Professional Documents

Culture Documents

Us2796785 PDF

Us2796785 PDF

Uploaded by

erzrzretgertfertge0 ratings0% found this document useful (0 votes)

16 views3 pagesThe invention relates to a TUBE BENDER having new and improved means to move around the periphery of the mandrel. A handle for preventing undesirable deformation of the tube and 13 is?xedly secured to the'mandrel and a hook 14 is longitudinal movement of the tube through the bender during the bending process.

Original Description:

Original Title

US2796785.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe invention relates to a TUBE BENDER having new and improved means to move around the periphery of the mandrel. A handle for preventing undesirable deformation of the tube and 13 is?xedly secured to the'mandrel and a hook 14 is longitudinal movement of the tube through the bender during the bending process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesUs2796785 PDF

Us2796785 PDF

Uploaded by

erzrzretgertfertgeThe invention relates to a TUBE BENDER having new and improved means to move around the periphery of the mandrel. A handle for preventing undesirable deformation of the tube and 13 is?xedly secured to the'mandrel and a hook 14 is longitudinal movement of the tube through the bender during the bending process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

June

1957

H. L. PHILIPPE

236,785

TUBE BENDER

Filed Dec. 30, 1955

T , >=:l':::::::_:

110

120

12d

browardlkplulli

2y V732

United States Patent

2,796,785

ice

Patented June 25, 1957

be apparent from the following description taken in

connection with the accompanying drawings, wherein:

Figure 1 is a fragmentary elevational view of a tube

2,7 96,785

bender embodying the invention;

Figure 2 is an elevational view thereof with the parts

thereof in a position assumed upon completion of a

TUBE BENDER

Howard L. Philippe, Chicago, 111., assignor to The lin

perial Brass Manufacturing Company, a corporation

tube bend;

Figure 3 is a sectional view, taken approximately along

the line 3--3 of Figure 1; and

of Illinois

Application December 30, 1955, Serial No. 556,638

5 Claims. (Cl. 81-15)

10

Figure 4 is an end view of the tube bender with the

parts in the position of Figure 2.

In the exemplary embodiment of the invention as dis

closed in the drawings, the tube bender generally desig

nated 10 may be seen to comprise a mandrel 11 having

This invention relates to a tube bender and in particu 15 a shoe element 12 pivotally secured thereto and adapted

lar to a tube bender having new and improved means

to move around the periphery of the mandrel. A handle

for preventing undesirable deformation .of the tube and

13 is ?xedly secured to the mandrel and a hook 14 is

longitudinal movement of the tube through the bender

pivotally mounted on the handle adjacent the mandrel

during the bending process.

for engaging a portion of the tube 20 to be bent for

Various forms of tube benders are known in the art 20 preventing lateral movement of the free end of the tube

having a mandrel with a peripheral, tube receiving, arcu

20 away from handle 13 during the bending operation.

ate groove and a shoe member pivotally carried by the

A new and improved tube receiving groove structure

is provided in the periphery of ' the mandrel 11 and in

mandrel for pressing the tube into the mandrel groove.

the face of shoe 12 comprising a recessed groove 11a in

It has been found, however, that the friction between the

shoe and the tube during the bending process tends to 25 the mandrel 11 and a shallow groove 12a in the shoe 12.

As will be brought out more clearly here following,

move the tube longitudinally through the mandrel groove

groove 11a acts effectively to prevent longitudinal move

in the direction of movement of the shoe, with an im

ment of tube 20 during the bending operation and the

perfect bend resulting. To prevent such longitudinal

con?guration of shallow groove 12a e?ectively minimizes

movement, various forms of tube retaining members are

used, for example, hooks and clamps which'are secured 30 frictional forces tending to move tube 20 longitudinally

during the bending operation while providing an im

in ?xed relationship to the mandrel and arranged to

engage the peripheral surface of the tubing adjacent

proved tube bending coaction.

the mandrel. Such members have the serious disad

vantage of gouging the tube surface during use and/or

Mandrel 11 comprises a generally cylindrical mem

ber having a bore 11b in which is freely pivotally

carried a headed pin 11c. Shoe 12 is similarly provided

requiring additional adjustment operations in making the

bend.

It has also been found that the tube tends to be de

formed during the bending operation by ?attening or

expanding laterally relative to the plane of the bend.

Such deformation is very undesirable as it tends to weaken

the tube and affects the cross sectional area of the flow

passage.

A principal object of the applicants invention is to

provide a tube bender having new and improved means

with a bore 1211 which carries a headed pin 12c. Extend

ing between pins 11c and 120 is a link 15 which is adapted

to allow movement of shoe 12 around the periphery of

mandrel 11 with grooves 11d and 12a in complementary

juxtaposed relationship} Pins 11c and 120 are,swaged

outwardly of link 15 to retain the mandrel and shoe

elementsin assembled relationship. Extending from shoe

12 is' a lever arm 12d permitting manual operation of

the shoe.

for effectively preventing longitudinal movement of the

' As'bestv seen in Figures 3 and 4,,mandrelvgroove 11a,

tube during the bending operation.

.

Another object is to provide a tube bender having new

.circulariinner surface 11d and-parallel, planar router sur

and improved means for preventing undesirable ?atten

faces lle.

in cross section, is generallyjU-shaped having 'a semi

Such structure effectively constitutes a re

cessed, semi-cylindrical, annular groove having parallel

ing deformation of the tube being bent.

Still another object is to provide a new and improved 50 annular surfaces 11e extending outwardly therefrom

tangential to the semi-cylindrical groove at the terminal

tube bender provided with a sliding shoe element having

edges thereof. Shoe groove 12a is made generally com

substantially less tube contacting area than the tube

plementary to the mandrel groove and extends substan

contacting area of the tube bender mandrel.

tially less than 180 but su?iciently to engage the greater

A further object of the invention is to provide such

a tube bender having tube retaining walls extending 55 portion of tube 20 extending from mandrel groove 11a.

In utilizing my tube bender, a tube 20 is inserted into

outwardly from the mandrel groove to grip tightly the

grooves 11a and 12a with shoe 12 positioned as seen in

tube when it tends to expand laterally during the bend

ing operation.

Yet another object is to provide a tube bender having

a mandrel and a sliding shoe element with comple

mentary tube receiving grooves therein and with the man

drel groove having a semicircular bottom and parallel,

straight sides.

Figure 1. Hook 14 is pivoted (to the left as seen in

Figure l) to engage the outer surface of tube 20 and

prevent movement of the tube away from handle 13.

Shoe 12 is then moved around the periphery of mandrel

11 through manual operation of leverarm 12d, while

mandrel 11 is ?xedly positioned by holding handle 13,

until the desired bend in tube 20 is obtained. To assist

A still further object is to provide a tube bender hav

65 in ascertaining the extent of. any bend formed, mandrel

ing a shoe adapted to engage a radially outer periphery

11 may be provided with a scale 11g showing the angular

of the tube over less than 180 extent to concentrate the

disposition of the portions of the periphery thereof.

stretching forces produced on the portion of the tube

The bending forces exerted on tube 20 by shoe 12

having the greatest forces produced on the portion of

cause the tube to tend to expand laterally in mandrel

the tube having the greatest stresses produced therein 70 groove 11a. However, ?ange surfaces lie of the man

during the bending operation.

Other features and advantages of this invention will

drel groove resist this lateral urging resulting in the tube

being forced into tight holding engagement therewith.

'-

2,796,785

Thus, undesirable ?attening deformation of the tube and

,-

'-

_*

2. A tube bender, of the character described, compris

ing: a rigid mandrel provided with an annular, peripheral

longitudinal movement of tube 20 through groove 110

during the bending operation are prevented Without the

need of additional tube constraining means. It should

'be noted, at this point, that the functioning of my groove

structure is antithetical to that of the conventional, solely

groove adapted to contact-a tube over more than 180

of the surface thereof; a bending shoe carried by the

mandrel to move in juxtaposition to the mandrel pe

riphery and having an annular groove adapted to contact

semi-circular groove structure. In my device lateralex

pansion is constrained so as to hold the tube ?rmly in the

less than 180 of the tube surface, said grooves having

complementary tube receiving relationship; means for pre

groove, Whereas in the conventional devices lateral ex- venting movement of a tube laterally from said grooves;

pansion is not so checked and actually tends to draw the 10 means forholding said mandrel; and means for moving

said shoe. 7

tube laterally from the groove (as the tube flattens its

cross section changes from circular to somewhat elliptical

3. A tube bender, of the character described, compris

and thus the half of its minor axis extending toward the I, ing: a mandrel provided with an annular, peripheral

vgroove bottom becomes less than the radius of the groove, '

groove having a cross section consisting of a semicircular

thus effecting a spacing of the tube from the groove

inner portion and a rectangular, radially extending outer

surface).

portion; a bending shoe carried by the mandrel to move

in juxtaposition to the mandrel periphery and having an

arcuate, annular groove of less than 180 extent, said

As shallow groove 12a of shoe 12 provides a reduced

area of sliding contact with tube 20, the frictional forces _

grooves having complementary tube receiving relation

produced by the action of the shoe against the tube are

correspondingly reduced, thus e?ectively minimizing the

20 ship; and means for preventing lateral movement of one

tendency of the shoe to move the tube longitudinally dur

portion of a tube in said grooves.

ing the bending operation. Further, as the force of bend

4. A tube bender of the character described, compris

ing is applied primarily to the radially outer portion of

ing: a rigid mandrel having a peripheral, 'U-shaped

the periphery of the tube 26 Where the greatest internal

groove, a handle ?xedly secured to said mandrel and hav

stresses are normally produced during the bending opera 25 ing a hook movably mounted thereon for holding a tube

tion, the stretching effect of the movement of shoe 12

to be bent against movement away from said handle; a

against tube 20 is concentrated Where most desired rather

than spread over the entire outer, semi-cylindrical surface

of the tube as is done with shoes having grooves of 180

bending shoe having a shallow groove and a lever arm

for manually operating said shoe; and link means for

pivotally connecting said shoe to said mandrel with said

30 grooves being positioned to form a tube receiving groove

structure and allowing said shoe to be moved around the

To remove the bent tube 20 from the tube bender 10,

extent.

shoe 12 is pivoted to space groove 12a away from groove

11a and hook 14 pivoted to lose engagement with the outer

surface of tube 20, allowing the bent tube to be Withdrawn

forcibly from its gripped retention in mandrel groove 11a.

While I have shown and described certain embodiments

of my invention, it is to be understood that it is capable

of many modi?cations. Changes, therefore, in the con

struction and arrangement may be made Without depart

.ing from the spirit and scope of the invention as de?ned

in the appended claims.

I_claim:

1. A tube bender, of. the character described, com

prising: a rigid mandrel provided with van annular, pe

ripheral groove having a U-shaped cross sectional con 45

?guration; a bending shoe carried by the mandrel to move

in juxtaposition to the mandrel periphery and having an

annular groove of less than 180 extent, said grooves

having complementary tube receiving relationship; means

,for preventing lateral movement of one portion of a tube 60

in said grooves; means for holding said mandrel; and

means for moving said shoe.

periphery of said mandrel to bend a tube therein.

5. In a tube bender of the character described, coact

ing mandrel and shoe elements, said elements de?ning

cooperatively a tube receiving groove having a cross sec

tion characterized by an arcuate inner portion, an arcuate

outer portion, and a straight, parallel sided intermediate

portion. -

References Cited in the ?le of this patent

UNITED STATES PATENTS

2,127,185

2,171,907

2,428,237

2,464,800

r

Parker ______________ __ Aug. 16, 1938

Beehler et at; _________ __ Sept. 5, 1939

McIntosh ___________ __ Sept. 30, 1947

~

Franck ______________ _.. Mar. 22, 1949

'FOREIGN PATENTS

417,656 ,

Great Britain _________ __ Oct. 3, 1934

464,413

Canada _____________ __ Apr. 18, 1950

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Regenerative Braking System ProjectDocument61 pagesRegenerative Braking System ProjectHello world100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Photographic History of The Civil War - Volume 08 Soldier Life Secret ServiceDocument392 pagesThe Photographic History of The Civil War - Volume 08 Soldier Life Secret Servicedayglowill5949100% (5)

- General Physics 1 CGDocument311 pagesGeneral Physics 1 CGCristine Quizano50% (2)

- Orion PDFDocument365 pagesOrion PDFLeggotunglei86% (7)

- AODDocument8 pagesAODPrakash Mishra100% (1)

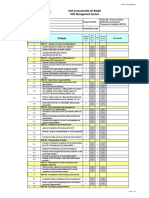

- HSE Evaluation CriteriaDocument2 pagesHSE Evaluation CriteriaChan RizkyNo ratings yet

- Present Perfect ContinuousDocument8 pagesPresent Perfect ContinuousNiaNo ratings yet

- Placenta and Trophoblast - Methods and Protocols (Vol 1) - M. Soares, J. Hunt (Humana, 2006) WW PDFDocument490 pagesPlacenta and Trophoblast - Methods and Protocols (Vol 1) - M. Soares, J. Hunt (Humana, 2006) WW PDFAlexandra IoanaNo ratings yet

- Stat I CH - 1Document9 pagesStat I CH - 1Gizaw BelayNo ratings yet

- I. Desired Educational Output I.1.Content StandardDocument7 pagesI. Desired Educational Output I.1.Content StandardTabada NickyNo ratings yet

- Quesions On Quantum MechanicsDocument1 pageQuesions On Quantum MechanicsGalatNo ratings yet

- Internet of Things in The Context of Industry 4.0: An OverviewDocument16 pagesInternet of Things in The Context of Industry 4.0: An OverviewNur Dini LeeNo ratings yet

- A Mechanical Analysis On Recycled PETHDPE Composites - Ávila, Duarte - 2003Document10 pagesA Mechanical Analysis On Recycled PETHDPE Composites - Ávila, Duarte - 2003Ana MangasNo ratings yet

- CodeDocument72 pagesCodeKushal BajracharyaNo ratings yet

- Name: Shintiya Gangsar Rahayu Class:2D/D4 I.Question AnswerDocument2 pagesName: Shintiya Gangsar Rahayu Class:2D/D4 I.Question AnswerAnisa SudarmajiNo ratings yet

- Gene Fine Structure Analysis in Prokaryotes and VirusesDocument32 pagesGene Fine Structure Analysis in Prokaryotes and Viruseserica williamsNo ratings yet

- Globalization Concept MapDocument7 pagesGlobalization Concept MapIntrovert DipshitNo ratings yet

- Food Handler's ManualDocument28 pagesFood Handler's ManualCarla RosaNo ratings yet

- Additives For Adhesives and Sealants Catalogue EuropeDocument24 pagesAdditives For Adhesives and Sealants Catalogue EuropeAlexi WiedemannNo ratings yet

- Physical Activity and Fitness For The Prevention of HypertensionDocument8 pagesPhysical Activity and Fitness For The Prevention of HypertensionFerdy LainsamputtyNo ratings yet

- Grade 8 Biology 3rd Round Model ExamDocument12 pagesGrade 8 Biology 3rd Round Model ExamEyob AlemuNo ratings yet

- Efficiency of Asphalt and Concrete in Road ConstructionDocument18 pagesEfficiency of Asphalt and Concrete in Road ConstructionTimothy James S ReyesNo ratings yet

- Cenozoic: From Wikipedia, The Free EncyclopediaDocument6 pagesCenozoic: From Wikipedia, The Free Encyclopediarkumar1313No ratings yet

- POF Study Report Telephone ExchangeDocument10 pagesPOF Study Report Telephone ExchangeImran chNo ratings yet

- Intellectual Property Rights An IntroductionDocument140 pagesIntellectual Property Rights An IntroductionSumatthi Devi ChigurupatiNo ratings yet

- JVC CD Receiver KD-S6350/KD-S590Document27 pagesJVC CD Receiver KD-S6350/KD-S590dzrNo ratings yet

- Shri Odop-1Document28 pagesShri Odop-1Manas DudhaniNo ratings yet

- Motorola APX2500 Specification Sheet ENGDocument4 pagesMotorola APX2500 Specification Sheet ENGAdrian McGannNo ratings yet

- Chakraborty 2018Document5 pagesChakraborty 2018iiee alcNo ratings yet

- Borax ComplexDocument10 pagesBorax Complexg.teissedreNo ratings yet