 mils) 4.3 m²/l (174 ft²/US gal)

Ref. P012 Page 5/6

PRODUCT DATA SHEET December 31, 2014 (Revision of November 28, 2014)

PPG HI-TEMP 1027™

Curing time for DFT up to 150 μm (6.0 mils)

Substrate temperature Dry to recoat/topcoat Dry to handle/ship

10°C (50°F) 24 hours 24 hours

20°C (68°F) 6 hours 24 hours

38°C (100°F) 5 hours 24 hours

150°C (300°F) 15 minutes N/A

Note: Drying times can vary based on environmental and substrate conditions. Do not exceed maximum dry film thickness

recommendations as this can affect dry times

SAFETY PRECAUTIONS

• The product is for use only by professional applicators in accordance with information in this product data sheet and the

applicable material safety data sheet (MSDS). Refer to the appropriate MSDS before using this material. All use and

application of this product should be performed in compliance with all relative federal, state and local, health, safety and

environmental regulations or in compliance with all pertinent local, regional and national regulations as well as good safety

practices for painting, and in conformance with recommendations in SSPC PA 1, “Shop, Field and Maintenance Painting of

Steel.”

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. P012 Page 6/6

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- PPG HI-TEMP 1027 NewDocument7 pagesPPG HI-TEMP 1027 NewsachinpsawantNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- PPG HI-TEMP 1027™: Product Data SheetDocument6 pagesPPG HI-TEMP 1027™: Product Data Sheettanmay rahmanNo ratings yet

- PPG Hi-Temp™ 222 G: Product Data SheetDocument6 pagesPPG Hi-Temp™ 222 G: Product Data SheetJefry SandyNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- PPG Hi-Temp™ 500Document6 pagesPPG Hi-Temp™ 500Marleo MorenoNo ratings yet

- en-US_P091Document8 pagesen-US_P091Cris gomezNo ratings yet

- PPG PDS Amercoat 370Document7 pagesPPG PDS Amercoat 370sanguripNo ratings yet

- Thermaline Heat Shield PDSDocument4 pagesThermaline Heat Shield PDSfrosted296No ratings yet

- Amercoat® 385: Product Data SheetDocument8 pagesAmercoat® 385: Product Data SheetNizar BouchaalaNo ratings yet

- Hi-Temp 1027 PDFDocument4 pagesHi-Temp 1027 PDFquiron2014No ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- Amercoat® 385: Product Data SheetDocument8 pagesAmercoat® 385: Product Data SheetSampath GaneshNo ratings yet

- SigmaPrime 200Document7 pagesSigmaPrime 200amshivNo ratings yet

- PPG Hi-Temp™ 1027 HDDocument5 pagesPPG Hi-Temp™ 1027 HDMarleo MorenoNo ratings yet

- HEAT RESISTANT SILICONE ALUMINIUM PAINTDocument3 pagesHEAT RESISTANT SILICONE ALUMINIUM PAINTrumi_2kNo ratings yet

- PPG HI-TEMP™ 1000: Product Data SheetDocument6 pagesPPG HI-TEMP™ 1000: Product Data SheetJefry SandyNo ratings yet

- Interplus 1180: Protective CoatingsDocument4 pagesInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNo ratings yet

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNo ratings yet

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaNo ratings yet

- Plasite 7159 HAR abrasion resistant epoxyDocument4 pagesPlasite 7159 HAR abrasion resistant epoxyRobertoNo ratings yet

- HEMPADUR SPEED-DRY ZP 500 Product Data SheetDocument3 pagesHEMPADUR SPEED-DRY ZP 500 Product Data SheetDHANOOPNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158JORGEALEXERNo ratings yet

- Apcoguard SF 725Document3 pagesApcoguard SF 725kiran vargheseNo ratings yet

- Boletim Técnico Interplus 356Document4 pagesBoletim Técnico Interplus 356Erik RochaNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Zinc Primer Product Data SheetDocument7 pagesZinc Primer Product Data Sheethk168No ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- PC 1787 - Apcotherm HR 600 PDFDocument3 pagesPC 1787 - Apcotherm HR 600 PDF41464147No ratings yet

- PC 7048 - Asian Epoxy Dual CoatDocument3 pagesPC 7048 - Asian Epoxy Dual CoatGunjan GaganNo ratings yet

- Sigmafast 278Document6 pagesSigmafast 278stolemkd3No ratings yet

- New Guard Coatings Group Protects with Epoxy PrimersDocument8 pagesNew Guard Coatings Group Protects with Epoxy PrimersshunanlatheefNo ratings yet

- Jotatemp 1000 Ceramic High-Heat Protective Coating TDSDocument5 pagesJotatemp 1000 Ceramic High-Heat Protective Coating TDSGurdeep Sungh AroraNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- 7) PPG Amercoat 385 - Pds - AiDocument4 pages7) PPG Amercoat 385 - Pds - AididbeauNo ratings yet

- ZRC Zero VocDocument2 pagesZRC Zero Vochksn77No ratings yet

- Semigloss 90 - 1210 PDSDocument6 pagesSemigloss 90 - 1210 PDSPablo PuebloNo ratings yet

- 1027 Application GuidelineDocument6 pages1027 Application GuidelineJORGEALEXERNo ratings yet

- Carbothane+134+HG+PDS+3 11Document2 pagesCarbothane+134+HG+PDS+3 11James Everett AbdulNo ratings yet

- PDS - 7863 - Sigmacap Zinc Silicate IIDocument5 pagesPDS - 7863 - Sigmacap Zinc Silicate IIIbrahim MahranNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Amerlock 400 Sigmacover 400Document6 pagesAmerlock 400 Sigmacover 400Vijay KumarNo ratings yet

- PC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540Document3 pagesPC 0189 - Heat Resisting Silicone Aluminium Paint - Apcotherm 540onshore purchase100% (1)

- Sigmacover 240 Data SheetDocument7 pagesSigmacover 240 Data Sheetantonio larottaNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- SigmaCover 280Document5 pagesSigmaCover 280ajuhaseenNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Zinga Technical Data SheetDocument6 pagesZinga Technical Data SheetVikas TanejaNo ratings yet

- Interseal 670 HS EN O-FDocument4 pagesInterseal 670 HS EN O-Fapde06No ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Thermaline 4700 PDSDocument4 pagesThermaline 4700 PDSLâm Trần BáNo ratings yet

- Sigmazinc 158Document7 pagesSigmazinc 158gstketutNo ratings yet

- 3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFDocument8 pages3mtm Scotch Weldtm Epoxy Adhesive 2216 B A PDFFran GaritaNo ratings yet

- Coating System Recommendation for Infrastructure ProjectDocument9 pagesCoating System Recommendation for Infrastructure ProjectHariHaranNo ratings yet

- SIgmaweld 199 - PDSDocument5 pagesSIgmaweld 199 - PDS이선엽No ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- AWS - Welding SymbolsDocument1 pageAWS - Welding SymbolsAli Saifullizan IsmailNo ratings yet

- Alloy904L SpecSheet PDFDocument2 pagesAlloy904L SpecSheet PDFPieter BrodeouxNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Welding Guidelines for Sandvik 2RK65Document6 pagesWelding Guidelines for Sandvik 2RK65qaNo ratings yet

- (EW-512-4) - Discontinuities and Defects - Training Workbook-Hobart Institute of Welding Technology (Yasser Tawfik)Document41 pages(EW-512-4) - Discontinuities and Defects - Training Workbook-Hobart Institute of Welding Technology (Yasser Tawfik)kirubha_karan2000100% (2)

- Hardtop XP Alu: Technical Data SheetDocument5 pagesHardtop XP Alu: Technical Data SheetargaNo ratings yet

- Selection of Suitable Welding Consumable For Given ApplicationDocument37 pagesSelection of Suitable Welding Consumable For Given ApplicationqaNo ratings yet

- Welding DefectsDocument122 pagesWelding DefectsqaNo ratings yet

- Manual For Surface Treatment of Stainless Steels: Lasting ConnectionsDocument40 pagesManual For Surface Treatment of Stainless Steels: Lasting ConnectionsAsgard Sanchez100% (1)

- A. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Document288 pagesA. O. Univ.-Prof. Dipl.-Ing. Dr. Mont. Erich Folkhard (Auth.) - Welding Metallurgy of Stainless Steels-Springer-Verlag Wien (1988)Graylab Technologies100% (1)

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Penguard Midcoat MIO: Technical Data SheetDocument4 pagesPenguard Midcoat MIO: Technical Data Sheetgst ajahNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetMohamed FarhanNo ratings yet

- 03 Essential Metallurgical AspectsDocument22 pages03 Essential Metallurgical AspectsqaNo ratings yet

- 02 - Overview of Welding ProcessesDocument11 pages02 - Overview of Welding ProcessesqaNo ratings yet

- 01 - Process Control IntroDocument16 pages01 - Process Control IntroqaNo ratings yet

- 21 Chemical Elements and Effects On Steel Mechanical Properties - Jeremy H. - Pulse - LinkedInDocument7 pages21 Chemical Elements and Effects On Steel Mechanical Properties - Jeremy H. - Pulse - LinkedInqaNo ratings yet

- Asme Sa 240 PDFDocument16 pagesAsme Sa 240 PDFqaNo ratings yet

- Physical Metallurgy: Lecture byDocument78 pagesPhysical Metallurgy: Lecture byqaNo ratings yet

- Cladding Clad RestorationDocument41 pagesCladding Clad RestorationBaveenaDinesh100% (2)

- Technology: Answers Drawing BDocument5 pagesTechnology: Answers Drawing BWellington S. França100% (1)

- Technology: Answers Drawing CDocument6 pagesTechnology: Answers Drawing Culsan busanNo ratings yet

- Cladding Clad RestorationDocument41 pagesCladding Clad RestorationBaveenaDinesh100% (2)

- AWS D10.4-86R - Recommended Practices For Welding Austenitic Chromium - Nickel Stainless Steel Piping and TubingDocument40 pagesAWS D10.4-86R - Recommended Practices For Welding Austenitic Chromium - Nickel Stainless Steel Piping and TubingqaNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportDocument5 pagesPrecision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportqaNo ratings yet

- Cladding Clad RestorationDocument41 pagesCladding Clad RestorationBaveenaDinesh100% (2)

- Typical Tube Expansion ReportDocument1 pageTypical Tube Expansion ReportqaNo ratings yet

- Contents2 PDFDocument1 pageContents2 PDFqaNo ratings yet

- Contents2 PDFDocument1 pageContents2 PDFqaNo ratings yet

- Англійська моваDocument42 pagesАнглійська моваUyên Trâm TrầnNo ratings yet

- Reliable Exports Lease DeedDocument27 pagesReliable Exports Lease DeedOkkishoreNo ratings yet

- 1.1.6 Einstein Coefficients - 1: Rate EquationDocument15 pages1.1.6 Einstein Coefficients - 1: Rate Equationshouravme2k11No ratings yet

- External Aids - IiiDocument84 pagesExternal Aids - IiiPrasun TiwariNo ratings yet

- Munit Blue Manual 1.8 enDocument21 pagesMunit Blue Manual 1.8 engiambi-1No ratings yet

- Test 1: in ChargeDocument9 pagesTest 1: in ChargeT. JHONNo ratings yet

- Under 13, 15 and Open NewDocument3 pagesUnder 13, 15 and Open NewPRADEEP PATHAKNo ratings yet

- Practical Accounting Problems SolutionsDocument11 pagesPractical Accounting Problems SolutionsjustjadeNo ratings yet

- 375 1425035526891 PDFDocument404 pages375 1425035526891 PDFjmhdeveNo ratings yet

- 1 Covered Bond Council Mortgage Loan Securitization FINAL 1Document3 pages1 Covered Bond Council Mortgage Loan Securitization FINAL 1Richard RydstromNo ratings yet

- Input Data Sheet For SHS E-Class Record: Learners' NamesDocument4 pagesInput Data Sheet For SHS E-Class Record: Learners' NamesJetro EspinasNo ratings yet

- Basic Concepts of A Business Concern-Corporate OrganizationDocument5 pagesBasic Concepts of A Business Concern-Corporate OrganizationMsw Ange100% (1)

- Oh DarlingDocument4 pagesOh DarlingLaurent BotzNo ratings yet

- Account activity and balance from 10 Apr to 22 AprDocument2 pagesAccount activity and balance from 10 Apr to 22 AprSRIDHAR allhari0% (1)

- Judicial Interference ComplaintDocument6 pagesJudicial Interference ComplaintNC Policy WatchNo ratings yet

- Capital Logic Interactive 224840Document12 pagesCapital Logic Interactive 224840nizarfeb0% (2)

- GE 3 Phil-His Finals-ModuleDocument20 pagesGE 3 Phil-His Finals-ModuleElsie Joy LicarteNo ratings yet

- Virtual Weddings Under Philippine Law - PFB.20-08-03Document4 pagesVirtual Weddings Under Philippine Law - PFB.20-08-03Pedro José Fausto BernardoNo ratings yet

- NPA Recruitment Strategy EDITEDDocument55 pagesNPA Recruitment Strategy EDITEDLisha Binong100% (1)

- RODRIGUEZ VS TAN HEIRS' RIGHT TO ADMINISTER ESTATEDocument2 pagesRODRIGUEZ VS TAN HEIRS' RIGHT TO ADMINISTER ESTATEtops videosNo ratings yet

- USA V Kevin Seefried Sentencing Memo by USADocument42 pagesUSA V Kevin Seefried Sentencing Memo by USAFile 411No ratings yet

- Accounts Form 4 - 2021Document51 pagesAccounts Form 4 - 2021gangstar sippas100% (1)

- Do We Live in A MeritocracyDocument2 pagesDo We Live in A MeritocracymimirosellNo ratings yet

- Pre-Need Manual of Examination - CL2018 - 01Document53 pagesPre-Need Manual of Examination - CL2018 - 01Ipe ClosaNo ratings yet

- SabioDocument2 pagesSabioPrecious TancincoNo ratings yet

- Syllabus - LABOR LAW 1-Atty. TiofiloDocument12 pagesSyllabus - LABOR LAW 1-Atty. TiofiloJeffrey MendozaNo ratings yet

- Dogwhistles, political manipulation analyzedDocument38 pagesDogwhistles, political manipulation analyzedMaria Fernanda Galvis GomezNo ratings yet

- CHAPTER 17 - RevisedDocument3 pagesCHAPTER 17 - RevisedJoy ReAliza GuerreroNo ratings yet

- Chapter 7 Audit of LiabilitiesDocument26 pagesChapter 7 Audit of LiabilitiesSteffany Roque100% (2)

- Vigilantibus Et Non Dormientibus Jura SubveniuntDocument3 pagesVigilantibus Et Non Dormientibus Jura SubveniuntferozekasNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Product Management: 7-Step Guide from Zero to Hero: Product ManagementFrom EverandProduct Management: 7-Step Guide from Zero to Hero: Product ManagementNo ratings yet