Wastewater Treatment Formula Sheet

1. Circumference, Area, Volume

a. Circumference

C = 3.1416 x Diamete r

b. Perimeter

P = [ 2 x Length ] + [ 2 x Width ]

c. Area

Rectangle

Area = Length x Width

Circle

Area = 0.785 x Diameter x Diameter

Area =

Triangle

1

x Base x Height

2

d. Volume

Volume = Length x Width x Depth

Rectangle

Volume = 0.785 x Diameter x Diameter x Depth

Cylinder

Cone

Volume = 0.262 x Diameter x Diameter x Height

Sphere

Volume = 0.524 x Diameter x Diameter x Diameter

2. Conversion Factors

a. ft3 to Gallons

Volume, Gallons = Volume, ft 3 x 7.48 Gallons / ft 3

Pounds = Gallons x 8.34 lbs/Gallon

b. Gallons to Pounds

Pounds = Concentration, mg/L x Tank Volume, MG x 8.34 lbs / MG / mg/L

c. mg/L to Pounds

Pounds/Day = Concentration, mg/L x Flow, MGD x 8.34 lbs / MG / mg/L

d. mg/L to Pounds/Day

e. mg/L to Kilograms/Day

Kilograms/Day = Conc. , mg/L x Flow, MGD x 3.785 lbs / MG / mg/L

f. mg/KG to Pounds/Ton

Pounds/Ton = Concentration, mg/KG x 0.002 lbs / ton / mg/KG

g. Pounds to mg/L

h. Pounds/day to mg/L

i. Pounds/day to MGD

3. Flow

a. MGD to GPD

b. MGD to GPM

c. MGD to CFS

Concentration =

Quantity, lbs

(Tank Volume, MG x 8.34 lbs / mg/L / MG)

Concentration =

Flow, MGD =

Quantity, lbs

(Flow, MGD x 8.34 lbs / mg/L / MG)

Quantity, lbs / day

( Concentration, mg/L x 8.34 lbs / mg/L / MG )

Flow, GPD = Flow, MGD x 1,000,000 gallons / MG

Flow, GPM =

Flow, MGD x 1,000,000 gallons / MG

1,440 minute / Day

Flow, cfs = Flow, MGD x 1.55 cfs / MGD

Virginia Department of Environmental Quality

All Rights Reserved

�4. Chemical Weight

Using Specific Gravity

Weight, lbs / Gallon = Specific Gravity x 8.34 lbs / Gallon

5. Population Equivalent

P.E., People =

BOD 5 , mg/L x Flow, MGD x 8.34 lbs / mg/L /MG

0.17 lbs BOD5 / Person / Day

6. Percent to Decimal Percent

Percent ( Decimal ) =

Percent

100

7. Percent Removal

[ Influent Concentration Effluent Concentration ] x 100

Influent Concentration

a. Based on Concentration

% Removal =

b. Based on Quantity (lbs,

lbs/day, KG or KG/day)

% Removal =

[ Influent Quantity Effluent Quantity ] x 100

Influent Quantity

HDT, Minutes =

Tank Volume, ft 3 x 7.48 gal / ft 3 x 1,440 Minutes / Day

Flow, Gallons / Day

8. Hydraulic Detention Time

a. HDT, Minutes

HDT, Hours =

b. HDT, Hours

Tank Volume, ft 3 x 7.48 gal / ft 3 x 24 Hours / Day

Flow, Gallons / Day

HDT, Days =

c. HDT, Days

Tank Volume, ft 3 x 7.48 gal / ft 3

Flow, Gallons / Day

9. Flow Measurement

a. Flow, (Fill and Draw), GPM

b. Flow (Velocity), cfs

Flow Rate, GPM =

Volume Added or Removed, Gallons

Time, Minutes

Flow ( Q ), cfs = Channel Width, ft x Water Depth, ft x Velocity, fps

Virginia Department of Environmental Quality

All Rights Reserved

�10. Grit Removal

a. Velocity (float method)

b. Velocity

Velocity, fps =

Velocity, fps =

c. Settling Time*

Distance Traveled, ft

Time Required, Seconds

Flow, MGD x 1.55 cfs / MGD

Channels in Service x Channel Width, ft x Water Depth, ft

Settling Time, Seconds =

d. Required Channel Length*

Channel Length, ft =

Water Depth, Feet

Settling Velocity, fps

Water Depth, Ft x Water Velocity, fps

Settling Velocity, fps

* The settling velocity must be given or determined experimentally.

11. Settling

a. Weir Overflow Rate

b. Surface Loading Rate

c. Solids Loading Rate

12. Ponds

a. Area in Acres

b. Volume in Acre-Feet

c. Flow in Acre-Feet/Day

d. Flow, Acre-Inches/Day

e. Hydraulic Detention

Time, Days

f. Hydraulic Loading

g. Organic Loading

h. Population Loading

Flow, Gallon / Day

Weir Length, ft

Weir Overflow Rate, GPD / ft =

Surface Loading Rate, GPD / ft 2 =

SLR, lbs / day / ft 2 =

Flow, Gallons / Day

Settling Tank Area, ft 2

Influent TSS, mg/L x Flow, MGD x 8.34 lbs / mg/L /MG

Settling Tank Area, ft 2

Area, acres =

Pond Volume, Acre Feet =

Area, ft 2

43,560 ft 2 / acre

Length, ft x Width, ft x Depth, ft

43,560 ft 3 / Acre Foot

Flow, Acre Ffeet / Day = Flow, MGD x 3.069 Acre Feet / MG

Flow, Acre Inches / Day = Flow, MGD x 36.8 Acre Inches / MG

Hydraulic Detention Time, Days =

Hydraulic Loading, Inches / Day =

O. L. , lbs BOD 5 / Acre / Day =

Pond Volume, Acre Feet

Influent Flow, Acre Feet / Day

Influent Flow, Acre Inches / Day

Pond Area, Acres

BOD5 , mg/L x Flow in , MGD x 8.34 lbs /mg/L /MG

Pond Area, Acres

P.L. , People / Acre / Day =

Population Served by System, People

Pond Area, Acres

Virginia Department of Environmental Quality

All Rights Reserved

�13. Trickling Filter

a. Total Flow (given flows)

b. Total Flow (given ratio)

Total Flow, MGD = Influent Flow, MGD + Recirculat ion Flow, MGD

Total Flow, MGD = Influent Flow, MGD x (1.0 + Recirculation Rate)

Hydraulic Loading, GPD / ft 2 =

c. Hydraulic Loading

Total Flow To Filter, GPD

Filter Area, ft 2

Total flow always includes recirculated flow.

O L, lbs BOD 5 / day / 1,000 ft 3 =

d. Organic Loading

BOD 5 IN, mg/L x Flow in , MGD x 8.34 x 1,000

Filter Volume, ft 3

Organic loading does not include recirculated flows

14. Rotating Biological Contactors

SBOD, mg / L = Total BOD5 , mg/L ( K Factor x Influent TSS mg/L)

a. Soluble BOD

Total Media / Train, ft 2 = ( Stage1 , ft 2 + Stage 2 , ft 2 + K + Stage n , ft 2 )

b. Total Media

Total Media, ft 2 = ( MediaTrain , ft 2 + Media Train , ft 2 + K + Media Train , ft 2 )

1

2

n

c. Hydraulic Loading

Hydraulic Loading, GPD / ft 2 =

d. Soluble Organic Loading

e. Total Organic Loading

SOL, lbs / 1,000 ft 2 / Day =

TOL, lbs / 1,000 ft 2 / Day =

Influent Flow MGD x 1,000,000 gal / MG

Total Media Area, ft 2

SBOD in , mg/L x Flow, MGD x 8.34 x 1,000

Total Media Area, ft 2

Total BOD in , mg/L x Flow, MGD x 8.34 x 1,000

Total Media Area, ft 2

15. Activated Sludge

a. Settled Sludge Volume

SSV, mL/L =

Settled Sludge Volume (SSV), mL x 1,000 mL/L

Sample Volume, mL

Settled Sludge Volume (SSV), mL x 100

Sample Volume, mL

b. Settled Sludge Volume

% SSV =

c. Return Rate (By SSV)

Return, MGD =

d. Return Rate (By SVI)

RASSS, mg/L =

% Return =

e. Return Rate

(Clarifier Mass Balance)

SSV 30

x Flow in , MGD

1000 SSV 30

1,000,000

SVI

Flow in x MLSS, mg/L

RASSS, mg/L MLSS, mg/L

[ MLSS, mg / L x ( FLowIn , MGD + RAS Flow , MGD ) ] + ( WAS Flow , MGD x WASSS, mg/L )

RASSS,mg/L + MLSS, mg / L

Virginia Department of Environmental Quality

All Rights Reserved

�15 . Activated Sludge (continued)

f. Clarifier Solids

(Core Sample)

SolidsC , lbs = Core Sample TSS , mg/L x VolumeC MG x 8.34 lbs / mg/L / MG

g. Clarifier Solids

(MLSS)

SolidsC = MLSS , mg/L x VolumeC , MG x 8.34 lbs / mg/L / MG

h. Clarifier Solids

(MLSS and RASSS)

MLSS, mg/L + RASSS, mg/L

x VolumeC , MG x 8.34 lbs / mg/L / MG

SolidsC , lbs =

2

C = Clarifier or Settling Tank

MLSS = Mixed Liquor Suspended Solids in milligrams / Liter

RASSS = Return Activated Sludge Suspended Solids in milligrams / Liter

i. Sludge Volume Index

j. F:M Ratio

k. Desired MLVSS, (lbs)

l. Desired MLVSS (mg/L)

m. Waste Volatile Solids

(Based on F:M)

n. Waste Rate, MGD

(Based on F:M)

o. MCRT, Days

p. Waste Solids, lbs/day

(Based on MCRT)

q. Waste Rate, MGD

(Based on MCRT)

r. Waste Rate, GPM

SVI =

Settled Sludge Volume, ( SSV )30 minutes x 1,000

MLSS, mg/L

Aeration Influent COD or BOD 5 , mg/L x Aeration Influent Flow, MGD x 8.34

MLVSS, mg/L x Aeration Volume, MG x 8.34

MLVSS, lbs =

Primary Effluent BOD5 or COD, mg/L x Flow, MGD x 8.34

Desired F : M Ratio

MLVSS, mg/L =

Desired MLVSS , lbs

(Aeration Volume, MG x 8.34)

Waste, lbs = Actual MLVSS, lbs Required MLVSS, lbs

Waste, MGD =

Waste Volatile Solids, lbs / day

(Waste Volatile Concentration, mg/L x 8.34)

[ MLSS, mg/L x ( Aeration , MG + Settling, MG ) x 8.34 ]

( WASSS, mg/L x WAS, MGD x 8.34 ) + ( TSS out , mg/L x Flow out , MGD x 8.34 )

( MLSS, mg/L x ( Aeration Vol., MG + Settling Vol., MG ) x 8.34 )

( TSS out , mg/L x Flow out , MGD x 8.34 )

Desired MCRT, days

Waste, MGD =

Waste Solids, lbs / day

Waste Activated Sludge Concentration, mg/L x 8.34

Waste Rate, gpm =

Waste Rate, MGD x 1,000,000 gal / MG

1,440 minutes / day

16. Chemical Addition

a. Demand

b. Dose, mg/L

c. Required Chemical

(Feed Rate, lbs/day)

Demand, mg/L = Dose, mg/L Residual, mg/L

Dose, mg/L =

Feed Rate, lbs / day

Daily Flow, MGD x 8.34 lbs / mg/L/ MG

Required Chemical industrial , lbs / Day =

Dose, mg/L x Daily Flow, MGD x 8.34 lbs / mg/L / MG

% ( decimal ) Active Ingredient in Industrial Chemical

Virginia Department of Environmental Quality

All Rights Reserved

�16.

Chemical Addition (Continued)

d. Feed Rate, gpd

Feed, gpd =

e. Feed Rate, gpm

Feed, gpm =

Required Chemical Industrial , lbs/day

Weight / Gallon of Chemical Industrial , lbs / gal

Required Chemical Industrial , lbs/day

Weight / Gallon of Chemical Industrial , lbs / gal x 1,440 minutes / day

Required Chemical industrial , lbs / day x 3,785 mL / gal

Weight / Gallon of Chemical Industrial , lbs / gal x 1,440 min / day

f. Feed Rate, mL/minute

Feed, mL / minute =

g. Supply Required

Required Supply, containers =

h. Supply on Hand

Supply on Hand, days =

i. Increases,

(price, usage, or for safety)

j. Chemical Cost

k. Chemical Makeup

(dry chemical)

l. Chemical Makeup

(solution)

17.

# Full Containers x Weight of Chemical in a Full Container, lbs / container

Chemical Feed Rate, lbs / day

Increase = Current Amount x [ 1.0 + % ( decimal ) Increase]

Required, lbs =

%Active Chemical working x Volume, gallons x 8.34 lbs / gallon

%Active Chemical supply

Volume Makeup =

m. Active Ingredient

Feed Rate, lbs / day x Days Supply Required, days

Weight of Chemical in a Full Container, lbs / container

Concentration Working x Volume Working

Concentration Makeup

Chemical Used Active Ingredient = Chemical Used, lbs x % Active Ingredient

Solids Pumping

a. Estimated Pump Rate

(gallons/minute)

b. Gallon pumped

GPD

c. Solids Pumped lbs/day

Rate, gpm =

GPD = Pump Rate, gpm x Cycles, Cycles / day x Cycle Time, minutes / cycle

Solids , lbs / day = Solids Volume , gpd x 8.34 lbs / gal % ( decimal ) Solids

d. Volatile Solids Pumped,

lbs/day

18. Thickening

a. Solids Loading Rate

(SLR) lbs/day/ft2

b. Solids Loading Rate

(SLR) lbs/hour/ft2

( TSS in - TSSout ) x Flow, MGD

% Solids x Pump Time, minutes / day

Volatile Solids , lbs / day = Solids Volume, gpd x 8.34 lbs / gal x % Solids x % Volatile Matter

All % values must be in decimal form.

SLR, lbs / day / ft 2 =

TSS in , mg / L x Flow in , MGD x 8.34 lbs / gallon

Thickener Area, ft 2

Solids Loading, lbs / hr / ft 2 =

Solids Applied, lbs / hour

Thickener Area, ft 2

Virginia Department of Environmental Quality

All Rights Reserved

�18. Thickening (continued)

c. Solids Volume

Ratio (SVR)

d. Hydraulic Loading

SVR =

Hydraulic

e. Air : Solids Ratio

Loading, gpd / ft 2 =

Air : Solids Ratio =

f. Concentration

Factor

Total Thickener

Thickener

Digestion

Digestion

e. Volatile Matter

Reduction

Volatile Solids Added, lbs / day

Digester Volume, ft 3

Time, days =

Digester Volume, gallons

Influent Flow, gpd

Time, days =

Digester Solids, pounds

Influent Solids, lbs / day

Chemical Used lab , mg x Digester Volume, MG x 8.34 lbs / mg / L /MG

Sludge Volume lab , Liters

% V. M. Reduction =

20. Anaerobic Digestion

a. Seed Volume

b. Volatile Solids Loading

Flow, gpd

Area, ft 2

% Solids Thickener Sludge out

% Solids Thickener Sludge in

Volatile Solids Loading, lbs /day / ft 3 =

Chemical Re q' d =

Influent

Air Flow Rate, ft 3 / minute x 0.075lbs / ft 3

Sludge Flow, gpm x % Solids x 8.34 lbs / gallon

Concentrat ion Factor =

19. Aerobic Digestion

a. Volatile Solids Loading

lbs/day/ft3

b. Digestion Time

(based on flow)

c. Digestion Time

(based on solids)

d. Chemical Requirement

( % V.M .in % V.M .out ) x 100

[ % V.M .in ( % V.M .in x % V.M .out ) ]

Seed, gallons = Digester Volume, gallons x Desired % Seed Volume

Volatile Solids Loading, lbs /day / ft 3 =

c. Volatile Acids/ Alkalinity

Ratio

d. Chemical Requirement

e. Volatile Matter

Reduction

f. Gas Production ft3/Day

Solids Blanket Volume, gallons

Thickener Influent Flow, gallons / day

V. A. : Alkalini ty Ratio =

Chemical Re q' d =

Volatile Solids Added, lbs / day

Digester Volume, ft 3

Volatile Acids, mg / L

Alkalinity , mg / L

Chemical Used lab , mg x Digester Volume, MG x 8.34 lbs / mg / L /MG

Sludge Volume lab , Liters

% V. M. Reduction =

( % V.M . in % V.M . out ) x 100

[ % V.M . in ( % V.M . in x % V.M .out ) ]

Gas , ft 3 = Volatile Solids in , lbs / day x % V. M. Reduction x Rate, ft 3 / lb V.M. Destroyed

Virginia Department of Environmental Quality

All Rights Reserved

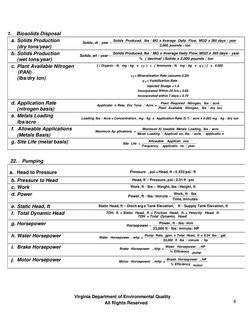

�21. Biosolids Disposal

a. Solids Production

(dry tons/year)

b. Solids Production

(wet tons/year)

c. Plant Available Nitrogen

(PAN)

(lbs/dry ton)

Solids , dt / year =

Solids , wt / year =

Solids Produced, lbs / MG x Average Daily Flow, MGD x 365 days / year

2,000 pounds / ton

Solids Produced, lbs / MG x Average Daily Flow, MGD x 365 days / year

% ( decimal ) Solids x 2,000 pounds / ton

[ ( Organic - N, mg / kg x f 1 ) + ( Ammonia - N, mg / kg x V 1 ) ] x 0.002

f 1 = Mineralization Rate (assume 0.20)

V 1 = Volatilization Rate

Injected Sludge = 1.0

Incorporated Within 24 hrs = 0.85

Incorporat ed within 7 days = 0.70

d. Application Rate

(nitrogen basis)

e. Metals Loading

lbs/acre

f. Allowable Applications

(Metals Basis)

g. Site Life (metal basis)

22.

Applicatio n Rate, Dry Tons / Acre =

Plant Required Nitrogen, lbs / acre

Plant Available Nitrogen, lbs / dry ton

Loading, lbs / Acre = Concentrat ion, mg / kg x Applicatio n Rate, D. T. / acre x 0.002 mg / kg / dry ton

Maximum Ap plications =

Maximum Al lowable Metals Loading, lbs / acre

Metal Loading / Applicati on, lbs / acre / applicatio n

Site Life =

Allowable Applicati ons

Frequency, applicatio ns / year

Pumping

a. Head to Pressure

Pressure , psi = Head, ft 0.433 psi / ft

b. Pressure to Head

c. Work

d. Power

Head, ft = Pressure , psi 2.31 ft / psi

e. Static Head, ft

f. Total Dynamic Head

g. Horsepower

h. Water Horsepower

Work , ft lbs = Weight , lbs Height , ft

Power , ft lbs / min ute =

Work, ft lbs

Time, min utes

Static Head, ft = Disch arg e Tank Elevation,

ft Supply Tank Elevation, ft

TDH, ft. = Static Head, ft. + Friction Head, ft. + Velocity Head, ft.

TDH = Total Dynamic Head

Horsepower =

Water Horsepower , whp =

Power , ft lbs / min

33,000 ft lbs / min ute / HP

Pump Rate, gpm x Total Head, ft x 8.34 lbs / gal.

33,000 ft lbs / minute / hp

i. Brake Horsepower

Brake Horsepower , bhp =

j. Motor Horsepower

Motor Horsepower , mhp =

Water Horsepower , HP

% Efficiency pump

Brake Horsepower , HP

% Efficiency motor

Virginia Department of Environmental Quality

All Rights Reserved

�k. Centrifugal Pump

Affinity Law

Capacity

Flow2 , cfs =

Head

Pump Speed2

Head1

Head2 =

Pump Speed1

3

Brake Horsepower

23. Electrical Energy

a. Hp to kilowatts (kW)

b. kW to kilowatt hrs

c. Power Cost

24. Sampling

a. Composite Sample

Volume, mL

Pump Speed2

Flow1, cfs

Pump Speed1

Pump Speed2

Bhp1

Bhp2 =

Pump Speed1

Kilowatts = Horsepower x 0.746 Kw / hp

Kilowatt

Hour = Kilowatts Used x Hours Operated

Cost = Kilowatt hours used x Cost / Kilowatt

Sample Volume

Plant FlowT , MGD x Total Sample Required, mL

# Samples To Be Collected x Average Daily Flow, MGD

T = Sample Collection Time

b. Proportioning Factor

(PF)

c. Sample Volume

(Using PF)

25. Alkalinity

a. Conventional

Proportion ing Factor =

Total Sample Required, mL

# of Samples Collected x Average Daily Flow, MGD

Sample Volume

, mL = Flow T x PF

T = Time sample

is collected.

Alkalinity

as CaCO

, mg/L =

A x N x 50,000

Sample Volume,

mL

A = Volume of Standard

Acid Used

N = Normality

of Standard

Acid

b. Low Level

Alkalinity

asCaCO

, mg/L =

( 2B - C ) x N x 50,000

Sample Volume, mL

B = Volume of Standard Acid Used to reach pH 4.3 - 4.5

C = Total volume of Standard Acid for titration

N = Normality of Standard Acid

Virginia Department of Environmental Quality

All Rights Reserved

�26. Hardness

a. EDTA Standardization

EDTA, CaCO 3 Equivalenc e ( B ) =

b. Hardness, mg/L Calcium

Carbonate

Volume of CaCO 3 Solution Titrated, mL

EDTA Titrant Used, mL

Hardness ( EDTA ) as CaCO3 =

A x B x 1,000

Sample Volume, mL

A = EDTA Used in Titration, mL

B = EDTA CaCO3 Equivalenc e, mL / mL

27. Ammonia Nitrogen

NH 3 N, mg / L =

a. Nesslerization

A

B

x

Sample Volume, mL

C

A = Micrograms of N from calibratio n curve

B = Volume of distillate collected

C = Volume of distillate used for nessleriza tion

Sample Volume = Original sample volume placed in distillati on flask

NH 3 N, mg / L =

b. Titration

A = Volume of titrant used for sample

B = Volume of titrant used for blank

Sample Volume = Volume of sample used for titration

28. Biochemical Oxygen Demand

a. Unseeded Samples

b. Seed Correction

Factor

c. Seeded Samples

( A B ) x 280

Sample Volume, mL

BOD5 , mg / L =

( D. O .Start , mg / L D. O .Final , mg / L ) x 300 mL

Sample Volume, mL

Seed Correction , mg / L =

BOD5 , mg / L =

29. Chemical Oxygen Demand

a. FAS Standardization (Open

Reflux)

b. FAS Standardization

(Closed Reflux)

BODseed

x mL Seed in the Sample Dilution

300 mL

[ ( D. O.Start , mg / L D. O . Final , mg / L ) Seed Correction ] x 300 mL

Sample Volume, mL

FAS, Molarity =

Volume of 0.0417M K 2Cr2O 7 , mL x 0.25

FAS Titrant Added, mL

FAS, Molarity =

Volume 0.0167 M K 2Cr2O7 , mL x 0.10

FAS Titrant Added, mL

COD as mg O 2 / L =

c. COD

( A B ) x C x 8000

Sample Volume, mL

A = FAS Used For Blank, mL

B = FAS Used For Sample, mL

C = FAS Molarity

Virginia Department of Environmental Quality

All Rights Reserved

10

�30.

Total Residual Chlorine

a. Iodometric Direct Titration

b. Iodometric Back Titration

(No Iodine correction)

c. Iodine Correction

d. Iodometric Back Titration

(With Iodine correction)

e. Iodometric Back Titration

Iodate Titrant

31.

TRC, mg/L =

( Titrant, mL Blank, mL ) x Titrant Normality, N x 35,450

Sample, mL

TRC, mg/L =

PAO Added, mL ( 5 x Iodine Used, mL ) x 200

Sample Volume, mL

Iodine Correction Factor =

TRC, mg/L =

Iodine Normality

0.0282 N

actual

PAO Added, mL ( 5 x Iodine Used, mL x CF ) x 200

Sample Volume, mL

TRC, mg / L =

( Iodate Used blank Iodate Used sample ) x 200

Sample Volume, mL

Dissolved Oxygen

a. Winkler Titration

D. O. , mg / L =

Titrant, mL x Normality x 8,000

Equivalent Sample Volume, mL

If N = 0.0250 & Sample Volume = 200 mL

then : Titrant Used = D.O. , mg / L

32. Fecal Coliform

a. Multiple Tube

b. Membrane Filtration

MPN / 100 mL = MPN chart x

Colonies / 100 mL =

Sample Volume In First Dilution chart

Sample Volume in First Dilution sample

Colonies Counted

x 100 mL

Sample Volume , mL

33. Nitrate Nitrogen

a. Brucine Sulfate

b. Cadmium Reduction

34.

NO 3 N, mg / L =

NO 3 N Concentrat ion, micrograms

Sample Volume In Reaction Tube, mL

NO 3 N, mg / L = Nitrate / Nitrite, mg / L Nitrite , mg / L

Nitrite Nitrogen

a. Diazotization

Diluted sample

NO 2 N = C x

V

S

C = NO 2 - N Concentrat ion, mg / L

V = Total volume after dilution, mL

S = Sample volume in dilution, mL

Virginia Department of Environmental Quality

All Rights Reserved

11

�35. Phosphorus

Phosphorus , mg P / L =

a. Phosphorus

Phosphorus From Standard Curve, mg x 1,000

Sample Volume, mL

36. Total Suspended Solids

Total Suspended Solids, mg / L =

a. TSS, mg/L

( A B ) x 1,000 mg / gram x 1,000 mL / L

Sample Volume, milliliter s

A = Weight of Dried Solids, Filter & planchet or dish in grams

B = Tare Weight ( Dried Filter & planchet or dish ) in grams

37. Total Kjeldahl

Nitrogen

TKN N, mg / L =

a. Nesslerization

A

B

x

Sample Volume, mL

C

A = Micrograms of N from calibratio n curve

B = Volume of distillate collected

C = Volume of distillate used for nessleriza tion

Sample Volume = Original sample volume placed in distillati on flask

TKN N, mg / L =

b. Titration

( A B ) x 280

Sample Volume, mL

A = Volume of titrant used for sample

B = Volume of titrant used for blank

Sample Volume = Volume of sample used for titration

38. Total Volatile Suspended Solids

Volatile Solids, mg / L =

a. TVSS, mg/L

( A C ) x 1,000 mg / gram x 1,000 mL / L

Sample Volume, milliliters

A = Weight of Dried Solids & Support

C = Weight of Ash & Support

39. Residual (Sludge) Solids Tests

a. % Solids

b. % Volatile Matter

% Solids =

% Volatile Matter =

% Moisture =

c. % Moisture

Dry Solids , grams

x 100

Residual ( Solids & Water ) , grams

( Dry Solids , grams - Ash , grams )

x 100

Dry Solids , grams

Residual ( Solids & Water ), grams - Dry Solids, grams)

x 100

Residual ( Solids & Water ), grams

or

% Moisture = 100 - % Solids

Virginia Department of Environmental Quality

All Rights Reserved

12

�40. VPDES Reporting

a. Average Monthly

Concentration

b. Average Weekly

Concentration

c. Average Daily

Concentration

d. Average Hourly

Concentration

e. Daily Quantity

AMC, mg / L =

( Test 1 + Test 2 + Test 3 + ... + Test n )

N ( Tests during month )

AWC, mg / L =

( Test 1 + Test 2 + Test 3 + ... + Test n )

N ( tests during calendar week )

ADC, mg / L =

( Test 1 + Test 2 + Test 3 + ... + Test n )

N ( Tests during day )

AHC, mg / L =

( Test 1 + Test 2 + Test 3 + ... + Test n )

N ( tests during 60 minute period )

DailyQuant ity, KG / Day = Conc. , mg / L x Flow, MGD x 3.785 lbs/MG/mg/L

Conc. = Individual Test Result in mg / L

Flow = Flow on day sample was collected in MGD.

f. Average Monthly

Quantity

g. Average Weekly

*Quantity

h. Geometric Mean

(Xy)

i. Geometric Mean

(log)

41. Nutrient General

Permit Reporting

a. Daily Loading,

lbs/day

b. Average Monthly

Load

c. Monthly Load

d. Annual Load,

Year to Date

e. Annual Load

f. Monthly

Concentration

g. Average Annual

Concentration

Year to Date

h. Average Annual

Concentration

AMQ, KG / day =

AWQ, KG / day =

( DQ 1 + DQ 2 + DQ 3 + ... + DQ n )

N ( Tests during month )

( DQ 1 + DQ 2 + DQ 3 + ... + DQ n )

N ( tests during calendar week )

Geometric Mean = n Test 1 x Test 2 x Test 3 x K x Test n

( log X 1 + log X 2 + log X 3 + K + log X n )

Geometric Mean = Antilog

N, Number of Tests

Daily Loading, lbs / day = Concentration, mg / L Flow , MGD 8.3438

Average Monthly Load =

Daily Loading, lbs / day

Number of Days samples were collected

Monthly Load = Average Monthly Load Number of Days in Month

+ K + Monthly Load

MonthlyLoad

Annual Load, lbs = Monthly Load

+ K + Monthly Load

Daily Concentration

Monthly Concentration =

Annual Load, Year to Date =

January

current month

Dec

Jan

Number of days samples were collected

Annual Concentration, YTD =

Annual Concentration =

Average Conc.

January

+ K + Average Conc.Current Month

Number of Months

Average Conc.

January

+ K + Average Conc.December

12

Provided by Virginia Department of Environmental Quality

13

�42. Conversion Factor Table

To Change From:

To:

Multiply

by:

Feet (ft)

Inches (in)

12

Yards (yd)

Feet (ft)

Yards (yd)

Inches (in)

36

Miles (mi)

Yards (yd)

1,760

Miles (mi)

Feet (ft)

5,280

Gallons (gal)

7.48

Cubic Feet (ft )

Pounds-Wastewater

(lbs)

62.4

Cubic Feet (ft 3)

Pounds-Air (lbs)

0.075

Gallons (gal)

Pounds (lbs)

8.34

Gallons (gal)

Liters (L)

3.785

Gallons

Kilograms

3.785

Million Gallons/Day

(MGD)

Gallons/Day (gpd)

1,000,000

Million Gallons/Day

(MGD)

Gallons/Minute (gpm)

694

Million Gallons/Day

(MGD)

Cubic Feet/Second

(cfs)

1.55

Million Gallons/Day

(MGD)

Acre-feet/day

3.069

Liters/Second (L/s)

Gallons/Minute (gpm)

15.85

Million Gallons/Day

(MGD)

Liters/second

43.8

Gallons/day

Cubic Meters/Day

0.003785

Acres (Ac)

Square Feet (ft 2)

43,560

Acre Feet (Ac-ft)

Gallons (gal)

325,829

Acre Inches (Ac-in)

Gallons (gal)

27,152

Liters (L)

Milliliters (mL)

1,000

Kilograms (Kg)

Pounds (lbs)

2.2

Meters (m)

Feet (ft)

3.3

Cubic Meters (m 3)

Gallons (gal)

269

Pounds (lbs)

Grams (g)

454

Ton (t)

Pounds (lbs)

2,000

Cubic Feet (ft )

Virginia Department of Environmental Quality

All Rights Reserved

14