Professional Documents

Culture Documents

Working Principle of Thermal Motor Protection Relay

Uploaded by

at35Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Working Principle of Thermal Motor Protection Relay

Uploaded by

at35Copyright:

Available Formats

elect rical-engineering-port al.

com

http://electrical-engineering-portal.com/working-principle-of-thermal-motor-protection-relay

Worki ng Pri nci pl e Of Thermal Motor

Protecti on Rel ay

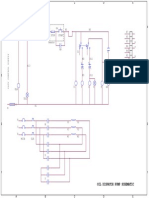

Fi gure 1 - Pri nci pl e of operati on of a three

pol e thermal l y del ayed bi metal motor

protecti on rel ay wi th temperature

compensati on

Edvard

Working Principle Of Thermal Motor Protection Relay

Principle of operation

Thermal motor protection relays contain three bimetal strips

together with a trip mechanism in a housing made of insulating

material. The bimetal strips are heated by the motor current,

causing them to bend and activating the trip mechanism af ter a

certain travel which depends on the current-setting of the relay.

The release mechanism actuates an auxiliary switch that breaks

the coil circuit of the motor contactor (Figure 1). A switching

position indicator signals the condition tripped.

A = Indirectly heated bimetal strips

B = Trip slide

C = Trip lever

D = Contact lever

E = Compensation bimetal strip

The bimetal strips may be heated directly or indirectly. In the f irst

case, the current flows directly through the bimetal, in the

second through an insulated heating winding around the strip.

The insulation causes some delay of the heat-f low so that the

inertia of indirectly heated thermal relays is greater at higher

currents than with their directly heated counterparts. Of ten both principles are combined.

For motor rated currents over approx. 100 A, the motor current is conducted via current transformers. The

thermal overload relay is then heated by the secondary current of the current transf ormer.

This means on one hand, that the dissipated power is reduced and, on the other, that the short-circuit

withstand capacity is increased.

The tripping current of bimetal relays can be set on a current scale by displacement of the trip mechanism

relative to the bimetal strips so that the protection characteristic can be matched to the protected object

in the key area of continuous duty.

The simple, economical design can only approximate the transient thermal characteristic of the motor.

For starting with subsequent continuous duty, the thermal motor protection relay provides perf ect

protection f or the motor. With f requent start-ups in intermittent operation the signif icantly lower heating

time constant of the bimetal strips compared to the motor results in early tripping in which the thermal

capacity of the motor is not utilized.

The cooling time constant of thermal relays is shorter than that of normal motors. This also contributes

to an increasing dif f erence between the actual temperature of the motor and that simulated by the thermal

relay in intermittent operation.

For these reasons, the protection of motors in intermittent operation is insufficient.

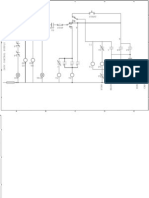

Fi gure 2 - Tri ppi ng tol erances for

temperature-compensated overl oad

rel ays for motor rotecti on under IEC

60947-4-1

Typi cal tri p characteri sti cs of a motor

protecti on rel ay

Temperat ure compensat ion

The principle of operation of thermal motor protection relays is based on temperature rise.

Theref ore the ambient temperature of the device af f ects the tripping specif ications. As the installation

site and hence the ambient temperature of the motor to be protected usually is dif f erent f rom that of the

protective device it is an industry standard that the tripping characteris-tic of a bimetal relay is temperature-

compensated, i.e. largely independent of its ambient temperature (see Figure 2 below).

I = Overload as a multiple of the set current

= Ambient temperature

- Limit values under IEC 60947-4-1

This is achieved with a compensation bimetal strip that makes

the relative position of the trip mechanism independent of the

temperature.

Cant see this video? Click here to watch it on Youtube.

Sensit ivit y t o phase f ailure

The tripping characteristic of three-pole motor protection relays

applies subject to the condition that all three bimetal strips are loaded with the same current at the

same time.

If , when one pole conductor is interrupted, only two bimetal strips are heated then these two strips must

alone produce the f orce required to actuate the trip mechanism. This requires a higher current or results in

a longer tripping time (characteristic curve c in Figure below).

I

e

= Rated current set on the scale

t = Tripping time

From a cold state:

a = 3-pole load, symmetrical

b = 2-pole load with dif f erential release

c = 2-pole load without dif f erential release

From the warm state:

d = 3-pole load, symmetrical

If larger motors (10 kW) are subjected to these higher currents

f or a longer time, damage should be expected.

In order to also ensure the thermal overload protection of the

motor in the cases of supply asymmetry and loss of a phase, high

quality motor protection relays have mechanisms with phase

f ailure sensitivity (differential release).

Resource: Low Voltage Switchgear and Controlgear Rockwell

You might also like

- P643 Transformer Differential Protection TestingDocument12 pagesP643 Transformer Differential Protection TestingsaadNo ratings yet

- Test Report For Feeder Protection RelayDocument3 pagesTest Report For Feeder Protection RelayHari haranNo ratings yet

- G60 TestedDocument4 pagesG60 TestedRagab TolbaNo ratings yet

- Functional Test of Thermal Overload ProtectionDocument1 pageFunctional Test of Thermal Overload ProtectionMihai BancuNo ratings yet

- FM Spae01 en BDocument12 pagesFM Spae01 en BSudhakar YsNo ratings yet

- VC-6000 Monitoring SystemDocument8 pagesVC-6000 Monitoring Systemahwaz89No ratings yet

- 7UT 613 Tfr. Diff. RelayDocument7 pages7UT 613 Tfr. Diff. RelayAbo Abdullah MohamedNo ratings yet

- P632 EN M R-32-D 311 652 Volume 2Document444 pagesP632 EN M R-32-D 311 652 Volume 2Đặng Phước ĐứcNo ratings yet

- Unit-I Circuit BreakersDocument13 pagesUnit-I Circuit Breakerspurushg62No ratings yet

- Ohb Manual SF6 CB ABBDocument35 pagesOhb Manual SF6 CB ABBkishansaiNo ratings yet

- YN1M303029-PNN - Rev 0Document33 pagesYN1M303029-PNN - Rev 0Neel Atiq100% (1)

- 20121130133052209Document5 pages20121130133052209freddysh4330No ratings yet

- Transformer Differential Protection Setting 1694146406Document50 pagesTransformer Differential Protection Setting 1694146406Yann LE BORGNENo ratings yet

- VT Guard Pro - Technical ArticleDocument4 pagesVT Guard Pro - Technical ArticleAdemir DzanicNo ratings yet

- Siemens 7SJ86 V7.00 Feeder PTT User Manual ENUDocument5 pagesSiemens 7SJ86 V7.00 Feeder PTT User Manual ENURaúlEmirGutiérrezLópezNo ratings yet

- Substation Testing and Commissioning: High Impedence Busbar ProtectionDocument8 pagesSubstation Testing and Commissioning: High Impedence Busbar ProtectionThirumal100% (1)

- Mog TrafoDocument27 pagesMog TrafoPandrayar MaruthuNo ratings yet

- Ccum 21Document4 pagesCcum 21Hari Krishna.MNo ratings yet

- Root-Cause Analysis of Transformer Failure Scenario at Power Sub-StationDocument6 pagesRoot-Cause Analysis of Transformer Failure Scenario at Power Sub-StationShashank ChawdharyNo ratings yet

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDocument67 pagesA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyNo ratings yet

- Trivector MeterDocument2 pagesTrivector MeterTarun AhujaNo ratings yet

- MiCOM P122CDocument8 pagesMiCOM P122Cকুররাতুল আইনNo ratings yet

- Testingcommissioning Blogspot QaDocument5 pagesTestingcommissioning Blogspot QaratheeshkumardNo ratings yet

- CSC-326 Catalogue PDFDocument24 pagesCSC-326 Catalogue PDFRavi Shankar VNo ratings yet

- Dokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerDocument4 pagesDokumen - Tips - Numerical Rho 3 Motor Protection Relay Easun R Current TransformerPAWAN RAJPUTNo ratings yet

- Disconnector Contact Condition PDFDocument130 pagesDisconnector Contact Condition PDFipraoNo ratings yet

- 1or 2 Pole Breaker For TractionDocument8 pages1or 2 Pole Breaker For Tractiongyanendra_vatsa4380No ratings yet

- MC 31Document33 pagesMC 31nick321walkerNo ratings yet

- Neutral Displacement Relay PDFDocument4 pagesNeutral Displacement Relay PDFjoydeep_d3232No ratings yet

- DGT801 Operation Manual Instruction of MmiDocument22 pagesDGT801 Operation Manual Instruction of MmiNaresh Kanuri67% (3)

- Definition of Basic Insulation Level BILDocument7 pagesDefinition of Basic Insulation Level BILPierre Enrique Carrasco FuentesNo ratings yet

- Mc31a Rev5Document33 pagesMc31a Rev5sanju939No ratings yet

- Reverse PowerDocument6 pagesReverse PowerEdward DineshNo ratings yet

- Causes of Over Fluxing in TransformerDocument3 pagesCauses of Over Fluxing in TransformerHamayoun Murtaza0% (1)

- Traductor Sineax m561 m562 m563Document18 pagesTraductor Sineax m561 m562 m563Marica CristiNo ratings yet

- Lecture On Protection System231113Document12 pagesLecture On Protection System231113Raman JainNo ratings yet

- Sverker 760Document6 pagesSverker 760Junior Ramirez ReyesNo ratings yet

- 7SK80 Protection of Medium-Power Motors A1 PDFDocument11 pages7SK80 Protection of Medium-Power Motors A1 PDFpothirajNo ratings yet

- 220kV Bahraich REL670settings (PG End)Document8 pages220kV Bahraich REL670settings (PG End)PRINCE SRIVASTAVANo ratings yet

- Introduction To Instrument TransformersDocument20 pagesIntroduction To Instrument TransformersAbdul'Azeez Stanley IgweNo ratings yet

- 7SR10Document12 pages7SR10Sanjeev VermaNo ratings yet

- Walt Kester, Joe Buxton: Section 5 Battery ChargersDocument25 pagesWalt Kester, Joe Buxton: Section 5 Battery Chargersarde50No ratings yet

- Transformer PtotectionsDocument19 pagesTransformer Ptotectionsbiju singhNo ratings yet

- Micom P341Document425 pagesMicom P341Vel MuruganNo ratings yet

- MVAXDocument24 pagesMVAXkedsoi2No ratings yet

- SIP5 6MD85-86 V07.50 Manual C015-9 en PDFDocument1,216 pagesSIP5 6MD85-86 V07.50 Manual C015-9 en PDFandreabautista1982No ratings yet

- Insulation Resistance Test of Circuit BreakerDocument2 pagesInsulation Resistance Test of Circuit BreakerVedant .ChavanNo ratings yet

- SIP5 7UM85 V07.30 Manual C027-2 enDocument1,756 pagesSIP5 7UM85 V07.30 Manual C027-2 enMarioyfernanda Guerra MuruaNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats DescriptionDocument4 pagesCommissioning Service Department Commissioning Standard Test Formats Descriptionm khNo ratings yet

- ADR241CDocument11 pagesADR241CNamrata ShettiNo ratings yet

- Normal Inverse IDMT Form 1.3/10 Relays Type 2TJM70: Easun ReyrolleDocument2 pagesNormal Inverse IDMT Form 1.3/10 Relays Type 2TJM70: Easun ReyrolleSasiKumar SivathangaveluNo ratings yet

- REF Fuse Application GuideDocument17 pagesREF Fuse Application GuidemuskanumeedNo ratings yet

- Ms MP Manual 2012Document8 pagesMs MP Manual 2012Arun KumarNo ratings yet

- Protection of Industrial SystemsDocument13 pagesProtection of Industrial SystemsJorge A. Perez YebraNo ratings yet

- Thermal Overload Motor Relay ProtectionDocument6 pagesThermal Overload Motor Relay Protectionميجا بروجكت (Mega Project)No ratings yet

- Motor Protection Voltage UnbalanceDocument7 pagesMotor Protection Voltage UnbalancehaamadhNo ratings yet

- Thermal Overload Motor Relay ProtectionDocument7 pagesThermal Overload Motor Relay ProtectionPierre Enrique Carrasco FuentesNo ratings yet

- Reverse Power Protection of Alternator PDFDocument29 pagesReverse Power Protection of Alternator PDFjupiterox75% (4)

- CBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.3Document21 pagesCBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.3at35No ratings yet

- CBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.4Document31 pagesCBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.4at35No ratings yet

- Biology Merit 1516Document90 pagesBiology Merit 1516at35No ratings yet

- Admitted List 17-7-2015Document35 pagesAdmitted List 17-7-2015BhojNo ratings yet

- Technical Specification For Pressure Relief ValvesDocument7 pagesTechnical Specification For Pressure Relief Valvesat35100% (1)

- Technical Specification For Pressure Relief Valves PDFDocument7 pagesTechnical Specification For Pressure Relief Valves PDFat35100% (1)

- Sources and Contributors To Short Circuit CurrentDocument2 pagesSources and Contributors To Short Circuit Currentat35No ratings yet

- Technical Specification For Level GaugesDocument6 pagesTechnical Specification For Level Gaugesat35100% (1)

- Sizing The DOL Motor Starter PartsDocument4 pagesSizing The DOL Motor Starter Partsat35No ratings yet

- AC Motors Protection Against Short CircuitsDocument4 pagesAC Motors Protection Against Short Circuitsat35No ratings yet

- Btech Merit 1516Document103 pagesBtech Merit 1516at35No ratings yet

- Allot List p4Document42 pagesAllot List p4at35No ratings yet

- Maintenance Management of Electrical Equipment Condition Monitoring Based Part 3Document4 pagesMaintenance Management of Electrical Equipment Condition Monitoring Based Part 3at35No ratings yet

- SOP EarthingDocument3 pagesSOP Earthingat35100% (1)

- STR Dlta 100 HPDocument1 pageSTR Dlta 100 HPat35No ratings yet

- Construction of 3phase AC Induction MotorsDocument3 pagesConstruction of 3phase AC Induction Motorsat35No ratings yet

- 6 Simple Rules To Ensure Substation SafetyDocument3 pages6 Simple Rules To Ensure Substation Safetyat35No ratings yet

- SR ScalesDocument9 pagesSR Scalesat35100% (1)

- Chengudu China ATS PanelDocument2 pagesChengudu China ATS Panelat35No ratings yet

- Chapter 3 Basics of Protective RelayingDocument17 pagesChapter 3 Basics of Protective Relayingkaren dejoNo ratings yet

- Durga New SRP Panel Schematic: M Start 10Document2 pagesDurga New SRP Panel Schematic: M Start 10at35No ratings yet

- Delhi Public School, Srinagar: Chapter 5 IndustriesDocument5 pagesDelhi Public School, Srinagar: Chapter 5 Industriesat35No ratings yet

- ATS SchematicDocument2 pagesATS Schematicat35No ratings yet

- Le Chatelier's Principle Virtual LabDocument8 pagesLe Chatelier's Principle Virtual Lab2018dgscmtNo ratings yet

- Karthik ResumeDocument2 pagesKarthik ResumeArun Raj ANo ratings yet

- Microeconomics Term 1 SlidesDocument494 pagesMicroeconomics Term 1 SlidesSidra BhattiNo ratings yet

- Research On Export Trade in BangladeshDocument7 pagesResearch On Export Trade in BangladeshFarjana AnwarNo ratings yet

- TMPRO CASABE 1318 Ecopetrol Full ReportDocument55 pagesTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloNo ratings yet

- Hydrogeological Survey and Eia Tor - Karuri BoreholeDocument3 pagesHydrogeological Survey and Eia Tor - Karuri BoreholeMutonga Kitheko100% (1)

- Britannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersDocument8 pagesBritannia Volume 12 Issue 1981 (Doi 10.2307/526240) Michael P. Speidel - Princeps As A Title For 'Ad Hoc' CommandersSteftyraNo ratings yet

- GTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerDocument1 pageGTA IV Simple Native Trainer v6.5 Key Bindings For SingleplayerThanuja DilshanNo ratings yet

- Better Photography - April 2018 PDFDocument100 pagesBetter Photography - April 2018 PDFPeter100% (1)

- Automated Dish Washer v1.1Document21 pagesAutomated Dish Washer v1.1Anonymous XXCCYAEY6M67% (3)

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Document293 pagesChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaNo ratings yet

- Power Control 3G CDMADocument18 pagesPower Control 3G CDMAmanproxNo ratings yet

- Part Time Civil SyllabusDocument67 pagesPart Time Civil SyllabusEr Govind Singh ChauhanNo ratings yet

- Ae - Centuries Before 1400 Are Listed As Browsable DirectoriesDocument3 pagesAe - Centuries Before 1400 Are Listed As Browsable DirectoriesPolNeimanNo ratings yet

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNo ratings yet

- Information Technology Project Management: by Jack T. MarchewkaDocument44 pagesInformation Technology Project Management: by Jack T. Marchewkadeeps0705No ratings yet

- QuinnmcfeetersresumeDocument1 pageQuinnmcfeetersresumeapi-510833585No ratings yet

- Homework 1Document8 pagesHomework 1Yooncheul JeungNo ratings yet

- Sistine Chapel Ceiling Lesson PlanDocument28 pagesSistine Chapel Ceiling Lesson PlannivamNo ratings yet

- Accounting Worksheet Problem 4Document19 pagesAccounting Worksheet Problem 4RELLON, James, M.100% (1)

- Practical Cs Xii Mysql 2022-23 FinalDocument9 pagesPractical Cs Xii Mysql 2022-23 FinalHimanshu GuptaNo ratings yet

- LRAD Datasheet 2000XDocument2 pagesLRAD Datasheet 2000XOkkar MaungNo ratings yet

- CDR Writing: Components of The CDRDocument5 pagesCDR Writing: Components of The CDRindikuma100% (3)

- Ebops PDFDocument2 pagesEbops PDFtuan nguyen duyNo ratings yet

- Powerwin EngDocument24 pagesPowerwin Engbillwillis66No ratings yet

- LM2TB8 2018 (Online)Document252 pagesLM2TB8 2018 (Online)SandhirNo ratings yet

- Understanding The Marshall AttackDocument6 pagesUnderstanding The Marshall Attacks.for.saad8176No ratings yet

- 1"a Study On Employee Retention in Amara Raja Power Systems LTDDocument81 pages1"a Study On Employee Retention in Amara Raja Power Systems LTDJerome Samuel100% (1)

- LavazzaDocument2 pagesLavazzajendakimNo ratings yet

- Chapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentDocument43 pagesChapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentHsieh Yun JuNo ratings yet