Professional Documents

Culture Documents

Demolition: Idaho National Laboratory

Uploaded by

pipilipipiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Demolition: Idaho National Laboratory

Uploaded by

pipilipipiCopyright:

Available Formats

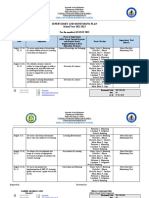

Form 412.09 (Rev.

09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 1 of 6

Subcontractors Program Requirements Document DAR Number:

506459

Manual: INL Subcontractor Requirements

1. PURPOSE

Proper monitoring and control of demolition activities ensures these activities are

accomplished in a safe manner and in accordance with existing requirements. This

document highlights requirements referenced in the Source Documents section, as well

as Contractor requirements. Any applicable regulatory or Contractor requirements must

be followed, with the most stringent requirement being met.

2. APPLICABILITY

This document applies to all subcontractors who conduct demolition activities at the INL,

as specified in their contract with Contractor. Stricter requirements may be imposed by

subcontractors upon their employees or subtier contractors. The requirements of this

document must be followed by subcontractors; however, the means of implementation

may vary as determined by the subcontractor.

3. REQUIREMENTS

3.1 Demolition shall meet the requirements of 29 CFR 1926 Subpart T Demolition.

Additional requirements specific to demolition are specified below.

3.2 A hazards analysis and a work plan shall be completed for the project before

demolition begins.

3.3 Demolition work shall be done by qualified personnel.

3.4 Training documentation shall be verified, with particular attention being paid to

mixed environments (such as an asbestos worker working in a confined space, in

a radiological area, or on a hazardous waste site).

3.5 The number of personnel allowed in the demolition area shall be limited to those

persons necessary to perform the work tasks.

3.6 Lines of demarcation shall be placed before any demolition work starts. Work

areas and adjacent affected areas shall be protected or closed to unqualified or

unauthorized personnel by the use of fences, signs, rope, or other appropriate

barriers.

Form 412.09 (Rev. 09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 2 of 6

3.6.1 The Contractor Point of Contact (POC) shall be consulted for direction

regarding additional signs, such as:

A. radiation signs

B. CERCLA postings

C. RCRA waste postings

D. asbestos removal or advisory signs

E. flammable or combustible material storage.

3.6.2 Warning lights shall be placed on or about all barricades as necessary to

prevent inadvertent pedestrian and vehicular access after dark.

3.7 Before demolition begins, an engineering survey of the structure shall be obtained

from the Contractor POC. This survey shall address, as a minimum:

A. the structure layout

B. the condition of the framing, floors, and walls

C. the possibility of unplanned collapse from weakness caused by age, fire,

or overuse of any portion of the structure (any adjacent structure where

employees or property may be exposed shall be similarly checked)

D. the existence of other potential or real demolition hazards.

3.8 All electric, gas, water, steam, sewer, and other service lines shall be shut off,

capped, or otherwise controlled outside the building or demolition area, in

accordance with RD -2012, Lockout and Tagout, before demolition is started.

3.9 Pedestrian and vehicular traffic shall be controlled in any area that is closer than

one-fourth of the height of the structure to the perimeter of the structure being

demolished.

3.10 Demolition within operating facilities will have additional requirements. These

requirements are:

3.10.1 Demolition within operating facilities primarily encompasses demolition

associated with component or system replacement or upgrade in or near

operating facilities.

Form 412.09 (Rev. 09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 3 of 6

3.10.2 Each project that includes demolition will require a subcontractor

generated demolition procedure that will positively identify systems to

be demolished. The plan shall as a minimum identify individual

components making up a system (for example electrical power, electrical

controls, fuel, steam). Special attention to lockout/tagout should be

considered for projects that systems are to be systematically de-

energized as demolition activities progress.

NOTE: See Appendix A for sample of demolition plan.

3.10.3 All personnel engaged in demolition activities shall be trained to the

demolition procedure.

4. DEFINITIONS

For definitions of terms used throughout the INL Subcontractor Requirements Manual,

refer to LST-359.

5. REFERENCES

5.1 Source Documents

29 CFR 1926, Subpart T, Demolition

DOE Order 440.1A Worker Protection Management for Federal and Contractor

Employees

American National Standards Institute (ANSI) Standard A10.6-1990, Safety

Requirements for Demolition Operations

6. APPENDICES

Appendix A Sample Demolition Plan

Form 412.09 (Rev. 09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 4 of 6

Appendix A

Sample Demolition Plan

1. PURPOSE

1.1 The purpose of this Technical Procedure Requirement is to establish

requirements by which demolition activities will be performed.

2. SCOPE AND APPLICABILITY

2.1 This guideline is applicable to mechanical and electrical demolition activities

within operating facilities. This guide will provide a consistent and positive

method for identification and removal of individual components within a system.

2.2 The definition of demolition is the removal of piping systems, electrical systems,

system components, or the removal of any item within an operating facility.

3. PREREQUISITES

3.1 The requirements for the implementation of this guideline shall be identified in

the project documents.

3.2 Personnel performing demolition activities shall be trained to the requirements of

this procedure and evidence of such shall be noted in the Pre Job Briefing and

training records.

4. INSTRUCTIONS

4.1 Planning and Coordination

4.1.1 The job supervisor shall coordinate all demolition efforts and interface

with the various crafts and Operations Support personnel involved.

Coordination will include outage planning, demolition walkdowns, and

will support safe operation of the facility as required.

4.1.2 The job supervisor shall walk the job daily with the individual crafts

involved in the demolition activities. The job supervisor may elect to

pass this requirement on to the individual craft foreman, however one

individual shall be responsible for all demolition activities associated

with the project.

Form 412.09 (Rev. 09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 5 of 6

4.2 Identification Marking

4.2.1 Color coded identification marking shall be applied to all systems shown

on the project documentation prior to starting demolition activities. The

color-coding shall identify the type of system and the date the system

was originally identified. Ribbon shall be used to identify the systems

and the color code shall be as follows:

Red electrical systems

Yellow mechanical piping systems

Blue mechanical HVAC systems

Green miscellaneous systems or components

4.2.2 The color code system shall include a positive means for verification that

a system or component is approved for removal. Orange ribbon shall be

used to flag systems that have been walked down and are ready for

removal (for example: Red ribbon for an electrical system accompanied

by an Orange ribbon indicating the component has been walked down

and is ready for removal). The orange ribbon shall be marked with the

date the component is to be removed.

4.2.3 If only a portion of a system is to be removed two orange ribbons shall

be applied approximately one inch apart on either side of where the line

is to be cut.

4.3 Pre Job Briefing

4.3.1 A Pre Job Briefing shall be held prior to each shifts demolition activities

to address the guidelines and safety requirements outlined in this

procedure. Pre Job Briefings shall include a review of the color code

system, the date that should be on the orange ribbon and a review of the

drawings at the job site identifying the components to be removed.

NOTE: Some projects may only provide schematic drawings. Special attention

should be place on the actual field conditions when using schematic

drawings for planning purposes.

4.4 Walkdown Verification

4.4.1 Initial walkdown. The systems shall be walked down initially at the start

of the project with Operations Support personnel. The initial walkdown

will be performed as verification that the correct system components

have been identified.

Form 412.09 (Rev. 09)

Idaho National Laboratory

RD-2024

0

DEMOLITION

Identifier:

Revision:

Effective Date: 05/24/06 Page: 6 of 6

4.4.2 Pre-demolition walkdown. Pre-demolition walkdowns with the job

supervisor and Operations Support personnel will be performed prior to

each shift to ensure the identification markings are correct. Orange

ribbon shall be applied to the systems for that shifts demo activity. The

job supervisor shall also remove orange flagging that is out of date. The

job supervisor shall discuss with operations support personnel all lockout

/ tagout requirements and ensure lockout / tagouts are in place prior to

flagging the system.

4.4.3 Changes. If there are changes to project scope or changes due to design

errors or omissions the new work shall be reviewed and walked down

prior to commencing.

4.4.4 Daily post demolition activities. The job supervisor shall perform a

walkdown at the end of the each shift and prior to weekend or holiday

breaks to ensure the job site has been left in a safe condition. The

walkdown should include construction signs and barriers and changes to

operational postings that may need to be updated due to removed

equipment and components.

4.5 Demolition

4.5.1 Employees shall only demolish systems that have orange ribbon with the

current date and a ribbon identifying the system type. If a system

contains a ribbon that has an old date or improper system identification

the employees shall notify the foreman or job supervisor.

4.5.2 Employees shall only demolish systems that they are qualified to

remove. The job supervisor shall ensure each worker meets the

qualifications required for assigned activities.

4.6 Post Demolition / Post Job Review

4.6.1 At the completion of demolition activities, the job supervisor shall

walkdown the project with the individual craft supervision and

Operations Support personnel to ensure all identified systems have been

removed and left in a safe condition for continued operation of the plant

and for follow-on installation crews.

4.6.2 The post demolition walkdown shall include a review of the drawings to

further ensure all system components have been removed.

You might also like

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- Method Statement For Underground Piping FCDocument17 pagesMethod Statement For Underground Piping FCmister pogi94% (17)

- Supervisory Plan 2022 2023Document4 pagesSupervisory Plan 2022 2023Jesieca Bulauan100% (12)

- Hvac Systems Commissioning ProceduresDocument38 pagesHvac Systems Commissioning ProceduresMafe SalazarNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Document20 pagesMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Tank Cleaning ProcedureDocument35 pagesTank Cleaning ProcedureAch Dja'far S93% (15)

- Dip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017Document2 pagesDip HIV Man (SA) Past Papers - 2015 2nd Semester 24-1-2017matenten100% (1)

- S Civ Site - 00Document8 pagesS Civ Site - 00HARINo ratings yet

- D 3843 - 93 - Rdm4ndmtukveDocument5 pagesD 3843 - 93 - Rdm4ndmtukveEmre DalgicNo ratings yet

- Mechanical Completion & ComissioningDocument56 pagesMechanical Completion & ComissioningRustam Riyadi100% (1)

- Removal of Equipment (SAMPLE)Document9 pagesRemoval of Equipment (SAMPLE)Hasann MaawiaNo ratings yet

- D 7167 Monitoring Performance of Safety Related Linings PDFDocument7 pagesD 7167 Monitoring Performance of Safety Related Linings PDFImmanuel100% (1)

- Washington Edu 2010 - Data Centers and Mission Critical Facilities Operations Procedures - Attachment ADocument10 pagesWashington Edu 2010 - Data Centers and Mission Critical Facilities Operations Procedures - Attachment AHarumNo ratings yet

- SECTION 23 05 00 Common Work Results For Hvac: Based On DFD Master Specification Dated 08/01/14Document9 pagesSECTION 23 05 00 Common Work Results For Hvac: Based On DFD Master Specification Dated 08/01/14htanhNo ratings yet

- Specification For Horizontal Directional DrillingDocument13 pagesSpecification For Horizontal Directional Drillingjua666nNo ratings yet

- SPC-0804.02-50.91 Rev D2 3D-CAD Model Review SpecificationDocument22 pagesSPC-0804.02-50.91 Rev D2 3D-CAD Model Review SpecificationAroon Kumar100% (1)

- OPGWDocument69 pagesOPGWmanoj_ujvnlNo ratings yet

- Di Tcp2017 DrainageDocument41 pagesDi Tcp2017 Drainagevin ss100% (1)

- MEEZA CRAC and Downflow SpecificationDocument57 pagesMEEZA CRAC and Downflow SpecificationSwamy Dhas DhasNo ratings yet

- Fall Arrest Spec PDFDocument6 pagesFall Arrest Spec PDFAnonymous I8nZsDqlmhNo ratings yet

- Testing and Commissioning Procedure For Plumbing and Drainage InstallationDocument76 pagesTesting and Commissioning Procedure For Plumbing and Drainage InstallationSean Chan100% (19)

- Aa - Spec - 248002 Materials Handling Machines Structural Components SpecificationDocument47 pagesAa - Spec - 248002 Materials Handling Machines Structural Components Specificationjonodo89100% (1)

- L2CIV003Document23 pagesL2CIV003Sanchay Singhal100% (1)

- Technical Specification For Communication EquipmentDocument79 pagesTechnical Specification For Communication EquipmentumamaheshwarraoNo ratings yet

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- 1statement of Standard 1Document23 pages1statement of Standard 1Ivan de Jesus Candelero MoralesNo ratings yet

- Volume IVDocument51 pagesVolume IVVansh PandyaNo ratings yet

- Introduction of Sub-Station: Marudhar Engg. CollegeDocument49 pagesIntroduction of Sub-Station: Marudhar Engg. Collegesorry2qazNo ratings yet

- NS168Document33 pagesNS168EBENo ratings yet

- Method of Statement For Bus DuctDocument11 pagesMethod of Statement For Bus DuctTalha AltafNo ratings yet

- PTS (Conductor Design and Installation Manual For Offshore Platform)Document303 pagesPTS (Conductor Design and Installation Manual For Offshore Platform)hash117100% (1)

- Astm d4286Document3 pagesAstm d4286Subodh KulkarniNo ratings yet

- HFY-PIP-SP-00007 X Specification For Contruction and Installation of Piping - A-CommentedDocument12 pagesHFY-PIP-SP-00007 X Specification For Contruction and Installation of Piping - A-CommentedVignesh PanchabakesanNo ratings yet

- Specification For Microtunnelling and Pipe JackingDocument13 pagesSpecification For Microtunnelling and Pipe Jackingganmoses100% (1)

- ABC Guide To Dropped ObjectDocument108 pagesABC Guide To Dropped ObjectLes Donaldson100% (5)

- Nepal Electricity Authority Distribution Network Improvement Project Bidding DocumentsDocument563 pagesNepal Electricity Authority Distribution Network Improvement Project Bidding DocumentsSamsonNo ratings yet

- U.S. Department of Energy: Order Washington, DCDocument43 pagesU.S. Department of Energy: Order Washington, DCPractical WanderlustNo ratings yet

- NRC Inspection Manual: February 5, 2019Document29 pagesNRC Inspection Manual: February 5, 2019elsayed abdemagiedNo ratings yet

- CCP NERC Const IAQ MGMT PlanDocument12 pagesCCP NERC Const IAQ MGMT PlanhihouNo ratings yet

- Solar Permitting GuidelinesDocument12 pagesSolar Permitting GuidelinesDanielNo ratings yet

- Functional Competency Directory For CTC Roles: Damodar Valley CorporationDocument7 pagesFunctional Competency Directory For CTC Roles: Damodar Valley Corporationlaloo01No ratings yet

- FCG Sample Fire Alarm CX SpecDocument12 pagesFCG Sample Fire Alarm CX SpecreedazNo ratings yet

- Design Criteria and Guidelines For Surface Infrastructure Mechanical and StructuralDocument68 pagesDesign Criteria and Guidelines For Surface Infrastructure Mechanical and Structuraljonodo89No ratings yet

- Z 007 5913722 PDFDocument56 pagesZ 007 5913722 PDFLegend AnbuNo ratings yet

- Wi-Trd-48 Balance Pipe ReplacementDocument13 pagesWi-Trd-48 Balance Pipe ReplacementKiana Raine VillanNo ratings yet

- PIP PCCLI001 Level Measurement Design CriteriaDocument10 pagesPIP PCCLI001 Level Measurement Design CriteriaM RNo ratings yet

- Kakatiya TPP I - Wet Ash Handling System, Rev 3 (09.10.2012)Document259 pagesKakatiya TPP I - Wet Ash Handling System, Rev 3 (09.10.2012)rukmagoudNo ratings yet

- Power Distribution EquipmentDocument7 pagesPower Distribution EquipmentWalidNo ratings yet

- SECTION 27 52 23 Nurse Call and Code Blue Systems Part 1 - General 1.1 Section SummaryDocument74 pagesSECTION 27 52 23 Nurse Call and Code Blue Systems Part 1 - General 1.1 Section SummaryAmira HassanNo ratings yet

- Method Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Document7 pagesMethod Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Hasann MaawiaNo ratings yet

- Applying safety standards throughout equipment lifetimeDocument8 pagesApplying safety standards throughout equipment lifetimePeerasut Thirakomen-BankNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Mission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsFrom EverandMission-Critical and Safety-Critical Systems Handbook: Design and Development for Embedded ApplicationsRating: 5 out of 5 stars5/5 (1)

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationFrom EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNo ratings yet

- Office WorkstationsDocument2 pagesOffice WorkstationspipilipipiNo ratings yet

- The Meditations of The Emperor Marcus Aurelius AntoninusDocument248 pagesThe Meditations of The Emperor Marcus Aurelius AntoninusMMMMM99999No ratings yet

- Samsung 3D Televizor LED LCD UE-46F6400Document2 pagesSamsung 3D Televizor LED LCD UE-46F6400pipilipipiNo ratings yet

- Guide to Villa Tokek Kecil Guesthouse in BaliDocument17 pagesGuide to Villa Tokek Kecil Guesthouse in BalipipilipipiNo ratings yet

- Gunter Levin The Integrated German BG System of PreventionDocument25 pagesGunter Levin The Integrated German BG System of PreventionpipilipipiNo ratings yet

- Door and mirror technical drawing dimensionsDocument1 pageDoor and mirror technical drawing dimensionspipilipipiNo ratings yet

- True Stories: Communication Is KeyDocument1 pageTrue Stories: Communication Is KeypipilipipiNo ratings yet

- T - Truckload WebDocument9 pagesT - Truckload WebpipilipipiNo ratings yet

- The Meditations of The Emperor Marcus Aurelius AntoninusDocument248 pagesThe Meditations of The Emperor Marcus Aurelius AntoninusMMMMM99999No ratings yet

- T - Strain WebDocument3 pagesT - Strain WebpipilipipiNo ratings yet

- Tight Squeeze?: Don't Risk It. Stay Out of The Way When Forklifts Are Working!Document1 pageTight Squeeze?: Don't Risk It. Stay Out of The Way When Forklifts Are Working!pipilipipiNo ratings yet

- T - Couriers WebDocument9 pagesT - Couriers WebpipilipipiNo ratings yet

- Hazard Solution: Get Help With Heavy or Awkward LoadsDocument1 pageHazard Solution: Get Help With Heavy or Awkward LoadspipilipipiNo ratings yet

- Forklift Safety: Stay Alert to Avoid Crushing InjuriesDocument1 pageForklift Safety: Stay Alert to Avoid Crushing InjuriespipilipipiNo ratings yet

- Manual lifting injuries prevention tips trucking industryDocument1 pageManual lifting injuries prevention tips trucking industrypipilipipiNo ratings yet

- True Stories: Preventing Falls From Worn StepsDocument1 pageTrue Stories: Preventing Falls From Worn StepspipilipipiNo ratings yet

- True Stories: Delivery Driver Fatally Injured in FallDocument1 pageTrue Stories: Delivery Driver Fatally Injured in FallpipilipipiNo ratings yet

- TDF 90932012Document1 pageTDF 90932012pipilipipiNo ratings yet

- 5 Forklif T 5 Freight: Drivers, Protect Yourself From The Hazards of Falling Freight While Loading and UnloadingDocument1 page5 Forklif T 5 Freight: Drivers, Protect Yourself From The Hazards of Falling Freight While Loading and UnloadingpipilipipiNo ratings yet

- Setting up a hazard free moving jobDocument6 pagesSetting up a hazard free moving jobpipilipipiNo ratings yet

- Serious Injuries Are Often Caused by Delayed MaintenanceDocument1 pageSerious Injuries Are Often Caused by Delayed MaintenancepipilipipiNo ratings yet

- Tarping Related Fall Injuries To Drivers: What HappenedDocument1 pageTarping Related Fall Injuries To Drivers: What HappenedpipilipipiNo ratings yet

- True Stories: Preventing Falls From Worn StepsDocument1 pageTrue Stories: Preventing Falls From Worn StepspipilipipiNo ratings yet

- Terminal, Yard, and Customer Site Slip, Trip and Fall Injuries To DriversDocument1 pageTerminal, Yard, and Customer Site Slip, Trip and Fall Injuries To DriverspipilipipiNo ratings yet

- True Stories: Don't Stop That Truck!Document1 pageTrue Stories: Don't Stop That Truck!pipilipipiNo ratings yet

- Serious Injuries Are Often Caused by Delayed MaintenanceDocument1 pageSerious Injuries Are Often Caused by Delayed MaintenancepipilipipiNo ratings yet

- Look before exiting your vehicle - safety tipsDocument1 pageLook before exiting your vehicle - safety tipspipilipipiNo ratings yet

- Don't Let Your Footwear Get You Down: True StoriesDocument1 pageDon't Let Your Footwear Get You Down: True StoriespipilipipiNo ratings yet

- FallDocument3 pagesFall395334016No ratings yet

- Want To Be A Pro?: Follow These Safe Steps To Strap Your LoadDocument1 pageWant To Be A Pro?: Follow These Safe Steps To Strap Your LoadpipilipipiNo ratings yet

- Murder Conviction UpheldDocument9 pagesMurder Conviction UpheldBobNo ratings yet

- GARAM ModelDocument40 pagesGARAM ModelprasunmathurNo ratings yet

- TECHNICALPAPER2Document8 pagesTECHNICALPAPER2spiderwebNo ratings yet

- Resilience WorkbookDocument54 pagesResilience WorkbookLeo Siu100% (1)

- Mumbai: City of DreamsDocument14 pagesMumbai: City of DreamsAnika WahalNo ratings yet

- ENGLISH CONTENT UNIT 4 2022 5tos.Document9 pagesENGLISH CONTENT UNIT 4 2022 5tos.Dylan QuiñónezNo ratings yet

- MS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Document6 pagesMS6711 Data Mining Homework 1: 1.1 Implement K-Means Manually (8 PTS)Yihan WangNo ratings yet

- Holzma PR Hob and Ex Linger Enu 18533Document7 pagesHolzma PR Hob and Ex Linger Enu 18533esfandiar232477No ratings yet

- Otr Product CatalogDocument116 pagesOtr Product CatalogIwan KurniawanNo ratings yet

- ESBG Financial Systems Difference EU-US PDFDocument12 pagesESBG Financial Systems Difference EU-US PDFDominiqueCarriouNo ratings yet

- Providing Clean Water and Financial Assistance in Binangonan RizalDocument29 pagesProviding Clean Water and Financial Assistance in Binangonan RizalArebeeJayBelloNo ratings yet

- Lect 1 Transforming EER Diagrams Into Relations (Part III)Document13 pagesLect 1 Transforming EER Diagrams Into Relations (Part III)KIM OFFNo ratings yet

- Flared Separable FittingDocument9 pagesFlared Separable FittingbenNo ratings yet

- Organization-and-Management Q1 LAS Wk1Document5 pagesOrganization-and-Management Q1 LAS Wk1Joyce CelineNo ratings yet

- Calculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofDocument46 pagesCalculate the proof strength of 70% v/v alcohol.Step 1) 70% v/v x 1.753 = 122.71Step 2) 122.71 - 100 = 22.71The proof strength of 70% v/v alcohol is 22.71% over proofPrashant307100% (1)

- Text 1 Is For No 1 - 4 The Rabbit Revenge: I. Pilihlah Salah Satu Jawaban Yang Benar!Document4 pagesText 1 Is For No 1 - 4 The Rabbit Revenge: I. Pilihlah Salah Satu Jawaban Yang Benar!Diandra MomentNo ratings yet

- SMS Security Android AppDocument8 pagesSMS Security Android AppSuman SouravNo ratings yet

- PR & PublicityDocument16 pagesPR & PublicityVipul Partap100% (2)

- HZVDocument6 pagesHZVnurrozaqNo ratings yet

- Practice Reading GraphsDocument4 pagesPractice Reading GraphsSharon TaylorNo ratings yet

- Employee Leave Management System: FUDMA Journal of Sciences July 2020Document7 pagesEmployee Leave Management System: FUDMA Journal of Sciences July 2020MOHAMMED ASHICKNo ratings yet

- Company Introduction PT GEADocument8 pagesCompany Introduction PT GEABegawan Half DoneNo ratings yet

- Myths of Membership The Politics of Legitimation in UN Security Council ReformDocument20 pagesMyths of Membership The Politics of Legitimation in UN Security Council ReformCaroline GassiatNo ratings yet

- Marivy Abella ResearchDocument43 pagesMarivy Abella ResearchRo Gi LynNo ratings yet

- Studi Kasus Pada PT Damar Bandha Jaya Corp. BogorDocument10 pagesStudi Kasus Pada PT Damar Bandha Jaya Corp. BogorMayHan13No ratings yet

- Open University of Tanzania Term PaperDocument7 pagesOpen University of Tanzania Term Paperafmzfmeeavndqe100% (1)

- Resume Masroor 3Document3 pagesResume Masroor 3mohammad masroor zahid ullahNo ratings yet