Professional Documents

Culture Documents

Bsen25817 PDF

Uploaded by

dzat_sudrazatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bsen25817 PDF

Uploaded by

dzat_sudrazatCopyright:

Available Formats

BSI BS*EN*25817 92 m Lb24bb9 0311749 723 m

BRITISH STANDARD BS EN

25817 : 1992

IS0 5817 : 1992

Arc-welded joints in

steel -

Guidance on quality

levels for imperfections

The European Standard EN 25817 : 1992 has the status of a

British Standard

i

UDC621.791.75.053 : 669.14 : 621.791.019

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

E S 1 BS+EN* 25817 92 LbZYbb?! 0311750 445 m

BS EN 25817 : 1992

Cooperating organizations

The European Committee for Standardization (CEN), under whose supervision

this European Standard was prepared, comprises the national standards

organizations of the following countries:

Austria

Belgium

Denmark

Finland

France

Germany

Greece

Iceland

Ireland

Italy

Luxembourg

Netherlands

Norway

Portugal

Spain

Sweden

Switzerland

United Kingdom

Oesterreichisches Normungsinstitut

Institut belge de normalisation

Dansk Standardiseringsraad

Suomen Standardisoimisliito, r.y.

Association fransaise de normalisation

Deutsches Institut fr Normung e.V.

Hellenic Organization for Standardization

Technological Institute of Iceland

National Standards Authority of Ireland

Ente Nazionale Italiano di Unificazione

Inspection du Travail et des Mines

Nederlands Normalisatie-instituut

Norges Standardiseringsforbund

Instituto Portugus da Qualidade

Asociacin Espaola de Normalizacin y Certificacin

Standardiseringskommissionen i Sverige

Association suisse de normalisation

British Standards Institution

This British Standard, having

been prepared under the

direction of the Welding

Standards Policy Committee,

was published under the

authority of the Standards

Board and cornes into effect on

15 October 1992

O BSI 1992

The following BSI references

relate t.o the work on this

standard:

Cornmittee reference WEE/-/I

Draft for comment 8!1566 DC

ISBN O 580 21245 9

Amendments issued since publication

Text affected

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Contents

Cooperating organizations

National foreword

Page

Inside front cover

i

Foreword ' 2

Rxt of EN 25817 3

National annex NA (informative) Committees responsible Inside back cover

National annex NB (informative) Cross-references Inside back cover

~~

National foreword

This British Standard has been prepared under the direction of the Welding

Standards Policy Committee and is the English language version of EN 25817,

Arc-welded joints in steel - Guidance on quality levels for impurfections,

published by the European Committee for Standardization (CEN).

EN 25817 : 1992 is identical with IS0 5817 : 1992 published by the

International Organization for Standardization (ISO). EN 25817 was produced as

a result of international discussion in which the UK took an active part.

There has previously been no direct British Standard equivalent to this

standard. It is simply intended as a possible reference/guidance for application

standards for designers if, and when, so required. Toavoid confusion, it is

emphasised that levels of detectable imperfection quoted are purely arbitrary

and intended for quality control purposes only. The various levels may be

referred to in whole, in part or in combination, or it may be decided that for

particular purposes, other levels are more appropriate. Consideration of any

specific requirements from this standard should be at the time of the

enquiry/contract stage and agreed between the contracting parties.

It is assumed that the execution of the provisions of the document is entrusted

to suitably qualified and experienced persons.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

B S I BS*EN*25817 92 .S 1624669 0311752 218 m

EUROPEAN STANDARD

NORME EUROPENNE

EUROPISCHE NORM

EN 25817

J uly 1992

UDC 621.791.75.053 : 669.14 : 621.791.019

Descriptors: Welded joints, arc welding, steels, acceptance testing, weld defects, acceptability

English version

Arc-welded joints in steel - Guidance on quality levels

for imperfections

(IS0 5817 : 1992)

Assemblages en acier soud larc - Guide

Lichtbogenschweifiverbindungen an Stahl -

des niveaux dacceptation des dfauts

Richtlinie fr Bewertungsgruppen fr

(IS0 5817 : 1992)

UnregelmlJigkeiten

(IS0 5817 : 1992)

This European Standard was approved by CEN on 1992-07-03. CEN members

are bound to comply with the CENKENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a

national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any

CEN member.

This European Standard exists in three official versions (English, French,

German). A version in any other language made by translation under the

responsibility of a CEN member into its own language and notified to the

Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium,

Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy,

Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland

and United Kingdom.

CEN

European Committee for Standardization

Comit Europen de Normalisation

Europisches Komitee fr Normung

Central Secretariat: rue de Stassart 36, B-1050 Brussels

O 1992 Copyright reserved to CEN members

Ref. No. EN 25817 : 1992 E

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Page 2

EN 25817 : 1992

Foreword

In 1991 CEN Technical Committee CEN/TC 121

Welding decided to submit IS0 5817 : 1992 -

Arc-welded joints in steel - Guidance on quality

levels for imperfections to the Unique Acceptance

Procedure.

The result was positive.

National standards identical to this European

Standard shall be published at the latest by

1993-01-31 and conflicting national standards shall

be withdrawn at the latest by 1993-01-31.

According to the CENXENELEC Common Rules,

the following countries are bound to implement

this European Standard: Austria, Belgium,

Denmark, Finland, Rance, Germany, Greece,

Iceland, Ireland, Italy, Luxembourg, Netherlands,

Norway, Portugal, Spain, Sweden, Switzerland and

United Kingdom.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Page 3

EN 25817 : 1992

Introduction

This International Standard should be used as a reference in the drafting

of application codes and/or other application standards. It may be used

within a total quality system for the production of satisfactory welded

joints. It provides three sets of dimensional values from which a

selection can be made for a particular application. The quality level

necessary in each case should be defined by the application standard

or the responsible designer in conjunction with the manufacturer, user

and/or other parties concerned. The level shall be prescribed before the

start of production, preferably at the inquiry or order stage. For special

purposes, additional details may need to be prescribed.

The quality levels given in this International Standard are intended to

provide basic reference data and are not specifically related to any

particular application. They refer to the types of welded joints in a fab-

rication and not to the complete product or component itself. It is poss-

ible, therefore, for different quality levels to be applied to individual

welded joints in the same product or component.

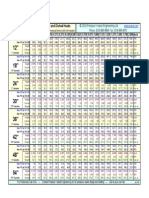

Quality levels are listed in table0.1.

Table 0.1 - Quality levels for weld imperfections

I

Level symbol Quality level

I

D

C

B

Moderate

Intermediate

Strlngent

The three quality levels are arbitrarily identified as D, C and B and are

intended to cover the majority of practical applications.

It would normally be hoped that for a particular welded joint the dimen-

sional limits for imperfections could all be covered by specifying one

quality level. In some cases, however, e.g. for certain type of steels and

structures as well as for fatigue loading or leak tightness applications,

it may be necessary to specify different quality levels for different

imperfections in the same welded joint or to include additional require-

ments.

The choice of quality level for any application should take account of

design considerations, subsequent processing, e.g. surfacing, mode of

stressing (e.g. static, dynamic), service conditions (e.g. temperature,

environment), and consequences of failure. Economic factors are also

important and should include not only the cost of welding but also that

of inspection, test and repair.

Although this International Standard includes types of imperfections

relevant to the arc welding processes given in clause 1, only those

which are applicable to the process and application in question need to

be considered.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

EN 25817 : 1992

Imperfections are quoted in terms of their actual dimensions, and their

detection and evaluation may require the use of one or more methods

of non-destructive testing. The detection and sizing of imperfections is

dependent on the inspection methods and the extent of testing specified

in the application standard or contract.

This International Standard does not include details of recommended

methods of detection and sizing and, therefore, it needs to be sup-

plemented by requirements for examination, inspection and testing. It

should be appreciated that methods of non-destructive examination may

not be able to give the detection, characterization and sizing necessary

for use within certain types of imperfections shown in table l.

Although this International Standard covers a material thickness range

of 3 mm to 63 mm, it may well be applicable to thicker or thinner joints

provided consideration is given to those technical factors which may

influence the situation.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Page 5

EN 25817 : 1992

Arc-welded joints in steel - Guidance on quality levels for

imperfections

1 Scope

This International Standard provides guidance on

levels of imperfections in arc-welded joints in steel.

Three levels are given in such a way as to permit

application for a wide range of welded fabrications.

The levels refer to production quality and not to the

fitness-for-purpose (see 3.1) of the product manu-

factured.

This International Standard applies to

- unalloyed and alloyed steels;

- the following welding processes and their de-

fined sub-processes in accordance with

IS0 4063:

11 metal-arc welding without gas protection;

12 submerged-arc welding;

13 gas-shielded metal-arc welding;

14 gas-shielded welding with non-consum-

able electrode;

15 plasma arc welding;

- manual, mechanized and automat,ic processes;

- all welding positions;

- butt welds, fillet welds and branch connections;

- materials in the thickness range 3 mm to

63 mm.

When significant deviations from the joint ge-

ometries and dimensions described in this Inter-

national Standard are present in the welded product,

it is necessary to evaluate to what extent the pro-

visions of this standard can apply.

Metallurgical aspects, e.g. grain size, hardness, are

not covered by this International Standard,

2 Normative references

The following standards contain provisions which,

through reference in this text, constitute provisions

of this International Standard. At the time of publi-

cation, the editions indicated were valid. All stan-

dards are subject to revision, and parties to

agreements based on this International Standard

are encouraged to investigate the possibility of ap-

plying the most recent editions of the standards in-

dicated below. Members of IEC and IS0 maintain

registers of currently valid International Standards.

IS0 2553:1984, Welds - Symbolic representation on

drawings.

I S0 4063:1990, Welding, brazing, soldering and braze

welding of metals - Nomenclature of processes and

reference numbers for symbolic representation on

drawings.

IS0 6520:1982, Classification of imperfections in

metallic fusion welds, with explanations.

3 Definitions

For the purposes of this International Standard, the

following definitions apply.

3.1 fltness-for-purpose: A product is fit for its in-

tended purpose when it functions satisfactorily in

service during its stipulated lifetime. The product

may deteriorate in service, but not to such a degree

that fracture and subsequent failure occurs. Prod-

ucts may, of course, be misused or overloaded: it is

presumed that the actual conditions during service

correspond to the intended conditions, including

statistical variations, e.g. live loads.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

ES1 BS+EN+25817 92 m l b 2 4 b b 9 03LL757 8 T T m

Page 6

EN 25817 : 1992

3.2 Weld thickness

3.2.1 fillet weld thickness, a; nominal throat thick-

ness: Height of the largest isosceles triangle that

can be inscribed in the weld section (see I S0 2553).

NOTE 1 In countries in which the leg length, z, is used

as the dimension of a fillet weld, the limits for

imperfections may be reformulated so that they refer to

the leg length.

3.2.2 butt weld thlckness, S: Minimum distance from

the surface of the part to the bottom of the pen-

etration, which cannot be greater than the thickness

of the thinner of the parts (see I S0 2553).

3.3 short imperfections: One or more imperfections

of total length not greater than 25 mm in any

100 mm length of the weld or a maximum of 25 %

of the weld length for a weld shorter than 100 mm.

3.4 long imperfection: One or more imperfections

of total length greater than 25 mm in any 100 mm

length of the weld or a minimum of 25 % of the weld

length for a weld shorter than 100 mm.

3.5 projected area: Area given by length of weld

examined multiplied by the maximum width of weld.

3.6 surface crack area: Area to be considered after

fracture.

4 Symbols

The following symbols are used in table l.

a nominal fillet weld throat thickness (fillet thick-

ness)

b width of weld reinforcement

d diameter of pore

h size (height or width) of imperfection

I length of imperfection

S nominal butt weld thickness or, in the case of

partial penetration, the prescribed depth of pen-

etration

t wall or plate thickness

z leg length of fillet welds (in case of isosceles

right angle triangular section z= a f i )

5 Evaluation of welds

Limits for imperfections are given in table 1.

A welded joint should normally be evaluated sep-

arately for each individual type of imperfection

(Nos. 1 to 25).

Different types of imperfection occuring at any

cross-section of the joint may need special con-

sideration (see No. 26).

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

B S I BS*EN*25837 92 m Lb24669 0333758 73b m

Page 7

EN 25817 : 1992

Table 1 - Limits for imperfections

-

NO.

-

1

lmperfeclion

designation

Llmits for imperfections for qurl l ty levels

Moderate Intermediate Stringent

D

IS0 6520

reference

100

Remarks

All types of yacks except micro cracks

(hd <1 mm ), crater cracks, see No. 2

The following conditions and limits for

imperfections shall be fulfilled:

a) Maximum dimension of the summation of the

proJ ected or surface crack area of the

imperfection

b) Maximum dimension of a single pore for

- butt welds

- fillet welds

c) Maximum dimension for a single pore

The total pore area within lhe cluster should be

summed and calculated as a percentage of the

greater of the two areas: an envelope surround-

ing all the pores or a circle with a diameter cor-

responding to the weld width

The permitted porous area should be local. The

possibility of masking other imperfections

should be taken into consideration.

The following conditions and limits for

imperfections shall be fulfilled:

a) Maximum dimension of he summation of the

projected or surface crack area of the

imperfection

b) Maximum dimension of a single pore for

- butt welds

- fillet welds

c) Maximum dimension for localized clustered

porosity

Long imperfections for

- butt welds

- fillet welds

In any case, maximum dimension for elongated

cavitles, wormholes

Short imperfections for

-- butt welds

- fillet welds

In any case, maximum dimension for elongated

cavities, wormholes

Cracks Not Demitted

T

2 Crater crack 104 Permitted Not permitted

3

-

4

Porosity and

gas pores

201 1

2012

2014

2017

2013

4 W

d <0.5 S

0, 5 a

5 mm

2 %

d d 0,4 S

0,4 u

4 mm

1 %

d G 0,3 S

0,3 a

3 mm

Localized

(clustered)

porosity

18 %

d d 0, 5 S

0,5 a

4 mm

8 %

d Q 0,4 S

0,4 u

3 mm

4 %

d Q 0,3 S

0,3 a

2 mm

5 Elongated

wormholes

cavities,

2015

20 16

~~ ~ ~

Not permitted

h 0,5 .r

0,5 a

2 mm

Not permitted

h <0.5 S

0.5 a

4 mm or Not

Larger Than

Thickness (NLTT)

h 0,4 S

0.4 u

3 mm or NLTT

h 6 0,3 S

0.3 a

2 mm or NLTT

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

7

-

8

9

Copper in-

clusions

Lack of

fusion (in-

complete

fusion)

Lack of pen-

etration (in-

complete

penetration)

I S0 6520

reference

300

3042

401

402

BSI BS+ENu25817 92 m 1b2Ybb9 0311759 b72 m

Remarks

Long Imperfections for

- butt welds

- flllet welds

clusions

In any case, maximum dimension for solid in-

~ ~~~

Short imperfections for

- butt welds

- fi l l et welds

In any case, maximum dimension for solid in-

clusions

Figure A

'Actual penetration

L Nominal penetration

Figure B

/-

Actual penetration

,r Nominal penetration

Figure C

L

Limits for

Moder6te

D

h <0,5 S

2 mm

h d 0,5 S

0.5 a

4 mm or Nol

Larger Than

Thickness (NLTT)

nperfections for qr

Intermediate

C

Not permitted

h d 0,4 J

0,4 a

3 mm or NLTT

1eVei6

Stringent

B

Not permltted

h =0.3 S

0.3 a

2 mm or NLTT

Not permitted

Permitted, but only Not permitted

intermlttently and

not breaking the

surfaces

I

Lang imperfections:

Not permitted

Short imr

h <0,2 S,

max. ' 2 mm

fections:

h 0,l J,

max. 1,5 mm

L

Not permltted

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Page 9

EN 25817 : 1992

1

I S0 6520

reference

y levels

Stringent

B

Limits for

Moderate

D

tperfec:ions for qu

Intermediate

C

mperfection

lesignallon

lad fit-up,

Illet welds

Remarks

in excessive or insufficient gap between the

)arts to be joined

h d 1 mm +0.3 II,

max. 4 mm

k <0, 5 mm +0.2 a,

max. 3 mm

I 0.5 mm +O, 1 u.

max. 2 mm

aps exceeding the appropriate limit may in

:ertaln cases be compensated for by a corre-

iponding increase in the lhroat

h d 1.5 mm h G f , O mm h 6 0,s mm

jmooth transition is required 501 1

501 2

502

J ndercut

Excess weld

neta1

Er

t

h i 1 mm +0.25 b,

max. 10 mm

h < t mm+0,15b,

max. 7 mm

hr 1 mmf 0, l bs

max. 5 mm

Smooth transition i s required

h <1 mm +0,15 b.

max. 4 mm

h d 1 mm +0,1 b,

max. 3 mm

Excessive

convexity

503

h 6 1 mm +0.25 b.

rnax. 5 mm

h 1 mm +0.15 u.

max. ? mm

For many applications a throat thickness greater

than the nominal one may not be a reason for

rejection

h d 1 mm t 0,3 a,

max. 5 mm

h d 1 mm +0, 2 a,

max. 4 mm

Fillet weld

throat thick-

havlng a

than the

ness greater

value

nominal

I weld

inal weld

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Page 10

EN 25817 : 1992

No.

-

15

-

16

17

Imperfection

designation

Fillet weld

havlng a

throat thick-

ness smaller

than the

nominal

value

Excessive

penelratlon

Local

protrusion

Llnear rnls-

alignment

IS0 6520

reference

504

504 1

507

Remarks

4 fillet weld with an apparent throat thickness

smaller than that prescribed should not be re-

;larded as being imperfect if the actual throat

thickness with a compensating greater depth of

penetration complies with the nominal value

t

The limits relate to devlatlons from the corred

position. Unless otherwise specified, the correct

posltlon i s that when lhe centrelines coincide

(see also clause 1).

t refers to the smaller thickness

h c

i

Figure A

Figure E

Limita for imperfections for qu;

Moderate Intermediate

Long Imperfections:

Not permitted

Short imperfecllons:

h <0, 3mmt O, l u

max. 2 mm max. 1 mm

h C 1 mm +1.2 b.

max. 4 mm max. 5 mm

h <1 mm +0,6 b.

ty l evel s

Strlngent

E

Not permitted

h <1 mm +0,3 b.

max. 3 mm

Permitted Occasional local excess permitted

Figure A -Plates and longituf

h C 0.25 r,

max. 4 mm max. 5 mm

h G 0.15 r,

ml welds

h 0, l t.

max. 3 mm

Figure E - Circumferential welds

h 0,5 t

max. 4 mm max. 2 mm max. 3 mm

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

Imperfection

deslgnatlon

Incompletely

filied groove

Sagging

Excessive

fillet weld

asymmetty

Root

concavity

Shrinkage

groove

Overlap

Poor restart

Stray flash

or arc strike

Spatter

BSI BS*EN*25817 92 m lb24669 0311762 167 U

Page 11

EN 25817 : 1992

I S0 6520

reference

51 1

509

512

515

5013

506

517

60 1

602

Remarks

Smooth transition is required

b

It is assumed that an asymmetric fillet weld has

not been expressly prescribed.

Smooth transition is required

E

Limits for imperfections for quality levels

Moderate

E C D

Stringent

Intermediate

Long imperfections:

Not permitted

I

h d 0.2 r,

max. 2 mm

h 1,5 mm

Short

Imperfections are

permitted

Permitted

:hofi imperfections:

h 6 0, l t, h G 0,05 r,

max. 1 mm max. 0,5 mm

h d 2mm+0, 15a h<1, 5mm

+0,l S a

Not permlttad

Not permitted

Acceptance may be influenced by post treatment.

Acceptance depends on type of parent metal, with particular

reference to crack sensitivity

Acceptance depends on applications.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

i O.

-

26

Imperfection

designation

Multiple

imperfectlons

i n any cross-

sedionl)

IS0 8520

reference

B S I BS* EN* 25817 92 m lb24bb9 03137b3 OT3

Li mi ts for i mpetfectl ons for qual l l y levels

Remarks Moderate Intermadl ate Stringent

D C B

For thicknesses S G 10 mm or a 4 10 mm or

Maximum to.

less, special mnslderatlon may be necessary.

0,25 or 0.25 a,

max. 10 mm

height of short i mp

0,2 S or 0.2 a.

max. i 0 mm

d o n s Z h

0,15 J or 0.15 a.

max. 10 mm

1) See annex A.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

BSI BS*EN*25817 92 D 1624669 03117b4 T3 T D

Page 13

EN 25817 : 1992

Annex A

(informative)

Additional information and guidelines for use of this International Standard

This International Standard specifies requirements

for three levels of acceptance for imperfections in

welded joints of steel for arc welding processes ac-

cording to the scope and for weld thickness 3 mm to

63 mm. It may be used - where applicable - for

other fusion welding processes or weld thicknesses.

Different parts are very often produced for different

applications but to similar requirements. The same

requirements should, however, apply to identical

parts produced in different workshops to ensure that

work is carried out using the same criteria. The

consistent application of this International Standard

is one of the fundamental cornerstones of a quality

assurance system for use in the production of

welded structures.

In table 1, figures for multiple imperfections (No. 26),

show a theoretical possibility of superimposed indi-

vidual imperfections. In such a case the total sum-

mation of all permitted deviations should be

restricted by the stipulated values for the different

quality levels. However, the value of a single

imperfection may exceed > h, e.g. for a single pore.

This International Standard may be used in con-

junction with a catalogue of realistic illustrations

showing the size of the permissible imperfections

for the various acceptance levels by means of

photographs showing the face and root side and/or

reproductions of radiographs and of photomacro-

graphs showing the cross-section of the weld. This

catalogue may be used with reference cards to as-

sess the various imperfections and may be em-

ployed when opinions differ as to the permissible

size of imperfections.

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

BSI BS* EN* 25817 92 m 1624669 03LL7b5 976 I

BS EN 25817 : 1992

National annex NA (informative)

Committees responsible

The United Kingdom participation in the preparation of this European Standard was entrusted by the

Welding Standards Policy Committee (WEE/-) to Echnical Committee WEE/-/1 upon which the following

bodies were represented:

Associated Offices Technical Committee

British Constructional Steelwork Association Ltd.

British Railways Board

British Steel Industry

Power Generation Contractors Association (BEAMA Ltd.)

Process Plant Association

Railway Industry Association of Great Britain

Welding Manufacturers' Association (BEAMA Ltd.)

Welding Institute

Chairman of WEE/36

Chairman of WEE/26

Chairman of WEE118

Chairman of WEE/34

Chairman of WEE/39

Chairman of WEE16

National annex NB (informative)

Cross-references

Publication referred to Corresponding British Standard')

IS0 4063 : 1990 BS EN 24063 : 1992 Welding, brazing, soldering and braze welding of metals -

nomenclature of processes and reference numbers for symbolic representation on

drawings

IS0 6520 : 1982 BS EN 26520 : 1992 Classification of imperfections in metallic fusion welds, with

explanations

') Where no identical or technically equivalent British Standard exists, the user is directed to the relevant European or

international standard, copies of which may be obtained from BSI Sales, Linford Wood, Milton Keynes MK14 6LE, telephone

O908 220022, telex 825777 BSIMK G or facsimile 0908 322484 (all other fax enquiries should be sent to 0908 320856).

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

BS EN

25817 : 1992

IS0 5817 : 1992

BSI

2 Park Street

London

W1A 2BS

BSI

Linford Wood

Milton Keynes

MK14 6LE

9210- 7- 1.5k- R

BSI BS*EN*258L7 92 m 1624669 03117bb 802 m

BSI - British Standards Institution

BSI is the independent national body responsible for preparing British

Standards. It presents the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Contract requirements

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct

application.

Revisions

British Standards are updated by amendment or revision. Users of British

Standards should make sure that they possess the latest amendments or

editions.

Any person who finds an inaccuracy or ambiguity while using this British

Standard should notify BSI without delay so that the matter may be

investigated swiftly.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying British Standards

Orders for all British Standard publications should be addressed to the Sales

Department at Milton Keynes.

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library, the Standardline Database, the BSI

Information Technology Service (BITS) and its Technical Help to Exporters

Service. Contact Customer Services, Information Services Group at Milton

Keynes: Tel: 0908 221166.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For

details of these and other benefits contact the Manager, Membership

Development at Milton Keynes: Tel: 0908 220022.

Copyright

Copyright subsists in all BSI publications and no part may be reproduced in

any form without the prior permission in writing of BSI. This does not

preclude the free use, in the course of implementing the standard of necessary

details such as symbols and size, type or grade designations including use by

incorporation into computer programs, but where these details are reproduced

including without limitation in printed form, in computer programs or in any

other form whatsoever, the permission in writing of BSI must be obtained and

if granted will be on terms including royalty, before the product is sold,

licensed or otherwise exploited for commercial gain. Enquiries about copyright

should be made to the Copyright Manager, Publications at Milton Keynes.

ISBN O 580 21239 4 WEE!-11

COPYRIGHT British Standards Institute on ERC Specs and Standards

Licensed by Information Handling Services

You might also like

- IGCSE Biology: Practice CORMS QuestionsDocument12 pagesIGCSE Biology: Practice CORMS QuestionsDaniel Conway63% (8)

- PD Cen-Tr 15589-2014 PDFDocument16 pagesPD Cen-Tr 15589-2014 PDFvirtechNo ratings yet

- IAB 001 Rev5 14 Rules Implementation IIW Guidelines NO TRACK CHANGES PDFDocument58 pagesIAB 001 Rev5 14 Rules Implementation IIW Guidelines NO TRACK CHANGES PDFGetapo RaminNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- Tc-1a 1992Document108 pagesTc-1a 1992WaronNo ratings yet

- Quality Requirements For Welding Fusion Welding of Metallic MaterialsDocument12 pagesQuality Requirements For Welding Fusion Welding of Metallic Materialspalani.djpNo ratings yet

- BS en 10306 - 2002Document18 pagesBS en 10306 - 2002subbarao100% (1)

- EN15085 IntroductionDocument89 pagesEN15085 IntroductionSubramanian R33% (3)

- BS en 440-95 PDFDocument14 pagesBS en 440-95 PDFAhmet Memiş100% (2)

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrNo ratings yet

- European Welding Inspection Personnel: EWF GuidelineDocument19 pagesEuropean Welding Inspection Personnel: EWF GuidelineBrandon EricksonNo ratings yet

- EN ISO 9606-1 (2013) (E) CodifiedDocument0 pagesEN ISO 9606-1 (2013) (E) Codifiedvimal_mech1230% (1)

- Fracture Testing According EN 9017Document3 pagesFracture Testing According EN 9017Anil100% (1)

- BS en Iso 9606-5 - 2000Document26 pagesBS en Iso 9606-5 - 2000jesoneliteNo ratings yet

- Test Report 11 Pcs Padeyes THR Room GCIIIDocument6 pagesTest Report 11 Pcs Padeyes THR Room GCIIIJurand Juri100% (1)

- BS en Iso 14731-2019Document20 pagesBS en Iso 14731-2019Hüseyin BuğdaycıNo ratings yet

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Document65 pagesWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- Updated Asnt-Ndt Level - II in RT Ut MT PTDocument4 pagesUpdated Asnt-Ndt Level - II in RT Ut MT PTJason RogersNo ratings yet

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Iso 3834 2 2005 en PDFDocument6 pagesIso 3834 2 2005 en PDFRamamoorthy SundarNo ratings yet

- Terms in Welding Standard en 15085Document6 pagesTerms in Welding Standard en 150850502raviNo ratings yet

- Iso 9712Document19 pagesIso 9712Daniel100% (1)

- Bs en Iso 15614 12 2014pdf PDFDocument20 pagesBs en Iso 15614 12 2014pdf PDFVasile TomsaNo ratings yet

- BS EN - Qualification CodesDocument4 pagesBS EN - Qualification CodesBalkishan DyavanapellyNo ratings yet

- Magnetic Particle TestingDocument2 pagesMagnetic Particle TestingThanhdong DoNo ratings yet

- NDE of BoilersDocument6 pagesNDE of Boilersshabbir626100% (1)

- 1143 EWF IIW Diploma Overview - August 2013Document2 pages1143 EWF IIW Diploma Overview - August 2013Sean ฌอนNo ratings yet

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Document8 pagesCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluNo ratings yet

- Visual TestingDocument59 pagesVisual TestingLeon Heart FCNo ratings yet

- BS en ISO 9016-2012 (Impact Test)Document16 pagesBS en ISO 9016-2012 (Impact Test)Dave CheungNo ratings yet

- Defectology NDT Final Edit PDFDocument132 pagesDefectology NDT Final Edit PDFIdjzulz Zulkifli100% (1)

- Ultrasonic Examination Austenitic and Dissimilar WeldsDocument6 pagesUltrasonic Examination Austenitic and Dissimilar WeldshocimtmNo ratings yet

- 3.3.3-Fillet Weld Design 9th Mar 21Document40 pages3.3.3-Fillet Weld Design 9th Mar 21Vivek kmNo ratings yet

- Rtfi Fundamental PresentationDocument112 pagesRtfi Fundamental PresentationABHI THAKKARNo ratings yet

- AWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringDocument33 pagesAWS A4.4 Standard Procedure For Determination of Moisture Content of Welding Fluxes and Welding Electrode Flux CoveringJairo ContrerasNo ratings yet

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- CSWIP-WI-1-91 9th Edition November 2010Document8 pagesCSWIP-WI-1-91 9th Edition November 2010Thamaraikani ManiNo ratings yet

- NDT Training BrochureDocument4 pagesNDT Training BrochureSafiq UddinNo ratings yet

- 00.ISO 9712 Scheme SGNDTDocument41 pages00.ISO 9712 Scheme SGNDTVuong Tran VanNo ratings yet

- WIS5 Symbols 05Document52 pagesWIS5 Symbols 05anon_90890103No ratings yet

- BS en Iso 3059-2012 - 2018-04-04 - 10-24-59 AmDocument10 pagesBS en Iso 3059-2012 - 2018-04-04 - 10-24-59 AmarbabNo ratings yet

- BS en 583-6-2008Document26 pagesBS en 583-6-2008sheldonNo ratings yet

- Corporate Presentation 3/26/2013 - 1Document18 pagesCorporate Presentation 3/26/2013 - 1Jose ManuelNo ratings yet

- BS EN 1291 1998, Nondestructive PDFDocument11 pagesBS EN 1291 1998, Nondestructive PDFRajan SteeveNo ratings yet

- BS en 3452-3-Penetrant Testing Reference BlocksDocument15 pagesBS en 3452-3-Penetrant Testing Reference Blocksshaggeruk100% (2)

- BS en 13479-2017 PDFDocument22 pagesBS en 13479-2017 PDFVũ Đình PhongNo ratings yet

- Part 1 (Final 2022-11-21)Document28 pagesPart 1 (Final 2022-11-21)saraNo ratings yet

- Visual Inspection - AWS & BS PDFDocument22 pagesVisual Inspection - AWS & BS PDFSelvakpm06No ratings yet

- BS 709 Destructive TestingDocument17 pagesBS 709 Destructive TestingGabrieleNo ratings yet

- En15085 Guideline-Part2 2017-11Document22 pagesEn15085 Guideline-Part2 2017-11Quality MSIPLNo ratings yet

- Aws D 1Document15 pagesAws D 1WagnerTarossiNo ratings yet

- DIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationDocument12 pagesDIN en ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and RotationHector Flores GarciaNo ratings yet

- BS709 1983Document17 pagesBS709 1983Sang SekNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- BS en 757-97 PDFDocument14 pagesBS en 757-97 PDFAhmet Memiş100% (1)

- Bom StartDocument39 pagesBom Startdzat_sudrazatNo ratings yet

- S 6000 ASME Ratio Flanged and Dished HeadsDocument4 pagesS 6000 ASME Ratio Flanged and Dished Headsdzat_sudrazatNo ratings yet

- S 2000 ASME Ratio Flanged and Dished HeadsDocument4 pagesS 2000 ASME Ratio Flanged and Dished Headsdzat_sudrazatNo ratings yet

- 80-10 F&D Heads 1.02 - 18ksiDocument4 pages80-10 F&D Heads 1.02 - 18ksidzat_sudrazatNo ratings yet

- Bs en 12072 PDFDocument12 pagesBs en 12072 PDFdzat_sudrazatNo ratings yet

- Bs en 288 6 PDFDocument10 pagesBs en 288 6 PDFdzat_sudrazatNo ratings yet

- Rancang Bangun S-TypeDocument21 pagesRancang Bangun S-Typedzat_sudrazatNo ratings yet

- ANSI B16.5 Class 400 Forged Flanges: Weld Neck Threaded Slip-OnDocument1 pageANSI B16.5 Class 400 Forged Flanges: Weld Neck Threaded Slip-Ondzat_sudrazatNo ratings yet

- Ansi B 16 2500 PDFDocument1 pageAnsi B 16 2500 PDFdzat_sudrazatNo ratings yet

- NVT Simulation of Argon Using Lennard-Jones PotentialDocument2 pagesNVT Simulation of Argon Using Lennard-Jones Potentialt_sairamNo ratings yet

- Basic VibrationDocument76 pagesBasic VibrationJack Adam100% (1)

- Unik 5000 Datasheet PDFDocument8 pagesUnik 5000 Datasheet PDFAbdullah SahibNo ratings yet

- 3d Woven Composite FatigueDocument11 pages3d Woven Composite FatigueSri SaiNo ratings yet

- Edm Die Sinker Form 20 30Document16 pagesEdm Die Sinker Form 20 30HaruDoT TVNo ratings yet

- Paper Mekanika ReservoirDocument23 pagesPaper Mekanika ReservoirAnonymous FcCosOLJNo ratings yet

- Penetration Limits of Conventional Large Caliber Anti Tank - Kinetic Energy ProjectilesDocument9 pagesPenetration Limits of Conventional Large Caliber Anti Tank - Kinetic Energy ProjectilesSteve RothwellNo ratings yet

- Picarro - G2301 Analyzer Datasheet - 211029Document2 pagesPicarro - G2301 Analyzer Datasheet - 211029AndrewNo ratings yet

- Activity Sheets For Chem With NamesDocument6 pagesActivity Sheets For Chem With Namesapi-283862617100% (1)

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedDocument19 pagesVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamNo ratings yet

- Refrigeration Oil PDFDocument17 pagesRefrigeration Oil PDFChristina PadillaNo ratings yet

- VIV Analysis of PipelineDocument5 pagesVIV Analysis of Pipelineศุภกฤต รักในหลวงNo ratings yet

- Hartford Evaluation Pipeline Design FactorsDocument94 pagesHartford Evaluation Pipeline Design FactorspiolinwallsNo ratings yet

- Photobleaching of 5,10,15,20 Tetrakis (M Hydroxyphenyl) PorphyrinDocument8 pagesPhotobleaching of 5,10,15,20 Tetrakis (M Hydroxyphenyl) PorphyrinEsteban ArayaNo ratings yet

- Part 2 Microscopic World (I) LQ AnswersDocument17 pagesPart 2 Microscopic World (I) LQ AnswersWing LamNo ratings yet

- Ficha T Cnica Yaravita CROPLIFT BIODocument1 pageFicha T Cnica Yaravita CROPLIFT BIOSantii PascualNo ratings yet

- Question Paper Unit g494 01 Rise and Fall of The Clockwork UniverseDocument20 pagesQuestion Paper Unit g494 01 Rise and Fall of The Clockwork UniversespdinleyNo ratings yet

- D3285Document3 pagesD3285Anil Pandey0% (1)

- Abel PD PumpsDocument8 pagesAbel PD PumpsvisitabhinavNo ratings yet

- Cebu City Department of ChemistryDocument7 pagesCebu City Department of ChemistryGeorgette RepunteNo ratings yet

- wch13 01 Que 20220524Document16 pageswch13 01 Que 20220524vintu pvNo ratings yet

- KC WS+rock-H - DatasheetDocument2 pagesKC WS+rock-H - DatasheetIoana PopescuNo ratings yet

- KitosanDocument24 pagesKitosanFarras MuhammadNo ratings yet

- State FunctionDocument15 pagesState FunctionmelprvnNo ratings yet

- Design of Composite Haunch Beams and Connections For Long Span Applications PDFDocument176 pagesDesign of Composite Haunch Beams and Connections For Long Span Applications PDFVance kang100% (1)

- Phast ManualDocument122 pagesPhast ManualMojtabaNo ratings yet

- Influence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootDocument11 pagesInfluence of Blanching On Antioxidant, Nutritional and Physical Properties of Bamboo ShootSharin Julia Krista SuniNo ratings yet

- Biological Toxins and BioterrorismDocument614 pagesBiological Toxins and BioterrorismVictor Carrillo100% (3)

- 2014 Van DijkDocument77 pages2014 Van DijkJungHyunParkNo ratings yet