Professional Documents

Culture Documents

Merchant Navy Class

Uploaded by

metroliner400gt0 ratings0% found this document useful (0 votes)

13 views2 pageshornby merchant navy service sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthornby merchant navy service sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesMerchant Navy Class

Uploaded by

metroliner400gthornby merchant navy service sheet

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

MERCHANT NAVY CLASS

LOCOMOTIVE AND TENDER

Operating and Maintenance Instructions

Hornby Hobbies Limited, Westwood, Margate, Kent CT9 4JX

4/970F 0202 Printed in China

This locomotive is for indoor use only and not

suitable for children under 14 years of age.

Handle with care.

The transformer is not a toy. It is a Transformer

for Toys. Before use, check that the transformer

is the correct voltage for your mains electricity

supply.

This locomotive is only to be used with

recommended transformers.

The transformer should be examined regularly for

damage to the casing, plug pins and output cable.

In the event of such damage, the locomotive

should not be used until the transformer is

replaced by an identical unit.

Before cleaning any part of the set, remove the

transformer from the power socket.

Do not use any liquid for cleaning.

This locomotive must not be connected to more

than the recommended number of power supplies.

The output terminals of the transformer must not

be connected directly, or indirectly, to the output

of any other AC circuit which is derived from a

transformer or mains power supply.

Please retain these details for future

reference.

Safety Notes

1 4

Television Suppression

Your Hornby locomotive incorporates radio and television interference suppressors. Should interference be

experienced despite these precautions, it may be due to close proximity of the model railway layout to receivers,

aerials, or their downlines. In this case, move the layout further away from aerials and receivers.

It is most important that track and wheels be kept absolutely clean.

Spare Parts and Service

Spare parts packs can be obtained from Hornby Service Dealers who are also able to offer a repair service.

General

Please read right through these instructions,

particularly the Safety Notes on page 4.

Hornby locomotives are precision built and, if treated

with care, will give many years of good service. The

Hornby Merchant Navy Class locomotive and tender

are produced to super detail standard and therefore

incorporate delicate, protruding detail and many small

parts. Care should be taken to avoid damage when

handling the model especially the Walschaerts valve gear,

coupling rods and the small detail parts of the locomotive

and tender bodies.

This locomotive should not be operated on track

curves of less than 438mm radius, which is Hornby

2nd radius track.

The ve-pole electric motor of the locomotive is

designed to be operated from a variable 12 volts,

DC power supply only. This should be obtained by

using a suitable Power Controller operated from the

normal domestic mains electricity supply.

NEVER CONNECT A LOCOMOTIVE DIRECTLY TO

THE MAINS ELECTRICITY SUPPLY.

The locomotive will normally draw a current of between

2 and 4 amp depending upon the track conguration

and whether or not gradients are included. There will

be a current surge on starting the locomotive.

Running Hints

If a locomotive ceases to respond normally to the

power controller, or runs badly, check that the

following are in order:

All electrical connections are correctly made and

the wall power socket is switched ON.

The power connecting clip is correctly inserted into

a suitable section of track.

All track sections are correctly tted together and

all shplates (rail-joiners) are tting tightly onto

adjoining metal rails.

All locomotive wheels are correctly positioned on

the track rails.

The tender drawbar pin is making contact with the

contacts on the locomotive drawbar and the upper

contacts of the drawbar are making contact with

the drawbar pin plate of the tender.

The direction control switch on the train controller

is set to operate in one direction or the other, and

not in the central OFF position.

Routine Maintenance

Track Cleaning In normal use, model railway layouts

will eventually accumulate a blackish deposit on the

running surfaces of the rails, and some of this will be

transferred onto the locomotives pick-up wheels.

The 12 volt DC supply is collected from the track

through the wheels on one side of the locomotive and

returned through the wheels on the other side. If the

deposit is allowed to build up, it will have the following

adverse effects:

The driving wheels will not be able to achieve

maximum traction

There will be a reduction in the power reaching the

locomotive motor

It is therefore essential that the track, and wheels, are

kept clean. This can be done by wiping the surfaces

with a clean, non-uffy cloth. More stubborn deposits

can be removed by using the Hornby Track Cleaning

Rubber, reference R8087, which can be obtained from

Hornby Service Dealers.

Motor The locomotive is tted with a sealed, long-

life, 5-pole motor which requires no maintenance.

After a considerable amount of use the motor may

require replacement and this should be carried out by

a Hornby Service Dealer. However, instructions for

motor replacement are given in Section 3 on page 3,

only for owners who are fully experienced in such tasks

and who have soldering facilities. Do not attempt this

work unless you are absolutely condent in being able

to successfully complete it.

Chassis The locomotive chassis may, from time to

time, pick up uff, fabric bres and pet hairs which can

become entangled in the gears and around axles. For

this reason, it is not advisable to run the locomotive on

track which is laid on a carpet. It is important to check

regularly and remove any such debris with the aid of

small tweezers.

Lubrication Although the locomotive was lubricated

during manufacture, the lubricant can sometimes dry

out in storage. Lubrication should be carried out at

approximately 6-monthly intervals, or every 100 hours

of running. Instructions for carrying out lubrication

procedures are given in section 1 on page 2.

Locomotive Bodywork The locomotive and tender

bodies are overall spray painted and the rest of the

decoration is applied by a printed process, not

transfers.

IMPORTANT

Only remove the locomotive and tender from the packaging by carefully

lifting them from the nger holes provided.

This locomotive is made to exacting ne scale standards and therefore

necessarily incorporates small, delicate, protruding parts handle with care.

Before using the model, read through the Operating and Maintenance

Instructions in this leaet.

12V

3 2

When tting the replacement motor, make sure

the worm and worm wheel are meshed correctly

before screwing the motor brackets back in place.

Ret the locomotive body before retting the rear

pony truck so that the rear chassis lugs are free to

enter their locations in the body.

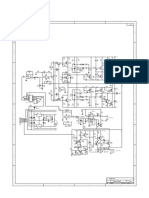

Fig. 2 Fig. 1 Fig. 3

Fig. 6

Fig. 7

Fig. 8

Lubrication

IMPORTANT Only apply small single drops of light

machine oil to the places indicated in red. This is best

achieved by making a simple oil dropper as illustrated

in Fig.1. Insert a straightened paper clip into a cork and

use a bottle cap as a container for the oil. A small drop of

oil can then be picked up by the dropper and applied in

exactly the right place. Immediately wipe off any excess

oil, especially from the locomotive and tender bodies.

Only lubricate moving parts.

Apply one drop of oil to each of the

Walchaerts valve gear and connecting rod

pivot points indicated in red in Fig.2, on

both sides of the locomotive.

Apply one drop of oil to each of the axle bearings

indicated in red. Do not oil the tender axles. Apply one

drop of oil, or a small bead of model railway grease, to

the gear A. (See Fig.3).

To replace the locomotive motor

Having removed the locomotive body, remove the rear

pony truck, as shown in Fig.7, which allows access to the rear

motor bracket screw. Remove the screw and, from the top

of the chassis, remove the front motor bracket screw.

The motor can now be lifted clear and replaced. (Fig.8).

A

Fig. 5

Fig. 4

Turn the locomotive upside

down and remove the screw

beneath the bogie. (Fig.5). Turn

the locomotive right way up and

ease the front end of the chassis

downward from the body. When

the front of the chassis is clear of

the body, pull the chassis forward

to disengage the rear chassis lugs

from the rear of the body. (Fig.6)

To remove the locomotive body

Important:

If your locomotive is tted with a speedometer, rst detach the

cable from the left hand rear driving wheel (Fig.4). Keep nut and

spacer safe until the body is replaced.

1

2 3

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Technical Note: Overview of ASCII/RS-485 Time ProtocolDocument8 pagesTechnical Note: Overview of ASCII/RS-485 Time Protocolmetroliner400gtNo ratings yet

- RoundaboutMap Web PDFDocument1 pageRoundaboutMap Web PDFmetroliner400gtNo ratings yet

- LokPilot V40 Family ESUKG en User-Manual Edition-6 Ebook 02Document76 pagesLokPilot V40 Family ESUKG en User-Manual Edition-6 Ebook 02metroliner400gtNo ratings yet

- GOLD SILVER Plus ManualDocument80 pagesGOLD SILVER Plus Manualmetroliner400gtNo ratings yet

- Ss 298c W Country 374Document1 pageSs 298c W Country 374metroliner400gtNo ratings yet

- County Castle ClassDocument1 pageCounty Castle ClassmattyNo ratings yet

- Memco 450 857 GB Memcom Reference ManualDocument18 pagesMemco 450 857 GB Memcom Reference Manualmetroliner400gtNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Prepositions of DirectionDocument5 pagesThe Prepositions of DirectionBondfriendsNo ratings yet

- Linde ManualDocument6 pagesLinde ManualArnaldo AndréNo ratings yet

- Research DesignDocument2 pagesResearch DesignRAMAKRISHNANNo ratings yet

- 2020 10 26 AGUS PRANOLO MR Ticket Receipt JKT DOH MAD ALC 26OCT2020Document2 pages2020 10 26 AGUS PRANOLO MR Ticket Receipt JKT DOH MAD ALC 26OCT2020mil crewingNo ratings yet

- ContainerDocument12 pagesContainerlakkekepsuNo ratings yet

- C10 Builder Guide - December 2017 PDFDocument132 pagesC10 Builder Guide - December 2017 PDFJuan Ignacio GeminianiNo ratings yet

- Electronic Ticket ReceiptDocument3 pagesElectronic Ticket ReceiptJan Irish33% (3)

- 40tonx58 Span-CraneDocument7 pages40tonx58 Span-CraneKoresh KhalpariNo ratings yet

- Theme Based Safety Discussion (TBT) - Mechanical Material HandlingDocument4 pagesTheme Based Safety Discussion (TBT) - Mechanical Material HandlingSANDEEP YAVANo ratings yet

- JK Tyre Report FinaDocument88 pagesJK Tyre Report FinaKumar ShubhamNo ratings yet

- Erste Bank Research Euro 2012Document10 pagesErste Bank Research Euro 2012Wito NadaszkiewiczNo ratings yet

- Civil Aviation Regulations 2016 ENGLISHDocument160 pagesCivil Aviation Regulations 2016 ENGLISHSaran RamanNo ratings yet

- Ingersoll Rand Air Compresor Manual80441512sierratspartsmanualDocument116 pagesIngersoll Rand Air Compresor Manual80441512sierratspartsmanualGiovanni B. S.100% (4)

- Amna Floor Plans 240618Document106 pagesAmna Floor Plans 240618Syed Mohammad Tariq ShahNo ratings yet

- ALTO PS4HA-AMP DiagramDocument1 pageALTO PS4HA-AMP DiagramMarco Pedrosa100% (3)

- The Stoneblower - Delivering The Promise: 1 Peter Mcmichael, Andrew McnaughtonDocument23 pagesThe Stoneblower - Delivering The Promise: 1 Peter Mcmichael, Andrew McnaughtonSuciu FlorinNo ratings yet

- LED Lighting Distribution Types: Quick Reference Guide Type IDocument2 pagesLED Lighting Distribution Types: Quick Reference Guide Type IwsilvacNo ratings yet

- Stakeholder Engagement PlanDocument101 pagesStakeholder Engagement PlanÖzgur ÇNo ratings yet

- ISYS2110 - Case 8.1 - G6 - Team 1Document6 pagesISYS2110 - Case 8.1 - G6 - Team 1Moonie090% (1)

- Triumph Service Bulletin 1954Document98 pagesTriumph Service Bulletin 1954tr_freundeNo ratings yet

- She Shuttle Time Table - PDF 1Document1 pageShe Shuttle Time Table - PDF 1eswar friendsNo ratings yet

- 14 CFR Part 1Document15 pages14 CFR Part 1AngeloRofelTabundaNavaNo ratings yet

- Gerhardt June 2015Document12 pagesGerhardt June 2015Fauquier NowNo ratings yet

- HEGN (Hurghada Intl)Document10 pagesHEGN (Hurghada Intl)Seyi WilliamsNo ratings yet

- Training Scania 2Document6 pagesTraining Scania 2Kharis Mahfudz0% (1)

- Kongo Class Guided Missile Destroyers - The King KongoDocument18 pagesKongo Class Guided Missile Destroyers - The King KongohindujudaicNo ratings yet

- Dry Bulk Cargo Handling in Perlis PortDocument5 pagesDry Bulk Cargo Handling in Perlis PortShahrul ShafiqNo ratings yet

- TA Bill FormatDocument4 pagesTA Bill FormatBikee Yadav100% (1)

- 132kV Underground Cable DesignDocument7 pages132kV Underground Cable DesignAdamNo ratings yet

- 757 Normal Checklist PDFDocument4 pages757 Normal Checklist PDFАлексей ЯрлыковNo ratings yet