Professional Documents

Culture Documents

Chromosome Model Design Specification PDF

Uploaded by

Rafael_Yevgeny0 ratings0% found this document useful (0 votes)

62 views10 pagesThis paper aims to develop a system for product modelling in which all of the information generated during a design process can be represented. An integrated product model is an important basis for concurrent engineering by providing a shared representation of the evolving design for team members. This paper focuses on how design specification data is managed in the system.

Original Description:

Original Title

CHROMOSOME MODEL DESIGN SPECIFICATION.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis paper aims to develop a system for product modelling in which all of the information generated during a design process can be represented. An integrated product model is an important basis for concurrent engineering by providing a shared representation of the evolving design for team members. This paper focuses on how design specification data is managed in the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

62 views10 pagesChromosome Model Design Specification PDF

Uploaded by

Rafael_YevgenyThis paper aims to develop a system for product modelling in which all of the information generated during a design process can be represented. An integrated product model is an important basis for concurrent engineering by providing a shared representation of the evolving design for team members. This paper focuses on how design specification data is managed in the system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

INTERNATIONAL CONFERENCE ON ENGINEERING DESIGN

ICED 97 TAMPERE, AUGUST 19-21, 1997

Johan Malmqvist and Peter Schachinger

Design Specifications, Product Models, Computer-Aided Design, Design Methodology

TOWARDS AN IMPLEMENTATION OF THE CHROMOSOME MODEL -

FOCUSING THE DESIGN SPECIFICATION

1 Introduction

The objective of this work is to develop a system for product modelling in which all of the

information generated during a design process can be represented. This information ranges from

abstract information like design specifications to detailed information like geometry models.

Such a system will have advantages compared to currently available commercial systems by

simplifying the reuse and redesign of old design solutions and by facilitating the verification

that a product meets its requirements. Moreover, an integrated product model is an important

basis for concurrent engineering by providing a shared representation of the evolving design for

team members.

In earlier work, one of the authors has presented a prototype version of such a system

[Malmqvist 1995ab]. The system is theoretically based on the chromosome model [Andreasen

1992]. This paper focuses on how design specification data is managed in the system. The issues

covered includes the basic requirements on the design specification, data models for specifi-

cation items, and the relationships between the design specification items and other product

models such as the function, organ and component structures and behavioural and life-phase

system models. A case study of an expansion tank is used to illustrate to use of the system.

2 Modelling the contents of the design specication

This section aims at clarifying what information should be included in a design specification

and to formulate that information in an Entity-Relationship diagram. Moreover, the potential

benefits of using a computerized design specification that is linked to the product model will be

highlighted.

A design specification states the task for a development project, including requirements,

objectives and relevant information. It aims at focusing the design process at identified

customer needs while ensuring that no requirement originating from any stakeholder, life-phase

or product aspect is forgotten during the development process. Moreover, it provides a basis for

analyzing the consequences of modifying requirements. It also serves to create a common

understanding of the project goals for the development team and is a instrument for

management control of the project progress. The potential benefits of well-managed work with

the design specification includes earlier, fewer design changes, shorter development lead times

and fewer quality problems. Hence, the design specification is a central reference document for

the design team during the design process.

The engineering literature provides several procedures for collecting the information to be

included in the design specification. (Confer, e.g., [Pugh 1991], [Pahl and Beitz 1996],

[Roozenburg and Eekels 1995], [Ulrich and Eppinger 1995]). The QFD methodology [Akao

1992] further provides a matrix-based framework for translating requirements between

different stakeholders in the process. The authors generally put forward three kinds of tools for

requirement formulation: methods for gathering customer needs, methods for translating

customer needs into engineering requirements and checklists that aim at ensuring that no vital

requirement is forgotten. Moreover, recommendations on how to state individual requirements

are given: Requirements should be given unambiguous, solution-independent formulations and

be clearly linked to customer needs. Requirements should further be stated in measurable (or,

at least, verifiable) units. It is further useful to distinguish between demands and wishes.

It is further important to recognize that the specification is a dynamic entity which changes and

expands during the design process. The high-level, form-independent requirements used during

conceptual design may need to be concretized to form-dependent ones during the design process

in order to be specific enough to set goals for the embodiment design [Otto 1996]. Moreover,

new requirements will be added due to the design decisions made, for instance to connect two

selected function carriers or to compensate for negative consequences of selecting a particular

design solution [Svendsen and Thorp Hansen 1993]. Different variants of the design process

may also require different methods for managing the design specification. In original design

projects only a few requirements are known at the outset of the design process, and most will

emerge during the process as the result of design decisions. This will necessitate frequent

updates of the specification if it is to be complete, and some method of distinguishing original

and derived requirements, or there is a risk that requirements that were included to compensate

for the effects of a certain design decision remain in the specification, although the decision that

lead to their inclusion may have been changed. On the other hand, in redesign projects, such

as the design of a new car year model, most requirements will be known in advance (and these

are numerous). In this case, good requirements management may support the design team in

focusing on the requirements that are important, different or new (called deltaSpecs below).

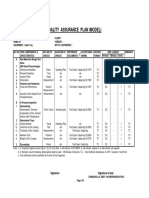

Based on the literature cited above, a formal data model for the design specification information

may be constructed (fig 1). The model describes the data items of the specification and the

relationships between the requirements. The relationships between the design specification and

the rest of the product model is elaborated on in section 3.

The model shows that a design specification consists of:

Metadata. A standard set of metadata attributes, such as identity, product and subsystem

name, description, version, status etc, is needed to administratively keep track of the speci-

cation.

Requirements. The design specication is decomposed into a set of requirements.

Referenced documents. The design specication may further refer to a set documents of

various kinds, such as old designs, customer surveys, laws and regulations.

The individual requirements items are then described by:

Metadata. These are similar to those of the design specication.

Value. Each requirement will have value, unit and tolerances specied.

Requirements class. Examples of requirement classes include performance and geometry.

The set of requirements classes used here is adopted from Pugh [1991].

Category. Requirements can be classied as demands (which can be sub-classied into

functional requirements and constraints), wishes (or objectives), options or information.

Direction. The Direction attribute of a wish category requirement provides further guidance

for its value. For instance, it may be desirable to minimize or maximize the value of the

requirement, or to hit a specied target value. This attribute may also refer to a value

function that species a rating scale for the attribute.

Importance. The importance of the attribute may be ranked on a scale.

Competition assessment. This attribute keeps track of the competition, as a list of brands

with associated values for the requirement.

Stakeholder. The stakeholder is the entity who requires the requirement, for instance, the

customer or the government.

Responsible. The person who is responsible for the satisfaction of the requirement.

Origin. The origin of the requirement is documented as original, derived due to a design

decision, compensating or interfacing.

IsDeltaSpec. This attribute marks a requirement that has changed since the last model of

the product. This is useful in redesign situations.

Descriptive documents may also be attached to the requirement. See above.

Further, we need to be able to register certain relationships between the requirements:

ConsistsOf relationships. A requirement may consist of sub-requirements. According to

Svendsen and Thorp Hansen [1993] three basic types of decomposition mechanisms for

requirements can be identied: A requirement may be decomposed by distribution, such

that it is only relevant to some sub-systems, or it may be decomposed by magnitude, such

that the value of the system requirement is a sum of the sub-system requirements. Typical

examples of the latter are cost and weight requirements. Finally, it may be decomposed by

transformation where the property type of a system requirement is transformed into a

different type of requirement. This kind of decomposition is dependent on the chosen

solution and on the context.

TradeOff relationships. In practice, requirements are not independent. Rather, conicts

between requirements (corresponding to the House of Quality (HoQ) roof) are likely to

exist. For redesigns, these may be known at the outset of the design process. For original

designs, trade-offs are likely to emerge during the design process.

InuencedBy relationships. Inuences between requirements is here used in a similarly

fashion to the translation between customer attributes and engineering characteristics in the

HoQ, i.e, as the HoQ matrix area.

This model has been implemented in the current version of the system (see section 4). The

system can then support a design team in generating and analyzing design specifications. While

this is valuable in itself, a more powerful support for the design process is obtained if the design

specification can also be effectively linked to the product model. How this can be achieved will

be discussed in the following section.

3 Modelling design specications and product models

In this section the relationships between the design specification and a product model are

analyzed, with the aim of identifying what relationships are important to be able to represent in

a design system.

The product modelling framework employed in this work is constituted by the chromosome

model [Andreasen 1992], which is based on the technical systems theory [Hubka and Eder

1988]. Hubka states that four different types of models are needed to describe a technical system

and the transformation process that it affects. These are termed the process, function, organ and

component structures, and are said to define the design characteristics of the system. The

chromosome expands this theory by adding genetic information, that captures the origin of

the design characteristics (hence chromosome). This is achieved by linking the structures

with causal relationships: the process determines the functions, the functions are created by the

organs, and the organs are materialized by the components. It has further been pointed out

[Mortensen and Andreasen 1996] that in order to derive the properties (weight, cost, etc) of a

product it is not sufficient to model only the product. We also need to model the various life-

phase systems (parts manufacturing, assembly and so on) that the product meets, since many

properties (e.g., assembly cost) are relational in the sense that they cannot be determined

without knowledge of the life-phase system.

The chromosome model offers a general framework for modelling the various aspects of

technical systems and is also strongly linked to design methodology. The theory further

provides a flexible design process model, by suggesting that the product chromosome (the set

of design characteristics) should be seen as a basic map, on which the progress of the design

Figure 1: Entity-Relationship diagram for design specication.

Design Specification

Requirement

Identity

Name

Description

IssuedBy

ApprovedBy

Version

Status

CreationDate

ChangeDate

Requirements Class

Identity

Name

Description

IssuedBy

ApprovedBy

Version

Status

CreationDate

ChangeDate

Value

Category

Direction

Importance

Competitor assessment

Stakeholder

Responsible

Origin

Referenced Documents

IsDeltaSpec

BelongsTo

HasMetadata

HasMetadata

Referenced Documents

HasAttributes

HasAttributes

ConsistsOf

ConsistsOf TradeOff

InfluencedBy

process is chartered. When the design is finalized, all design characteristics will have been

established but the sequence of the design activities, which are described as navigations on the

map, is not prescribed. We have in earlier work [Malmqvist 1995b] argued that this property

and the fact that the causal relationships constitute the genetic information of the system makes

the chromosome model well suited as a basis for a design history system. Particularly, the

benefits of using an extended function-means tree as a tool for design history representation

were put forward in that paper. We are further expanding on that basis here.

Having clarified the contents of the design specification and of the product model we may now

proceed to discuss the relationships between the specification and the product model. We

suggest that at least four principally different relationships can be identified:

Measures relationships. The most obvious link between the design specication is when

the performance of the design is to be evaluated against a requirement. This type of relation

will then link a requirement and a property model that is used to assess the actual value of

the property. A property model may in this context be a computational procedure, a experi-

mental test or a subjective assessment. The utilization of this kind of relation facilitates

checking that a design meets its requirements by comparing the desired and actual states of

the properties. Alternatively, a value function could be used to grade the design according to

some scale.

CorrespondsTo relationships. Some items of the design specication directly corresponds

to elements in the product models. For instance, this applies to functions stated in the design

specication that have direct correspondents in the function-means tree and the function

structure of the product model. This relationship may also link a design specication item to

a solution element (means/organ/component) if the design specication states that a

particular design solution should be used (carry-over, design re-use). While such

requirements are not recommended in the design methodology literature, which states that

requirements should be given solution-neutral formulations, they are common in practice.

RequirementsOn relationships. In general, a design decision, e.g., the selection of a

particular means to solve a certain functional requirement, will generate new requirements

to support the means, to connect the means to other means or to compensate for negative

effects caused by the means (e.g., noise). It is then important to keep track of this

dependency so that if the means is (ex)changed, its generated requirements will also be

(ex)changed. The inclusion of RequirementsOn relationships in the model enables the

detection of such requirements.

IsSolvedBy relationships. IsSolvedBy relationships link a requirement and the means that

has been chosen to satisfy the relation. Note that this kind of relation may also be

represented via the function-means tree.

The resulting product information model is shown in figure 2 as an Entity-relationshipship

diagram. Including the design specification data into this model simplifies the verification of

requirements and the analysis of the consequences of requirements changes. Moreover, this

kind of integrated product model is an important basis for concurrent engineering by providing

a shared representation of the evolving design for team members.

4 Implementation

In order to verify and experiment with the ideas expressed in the previous sections, a prototype

design system has been developed. The aim of this system is to provide an environment for

experimentation with design methods based on design theory. While the implementation of this

system is not complete, the main framework exists [Malmqvist 1995a]. The emphasis is placed

on verification of theories for managing the information created during the design process rather

than on creating a working system for synthesis, which would require a larger knowledge base.

METIS Software [NCR Norge A/S 1996], a general tool for developing systems for managing

complex information structures, was used to implement the system. METIS provides a generic

set of system modelling concepts and operations. Object-oriented techniques (type hierarchies)

are then used to create objects, relationships and methods tailored to a particular situation. The

objects are defined by attributes and methods, and may also include so-called information

elements which contain references and parameters to invoke external processes and systems,

such as CAD or word processing programs. Information elements can also be scanned pictures

or refer to external database files. This enables the construction of very heterogeneous and

complex models. System models can be visualized and edited in network, as well as matrix

fashion as indicated in fig. 4. A hierarchic visualization is also available.

The system has been tested on a number of problems, some originating from industry. The tests

have demonstrated the feasibility of the approach, though there is a need for further verification.

Figure 2: Entity-Relationship diagram for design specication and product model.

Requirement

ConsistsOf

ConsistsOf

TradeOff InfluencedBy

ConsistsOf

ConsistsOf

Process structure

ConsistsOf

ConsistsOf

ConsistsOf

Function structure

Organ structure

Component structure

Means

HasInfluenceOn

I

s

S

o

l

v

e

d

B

y

H

a

s

A

l

t

e

r

n

a

t

i

v

e

R

e

q

u

i

r

e

m

e

n

t

s

O

n

ProcRelation

FuncRelation

OrganRelation

CompRelation

C

o

n

t

r

i

b

u

t

e

s

T

o

M

a

t

e

r

i

a

l

i

z

e

d

B

y

I

s

S

o

l

v

e

d

B

y

R

e

q

u

i

r

e

m

e

n

t

s

O

n

N

e

e

d

s

E

f

f

e

c

t

s

N

e

e

d

s

P

r

o

c

e

s

s

Func Req Objective Constraint Evaluation

Property value

Test procedure

Computational model

Subj assessement

Uses

I

s

D

e

t

e

r

m

i

n

e

d

B

y

ConsistsOf

ConsistsOf

B

a

s

e

d

O

n

Measures

R

e

q

u

i

r

e

m

e

n

t

s

O

n

I

s

S

o

l

v

e

d

B

y

CorrespondsTo

C

o

r

r

e

s

p

o

n

d

s

T

o

C

o

r

r

e

s

p

o

n

d

s

T

o

C

o

r

r

e

s

p

o

n

d

s

T

o

PROPERTIES PRODUCT CHROMOSOME

DESIGN SPECIFICATION

FUNCTION-MEANS TREE

Lifephase system

LIFE-PHASE SYSTEMS

As an example, consider fig 4 which shows a design specification and a product model for an

expansion tank, used to maintain a constant water level in an automobile engine cooling system.

The figure illustrates a scenario of tracing the relationships between a requirement and the

components that realizes the requirement (function). The basic question is: Which components

will be affected by a change to a certain requirement? (or vice versa). In this case, the

requirement that designer chooses to examine is that the expansion tank system should alert the

driver when the water level is lower than a certain level (1). The designer could then follow the

CorrespondsTo relation to the function-means tree to learn that the alert function is triggered by

an electrical switch and that it also requires a supporting function: transient oscillations in the

water level need to be dampened out or else false alerts may result. This is solved by dampening

ribs (2). For further insight into the context of the requirement the designer could follow links

to the function structure (3) and the organ structure (4). The organ structure is linked to the

component structure (5). By this traversal, it is shown that a change to the alert driver

requirement may lead to changes to two component (structures), namely the indicator assembly

and the expansion tank, since the latter houses the dampening ribs. It is further evident from the

figure that overall structure of the models become quite complex, and that navigating in the

information may be difficult. However, the ability to visualize system relationships in matrices

is very helpful when analyzing system structures. As an example, a matrix depicting the

relationships between the organ and component structures is shown. Such a matrix can be used

to analyze the amount of function sharing in the system. It also makes it clear that a changes to

the expansion tank may affect almost all of the functions in the system, as there is a (almost)

one-to-one mapping between the functions and organs. Similar matrices are available in the

system for analysis of any kind of relationships in or between system models

5 Related work

The framework proposed in this paper is based on the chromosome model developed at TU

Denmark by Andreasen [1992] and co-workers. Design specifications in relation to this model

have been adressed by Svendsen & Thorp Hansen [1993]. The present paper builds on that work

by connecting the design specification to the different parts of the chromosome model This

work further contributes with an implementation that can be used as a test-bed for experimen-

tation with product models based on the chromosome framework. This is in our opinion crucial

as the chromosome model leads to large and complex product models. Such models are difficult

to record, keep updated and analyze on paper. An important precondition for testing utilizing

the chromosome model in full is therefore that there exists enabling computer support. The

current system can also be compared to systems aimed at supporting Systems Engineering, such

as RDD-100 [Ascent Logic 1996]. This system also enables traceability from requirements to

functions, and from functions to components. However, its terminology is limited from a

(mechanical) design methodology viewpoint: RDD-100 does not distinguish between organs

(function carriers) and components and there is no correspondent to the function-means tree

employed here as a design history representation. We argue that the same argument may be

employed for comparisons between the current system and such that are based on QFD - the

current system has a richer vocabulary for supporting design work. Finally, the current system

is also related to work that has aimed at developing computational support for conceptual design

(Tomiyama et al. [1994]; Sharpe [1996]). While these systems provide more powerful support

for synthesis than the current, by including design solution libraries, the design specification is

not adressed in detail in these works. Rather, the problem is stated as a function (structure).

While this may be sufficient for guiding the search for solutions during conceptual design, a

more comprehensive approach towards design specifiations is needed if the system shall be

used also during the latter design phases

6 Conclusions

The inclusion of the design specification in a integrated product model has benefits in terms of

increased traceability of design decisions and simplified redesign due to requirements changes.

To achieve this, the contents of the design specification and the relationships between the rest

of the product model needs to be adressed. The contents of the design specification are well

described in the design methodology literature. The relationships, however, are not equally well

treated in the literature. In this paper, four relation types are identified and have been

implemented in a product modelling system. The paper demonstrates through an example how

the proposed product model traces a design decision from a requirement through the function-

means tree and further to an individual component.

Figure 3: Trace from a requirement to its realizing components.

Expansion tank component structure

Coolant

Pressure

cap

spatial

relation

t

spatial

relation

from

Expansion

tank

spatial

relation

t

spatial

relation

from

energy

flow to

energy

flow

from

spatial

relation

t

spatial

relation

t

Hose

spatial

relation

t

spatial

relation

from

spatial

relation

t

material

flow to

material

flow

from

Hose

spatial

relation

t

spatial

relation

from

spatial

relation

t

material

flow to

material

flow

from

MVD

relation

from

MVD

relation

from

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

Indicator

assembly

spatial

relation

t

spatial

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

Design Specification

Environment

Weight

Maintenance

Aesthetics,

appearance

& finish

Materials

Life in

service

Quality &

reliability

Safety

Processes

Manufacturing

facility

Packing

Shipping

Installation

Quantity

Target

product

cost

Disposal Competition

Product

life span

Market

constraints

Shelf life

(storage)

Time-scales Legislative

requirements

Standards

&

specifications

Documentation

Political &

social

implications

Patents,

literature

& product

data

Total

system

performance

specification

Interfacing

&

geometric

requirements

Testing

Function structure

Organ structure

Component structure

Function Means Tree

Maintain constant water level in cooling system

Expansion tank systemsolved by solves

Enable coolant refill Maintain constant water level Enable inspection of water level

Enable open/closed lid Connect to maximum level area

requires

is required by

requires is required by

requires

is required by

Refill opening - above maximum water level solved by solves

requires

is required by

requires

is required by

Lockable lid solved by solves Tube connection solved by solves Tube connection CAD model

FM Tree RM

. Means

Requirements

FM SS use used by

X-axis consist of

part of X-axis in

Y-axis consist of

part of Y-axis in

Expansion tank solved by solves

Enable input from high pressure section Store pressurized fluid De-air water Enable output to low pressure section Manage internal pressure overflow

requires

is required by

requires

is required by

requires

is required by

requires

is required by

requires

is required by

Tube connection Pressure tank Slow steady flow Tube connection Pressure valve solved by solves solved by solves solved by solves solved by solves solved by solves

Enable off-line inspection Alert driver if low water level detected when driving

Transparent wall between mimimum and maximum levels Electrical indicator at minimum level solved by solves solved by solves

Connect to system section with minimum water level Change electrical state when low water level detected Stabilize measured water level

requires is required by requires is required by requires is required by

Req to functions

P_0 Preparation process

Expansion

tank

system in

prepared

state

W_0 Working process

P_1 Inspect current water level

P_2 Open lid P_3 Fill expansion vessel system with water P_4 Close lid

Expansion system water level

Expansion vessel: State: lid open, non-filled Expansion vessel; State lid open, filled

Expansion vessel system Water Expansion vessel; State: lid closed, filled

Required water level

W_1 Vary water level

W_2 Channel water from high-level section

W_3 Detect if water level <= minimum W_4 Detect pressure overflow

W_5 De-air water

W_6 Alert driver

W_7 Channel through pressure valve Water level

Water level Water level

Low water level signal Open pressure valve signal

W_8 Store pressurized water and air W_9 Channel water to low-pressure section

Water level

Expansion vessel system Water level-affecting perturbations Water level

Low water level signal to driver Excess water Water to low pressure sections

Expansion vessel system

OS RM

.. Organ

Organ

OS RM SS use used by

Expansion tank component structure

Coolant

Pressure cap spatial relation t spatial relation from

Hose clip

Hose clip

Expansion tank spatial relation t

spatial relation from energy flow to

energy flow from

spatial relation t spatial relation from

spatial relation t

spatial relation from

Hose spatial relation t spatial relation from

spatial relation t spatial relation from material flow to

material flow from

Hose spatial relation t

spatial relation from

spatial relation t

spatial relation from material flow to material flow from

CS RM

- Component

Component

CS SS

use

used by

X-axis consist of

part of X-axis in

Y-axis consist of

part of Y-axis in

Customer

Ergonomics

MVD relation to

MVD relation to

MVD relation to

MVD relation from

MVD relation from

PS-OS-RM

PS-OS-PAT Organs

Functions

PS-OS-SS

use

used by

X-axis consist of

part of X-axis in

Y-axis consist of

part of Y-axis in

Y-axis consist of

part of Y-axis in

requirement to

from requirement from requirement

MVD relation to

MVD relation from MVD relation from

MVD relation from

OS-CS-RM

+ Components

Organs

OS-CS-SS

MVD relation from

MVD relation from MVD relation from

MVD relation from

MVD relation from MVD relation from

MVD relation from

MVD relation from

MVD relation from

MVD relation from

MVD relation from MVD relation from

Indicator assembly spatial relation t spatial relation from MVD relation from MVD relation from

X-axis consist of

part of X-axis in

Y-axis consist of

part of Y-axis in

Properties

Pressure

cap

opening

pressure

evaluation

Pressure

cap

opening

pressure

test

MVD relation to

MVD relation from

MVD relation to

MVD relation from

Impact

resistance

test

Dynamic

pressure

test

Static

resistance

to

pressure

test

Burst test

Burst

evaluation

MVD relation to

MVD relation from

Ageing

test

Thread

strength

test

Level

indicator

tests

from requirement

from requirement

from requirement

Sealed hole in tank Electrical switch mechanism Ribs solved by solves solved by solves solved by solves MVD relation to

MVD relation from

MVD relation from

Y-axis consist of

part of Y-axis in

X-axis consist of

part of X-axis in

use

used by

MVD relation from

Performance

Main function

The function of

the expansion

vessel is to work

as an expansion

volume for the

engine cooliing

system

Refilling function

The expansion

vessel should be

refillable

Enable water

level inspection

Alert driver if

water level <=

minimum

Minimal leakage

requirement

to

requirement

to

requirement

to

requirement

to

Alert driver if low

water level

detected when

driving

Electrical

indicator at

minimum level

solved

by

solves

Connect to

system section

with minimum

water level

Change electrical

state when low

water level

detected

Stabilize

measured water

level

requires

is

required

by

requires

is

required

by

requires

is

required

by

from

requirement

Sealed hole in

tank

Electrical switch

mechanism

Ribs

solved

by

solves

solved

by

solves

solved

by

solves

MVD

relation

from

MVD

relation

from

1

5

3

4

2

Acknowledgements

Mitchell Tan Gin Teck is acknowledged for work on a prototype version of the current system

[Gin Teck 1995].

Figure 4: Component structure for expansion tank as a network structure , with attached drawing. The

component structure shown here is a subset of the total model shown in g 4.

Figure 5: Relationship matrix between the organ and component structures.

Expansion tank component structure

Coolant

Pressure

cap

spatial

relation

t

spatial

relation

from

Hose clip

Hose clip

Expansion

tank

spatial

relation

t

spatial

relation

from

energy

flow to

energy

flow

from

spatial

relation

t

spatial

relation

from

spatial

relation

t

spatial

relation

from

Hose

spatial

relation

t

spatial

relation

from

spatial

relation

t spatial

relation

from material

flow to

material

flow

from

Hose

spatial

relation

t

spatial

relation

from

spatial

relation

t

spatial

relation

from

material

flow to

material

flow

from

p

X

in

p

Y

in

MVD

relation

from

MVD

relation

from

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

Indicator

assembly

spatial

relation

t

spatial

relation

from

MVD

relation

from

MVD

relation

from

MVD

relation

from

Drawing attached

to expansion tank

object

+

Components

Organs

E

x

p

a

n

s

i

o

n

t

a

n

k

c

o

m

p

o

n

e

n

t

s

t

r

u

c

t

u

r

e

C

o

o

l

a

n

t

P

r

e

s

s

u

r

e

c

a

p

H

o

s

e

c

l

i

p

H

o

s

e

c

l

i

p

E

x

p

a

n

s

i

o

n

t

a

n

k

H

o

s

e

H

o

s

e

I

n

d

i

c

a

t

o

r

a

s

s

e

m

b

l

y

Expansion

vessel system

Refill opening

Lockable lid

Tube connection

Expansion

vessel

Tube connection

Pressure tank

Slow steady flow

Tube connection

Pressure valve

Transparent wall

Electrical level

indicator

Sealed hole in tank

Damping ribs in tank

Indicating mechanism

References

Akao, Y., Quality Function Deployment. Integrating Customer Requirements into Product

Design, Productivity Press, Cambridge, MA, USA, 1990.

Andreasen, M. M., Designing on a Designers Workbench (DWB), Proceedings of the 9th

WDK Workshop, Rigi, Switzerland, 1992.

Ascent Logic Corp., Introduction to RDD-100, version 4.1, San Jos, CA, USA, 1996.

Gin Teck, M. T., Computer Tool for Design Specification Modelling, Technical Report,

Machine & Vehicle Design, Chalmers University of Technology, Gteborg, Sweden, 1995.

Hubka, V. and Eder, W. E., Theory of Technical Systems, Springer-Verlag, Berlin, 1988.

Malmqvist, J., A Computer-based Approach Towards Including Design History Information

in Product Models and Function-Means Trees, Proceedings of DTM-95, Boston, 1995a, pp

593-602.

Malmqvist, J. Improved Function-Means Trees by Inclusion of Design History Information,

Proceedings of ICED-95, Praha, Czech Republic, 1995b, pp 1415-1423.

Mortensen, N. H., Andreasen, M. M., Designing in Interplay with a Product Model - Explained

by Design Units, Proceedings Tools and Methods for Concurrent Engineering, Budapest,

1996.

NCR Norge A/S, Metis Users Guide, version 1.9.1, Horten, Norway, 1996.

Otto, K. N., Forming Product Design Specifications Proceedings of the 1996 ASME Design

Engineering Technical Conferences, Irvine, CA, USA, 1996, Paper No 96-DETC/DTM-1517.

Pahl, G. and Beitz, W., Engineering Design, 3rd edition. Springer-Verlag, Berlin, 1995.

Pugh, S., Total Design, Addison-Wesley, Wokingham, 1991.

Roozenburg, N. F. M. and Eekels, J., Product Design Fundamentals and Methods, Wiley &

Sons, Chichester, 1995.

Sharpe, J. E. E., Integrated Platform for AI Support of Complex Design - Part I & II,

Concurrent Engineering - Research and Applications, Vol. 3, 1995, pp 295-318.

Svendsen, K.-H. and Thorp Hansen, C., Decomposition of Mechanical Systems and

Breakdown of Specifications, Proceedings of ICED-93, Den Haag, The Netherlands, 1993, pp

119-126.

Tomiyama, T., Kiriyama, T. and Umeda, Y., Towards Knowledge Intensive Engineering,

Proceedings of the 1994 Lancaster International Conference on Engineering Design, Lancaster,

1994, pp 319-338.

Ulrich, K. T. and Eppinger, S. D., Product Design and Development, McGraw-Hill, New York,

1995.

Dr Johan Malmqvist

Chalmers University of Technology

Machine & Vehicle Design

S - 412 96 Gteborg

Sweden

tel: +46 - 31 - 772 1382

fax: +46 - 31 - 772 1375

e-mail: joma@mvd.chalmers.se

You might also like

- Andy SummersDocument11 pagesAndy SummersRafael_YevgenyNo ratings yet

- Andy SummersDocument11 pagesAndy SummersRafael_YevgenyNo ratings yet

- Licks & Riffs - Hot Country Guitar PDFDocument2 pagesLicks & Riffs - Hot Country Guitar PDFRafael_YevgenyNo ratings yet

- Welding Neck Flange Design - 5!5!04Document3 pagesWelding Neck Flange Design - 5!5!04Rafael_YevgenyNo ratings yet

- Understanding Static Wind Forces on Steel ChimneysDocument9 pagesUnderstanding Static Wind Forces on Steel ChimneyszmtdialogNo ratings yet

- WN - Ring Flange CalculationDocument3 pagesWN - Ring Flange CalculationRafael_YevgenyNo ratings yet

- Pentatonic Five PositionsDocument1 pagePentatonic Five PositionsRafael_YevgenyNo ratings yet

- SongbookDocument35 pagesSongbookАлексей ГрабкоNo ratings yet

- 05a13 - Dynamic Stability Design of Stacks and Towers - Transactions of Asme - Nov-1966 PDFDocument7 pages05a13 - Dynamic Stability Design of Stacks and Towers - Transactions of Asme - Nov-1966 PDFRafael_YevgenyNo ratings yet

- SI UnitsDocument90 pagesSI UnitsManas KarnureNo ratings yet

- Piping Stress AnalysisDocument51 pagesPiping Stress Analysissandygo100% (4)

- Appendix 41Document5 pagesAppendix 41Rafael_YevgenyNo ratings yet

- Nonlinear Static Stress Analysis Tutorial: 2-D Cantilever Beam ModelDocument44 pagesNonlinear Static Stress Analysis Tutorial: 2-D Cantilever Beam ModelRafael_YevgenyNo ratings yet

- WN - Ring Flange CalculationDocument3 pagesWN - Ring Flange CalculationRafael_YevgenyNo ratings yet

- Development of in - Structure Design Spectra - KozloduyDocument9 pagesDevelopment of in - Structure Design Spectra - KozloduyRafael_YevgenyNo ratings yet

- PVEliteDocument580 pagesPVEliteSudhanshu Shekhar100% (2)

- The Fundamentals of Modal TestingDocument56 pagesThe Fundamentals of Modal TestingAsier Tejada OseguiNo ratings yet

- Pvelite Seminar NotesDocument314 pagesPvelite Seminar NotesRafael_Yevgeny100% (3)

- Harmony For MusiciansDocument81 pagesHarmony For MusiciansRafael_YevgenyNo ratings yet

- Technology and Geometry in The Design of Gothic Vaults in Great BritainDocument18 pagesTechnology and Geometry in The Design of Gothic Vaults in Great BritainRafael_YevgenyNo ratings yet

- Developing A VideogameDocument3 pagesDeveloping A VideogameRafael_YevgenyNo ratings yet

- 05a13 - Dynamic Stability Design of Stacks and Towers - Transactions of Asme - Nov-1966Document7 pages05a13 - Dynamic Stability Design of Stacks and Towers - Transactions of Asme - Nov-1966Rafael_YevgenyNo ratings yet

- Pressurevesselinspection 121221064634 Phpapp02Document35 pagesPressurevesselinspection 121221064634 Phpapp02Senthil KumarNo ratings yet

- Real-time Earthquake Damage Assessment Using CAVDocument5 pagesReal-time Earthquake Damage Assessment Using CAVRafael_YevgenyNo ratings yet

- Expansion Bellows 4Document1 pageExpansion Bellows 4Rafael_YevgenyNo ratings yet

- Spectroscopic Study of The R-Process Waiting-Point Nuclide CDDocument17 pagesSpectroscopic Study of The R-Process Waiting-Point Nuclide CDRafael_YevgenyNo ratings yet

- Creep Failure and Fracture of Polyethylene in Uniaxial ExtensionDocument5 pagesCreep Failure and Fracture of Polyethylene in Uniaxial ExtensionRafael_YevgenyNo ratings yet

- Inspection Personnel ExamDocument9 pagesInspection Personnel ExamRafael_YevgenyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sai Hadoop ResumeDocument5 pagesSai Hadoop ResumeSaikumar AvanigaddaNo ratings yet

- VDM++ Toolbox Use ManualDocument120 pagesVDM++ Toolbox Use ManualHernan FaustinoNo ratings yet

- Standard and Specification of Recovered Waste Oil PDFDocument10 pagesStandard and Specification of Recovered Waste Oil PDFShaiful AnnuarNo ratings yet

- General SpecificationsDocument216 pagesGeneral Specificationspuwe qiheNo ratings yet

- Mis PPT FinalDocument44 pagesMis PPT Finalmonika19mayNo ratings yet

- Wrongb 018-005 WaterproofingDocument4 pagesWrongb 018-005 WaterproofingAmy FitzpatrickNo ratings yet

- GEC Production Planning and Control Course ModuleDocument21 pagesGEC Production Planning and Control Course ModuleRamteja Goud KosuriNo ratings yet

- PT Konsultan International: T.Y.LinDocument15 pagesPT Konsultan International: T.Y.LinWempy WiryaatmajaNo ratings yet

- Sample 2x50MW Coal Fired Thermal Power Plant Proposal and QuotationDocument6 pagesSample 2x50MW Coal Fired Thermal Power Plant Proposal and Quotationiwan_renaldiNo ratings yet

- Requirements Engineering: Ian Sommerville,, 9 Edition Pearson Education, Addison-WesleyDocument77 pagesRequirements Engineering: Ian Sommerville,, 9 Edition Pearson Education, Addison-WesleyJoy DharNo ratings yet

- Foundations Bill of QuantitiesDocument40 pagesFoundations Bill of QuantitiesAnonymous 7ZYHilDNo ratings yet

- Structural Analysis and Design Lectures PDFDocument354 pagesStructural Analysis and Design Lectures PDFgongmaozheNo ratings yet

- CCPPDocument173 pagesCCPPscribdhas2006No ratings yet

- Grouting ManualDocument36 pagesGrouting ManualJorgeaul100% (1)

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- 1.hostel Buildind Main Project ReportDocument58 pages1.hostel Buildind Main Project ReportRavi Viswam90% (10)

- Specification For Calcium Hypochlorite1Document5 pagesSpecification For Calcium Hypochlorite1Danial RH AbtahiNo ratings yet

- ASME Review Guide for Quality Control SystemsDocument12 pagesASME Review Guide for Quality Control SystemsSathish KumarNo ratings yet

- Astm A101 PDFDocument8 pagesAstm A101 PDFtrjithinrajNo ratings yet

- VIT-Mart Billing System SRSDocument11 pagesVIT-Mart Billing System SRSChandanKumar100% (2)

- Edi 300 PDFDocument98 pagesEdi 300 PDFLuis Mesones RamirezNo ratings yet

- Changes From DOD-STD-2167A To MIL-STD-498Document24 pagesChanges From DOD-STD-2167A To MIL-STD-498kannaravikanthNo ratings yet

- SPI Design ProcedureDocument104 pagesSPI Design ProcedureKamlesh DaveNo ratings yet

- Inspection Test Plan For Stat XDocument4 pagesInspection Test Plan For Stat XGinish KumarNo ratings yet

- Bond Ek Design and Construction Manual June 2012Document56 pagesBond Ek Design and Construction Manual June 2012rocketNo ratings yet

- FS and Data Mappimng - Concur-TVCLDocument6 pagesFS and Data Mappimng - Concur-TVCLgirijadevi760% (1)

- Scope: General Inspection Guidelines For Inspection of FittingsDocument3 pagesScope: General Inspection Guidelines For Inspection of Fittingszahid_497No ratings yet

- Understanding NIST HL7 v2 Test Tools: Focus On ONC 2015 Health IT CertificationDocument61 pagesUnderstanding NIST HL7 v2 Test Tools: Focus On ONC 2015 Health IT CertificationSpit FireNo ratings yet

- Regular ExcavationDocument3 pagesRegular ExcavationNoelia GarcíaNo ratings yet