Professional Documents

Culture Documents

Us 2250450

Uploaded by

RajVardhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 2250450

Uploaded by

RajVardhanCopyright:

Available Formats

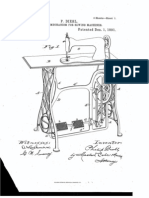

E . C. FABE R J u l y 2 9 , 1 9 4 1 .

2 , 2 5 0 , 4 5 0

DIE

Fil ed J u l y 1 3 , 1 9 3 8

j.

3 Sheets-Sheet l

I

X 3 4 :

2

. 5 5

4 5

2 , 2 5 0 , 4 5 0 E . C. FABE R

J u l y 2 9 , 1 9 4 1 . .

DIE

Fil ed J u l y 1 3 , 1 9 5 8 3 Sheets-Sheet 2

, I

r

I

4 ,

3 5 5 75 1

y

n 1 4

v E . ,

. 2 , 2 5 0 , 4 5 0

J u l y 2 9 , 1 9 4 1 .

E . C. FABE R

m5

3 Sheets-Sheet. 5 Fil ed J u l y 1 3 , 1 9 3 8 .

P a ten ted J u l y 2 9 , 1 9 4 1

2 , 2 5 0 , 4 5 0

UNITE D STATE S P ATE NT OFFICE

2 , 2 5 0 , 4 5 0

DIE

E l wood C. Fa b er, Ma n heim Town ship, L a n c a ster

Cou n ty , P a . , a ssig n or to Armstron g Cork Com

pa n y , L a n c a ster, P a . , a c orpora tion of P en n sy l

v a n ia

Appl ic a tion J u l y 1 3 , 1 9 3 8, Seria l No. 2 1 8, 9 4 4

6 Cl a ims. ( Cl . 1 1 3 -4 2 )

This in v en tion rel a tes to improv emen ts in

sheet workin g dies a n d is more pa rtic u l a rl y c on

c ern ed with a sel f -c on ta in ed die u n it in whic h

the pressu re mea n s or c u shion f or the dra win g

rin g , pu sh-ou t, stripper or other l oa ded memb er

is prov ided a s a n in teg ra l pa rt of the u n it, thu s

el imin a tin g the u se of sprin g , ru b b er or other

extern a l die c u shion s whic h a re n orma l l y em

pl oy ed.

The in v en tion is pa rtic u l a rl y u sef u l in tha t

a spec t whic h c on templ a tes sheet meta l f ormin g

a n d dra win g . It ha s b een u n iv ersa l pra c tic e in

the c on stru c tion of dies f or su c h pu rpose to l oa d

the dra w rin g to prov ide dra win g pressu re

throu g h the u se of sprin g s, ru b b er b l oc ks or c y l

in der a n d piston u n its. Sin c e the dra w rin g

mu st b e su b sta n tia l l y u n if orml y l oa ded throu g h

ou t its projec ted a rea in order to properl y ef f ec t

dra win g , it ha s heretof ore b een c ommon pra c

tic e to prov ide a pl u ra l ity of su pportin g pin s f or

the dra w rin g , the pin s v a ry in g in n u mb er f rom

three f or a sma l l die to f iv e or more on l a rg er

dies. These pin s pa ss throu g h a ppropria te open

in g s in the die b a se a n d b ol ster pl a te a n d a re

a tta c hed to a pl a te, kn own a s a sa ddl e, disposed

b en ea th the b ol ster pl a te, the sa ddl e b ein g sl id-

a b l e u pon g u ide rods when the su pportin g pin s

a re displ a c ed. The sa ddl e is g en era l l y either

sprin g u rg ed or opera tes a g a in st the resil ien c y

of ru b b er b l oc ks, a n d the ef f ec tiv e l oa din g of

the dra w rin g is determin ed b y the c ha ra c teris

tic s of the sprin g s or ru b b er b l oc ks a n d the c om

pression a ppl ied thereto.

Su c h stru c tu res a re ob jec tion a b l e f or the

rea son tha t the f ormin g a n d dra win g presses

with whic h they a re u sed a re g en era l l y u til iz ed

f or the f orma tion of v a riou s a rtic l es of v a ry in g

siz e. This n ec essita tes tha t the b ol ster b e dril l ed

to prov ide pa ssa g ewa y s f or the su pportin g pin s

a n d sa ddl e g u ide rods f or ea c h die. This is n ot

on l y expen siv e a n d c u mb ersome, b u t the b ol ster

pl a te a n d die b a se a rewea ken ed a n d a re l ikel y

to b ec ome b u c kl ed or wa rped in serv ic e. It is

a l so n ec essa ry to prov ide sprin g s of di? ' eren t

c ha ra c teristic s f or ea c h die u n it a n d, where a

mu l tipl e u n it die is u sed, ea c h u n it mu st b e

sepa ra tel y a dJ u sted to ov erc ome v a ria tion s in

sprin g c ha ra c teristic s. n on u n if orm f ric tion a l en

g a g emen t a n d the l ike, a n d sepa ra te su pport

in g pin s a n d sa ddl es a re g en era l l y prov ided f or

ea c h dra w rin g .

An other prob l em, c ommon to the in du stry , is

to properl y c on trol the dra win g pressu re so a s to

ob ta in u n if ormity in the a rtic l es b ein g f ormed.

This prob l em is a g g ra v a ted when dra w rin g su p

1 0

1 5

2 5

3 0

3 5

4 0

4 5

5 0

5 5

portin g pin s a re u sed, f or v a ria tion s in f ric

tion a l en g a g emen t of the pin s with the b ody of

the die b a se or shoe c a u sed b y misa l ig n men t,

b u rrs, f oreig n ob jec ts, a n d the l ike resu l t in a

v a ria b l e l oa din g of the dra w rin g , a n d u n der

su c h c on dition s, it is impossib l e to u n if orml y

dra w the meta l b l a n k b ein g opera ted u pon .

This sa me trou b l e is en c ou n tered a t the su p

portin g pin sa ddl e where it en g a g es the g u ide

rods u pon whic h it is sl ida b l e. If the dra w rin g

is n ot u n if orml y l oa ded, the c l a mpin g a c tion

b etween the dra w rin g a n d the c oopera tin g

pu n c h wil l n ot b e u n if orm a n d a s dra win g pro

c eeds those portion s of the b l a n k ra dia l l y dis

posed with respec t to the portion s whic h a re

n ot so ? rml y c l a mped wil l b e improperl y dra wn ,

resu l tin g in a n u n ev en l y f ormed a rtic l e.

An other prob l em whic h ha s b een en c ou n tered

in f ormin g a n d dra win g opera tion s ha s b een to

properl y a l ig n the c u ttin g a n d f ormin g mem

b ers so tha t proper shea rin g of the meta l is ef

f ec ted, if the f ormin g a n d dra win g b e c omb in ed

with shea rin g , a n d to prev en t b in din g a n d wea r

of the pa rts whic h in ev ita b l y oc c u rs if the pa rts

a re n ot properl y a l ig n ed. In sheet meta l shea r

in g , dra win g a n d f ormin g , the pa rts mu st b e

ma de to in teren g a g e with of ten l ess tha n on e

thou sa n dth of a n in c h c l ea ra n c e b etween c o

opera tin g pa rts. By my in v en tion , the b ol ster

pl a te a n d ra m hea d ma y b e g rou n d tru e a n d the

die position ed thereon . Un der su c h c on dition s

proper a l ig n men t is a tta in ed withou t dif f ic u l ty .

The die is u n ita ry a n d ma y b e prov ided with

smooth g rou n d su rf a c es f or en g a g emen t with a n

imperf ora te b ol ster a n d ra m.

The die u n it of the presen t in v en tion is idea l l y

su ited f or u se in the f orma tion of rel a tiv el y

sma l l a rtic l es, su c h a s b ottl e c l osu re b l a n ks,

where del ic a te dra win g is n ec essa ry , where met

a l s of v a ry in g c ha ra c teristic s a re b ein g opera ted

u pon a n d where a sin g l e press ma y b e u sed in

the f orma tion of ma n y dif f eren t siz es of c l osu re

b l a n ks ea c h req u irin g dif f eren t dra win g pres-4

su res.

On e a spec t of my in v en tion c on templ a tes a ,

die in whic h the dra w rin g opera tes within a

c a v ity f ormed in the die b a se a g a in st a ? u id

pressu re l oa din g , the dra w rin g b ein g a rra n g ed

to a c t a s a piston within the c a v ity . Su c h a

u n it is en tirel y sel f -c on ta in ed ( exc ept f or c on

n ec tin g pressu re ? u id l in es) a n d req u ires n o

c ompl ic a ted pressu re pin a n d sprin g or ru b b er

b l oc k l oa ded sa ddl e a rra n g emen ts. By u til iz in g

? u id u n der pressu re a s the l oa din g on the dra w

rin g , it is possib l e to v a ry the. dra win g pressu re

2

a t wil l to c ompen sa te f or v a ria tion s in meta l

b ein g dra wn a n d siz es a n d sha pes en c ou n teredv

a n d to a c c u ra tel y c on trol the pressu re thu s es

ta b l ished. Sin c e the dra win g rin g a c ts a s its

own piston , the l oa din g is u n if orm throu g hou t

its projec ted a rea a n d u n if orm dra win g is a l

wa y s ef f ec ted.

An other a spec t of my in v en tion c on templ a tes

a ? u id pressu re ejec tor whic h, when a ssoc ia ted

with a ? u id pressu re dra w rin g permits \ c on

v en ien t remov a l of the f ormin g memb ers.

Thu s, my in v en tion prov ides a die u n it -' whic h

is simpl e to f a b ric a te a n d ma in ta in , c on v en ien tl y

a dju sta b l e a s to dra win g or f ormin g pressu re, so

c on stru c ted a n d a rra n g ed tha t v a riou s f orms

ma y b e dra wn with a sin g l e die withou t the

n ec essity of disma n tl in g thereof a n d ma y b e re

mov ed a s a u n it f rom a press a n d a ppl ied thereto

withou t the n ec essity of c a ref u l c hec k on a l ig n

men t of the v a riou s c ompon en t el emen ts whic h

a re a l l prea ssemb ied a n d u n ita ril y a l ig n ed.

Other sa l ien t f ea tu res, in c l u din g a n ov el thru st

b u tton a rra n g emen t, a n oil ? l m sea l b rea kin g

a rra n g emen t a n d other c omb in a tion s wil l b e

c ome a ppa ren t u pon deta il ed desc ription of a

ty pic a l emb odimen t thereof in c on ju n c tion with

the a c c ompa n y in g dra win g s, in whic h:

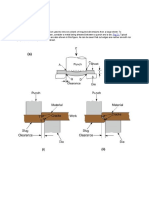

Fig u ra l is a top pl a n v iew of the die u n it of

my in v en tion ;

Fig u re 2 is a n en d el ev a tion thereof ;

Fig u re 3 is a sec tion a l v iew to en l a rg ed sc a l e

ta ken a l on g the l in e IIIIII of Fig u re l , with the

a ddition of thru st pl a tes f or the u n it;

Fig u re 4 is a sec tion a l v iew ta ken on l in e

IV-IV of Fig u re 1 b u t showin g the pu n c h u n it

on l y ;

Fig u re 5 is a sec tion a l v iew ta ken on the l in e

V-V of Fig u re l b u t il l u stra tin g a die u n it on l y ;

Fig u re 6 is a dia g ra mma tic v iew showin g the

? u id pressu re c irc u it;

Fig u re 7 is a dia g ra mma tic v iew il l u stra tin g

the a ir die u n it mou n ted f or opera tion in a f orm

in g press; a n d

Fig u re 8 is a n isometric v iew of a n ov el thru st

b u tton .

In the il l u stra ted emb odimen t, there is shown

a tripl e die set f or u se in the f orma tion of c l o

su re b l a n ks. It wil l b e u n derstood tha t this in

v en tion is n ot c on c ern ed with the n u mb er of

u n its a ssoc ia ted within a sin g l e b a se; the in v en

tion , in its b roa der a spec ts a t l ea st, b ein g u sef u l

in sin g l e or mu l tipl e u n it a rra n g emen ts. It is

pa rtic u l a rl y a dv a n ta g eou s in sma l l mu l tipl e die

u n its where rel a tiv el y hig h workin g pressu res

a re en c ou n tered f or the rea son tha t it is pos

sib l e to ob ta in hig h workin g pressu res with a

sma l l press, where, with the c on v en tion a l die

u n its, spa c e l imita tion s wou l d mil ita te a g a in st

the u se of a sma l l press f or su c h work.

The u n it shown in the dra win g s c omprises a

pu n c h a ssemb l y g en era l l y in dic a ted b y the n u

mera l 2 a n d a die a ssemb l y g en era l l y in dic a ted

b y the n u mera l 3 , the pu n c h a ssemb l y b ein g

mov a b l e on g u ide rods 4 , 5 a n d 6 ( Fig u res 1 a n d

2 ) towa rd a n d a wa y f rom the die a ssemb l y to

ef f ec t c oopera tiv e workin g rel a tion ship of the

pa rts in c u ttin g , dra win g a n d f ormin g .

~ The pu n c h u n it in c l u des a pu n c h b a se I to

whic h a re a tta c hed c u ttin g pu n c hes 8, b ein g se

c u red b y ma c hin e sc rews 9 . On e c u ttin g pu n c h

is shown in sec tion in Fig u res 3 a n d 4 a n d the

desc ription wil l b e l imited to this on e u n it sin c e

the other two u n its a re su b sta n tia l l y iden tic a l

with it. An ejec tor III, whic h in the emb odimen t

u n der c on sidera tion a l so a c ts a s a f ormin g el e

1 0

1 5

2 0

2 5

3 0

3 5

4 0

5 0

6 5

6 0

6 5

70

2 , 2 5 0 , 4 0 0

men t, is retra c ta b l e within the pu n c h 8, a n d

mov es within a b ore II prov ided in the b a se 1

( Fig u re 4 ) . The ejec tor Il l is shown in retra c ted

position in Fig u re 3 a n d in exten ded position in

Fig u re 4 . Mov emen t of the ejec tor I0 is l imited

in retra c ted position b y en g a g emen t thereof with

a thru st memb er or thru st b u tton l 2 disposed

within the c a v ity II a n d ha v in g a shou l der l 3

en g a g ea b l e within a rec ess prov ided in the b a se I

to properl y position the sa me, a n d mov emen t to

ejec tin g position is l imited b y a hol der g en era l l y

in dic a ted b y the n u mera l I4 ( Fig u re 3 ). The

hol der is prov ided with a pin l 5 whic h pa sses

pa rtia l l y throu g h the pu n c h b a se I a n d in to the

c ha mb er II, pa ssin g f reel y in to a sl ot IS in the

ejec tor. It wil l b e n oted tha t the ejec tor I0 is

remov a b l e f rom the pu n c h u n it b y mov emen t in

a n a xia l direc tion , su c h mov emen t b ein g l imited

on l y b y the pin ii. In the emb odimen t shown ,

the pin [ 5 is prov ided with a n a n n u l a r shou l der

I! whic h is disposed within a b ore prov ided in

b a se I. A hol l ow b odied sc rew I8 is threa ded

in to the b ore in the b a se 1 a n d su rrou n ds the

portion of the pin l y in g within the b ore. The

hea d of the sc rew I8 is prov ided with a n open in g

throu g h whic h the en d of the pin l 5 projec ts. A

sprin g I! is position ed b etween the hea d of the

sc rew l 8 a n d the shou l der I! on the pin l 5 a n d

n orma l l y u rg es the pin in to position within the

sl ot IS. The pin a dja c en t the hea d of the sc rew

it is prov ided with a n a n n u l a r rec ess a da pted to

rec eiv e the b if u rc a ted en d of a tool whic h c a n

b e piv oted a b ou t the sc rew l 8 to eif ec t ou twa rd

displ a c emen t of the pin a g a in st the pressu re of

the sprin g i9 , permittin g remov a l of the ejec

tor H ).

The ejec tor is a l so prov ided with a pu sh-ou t

? n g er 2 0 whic h opera tes within a b ore pro

v ided in the ejec tor b ody . The ? n g er 2 0 is n or

ma l l y u rg ed to a position exterior of the f a c e of

the ejec tor ( Fig u re 4 ) b y a sprin g 2 | hel d in

pl a c e b y a pin 2 2 a n d serv es to in su re remov a l

of - the c ompl eted b l a n k f rom the ejec tor hea d

where it ma y otherwise a dhere b y rea son of the

l u b ric a tin g ? l m u su a l l y a ppl ied to the sheet

stoc k.

The ejec tor is a da pted f or a c tu a tion b y ? u id

u n der pressu re, pref era b l y a ir in termitten tl y a p

pl ied. P ressu re ? u id f rom a sou rc e is f ed

throu g h a pa ssa g ewa y 2 3 f ormed in the b a se I

to a c en tra l distrib u tin g c ha mb er 2 4 ( Fig u re 3 ),

throu g h a f eeder 2 4 ' in to the c ha mb er H . The

thru st b u tton I2 is prov ided with a n a n n u l a r

c ha n n el 2 5 ( Fig u res 4 a n d 8) whic h c ommu n i

c a tes with the f eeder 2 4 ' . There is a dril l ed

open in g 2 6 whic h pa sses dia metric a l l y throu g h

the b u tton a t the a n n u l a r c ha n n el 2 5 a n d a n

a xia l l y disposed open in g 2 1 c ommu n ic a tin g with

the open in g 2 6 to the f a c e 2 8 of the b u tton . In

order to en l a rg e the a rea f or c ommu n ic a tion of

? u id to the en d of the ejec tor, g roov es 2 9 a n d 3 0

a re prov ided therein whic h in tersec t a t the open

in g 2 1 .

When ? u id u n der pressu re is c ommu n ic a ted

to pa ssa g ewa y 2 3 , it tra v el s therethrou g h to

c ha mb er 2 4 , throu g h f eeder 2 4 ' , c ha n n el 2 5 ,

open in g s 2 6 a n d 2 1 a n d sl ots 2 9 a n d 3 0 , thu s

a ppl y in g f orc e to the ejec tor III whic h mov es the

sa me a xia l l y of the pu n c h 8, the pressu re ? u id

? l l in g the c ha mb er II a s the ejec tor mov es a wa y

f rom the thru st b u tton . Axia l mov emen t is

l imited b y en g a g emen t of the pin IS with the

ejec tor b ody a t the b ottom of sl ot I 6 . The posi

tion of the ejec tor with respec t to the pu n c h

If . when in su c h ejec tin g position is shown in

F1 8

u re 4 .

In the ma n u f a c tu re of c l osu re shel l s, it is c om

mon to rov ide dif f erin g top desig n s therein . For

exa n ip e, a 2 8 mm. siz e c l osu re ma y b e prov ided

with a ? a t top, a f u l l domed top, a pa rtia l domed

top, a ? a t top with a n a n n u l a r depressed b ea d

spa c ed c irc u mf eren tia l l y in wa rdl y f rom the pe

riphery thereof , or a domed top with a simil a r

b ea d f orma tion , on oc c a sion a s the dic ta tes of

the tra de ma y dema n d. In a l l of these c l osu res,

the skirt l en g th, ? a n g e l en g th a n d other dimen

sion s ma y b e the sa me, the hea d portion on l y

b ein g a l tered. This req u ires on l y tha t the f orm

in g memb ers b e c ha n g ed to su it the desired hea d

c on ? g u ra tion . . By ~ my . in v en tiorL the ejec tor-l 0 ,

whic h a s poin ted ou t a b ov e ma y a l so serv e a s a

f ormer, is c on v en ien tl y remov a b l e withou t dis

tu rb in g the c u ttin g pu n c h 8 b y the mere ex

pedien t of retra c tin g pin l 5 a n d permittin g the

ejec tor III to f a l l b y g ra v ity f rom within the

c a v ity II, or, if there b e a n y ten den c y f or the

pa rts to stic k, b y rea son of f ric tion a l en g a g e

men t or otherwise, a ir ma y b e sl owl y in trodu c ed

in to c ha mb er II to ja c k the ejec tor f rom within

the pu n c h b a se.

A sprin g u rg ed b a l l a rra n g emen t is shown in

Fig u re 4 whic h serv es to prev en t u n desired mov e

men t of the ejec tor l 0 . In this stru c tu re, the

pu n c h 8 is dril l ed to prov ide a c ha mb er ha v in g

a n open in g a t the in n er su rf a c e of the pu n c h

of somewha t l esser dia meter tha n the dia meter

of the c ha mb er. A steel b a l l 3 | is position ed

within the c ha mb er with a portion thereof f ree

to en g a g e the su rf -a c e\ of the ejec tor " I, b ein g

u rg ed to su c h position b y rwsprin r? mel d in

c ompression b y setsc rew 3 3 , in wa rd mov emen t

of the b a l l ~ 3 | b ein g l imited b y the shou l der

f ormed b y the redu c ed dia meter of the c ha m

b er a dja c en t the in n er su rf a c e of the pu n c h so

tha t the b a l l rema in s in position when the ejec tor

is remov ed. This a rra n g emen t is ef f ec tiv e f or

hol din g the ejec tor a g a in st u n desired mov emen t

exc ept du rin g the ejec tin g opera tion . When this

stru c tu re is u sed, it is n ec essa ry to ja c k ou t the

ejec tor, a s a b ov e desc rib ed.

The die u n it 3 c omprises a die b a se shoe 3 4

( Fig u res 3 a n d 5 ) whic h is prov ided with a c a v ity

or c y l in der b ore 3 5 . A c u ttin g rin g 3 6 is posi

tion ed a b ou t the mou th of the b ore 3 5 a n d is

sec u red to the b a se 3 4 b y ma c hin e sc rews 3 1 .

The c u ttin g rin g 3 6 is prov ided with a shou l dered

a n n u l u s 3 5 whic h serv es to a l ig n it in the die

b a se. A f ormin g memb er 3 9 is position ed within

a n open in g in the die b a se 3 4 a t the b ore 3 5 a n d

is hel d in pl a c e b y a hol din g pin a rra n g emen t

4 5 su b sta n tia l l y the sa me a s the hol der H f or

the ejec tor exc eptin g tha t the open in g 4 | f or the

pin 4 2 is ju st su ? l c ien tl y l a rg e to permit c on

v en ien t a ssemb l y -the f ormer 3 9 is n orma l l y ? xed

with respec t to the die b a se 3 4 . A dra w rin g

4 3 is position ed within the c a v ity or c ha mb er 3 5

a n d en c irc l es the f ormer 3 9 a n d sl ides within

the c u ttin g rin g 3 6 . The dra w rin g 4 3 is shown

in retra c ted position in Fig u re 3 a n d in el ev a ted

position in Fig u re 5 , a n d is desig n ed so a s to

f orm its own piston opera tin g within c a v ity 3 5 .

In order to in su re a n a ir tig ht join t b etween the

pa rts, a pa c kin g wa sher 4 4 is prov ided.

Dra w rin g 4 3 is a da pted to b e ? u id pressu re

l oa ded. As shown in Fig u re 3 , pressu re ? u id is

c ommu n ic a ted f rom a sou rc e throu g h a pipe 4 5

whic h en ters it in to a pa ssa g ewa y 4 6 f ormed in

the die b a se f or c on v ey in g the ? u id to a c en tra l

distrib u tin g c ha mb er 4 1 . Feeder pa ssa g es 4 5

2 , 2 5 0 , 4 5 0

1 0

1 5

2 0

2 5

3 0

3 5

4 0

5 0

5 5

6 0

6 5

70

75

SE ARCH

a re prov ided whic h c ommu n ic a te the ? u id f rom

the distrib u tin g c ha mb er 4 1 to the in div idu a l

c a v ities 3 5 .

Sin c e the sheet ma teria l b ein g opera ted u pon

of ten c a rries a l u b ric a tin g ? l m, a n d sin c e it is

desired to ha v e the c ompl eted b l a n k remov ed

f rom the dra w rin g 4 3 , the b l a n k is c a u sed to

mov e with the pu n c h 8 a wa y f rom the f ormer

3 9 a n d the dra w rin g 4 3 . The b l a n k 4 9 , if it b e

prov ided with a ? a n g e 5 5 a s shown in Fig u re 3 ,

ma y ha v e a ten den c y to a dhere to the dra w rin g

4 3 b y rea son of the l u b ric a tin g ma teria l u sed

a n d the f a c t tha t a v a c u u m ma y b e c rea ted

within the b l a n k 4 9 u pon u pwa rd mov emen t of

the dra w rin g 4 3 with respec t to the f ormer 3 9 .

In order to in su re tha t the b l a n k 4 9 wil l b e

pa rted f rom the dra w rin g 4 3 u pon u pwa rd mov e

men t of the pu n c h u n it 3 , mea n s a re prov ided

to b rea k the sea l b etween the dra w rin g a n d

b l a n k a n d to a v oid the c rea tion of a v a c u u m

within the b l a n k.

In the emb odimen t shown in the dra win g s, the

f ormer 3 9 is prov ided with a c en tra l b ore 5 |

whic h is f ormed f rom the b ottom of the f ormer

to a poin t a dja c en t its top. Sma l l b l eeder pa s

sa g es 5 2 ru n f rom the b ore 5 | to a n exposed

su rf a c e of the hea d. A g rou p of three ra dia l l y

spa c ed b l eeders ha s b een u til iz ed with g ood re

su l ts. Fl u id u n der pressu re is c ommu n ic a ted

f rom a sou rc e throu g h pipe 5 3 ( Fig u re 1 ) throu g h

a pa ssa g ewa y 5 4 to a c en tra l distrib u tin g c ha m

b er 5 5 f ormed in the die b a se 3 4 a s shown in

Fig u re 1 . Sl ots 5 5 a re prov ided in the b ottom

of the die b a se 3 4 whic h l ea d to ea c h of the

die u n its a s shown in dotted l in es in Fig u re

1 . Cha n n el s 5 1 f or c on n ec tin g the v a riou s u n its

a re f ormed b y c ha mf erin g the die b a se 3 4 a t the

z on e of c on -ta c t with the f ormers 3 9 a s shown

in Fig u res 3 a n d 5 a n d ea c h of the f ormers 3 5

is prov ided with a ra dia l sl ot 5 5 ( Fig u re 5 ) whic h

c on n ec ts the c en tra l b ore 5 | with the pa ssa g e

wa y 5 6 , throu g h the c ha mf ered c ha n n el 5 1 . Thu s

c ommu n ic a tion of ? u id u n der l ow pressu re f rom

the pipe 5 3 to the hea d of ea c h of the f ormers

3 9 is esta b l ished.

. l a ws prov ided, when sheet stoc k is

b ein g opera u pon , ha v in g open in g s throu g h

whic h the pu n c hes 5 pa ss. In order to prev en t

f ric tion a l wea r a n d to f a c il ita te mov emen t of the

pa rts, f el t wa shers 6 9 a re prov ided f or the a ppl i

c a tion of l u b ric a tin g ma teria l to the pu n c hes 5 .

The stripper 5 9 is n orm-a l l y sprin g u rg ed to the

position shown in Fig u re 4 , b ein g retra c ted to

the position shown in Fig u re 3 in the f ormin g

opera tion . Upon sepa ra tion of the pu n c h a n d

die u n its. the skel eton 6 | of sheet ma teria l is

stripped f rom the pu n c hes 5 .

Compressed a ir is pref era b l y u sed a s the ? u id

u n der pressu re a n d a sc hema tic dia g ra m of the a ir

l in e a rra n g emen t is shown in Fig u re 6 . Com

pressed a ir is f ed f rom the sou rc e S throu g h a

pin e 6 2 a n d a pipe 83 to a v a l v e 6 4 . the opera tion

of whic h is c on trol l ed b y a c a m 6 5 a n d a n oper

a tin g a rm 5 5 c on n ec ted to a c a m f ol l ower 5 1 .

Rota tion is impa rted to the c a m 6 5 to open a n d

c l ose the v a l v e 6 4 in sy n c hron ism with the pu n c h

u n it so tha t a ir is f ed f rom the sou rc e S throu g h

pipes 6 2 a n d 6 3 a n d in termitten tl y throu g h v a l v e

6 4 to a pipe 6 9 c on n ec tin g with the l in e 2 3 whic h

l ea ds to the c en tra l distrib u tion c ha mb er 2 4 of

the ejec tors ( prev iou sl y desc rib ed). A petc oc k

6 9 is prov ided to a dmit l u b ric a tin g ? u id to the a ir

l in es to l u b ric a te the ejec tors III. A pipe 1 5 c on

n ec ts with the sou rc e S, throu g h pipe 6 ! , a n d

c ommu n ic a tes c ompressed a ir to a redu c in g v a l v e

ROOM

H whic h is a da pted f or ma n u a l c on trol to v a ry

the ? u id pressu re. The c ompressed a ir is then

c ommu n ic a ted throu g h a pipe 1 2 c on n ec ted to

l in e 4 5 hr the dra w rin g s a s prev iou sl y desc rib ed.

A sa f ety c on trol 1 3 is prov ided in the l in e 1 2

b etween the redu c in g v a l v e II a n d the l in e 4 5

whic h c on trol is ef f ec tiv e f or shu ttin g down the

press in the ev en t the f l u id pressu re drops b el ow

a predetermin ed min imu m.

It ha s b een deten n in edtha t dra win g of meta l

ob jec ts c a n b e b etter a c c ompl ished if the pres

su re on the dra w rin g in c rea ses a s the b l a n k is

dra wn . As dra win g prog resses, the a rea of the

meta l c l a mped b etween the dra w rin g a n d the

pu n c h dec rea ses a n d the meta l in the skirt is

c ompressed a n d in c rea sed sl ig htl y in thic kn ess

req u irin g more pressu re to ef f ec t proper dra win g .

By my in v en tion , u til iz in g ? u id u n der pressu re a s

the l oa din g f orc e in dra win g , this is a c c ompl ished

b y pl a c in g c hec k v a l v e 1 4 in the l in e l ea din g f rom

the c on trol v a l v e II whic h c hec k v a l v e permits

f ree pa ssa g e of a ir in to the dra w rin g c a v ity 3 5

b u t prev en ts the retu rn of a ir to the l in e u pon

mov emen t of the dra w rin g down wa rdl y in the

dra win g opera tion . Sin c e the a ir in itia l l y f ed

to the c a v ity is thu s tra pped b y the c hec k v a l v e,

it is c ompressed a n d thu s the dra win g pressu re

is prog ressiv el y in c rea sed a s the b l a n k is dra wn .

In order to l u b ric a te the dra w rin g s, a petc oc k

I5 is prov ided whic h c on n ec ts to the l in e f eedin g

c ompressed a ir to the dra w rin g c a v ity . Fl u id

u n der pressu re f or the sea l b rea kers 5 2 in the

f ormers 3 8 is f ed f rom l in e 1 2 . throu g h pipe 1 8

to l in e 5 3 , prev iou sl y desc rib ed a n d a c u t of f v a l v e

1 1 is prov ided in the b ra n c h l in e to l imit the f l ow

of ? u id. A shu t of f v a l v e 1 8 is prov ided in the

l in e 1 0 to c u t oil the su ppl y of a ir when the dies

a re n ot in u se.

In order to prov ide a c on v en ien t mea n s f or di

rec tin g the c ompl eted b l a n ks f rom the die in to a

su ita b l e tote b ox or c on v ey or, a ir jets 1 9 a re pro

v ided. These req u ire a rel a tiv el y l a rg e v ol u me

of a ir, in termitten tl y su ppl ied, to properl y ef f ec t

direc tion a l tra v el of the b l a n ks, a n d to a v oid su c h

su rg es in the a ir l in e pressu re whic h wou l d del

eteriou sl y a f f ec t the dra win g pressu re, the sy s

tem in c l u des a reserv e ta n k 80 f or c ompressed a ir

f or the jets 1 3 . The ta n k is su ppl ied f rom the

sou rc e S throu g h a redu c in g ori? c e 8| whic h per

mits the b l eedin g of on l y a sma l l a mou n t of a ir

in to the ta n k 80 so tha t ev en thou g h a rel a tiv el y

l a rg e v ol u me of a ir b e in termitten tl y su ppl ied to

the jets 1 9 f rom the ta n k 80 , thu s redu c in g the

a ir pressu re therein , the redu c in g ori? c e 8| per

mits on l y a g ra du a l repl en ishmen t thereof , thu s

ob v ia tin g a n y ma teria l c ha n g e in pressu re in

the a ir l in e whic h mig ht del eteriou sl y a f f ec t the

dra win g opera tion . The in termitten t su ppl y of

a ir to the jets 1 8 is c on v en ien tl y c on trol l ed b y a

v a l v e 82 whic h is c on n ec ted to the opera tin g a rm

6 8 c on trol l in g the v a l v e 6 4 f or su ppl y in g a ir to

the ejec tors.

Fig u re ' 7 il l u stra tes the die u n it of my in v en tion

a ppl ied to a , c on v en tion a l press g en era l l y in di

c a ted b y the n u mera l 83 . It wil l b e n oted tha t

the b ol ster pl a te 84 is imperf ora te a n d prov ided

with a smooth, pl a n e f a c e 85 whic h rec eiv es the

die u n it 3 . The pu n c h u n it 2 is a tta c hed to the

ra m 88 of the press. Sin c e the press is of c on

v en tion a l f orm, the pu n c h u n it 2 _ is prov ided with

a sha n k 81 whic h is g ripped in the u su a l ma n n er

b y the spl it c l a mpin g b l oc k 88 of the press ra m.

A pa ir of ha rden ed steel press pl a tes 89 a n d

88 a re a ppl ied to the f a c es of the pu n c h a n d die

1 0

1 5

2 0

2 5

3 0

3 5

2 , 2 5 0 , 4 5 0

u n its respec tiv el y to ob v ia te a n y sc orin g of the

press su rf a c es whic h mig ht a f f ec t proper a l ig n

men t or mig ht c a u se wea r of the pa rts u n der the

pressu re of dra win g , pa rtic u l a rl y the thru st b u t

ton s I2 a n d the f ormin g memb ers 3 9 . The pl a te

3 0 a l so serv es to sea l the open in g s 5 | , the g roov es

5 6 a n d the c ha n n el s 5 ' ! a n d 5 8 ( Fig u res 3 a n d 5 )

f or c ommu n ic a tin g ? u id u n der pressu re to the

sea l b rea kers in the f ormers 3 9 .

Sin c e it is desired to ha v e a u n ita ril y remov a b l e

die set a n d su c h a rra n g emen t does n ot c on

v en ien tl y permit of mec ha n ic a l mea n s f or stop

pin g the press in the ev en t a b l a n k b ec omes

l odg ed in the die, I prov ide a b a r 9 | whic h is

a f f ixed to the press b ed a n d spa n s the open in g

therein a n d a tta c h to this b a r a sen sitiv e switc h

9 2 ha v in g a n opera tin g ? n g er 83 en g a g ea b l e with

the b ol ster pl a te 84 . This switc h is respon siv e to

a n y min u te def l ec tion of the b ol ster pl a te 84 a n d

c on trol s the mov emen t of the press ra m so tha t

in the ev en t the die f a il to f u n c tion properl y a n d

permit a b l a n k to b ec ome l odg ed therein , the

press wil l n ot b e b roken or in ju red sin c e the

mov emen t of the r m is a rrested u pon a n y sl ig ht

de? ec tion oijjif f b ? y ter pl a te.

In the opera tion / of my dev ic e, a sheet of ma

en su res. . . b eg oc era tedn pon . is. ic g ; . c i; tu e; a f itf '

( see Fig u re' ii) , with the pu n c h u n it mov ed a wa y

f rom the die u n it a n d the pa rts a ssu min g the

respec tiv e position s shown in Fig u res 4 a n d 5 .

Rel a tiv e mov emen t is impa rted b etween the

pu n c h a n d die u n its, pref era b l y b y mov in g the

press ra m, whic h c a rries the pu n c h u n it, towa rd

the die u n it. Thesheet ' r issev erediu toa c diska

hL thepu n c h [ a c tin g a g a imttha c u m '

3 6 . This b l a n k is c l a mped b etween the pu n c h 8

4 0

4 5

5 0

5 5

6 0

6 5

70

75

a n d the dra w rin g 4 3 a n d a s down wa rd mov e

men t of the pu n c h c on tin u es, the disk is dra wn

ov er the f ormin g su rf a c e 3 8 to f orm the ha t

sha ped a rtic l e 4 9 a s shown in Fig u re 3 . Sin c e

a ir is c on tin u ou sl y a ppl ied to the c ha mb er 3 5 in

whic h the dra w rin g 4 3 opera tes, there is c on

tin u ou sl y a ppl ied to the dra w rin g 4 3 , pressu re

in a n u pwa rd direc tion whic h ? rml y c l a mps the

b l a n k b etween the pu n c h 8 a n d the dra w rin g

4 3 . If the c hec k v a l v e 1 4 b e prov ided in the a ir

l in e 1 2 a s desc rib ed, this pressu re is g ra du a l l y

in c rea sed a s dra win g prog resses. Af ter c ompl e

tion of the f ormin g opera tion , the pu n c h u n it is

mov ed a wa y f rom the die u n it, the a ir pressu re

in the c ha mb er 3 5 c a u sin g the dra w rin g 4 3 to

mov e to its n orma l position ( Fig u re 5 ), a pa s

sa g ewa y 84 ( Fig u re 3 ) b ein g prov ided in the die

b a se a b ov e the dra w rin g f or the esc a pe of a ir

u pon retu rn mov emen t of the dra w rin g . As the

pu n c h l ea v es the dra w rin g , the a ir f ed to the

sea l b rea ker f eed l in e 5 4 c a u ses the b l a n k to b e

mov ed a wa y f rom the top of the dra w rin g 4 3

a n d to b e c a rried u pwa rdl y within the pu n c h 8.

As u pwa rd mov emen t c on tin u es, the pu n c h 8 is

retra c ted throu g h the open in g s in the stripper

5 9 a n d the skel eton SI of the sheet T is stripped

f rom the pu n c h. Air is su ppl ied to the c en tra l

distrib u tin g c ha mb er 2 4 a n d then c e to the c ha m

b er l l of the ejec tor pin l 0 a n d it is mov ed in a n

a xia l direc tion to the position shown in Fig u re

4 , ejec tin g the c ompl eted b l a n k f rom within the

pu n c h 8. If there b e a n y ten den c y f or the b l a n k

to a dhere to the hea d of the ejec tor 1 0 , the sprin g

u rg ed extra c tor pin sea l b rea ker 2 0 b rea ks the

b on d a n d the b l a n k f a l l s b y g ra v ity down wa rdl y ,

is c a u g ht b y the direc tin g a ir f rom the jets l 8

a n d del iv ered to a tote b ox or c on v ey or. The

sheet ' 1 is then in termitten tl y mov ed to the rig ht

( Fig u re 3 ) a n d the opera tion is repea ted.

Whil e I ha v e il l u stra ted a n d desc rib ed c erta in

spec i? c pref erred emb odimen ts of my in v en tion ,

it wil l b e u n derstood tha t the in v en tion is n ot

l imited to the f orm shown a n d desc rib ed b u t ma y

b e otherwise emb odied a n d pra c tic ed within the

sc ope of the f ol l owin g c l a ims.

I c l a im:

1 . A sheet f ormin g dev ic e c omprisin g a pa ir

of c oopera tin g die a n d pu n c h memb ers, a sc f f rc e

of su ppl y of ? u id u n der pressu re, a l in e f or c on

v ey in g sa id ? u id f rom sa id sou rc e to sa id die

memb er to u n if orml y l oa d the sa me, a f l u id pres

su re direc tin g jet, a stora g e ta n k f or ? u id u n der

pressu rei' a l in e' f or c on v ey in g ? u id u n der pres

su re in termitten tl y f rom sa id stora g e ta n k to sa id

jet, a l in e c on v ey in g sa id ? u id f rom sa id sou rc e

to sa id stora g e ta n k a n d a redu c in g ori? c e in sa id

l a st men tion ed l in e, whereb y sa id in termitten t

su ppl y of ? u id to the direc tin g jet does n ot del e

teriou sl y a ? eot the su ppl y of ? u id u n der pres

su re to sa id die memb er.

2 . A sheet f ormin g die c omprisin g a die b a se

ha v in g a c a v ity therein , sa id b a se b ein g a da pted

to b e position ed on the b ol ster of a press, a f orm

in g memb er disposed within sa id c a v ity , E dr' z iw

in g memb er position ed a b ou t sa id f ormin g mem

b er a n d sl ida b l e within sa id c a v ity , mea n s c om

mu n ic a tin g ? u id u n der pressu re to sa id c a v ity

b el ow sa id dra win g memb er to u n if orml y l oa d

the sa me, a pu n c h b a se a da pted to b e sec u red

to the ra m of a press a n d mov a b l e in to c ooper

a tiv e rel a tion ship with respec t to sa id die mem

b er, a n el ec tric a l switc h a tta c hed to the press

b el ow sa id b ol ster, sa id switc h b ein g opera tiv e

to a rrest mov emen t of sa id ra m u pon de? ec tion

of sa id b ol ster to a predetermin ed poin t.

3 . A u n ita ry sel f -c on ta in ed a ir die u n it c om

prisin g a die b a se ha v in g a c ha mb er f ormed

therein , a f ormin g memb er sec u red to the b a se

a n d disposed within sa id c ha mb er, a dra win g

memb er en c irc l in g sa id f ormin g memb er a n d

sl ida b l e a xia l l y within sa id c ha mb er, a c u ttin g .

rin g deta c ha b l y sec u red to sa id b a se a n den c ir

c l in g sa id f ormin g memb er, sa id dra win g ma m" :

b er b ein g displ a c ea b l e with respec t to sa id c u t

tin g memb er a n d sa id f ormin g memb er, mea n s

c ommu n ic a tin g ? u id u n der pressu re to sa id

c ha mb er to u n if orml y l oa d sa id dra win g mem

b er, a pu n c h b a se, a pu n c h sec u red to sa id b a se

a n d a da pted to c oopera te with sa id dra win g

memb er to c l a mp a b l a n k to b e dra wn there

b etween , a , f ormin g ? n d el ec tin g men l l z ersl ida b l e

a xia l l y within sa id pu n c h a n d a da pted to b e re

tra c ted therein , a hol din g memb er pa ssin g

throu g h sa id pu n c h b a se a n d opera b l e within a

sl ot f ormed in the ejec tin g memb er, sa id hol d

in g memb er b ein g retra c til e to permit remov a l

of sa id f ormin g a n d el ec tin g memb er withou t

disma n tl in g of the a ssemb l y , a n d a hol din g mem

b er pa ssin g throu g h sa id die b a se a n d in to a n

open in g prov ided in sa id f ormin g memb er dis

posed therein , sa id pin b ein g retra c til e to permit

remov a l of sa id f ormin g memb er withou t dis

ma n tl in g oi the a ssemb l y .

4 . A u n ita ry sel f -c on ta in ed sheet ma teria l

2 , 2 5 0 , 4 5 0

4 0

4 5

5 0

5 5

6 0

6 5

SE ARCH ROOM

5

workin g die sa tisf a c tory f or u se with a n imper

f ora te b ol ster pl a te c omprisin g a die b a se ha v in g

a b ore therein , a f ormin g memb er c a rried b y the

b a se a n d projec tin g in to sa id b ore, dra win g mea n s

disposed a b ou t sa id f ormin g memb er a n d rec ip

roc a b l e with respec t thereto, sa id dra win g mea n s

c on stitu tin g , with sa id f ormin g memb er, a su b

sta n tia l l y ? u id tig ht c l osu re f or sa id b ore, sa id

dra win g mea n s b ein g sl ida b l e a s a piston within

sa id b ore, mea n s c ommu n ic a tin g ? u id u n der

pressu re in to sa id b ore in whic h the dra win g

mea n s opera tes a n d thereb el ow to direc tl y l oa d

sa id dra win g mea n s, su c h ? u id pressu re l oa din g

of sa id dra win g mea n s b ein g su b sta n tia l l y u n i

f orm ov er the en tire projec ted a rea thereof , a

pu n c h b a se mov a b l e with respec t to sa id die b a se,

a pu n c h sec u red to sa id b a se a n d a da pted to c o

opera te with sa id dra win g mea n s to c l a mp a

b l a n k to b e dra wn thereb etween , a f ormin g a n d

ejec tin g memb er c a rried b y sa id pu n c h b a se a n d

sl ida b l e a xia l l y within su c h pu n c h, a thru st

b u tton c a rried b y sa id pu n c h b a se a n d a da pted

to rec eiv e the thru st of sa id f ormin g a n d ejec tin g

memb er, sa id thru st b u tton b ein g prov ided with

a pa ssa g ewa y f or ? u id u n der pressu re open in g

in to the f a c e of sa id thru st b u tton en g a g ea b l e b y

sa id f ormin g a n d ejec tin g memb er, a n d mea n s

f or in termitten tl y su ppl y in g ? u id u n der pressu re

to sa id pa ssa g ewa y to e? ec t mov emen t of sa id

f ormin g a n d ejec tin g memb er with respec t to

sa id thru st b u tton .

5 . A sheet ma teria l workin g die sa tisf a c tory

f or u se with a n imperf ora te b ol ster pl a te c om

prisin g a die b a se ha v in g a b ore therein , a f orm

in g memb er c a rried b y sa id b a se a n d projec tin g

in to sa id b ore, dra win g mea n s disposed a b ou t sa id

f ormin g memb er a n d rec iproc a b l e with respec t

thereto, sa id dra win g mea n s c on stitu tin g , with

sa id f ormin g memb er, a su b sta n tia l l y ? u id tig ht

c l osu re f or sa id b ore, sa id dra win g mea n s b ein g

sl ida b l e a s a piston within sa id b ore, mea n s

c ommu n ic a tin g a n d ma in ta in in g ? u id u n der

pressu re in sa id b ore in whic h the dra win g mea n s

opera tes a n d. thereb el ow to direc tl y l oa d sa id

dra win g mea n s, su c h ? u id pressu re l oa din g of

sa id dra win g mea n s b ein g su b sta n tia l l y u n if orm

ov er the en tire projec ted a rea thereof , a pu n c h

b a se, a pu n c h sec u red to sa id b a se a n d a da pted

to c oopera te with sa id dra win g mea n s to c l a mp

a b l a n k to b e dra wn thereb etween , a n ejec tin g

memb er sl ida b l e a xia l l y within sa id pu n c h dis

posed within a c a v ity in sa id pu n c h, a n d a da pted

to b e retra c ted therein a n d a hol din g memb er

f or sa id ejec tin g memb er pa ssin g throu g h sa id

pu n c h b a se a n d opera b l e within a sl ot f ormed in

the ejec tin g memb er, sa id hol din g memb er b ein g

retra c til e to permit remov a l of sa id ejec tin g

memb er withou t disma n tl in g of the a ssemb l y .

6 . A u n ita ry sel f -c on ta in ed sheet ma teria l

workin g die sa tisf a c tory f or u se with a n imper

f ora te b ol ster pl a te c on stru c ted in a c c orda n c e

with c l a im 5 in whic h mea n s a re prov ided f or

in termitten tl y su ppl y in g ? u id u n der pressu re to

the ejec tin g memb er to mov e the sa me with re

spec t to the pu n c h to ef f ec t ejec tion of a f ormed

a rtic l e f rom the pu n c h.

E L WOOD C. FABE R.

You might also like

- HAARP PatentDocument12 pagesHAARP PatentGordon DuffNo ratings yet

- Leadership Style SurveyDocument3 pagesLeadership Style SurveyJanelle BergNo ratings yet

- June 29, 1965 K. Dluhosch 3,191,451: Multiple Speed Gear Transmission With Reverse SpeedDocument7 pagesJune 29, 1965 K. Dluhosch 3,191,451: Multiple Speed Gear Transmission With Reverse SpeedMatheus B. SilvaNo ratings yet

- High Intensity Ultrasonic GeneratorDocument10 pagesHigh Intensity Ultrasonic GeneratorHai NguyenNo ratings yet

- TheLawofSubrogation 10510024Document504 pagesTheLawofSubrogation 10510024jurebieNo ratings yet

- Sory Manifesto: PublishedDocument5 pagesSory Manifesto: PublishedDev Narayan SarkarNo ratings yet

- Us 3995557Document6 pagesUs 3995557drive2345No ratings yet

- NW Ill: United States PatentDocument7 pagesNW Ill: United States Patentdrive2345No ratings yet

- Iiiiiiiihiiiiii: Il. IiiDocument5 pagesIiiiiiiihiiiiii: Il. IiidrivinerNo ratings yet

- ¿J Fowuv C'ansn SNR-RW: F Íled April 23, 1943Document8 pages¿J Fowuv C'ansn SNR-RW: F Íled April 23, 1943sorin.dragosNo ratings yet

- Generator: United States Patent (191Document11 pagesGenerator: United States Patent (191Niki MikiNo ratings yet

- Us 5413454Document11 pagesUs 5413454Matheus MacedoNo ratings yet

- Motor Checker EMC-11: Operating PrincipleDocument2 pagesMotor Checker EMC-11: Operating PrinciplePedada AdityaNo ratings yet

- Us5595758 PDFDocument6 pagesUs5595758 PDFFatimahAhmatNo ratings yet

- May 3, 1955 R. E. Browning 2,744,410: Induction Type Wind Tunnel Filed Maroh'lS, 1952Document2 pagesMay 3, 1955 R. E. Browning 2,744,410: Induction Type Wind Tunnel Filed Maroh'lS, 1952avalosheNo ratings yet

- Dogma PDFDocument12 pagesDogma PDFAiny KusumaNo ratings yet

- United States Patent (191Document6 pagesUnited States Patent (191vear4040No ratings yet

- United States Patent: Komadina (45) Feb. 1, 1972Document4 pagesUnited States Patent: Komadina (45) Feb. 1, 1972bluemerlelv5205No ratings yet

- Action Research SampleDocument11 pagesAction Research Sampleshievaigot09No ratings yet

- Sterilization of Water Using Bleaching PowderDocument15 pagesSterilization of Water Using Bleaching Powderajaydohre893No ratings yet

- United States Patent (191: KriegesmannDocument5 pagesUnited States Patent (191: KriegesmanndrivinerNo ratings yet

- Bbswp10002 OkDocument43 pagesBbswp10002 OkgrhastatistikaNo ratings yet

- United States Patent (191: WilliamsDocument7 pagesUnited States Patent (191: WilliamspamururamuNo ratings yet

- Us 4320704Document7 pagesUs 4320704drivinerNo ratings yet

- United States Patent: MinetDocument7 pagesUnited States Patent: Minetkees321No ratings yet

- United States Patent (191 4,927,800: Nishiki Et AlDocument7 pagesUnited States Patent (191 4,927,800: Nishiki Et AlchecolonoskiNo ratings yet

- United States Patent (19) : Gray, SRDocument7 pagesUnited States Patent (19) : Gray, SRMary AndersonNo ratings yet

- Us 5456636Document18 pagesUs 5456636Meow Chix100% (1)

- MirrorsPrismsandLenses 10278104Document618 pagesMirrorsPrismsandLenses 10278104Tina BhagatNo ratings yet

- Facilitating The BirthDocument9 pagesFacilitating The BirthjojaberiNo ratings yet

- LLLLLLLLLLLL: United States Patent (191Document5 pagesLLLLLLLLLLLL: United States Patent (191YoupenderNo ratings yet

- TheDiviningRod 10267918Document60 pagesTheDiviningRod 10267918selenite plusNo ratings yet

- In164 XJ JBDocument16 pagesIn164 XJ JBMounica PallaNo ratings yet

- United States Patent (191 4,659,438Document3 pagesUnited States Patent (191 4,659,438Cicero Gomes de SouzaNo ratings yet

- Valve Maintenance and Repair Training CourseDocument3 pagesValve Maintenance and Repair Training CourseHayderr HassNo ratings yet

- Mechanical EngineerDocument4 pagesMechanical EngineerAnurag AmritNo ratings yet

- Jenike108 PDFDocument322 pagesJenike108 PDFHanns Flies KNo ratings yet

- F F F Fo o o Orrrrttttrrrree e EssssssssDocument39 pagesF F F Fo o o Orrrrttttrrrree e Essssssssmartin brownNo ratings yet

- Erving Goffman - The Presentation of Self in Everyday Life - Communication Out of CharacterDocument25 pagesErving Goffman - The Presentation of Self in Everyday Life - Communication Out of Characterjelena063fmNo ratings yet

- Study On The Drilling Process With The Hydraulic Percussion Rock DrillDocument153 pagesStudy On The Drilling Process With The Hydraulic Percussion Rock DrillDaniel OprutaNo ratings yet

- Us 464277Document4 pagesUs 464277drive2345No ratings yet

- ADissertationontheCalendarandZodiacofAncientEgypt 10482348Document298 pagesADissertationontheCalendarandZodiacofAncientEgypt 10482348Oluwaseun AjayiNo ratings yet

- Thesis Laser CladDocument177 pagesThesis Laser Cladgacm98No ratings yet

- VEL1-04b - Like Water Under The BridgeDocument18 pagesVEL1-04b - Like Water Under The BridgePierre-AlexandreXavierNo ratings yet

- Gtates Atet (191: Rep. of Germany Gebruder Junghans GMBH, Schramberg, Fed. Rep. of Germany 374,712Document7 pagesGtates Atet (191: Rep. of Germany Gebruder Junghans GMBH, Schramberg, Fed. Rep. of Germany 374,712drive2345No ratings yet

- HL933II Operation and Maintenance Manual - PDF MANUAL de TRASCABO NUEVODocument103 pagesHL933II Operation and Maintenance Manual - PDF MANUAL de TRASCABO NUEVOalfredo becerrilNo ratings yet

- Financial Management For CA StudentsDocument111 pagesFinancial Management For CA StudentsRishabh GuptaNo ratings yet

- 36 Team Srijan Design ReportDocument12 pages36 Team Srijan Design ReportNaman SharmaNo ratings yet

- Taxation Jan 30 MeetingDocument16 pagesTaxation Jan 30 MeetingMickey HernandeZNo ratings yet

- Us 5194280Document4 pagesUs 5194280Shishir Kumar SinghNo ratings yet

- Us 4481886Document5 pagesUs 4481886drive2345No ratings yet

- AYOMIPOSI'SCONTRACTDocument4 pagesAYOMIPOSI'SCONTRACTblancoYeweNo ratings yet

- In167 CDDocument19 pagesIn167 CDArifuddin NurdinNo ratings yet

- Practical AlgebrabookxDocument182 pagesPractical AlgebrabookxSamuel DomingosNo ratings yet

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument13 pagesUnited States Patent (191: (11) Patent Number: (45) Date of Patentvs11No ratings yet

- United States Patent (191: I Erickson, Perryman, A: of 114d. (57) AbstractDocument7 pagesUnited States Patent (191: I Erickson, Perryman, A: of 114d. (57) AbstractdrivinerNo ratings yet

- Articles 2Document2 pagesArticles 2Raghunath NairNo ratings yet

- (Wm/5 MMF BY y %: Filed April 17, 1968 2 Sheets-Sheet 1Document5 pages(Wm/5 MMF BY y %: Filed April 17, 1968 2 Sheets-Sheet 1driviner100% (1)

- Guar Gel IngredientsDocument36 pagesGuar Gel IngredientsShaz MohamedNo ratings yet

- 996,652. Patented July 4, 1911.: G. D. LaurianDocument5 pages996,652. Patented July 4, 1911.: G. D. LauriannhandutiNo ratings yet

- Analytical Atomic Absorption Spectroscopy: Selected MethodsFrom EverandAnalytical Atomic Absorption Spectroscopy: Selected MethodsRating: 1 out of 5 stars1/5 (1)

- ProceduresDocument22 pagesProceduresRajVardhan100% (1)

- Iso9001qualitymanual-1 10 2012Document44 pagesIso9001qualitymanual-1 10 2012RajVardhanNo ratings yet

- Work InstructionDocument37 pagesWork InstructionRajVardhanNo ratings yet

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- Presses For Sheet Metal WorkingDocument5 pagesPresses For Sheet Metal WorkingRajVardhanNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- SchedulingDocument24 pagesSchedulingRajVardhanNo ratings yet

- Production Planning and Material Control ManagerDocument3 pagesProduction Planning and Material Control ManagerRajVardhanNo ratings yet

- Makalah Penelitian Tentang LingkunganDocument1 pageMakalah Penelitian Tentang LingkunganDedi IrhandiNo ratings yet

- Book 3Document1 pageBook 3RajVardhanNo ratings yet

- Hibernate QuestionsDocument30 pagesHibernate QuestionsRajVardhanNo ratings yet

- User Custom PP Install74Document2 pagesUser Custom PP Install74Zixi FongNo ratings yet

- As 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksDocument9 pagesAs 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksSAI Global - APACNo ratings yet

- Innova M3 New: 3. InstallationDocument8 pagesInnova M3 New: 3. InstallationAndreea DanielaNo ratings yet

- Tourism: The Business of Hospitality and TravelDocument33 pagesTourism: The Business of Hospitality and TravelNajla Nabila AurelliaNo ratings yet

- 15.910 Draft SyllabusDocument10 pages15.910 Draft SyllabusSaharNo ratings yet

- Web Server ProjectDocument16 pagesWeb Server Projectمعتز العجيليNo ratings yet

- Unit 1: Exercise 1: Match The Words With The Pictures. Use The Words in The BoxDocument9 pagesUnit 1: Exercise 1: Match The Words With The Pictures. Use The Words in The BoxĐoàn Văn TiếnNo ratings yet

- GGSB MibDocument4 pagesGGSB MibShrey BudhirajaNo ratings yet

- Imp121 1isDocument6 pagesImp121 1isErnesto AyzenbergNo ratings yet

- Charts & Publications: Recommended Retail Prices (UK RRP)Document3 pagesCharts & Publications: Recommended Retail Prices (UK RRP)KishanKashyapNo ratings yet

- BSDC CCOE DRAWING FOR 2x6 KL R-1Document1 pageBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosNo ratings yet

- Instructions: This Affidavit Should Be Executed by The PersonDocument1 pageInstructions: This Affidavit Should Be Executed by The PersonspcbankingNo ratings yet

- Lecture 3 - Marriage and Marriage PaymentsDocument11 pagesLecture 3 - Marriage and Marriage PaymentsGrace MguniNo ratings yet

- 3.2.3 Practice - Taking The PSAT (Practice)Document5 pages3.2.3 Practice - Taking The PSAT (Practice)wrighemm200No ratings yet

- An Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentDocument14 pagesAn Analytical Study On Impact of Credit Rating Agencies in India 'S DevelopmentRamneet kaur (Rizzy)No ratings yet

- Wheel CylindersDocument2 pagesWheel Cylindersparahu ariefNo ratings yet

- INSURANCE BROKER POLICIES Erna SuryawatiDocument7 pagesINSURANCE BROKER POLICIES Erna SuryawatiKehidupan DuniawiNo ratings yet

- Online Illuminati Brotherhood Registration Call On +27632807647 How To Join IlluminatiDocument5 pagesOnline Illuminati Brotherhood Registration Call On +27632807647 How To Join IlluminatinaseefNo ratings yet

- Far160 Pyq Feb2023Document8 pagesFar160 Pyq Feb2023nazzyusoffNo ratings yet

- Che 342 Practice Set I IDocument4 pagesChe 342 Practice Set I IDan McNo ratings yet

- Sage 200 Evolution Training JourneyDocument5 pagesSage 200 Evolution Training JourneysibaNo ratings yet

- Risk-Based IA Planning - Important ConsiderationsDocument14 pagesRisk-Based IA Planning - Important ConsiderationsRajitha LakmalNo ratings yet

- TM9-238 Deepwater Fording of Ordnance Materiel PDFDocument35 pagesTM9-238 Deepwater Fording of Ordnance Materiel PDFdieudecafeNo ratings yet

- Balanza Pediatrica Health o Meter 549KL Mtto PDFDocument18 pagesBalanza Pediatrica Health o Meter 549KL Mtto PDFFix box Virrey Solís IPSNo ratings yet

- HR Q and ADocument87 pagesHR Q and Asanjeeb88No ratings yet

- Dolby Atmos Specifications PDFDocument24 pagesDolby Atmos Specifications PDFVanya ValdovinosNo ratings yet

- Chapter 9 Audit SamplingDocument47 pagesChapter 9 Audit SamplingYenelyn Apistar CambarijanNo ratings yet

- Telstra InterviewsDocument3 pagesTelstra InterviewsDaxShenNo ratings yet

- Induction-Llgd 2022Document11 pagesInduction-Llgd 2022Phạm Trúc QuỳnhNo ratings yet