Professional Documents

Culture Documents

Icieom2012 Submission 328

Uploaded by

Anonymous ffje1rpaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Icieom2012 Submission 328

Uploaded by

Anonymous ffje1rpaCopyright:

Available Formats

Maintenance Management Based on Organization Maturity

Level

Marcelo A. Oliveira*, Isabel Lopes*, Danielle L. Figueiredo*

*

Algorithm Research center, School of Engineering, University of Minho, Campus of Azurm, 4800-058 Guimares, Portugal

Email: marcelo@maoconsultoria.com , ilopes@dps.uminho.pt, danielle_lima@ig.com.br

Abstract

This article aims to discuss the management process of the maintenance function of companies depending on the

degree of organization maturity concerning maintenance. Maintenance management makes use of some tools and

techniques to improve efficiency and minimize the impacts of unplanned stoppages, such as Reliability Centered

Maintenance (RCM), Total Productive Maintenance (TPM) and the Failure Mode and Effects Analysis (FMEA). The

identification of the degree of maturity on maintenance, leads us to a better planning of actions to implement the

more appropriate management strategy and to propose suitable computerized tools, performance indicators,

technical analysis and management tools and techniques, providing a set of potential improvements necessary for the

successful evolution of the maintenance process and the resulting progress in the maintenance maturity level.

Understanding the aspects which define the degree of maturity of an organization may not be an easy task. In this

paper, a study of the maintenance function of some companies was carried out in order to define their maturity levels

regarding maintenance. A maturity model is also proposed for the maintenance function through the definition of

dimensions and levels. Aspects related to maturity levels have been fairly dealt with in various segments of the

knowledge and the use of the proposed models have contributed to the achievement of better results in

organizations in general.

Keywords: maintenance strategy; production management; maintenance management; maturity grid.

Introduction

In past times, product development and manufacturing engineering were dominant in the industrial

environment, and operation (production activities) and maintenance had low priority corporate strategies.

Some time afterwards, both the operation and maintenance began to occupy a prominent role. Nowadays

maintenance has a strategic role within organizations, it is responsible for ensuring the availability of

equipment and facilities. In addition, it needs to help the production process giving reliability and

appropriate security costs.

Maintenance management uses some tools and techniques to improve efficiency and minimize losses,

such as the Reliability Centered Maintenance (RCM), Total Productive Maintenance (TPM), Analysis of the

Failure Mode and Effects (FMEA).

According to Munk (1999), in organizations, teams can break down the traditional interdepartmental

barriers and facilitate the operation of the functional structure, improving communications, coordination

and integration and, above all, imposing a quicker reaction time. Teams are a powerful mechanism of

integration within informal organizational structures. For individuals, teams bring more social and

emotional involvement, more participation in decision making, greater penetration in the affairs of the

company, greater commitment and therefore more motivation.

Clarke and Garside (1997) propose a model that combines five features for managing the maintenance

function: commitment, culture, communication, tools and methodologies and conflict management.

However for models to maintenance management orientation, a proper investigation and

recommendation are still missing. The identification of the maturity level on maintenance allow a better

planning of actions, selecting suitable computerized tools, performance indicators, management tools

ID328.1

ICIEOM 2012 - Guimares, Portugal

and techniques. Based on the maturity level of the organization, suitable more recommendation for

maintenance management can be defined.

Aspects related to maturity levels have been well covered in various segments of the practical knowledge

and the proposed models have contributed to the achievement of better results in organizations in

general.

The aim of this paper is to propose a maturity model regarding maintenance. This maturity model will

allow in further research to define the appropriate management actions to achieve high levels of maturity

for each level of the model.

Through survey, strategic points for the maintenance management will be evaluated in order to identify

the current situation and generate preliminary data needed for a proposed maturity model for

maintenance management.

This paper is organized as follow. The second section presents a literature review, describing maintenance

management topics and maturity models concepts. The third section addresses data collection and

analysis, evaluating the maintenance management of a group of organizations that act in different

sectors. Dimensions and levels for maintenance maturity assessment are suggested in section 4. The last

section presents the conclusion and future work.

Literature Review

2.1 Maintenance Management

According to Filho (2008), the maintenance management is an integral part of the company and aims to

manage the maintenance in the broadest sense of the word. The maintenance management is a set of

actions, rules and procedures of a maintenance system that assigns targets to the maintenance team and

the organization it serves.

The maintenance management establishes goals and objectives through standards and work procedures

in order to obtain a better utilization of available resources, which are staff, equipments and materials.

According to Kardec and Lafraia (2007), modern management must be underpinned by a vision and

governed by processes management where the full satisfaction of its customers is a result of the quality of

its products and services.

In accordance with this line of thought, the maintenance management is considered strategic when it is

results-driven business organization. And this implies that, besides having to assure the functional

availability of equipment and facilities of a production process or service, safety and environmental factors

as well as cost need to be considered.

For Kardec and Nascif (2007), the systemic view of the business and changing paradigms and concepts

will lead to major innovations in the process of maintenance management.

According to Cuignet (2006), the objectives of maintenance must be connected to the overall objectives

of the company once maintenance affects the profitability of the production process through its influence

on the volume and quality of production and associated cost. If, on the one hand, there is a concern with

improving performance and availability of equipment, on the other we have the cost factor associated

with the management process.

Still to this author, the search for a balance between benefit and cost to maximize the positive

contribution of maintenance to the overall profitability of the company is the secret of this step, so that all

the actions necessary to achieve this equilibrium is the management of maintenance itself.

Currently, to manage the maintenance, excluding the complexity factor, large numbers of activities are

necessary and should be known by the manager, namely: general knowledge in maintenance, planning,

people management, assets and equipments knowledge, lubrication and calibration, material

ID328.2

Maintenance Management Based on Organization Maturity Level

management, maintenance techniques, knowledge in computers and computerized processes, basic of

production management and basic of quality management.

Some parallels can easily be made between maintenance management and certain tenets of quality

management. Crosby (1990), states that quality is defined as conformance to product requirements.

He also shows that quality is achieved through prevention and not through inspection and the optimal

performance standard of quality is zero defects. He also states that quality is measured by the price of

non-compliance.

In the view of maintenance, quality is closely associated with the systematic prevention of events that

result in the stoppage of an asset and this prevention is strongly linked with the adopted management

strategy. The quest for zero defects in the maintenance, as well as a paradigm to be broken, it is a goal to

be achieved through the use of modern techniques of management activities in line with the

organization's strategy. The standard of maintenance performance is associated with the absence of

assistance and not by running out of acceptable standards.

From the standpoint of management, the most appropriate maintenance is one that combines different

methods and techniques, according to the nature and criticality of the equipment for maintenance, in

order to obtain operational efficiency and economic.

2.2 Maintenance Policies and models

Maintenance policies applied correctly aimed at preventing and/or eliminating the occurrence of failures.

Lack of fulfillment of what was previously defined as "proper performance" is defined as failure.

According to Kardec (2002), fault is "an abnormal physical state in a system that is a threat to the

operation thereof. Abnormal is defined as the deviation of some measurable parameter beyond the

limits considered desirable for the normal operation.

For Smith (2004), maintenance aims to "preserve the functional capabilities of equipment and systems in

operation". According to Moubray (2000), the purpose of maintenance is to "ensure that physical assets

continue to do what the users want them to do.

SAE JA1011 states that maintenance should ensure that "physical assets continue to perform their

planned functions.

The maintenance really only fulfils its role when it comes before and can predict possible events that can

paralyze and damage production, with consequent loss of volume, increased of operation expenses and

reduction of the business margins.

To achieve what it is called World Class Maintenance (WCM), it is necessary to improve adopted

maintenance processes.

According to Kardec (2002), plants coexist with certain types of maintenance (or maintenance policies)

and progress of organization's management will allow the application of the most convenient such as

corrective, preventive, predictive and maintenance engineering.

Various tools available today have adopted the word maintenance. It is important to note that these are

not new types of maintenance but tools that allow the application of the main types of maintenance

mentioned above. Highlighted among them are: Maintenance Engineering; Lean Maintenance; Total

Productive Maintenance; Reliability Centered Maintenance; Reliability Based Maintenance and Condition

Based Maintenance.

2.3 Maintenance Indicators

For Weber and Thomas (2005), performance measurement is fundamental for management once it

identifies the difference between the actual performance and the performance intended to be achieved.

According to Kardec and Lafraia (2002), maintenance indicators are developed and used by managers in

order to achieve the goals set by companies.

ID328.3

ICIEOM 2012 - Guimares, Portugal

The literature, in the context of maintenance, provides various expressions and terminology for

performance indicators, once they eventually adapt to the reality of companies (Tavares, 1999). Indicators

are usually grouped into:

Asset management;

Costs management;

Manpower management;

Maintenance activities;

Maintenance organization.

The pursuit of World Class Excellence involves the identification and adaptation of best practices. This

means changing the way of acting which obviously requires some time, from planning to implementation

and evaluation of practical results.

EN15341 (2009) Standard highlights that maintenance performance is the result of complex activities,

which can be evaluated by appropriate indicators to measure actual and expected results. Performance

indicators are necessary to ensure stability and predictability of the maintenance process.

In general, indicators are measures or numerical data set about processes that we want to control, and

maintenance, generally include: availability, costs, production losses due maintenance activities, Rework,

Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR) and Overall Equipment Effectiveness

(OEE).

Maintenance costs are linked to the adopted practices. In a unit where maintenance is performed in a

reactive way, setting an unplanned corrective maintenance, costs are higher.

Paradoxically, it is important to note that not always the minimum cost is the best value. Strategic vision

and proper planning for the functions related to training teams and operational resources (parts,

equipment and tools) need to be considered. According to Filho (2008), performance measurement

becomes useless if it is not accompanied by a group of actions. The maintenance policies and associated

prevention strategy must ensure balanced improvement of performance indicators, as suggested in figure

1(Semitan, Oliveira & Maciel, 2009).

Figure 1 - Proposed Indicators Model

In addition to the identification process of managing more suitable indicators, Norton and Kaplan (1996)

suggested the use of the scorecard Balance (BSC) as a methodology for performance management, where

the strategy could be translated in operational terms, so that past performance measures serve to direct

the value of performance measures for the future. Alsyouf (2006) proposes to use this tool to measure

performance in the maintenance area of an organization.

ID328.4

Maintenance Management Based on Organization Maturity Level

2.4 Maturity Models

Nunes (2008) highlights the Maturity Theory of Argyris, presented in Personality and Organization, which

is one of many theories that attempt to explain nature and human behavior. According to this theory, the

development of a person takes place over a continuous range of an immature state to a state of maturity.

A mature person is characterized by being active, independent, self confident and controlled. On the

other end, an immature person is passive, dependent, lacks confidence and feels the need to control

others.

In his studies of process maturity, Smith (2008) gives the basic concept, under the term maturity, the

aspect that mature organizations do things in a systematic and that the immature reach their results

thanks to the heroic efforts of individuals using approaches that they create more or less spontaneously.

Mature organizations achieve their quality objectives, timelines and costs consistently and efficiently.

Immature organizations create goals, but too often lose their targets by wide margins of error.

The term maturity is introduced in various segments of knowledge, such as project management, Quality

management and computerized systems development. Crosby (1979) structured a model, designated by

Quality Management Maturity Grid, based on five levels of maturity for the incremental adoption of

quality concepts in an organization. The proposed model considers the following maturity levels:

I.

II.

III.

IV.

V.

Uncertainty

Awakening

Enlightenment

Wisdom

Certainty

Maturity levels are assigned to the following categories of dimensions:

I.

II.

III.

IV.

V.

VI.

Management understanding and attitude

Quality organization status

Problem Handling

Cost of quality as a percentage of sales

Quality improvement actions

Summary of company quality posture

Often, the proper functioning of organizations (in terms of work specialization, chain of command, the

degree of delegation, the degree of control, etc.) is in itself an obstacle for officials to achieve a naturally

high degree of maturity.

In addition, organizations expect that their employees are passive, dependent and have a short term

perspective, producing without requiring a high degree of control.

In accordance with Clarkson, Maier and Moultrie (2009), a large number of maturity models have been

proposed to assess a range of capabilities, including quality management, software development, supplier

relationships, efficient research and development, product, collaboration and communication. These

evaluations focus on a particular domain of knowledge that can result in several practical approaches

confusing or contradictory. However, their study does not direct specific recommendations for the type of

maintenance management of an organization.

Based on Crosbys maturity grid for Quality, Fernandez et al. (2003) propose a maintenance maturity grid.

However, the authors only emphasize quality management criteria for maintenance.

Data collection and Analysis

A survey was undertaken in some industrial plants of the industrial pole of Manaus, in Amazonas state

(Brazil), in order to study different processes and identify their management strategies.

ID328.5

ICIEOM 2012 - Guimares, Portugal

The maintenance management of companies in the plastic industry, manufacturing of mobile phones,

modems, set top boxes, televisions, laptops, audio, CD and DVD manufacturing, motorcycles, air

conditioners, cameras, alarm and protection systems, car alarms, naval industry, metallurgical industry and

support activities of IT infrastructure in government departments were analyzed (see figure 2).

About the companies, nine of them are considered small companies, eight, medium companies and three,

large companies. All companies of this survey have ISO 9001 certification. Besides, large companies have

ISO 14000 certification.

Personal Care

Paper

Naval

Motorcycle

Metallurgical

Government

Electronics

Air Conditioner

2

0

10

Figure 2 Surveyed Company

Through field research using semi-structured interviews, data related to the management aspects of the

strategies and maintenance activities of the company were collected. In the survey, information about

maintenance management function was gathered, such as:

Use of key process indicators;

Management of maintenance costs;

Qualification of the maintenance team

Application of management support.

The collected information in the companies was analyzed and classified in the following management

dimensions:

Maintenance Policies: to identify the current maintenance type;

Maintenance Planning and Organization: to identify CMMS utilization;

Maintenance KPI Management: to identify the current KPI and their management;

Maintenance Training Strategy: to identify the training level and knowledge of maintenance crew.

Table 1 presents the results for each company and also shows how maintenance activities are organized

and how each company manages them according to their own policies and strategies.

The results reveals that most organizations adopt corrective policy, have low competence investment

(personal and technical training), no performance indicator and have poor maintenance activities

planning.

According to the data obtained in the investigation and displayed in Figure 3, only 45% of companies

have adopted a preventive policy or rather merge preventive and corrective policies. The majority focuses

on correction, which can result in a strategy focusing on production rather than productivity and

efficiency, which usually increases the probability of equipment downtime.

ID328.6

Maintenance Management Based on Organization Maturity Level

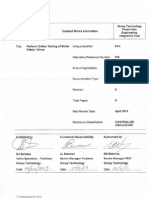

Table 1 Maintenance Strategy Organization

Company

Sector

Maintenance Policie Prevailing

Maintenance Organizational & Planning

Maintenance KPI Management

Maitenance Training

Paper

Corrective

Spreadsheet

Not Available

Low

Electronics

Corrective

Spreadsheet

Not Available

Low

Electronics

Corrective and preventive

Spreadsheet

Basic KPI's: MTBF, Costs and Availability

Medium

Electronics

Corrective and preventive

Spreadsheet

Not Available

Low

Air Conditioner

Corrective

Spreadsheet

Not Available

Low

Naval

Corrective

Spreadsheet

Not Available

Low

Naval

Corrective

Spreadsheet

Not Available

Low

Electronics

Corrective and preventive

Spreadsheet

Basic KPI's: MTBF, Costs and Availability

Low

Electronics

Corrective

Not Available

Not Available

Low

10

Paper

Corrective and preventive

Spreadsheet

Not Available

Low

11

Electronics

Corrective and preventive

Spreadsheet

Basic KPI's: MTBF, Costs and Availability

Low

12

Motorcycle

Corrective and preventive

Spreadsheet

Not Available

Medium

13

Electronics

Maintenance Engineering

CMMS

Basic KPI's: MTBF,MTTR, Costs and Availability

Medium

14

Paper

Corrective

Spreadsheet

Not Available

Low

15

Personal Care

Corrective and preventive

Spreadsheet

Basic KPI's: MTBF, Costs and Availability

Medium

16

Government

Corrective

Not Available

Not Available

Low

17

Air Conditioner

Corrective and preventive

Spreadsheet

Not Available

Low

18

Electronics

Corrective

Spreadsheet

Not Available

Low

19

Electronics

Corrective and preventive

Spreadsheet

Basic KPI's: MTBF, Costs and Availability

Medium

20

Metallurgical

Corrective

Spreadsheet

Not Available

Low

A percentage of 5% adopt management models based on engineering maintenance, although initiatives

to implement TPM (Total Preventive Maintenance) and RCM (reliability centered maintenance) have been

implemented without success.

100%

80%

60%

50%

45%

40%

20%

5%

0%

0%

Corrective

Preventive &

Corrective

Maintenance

Engineering

Predictive

Figure 3 Maintenance Policies

Furthermore, regarding planning of maintenance activities, a percentage of 85% companies use

spreadsheets to support the management and control of maintenance activities as indicated by figure 4.

This ongoing research aims in the future to propose a simple and economical information system to make

the maintenance management processes equally simple, objective and efficient, a system enabling the

user to use 100% of its operating capacity. The management system will support the manager in more

responsive decision-making based on results presented for a certain period of time.

100%

80%

60%

40%

20%

0%

85%

Spreadsheet

10%

5%

No System

CMMS

Figure 4 Maintenance Organization & Planning

Concerning the application of maintenance indicators, to better define maintenance strategies, the study

reveals a reduced utilization which can point to a lack of skills and knowledge of the team about concepts

related to management and control activities of maintenance (see figure 5).

Besides, companies that have any kind of indicators use MTBF, MTTR, Availability and Costs for

maintenance management.

ID328.7

ICIEOM 2012 - Guimares, Portugal

100%

70%

30%

50%

0%

No KPI

KPI Utilization

Figure 5 Maintenance KPI

Nevertheless, most companies show a little investment in staff qualification, either in aspects related to

technical activities, whether in concepts related to maintenance management, as shown in figure 6. Low

level training is considered when the company maintenance crew has minimal information about

maintenance activities and poor knowledge about equipment and process, with no investment in

qualification. For medium level training the crew has enough concepts about process and equipment and

some investment is made to qualify them. For high level training, the crew has strong knowledge about

process, equipments, management tools, clear failure analyses methodologies and investment in

qualification.

100%

75%

50%

25%

0%

0%

Low

Medium

High

Figure 6 Maintenance Training

Proposed dimensions and levels for maintenance maturity assessment

The maintenance function can be analyzed and evaluated in order to propose a gradual progress in the

pursuit of world class performance, increasing the operational availability company equipment, its

productivity and intellectual capital of technical teams for maintenance management.

Based on the study presented in the previous section and on experience, dimensions and levels for

maturity assessment was defined and presented in table 2.

Maturity grid proposed so far covers quality dimensions and this study intends to provide criteria to

identify the current maturity level and the steps to move forward to high maturity levels.

Table 2 - Proposal for dimensions and levels of maturity

Dimension

Low maturity

Medium maturity

Maintenance Strategy

Corrective

strategy only

Corrective

strategy

KPIs (Availability,

MTTR)

Not available

MTBF, MTTR, Costs, Availability

MTBF, MTTR, Costs, Availability,

OEE, Reliability, Training Rate,

Failure Rate

Maintenance Data System

(CMMS)

No CMMS

Spreadsheet

CMMS

Customized CMMS

Technical

(culture)

Corrective

mind

Use preventive tools such as

FMEA, 8D

Use failure analysis tools, such as

FMEA, 8D, RCA, FTA, Reliability

Model

Not Available

TPM

TPM,

RCM,

Engineering

Competences

Management Models

ID328.8

MTBF,

High maturity

and

Preventive

or

General

Predictive strategy

Maintenance

Maintenance Management Based on Organization Maturity Level

Finally, this assessment allows us to establish criteria and steps to support companies to move from low

performance to world class performance in maintenance management due to clear strategy and

commitment, according to figure 7.

Figure 7 - Maturity level upgrade in organizations

Then, based on the research proposal, most surveyed companies can be classified as organizations that

are in an initial maturity stage, as showed in figure 8.

5% 0%

Low Maturity

95%

Medium Maturity

High Maturity

Figure 8 Maintenance Management Strategy

Conclusion and future work

A systematic way to understand the steps in a process of maintenance management activities should

emphasize the existence of an effective planning and monitoring of activities using the most appropriate

resource and applying the more advantageous tool and techniques. The proposed maturity model will

allow defining the more appropriate strategy and maintenance tool, techniques and indicators for each

level.

The effectiveness of the maintenance function in an industrial unit depends on the equipment involved,

the training of personnel, and mainly on the adopted strategy for maintenance management. In addition

to modern equipment, it is necessary to understand the concern about flaws, in its details, in order to

attack not the consequences but the causes using the most appropriate tools and techniques.

Additionally, the use of complex computer systems generally do not simplifies the maintenance

management, because it takes a long time in the design, analysis and storage of information, which

suggests studying the development of a more simple and straightforward system.

In the ongoing research, it is intended to develop a computer system which allow both the determination

of some vital rates (such as the frequency of failure, time to resolution of a given problem, availability,

cost) and the formation of action plans for maintenance improvement using tools such as FMEA's and

8D.

ID328.9

ICIEOM 2012 - Guimares, Portugal

Most companies have a basic level of maintenance management which means that they have

opportunities to make improvements and to obtain important gains. They have also the capacity to

become more competitive, increasing throughput and reducing losses.

As future activities, the maturity model dimensions and levels will be validated and the steps needed to

move forward to higher maturity level will be defined.

References

Assis, R. (2010). Decision support in maintenance management of physical assets. 1st edition. Portugal: Lidel Edies

Tcnicas Ltda.

Cabral, J. P. S. (2006). Organization and Maintenance Management: from concepts to practice. 6st edition. Portugal:

Lidel Edies Tcnicas Ltda.

Cuignet, R. (2006). Maintenance Management: Improve operational and financial performance of its maintenance.

Portugal: Lidel Edies Tcnicas Ltda.

Crosby, P. B. (1979). Quality is free: The art of making quality certain. New York, NY: McGraw-Hill Companies.

Crosby, B.P. (1990). Quality : Seriously. So Paulo: McGraw-Hill Companies.

Clarke, A., & Garside, J. (1997). The development of a best practice model for change management. European

Management Journal, 15, no. 5.

Clarkson. J. P., Maier, A. M. & Moultrie, J.(2009). Development maturity grids for assessing organizational capabilities:

Practitioner guidance. University of Cambridge.

Fernandez, O. & Labib, W. (2003). A decision support maintenance management system: Development and

Implementation. International Journal of Quality & Reliability Management, Vol.20, No 8, pp. 965-979.

Filho, G. B.(2006). Maintenance Indicators. Rio de Janeiro, RJ: Editora Cincia Moderna.

Garg, A. & Deshmukh, S. G. (2006). Maintenance management: literature review and directions. International Journal

of Quality in Maintenance, Vol.12, pp. 205-238.

Higgins, L. R., & Mobley, K. R. (2001). Maintenance Engineering Handbook. New York, NY: McGraw-Hill.

Kardec, A., & Lafraia, J. R. (2002). Maintenance: Strategic Management and Reliability. So Paulo, SP: Qualitymark

Editora.

Kardec, A., & Nascif, J. (2002). Maintenance: Strategic Management. So Paulo, SP: Qualitymark Editora.

Kaplan R. & Norton, D. (1996). The balanced scorecard: Translating strategy into actions. Boston, MA: Harvard

Business School Press.

Kans, M. & Ingwald, A. (2007). Commom data base for cost-effective improvement of maintenance performance.

International Journal of Production Economics, Vol.113, pp. 734-747.

Lafraia, J. R. B. (2001). Reliability, Mantenability and Availability Guidance. Rio de Janeiro, RJ: Qualitymark Editora Ltda.

Levitt, J. (1997). The Handbook of Maintenance Management. New York, NY: Industrial Press Inc.

Munk, L. (1999). The effective formation of work teams: An approach in the light of organizational changes. Master

Tesis, Santa Catarina federal University, 115 pgs.

Europe Standard EN15341:2009. Maintenance: maintenance performance indicators (KPI). Quality Portuguese

Institute, 30 pgs.

SAE JA 1011:1999 Standard. Evaluation criteria for process reliability-centered maintenance. Consulting on

18/08/2010, available at http://www.sae.org.

Nunes, P. (2008). Concept of Argyriss Maturity Theory. Consulting on 02/06/2010, available at

http://www.knoow.net/cienceconempr/gestao/teoriamaturidadeargyris.htm.

Semitan, M. C., Oliveira, M. A. & Maciel, E. L. F.(2009). 9 International Reliability Symposium: RCM: Asset effectiveness

management Case. Curitiba, PR: Reliasoft Co.

Weber, A. & Thomas, R. (2005). Key performance indicators: Measuring and Managing the Maintenance Function.

Consulting on 10/08/2010, available at http://www.plant-maintenance.com/articles/KPIs.pdf.

ID328.10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Writing White PapersDocument194 pagesWriting White PapersPrasannaYalamanchili80% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Safety Relief Valve Set Pressure and Seat Leakage TestDocument30 pagesSafety Relief Valve Set Pressure and Seat Leakage TestAnonymous ffje1rpa100% (1)

- Numatics Valve TrainingDocument57 pagesNumatics Valve TrainingRaymond EsmeraldaNo ratings yet

- Additel 918 ManualDocument2 pagesAdditel 918 ManualAnonymous ffje1rpaNo ratings yet

- GOSeDocument9 pagesGOSeAnonymous ffje1rpaNo ratings yet

- 01-Beginning Vibration AnalysisDocument153 pages01-Beginning Vibration AnalysisAnonymous ffje1rpa100% (1)

- Presentacion IlearnDocument38 pagesPresentacion IlearnAnonymous ffje1rpaNo ratings yet

- C1 Compressor: Plant CharleroiDocument9 pagesC1 Compressor: Plant CharleroiAnonymous ffje1rpaNo ratings yet

- Balancing: One Plane/two PlanesDocument19 pagesBalancing: One Plane/two PlanesAnonymous ffje1rpaNo ratings yet

- Shaft Alignment: Nizwa College of TechnologyDocument15 pagesShaft Alignment: Nizwa College of TechnologyAnonymous ffje1rpaNo ratings yet

- Cooler Drain LocationDocument1 pageCooler Drain LocationAnonymous ffje1rpaNo ratings yet

- Chapter 1 Ref CyclesDocument31 pagesChapter 1 Ref CyclesAnonymous ffje1rpaNo ratings yet

- 077instrument Calibration RecordDocument100 pages077instrument Calibration RecordAnonymous ffje1rpaNo ratings yet

- Advanced NDT 2Document56 pagesAdvanced NDT 2Anonymous ffje1rpa83% (6)

- Acid Cleaner Life ExtensionDocument33 pagesAcid Cleaner Life ExtensionAnonymous ffje1rpaNo ratings yet

- Sadat City Factories List 2009Document39 pagesSadat City Factories List 2009Anonymous ffje1rpaNo ratings yet

- 4.hydrogen Generator System and FunctionsDocument4 pages4.hydrogen Generator System and FunctionsAnonymous ffje1rpaNo ratings yet

- Basic-Concepts MTBFDocument15 pagesBasic-Concepts MTBFAnonymous ffje1rpaNo ratings yet

- Aps Loto Sample 2014Document4 pagesAps Loto Sample 2014Anonymous ffje1rpaNo ratings yet

- Detail WI Online TestingDocument9 pagesDetail WI Online TestingAnonymous ffje1rpaNo ratings yet

- Manufacturer Tmagpumps Model AM Series Motor E.X Power 1/4 HP Flow Rate 24 GPM Fluide Different ChemicalsDocument1 pageManufacturer Tmagpumps Model AM Series Motor E.X Power 1/4 HP Flow Rate 24 GPM Fluide Different ChemicalsAnonymous ffje1rpaNo ratings yet

- ROTAREX Przeglad ProduktowDocument2 pagesROTAREX Przeglad ProduktowAnonymous ffje1rpaNo ratings yet

- Lubricating Oil Monthly ReportDocument2 pagesLubricating Oil Monthly ReportAnonymous ffje1rpaNo ratings yet

- Harmonic Distortion CSI-VSI ComparisonDocument4 pagesHarmonic Distortion CSI-VSI ComparisonnishantpsbNo ratings yet

- U90 Ladder Tutorial PDFDocument72 pagesU90 Ladder Tutorial PDFMarlon CalixNo ratings yet

- Jurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Document9 pagesJurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Yogi TioNo ratings yet

- PSA Technology-More Than A Hydrogen Purifier: TOBIAS KELLER and GOUTAM SHAHANI, Linde EngineeringDocument2 pagesPSA Technology-More Than A Hydrogen Purifier: TOBIAS KELLER and GOUTAM SHAHANI, Linde EngineeringChem.EnggNo ratings yet

- Eco SPARDocument3 pagesEco SPARMohammad LabinNo ratings yet

- PepsiCo Strategic Plan Design PDFDocument71 pagesPepsiCo Strategic Plan Design PDFdemereNo ratings yet

- Business Ethics Final Work Brief 2Document6 pagesBusiness Ethics Final Work Brief 2KALIZA TRESSY MEGHANNo ratings yet

- What Is Highway EngineeringDocument4 pagesWhat Is Highway EngineeringNagesh SinghNo ratings yet

- Management Thoughts Pramod Batra PDFDocument5 pagesManagement Thoughts Pramod Batra PDFRam33% (3)

- W6 Lesson 7 Find, Evaluate, and Use Online Information ResourcesDocument14 pagesW6 Lesson 7 Find, Evaluate, and Use Online Information Resourcescharimaine hernandezNo ratings yet

- Difference Between Art. 128 and 129 of The Labor CodeDocument3 pagesDifference Between Art. 128 and 129 of The Labor CodeKarl0% (1)

- Revised Full Paper - Opportunities and Challenges of BitcoinDocument13 pagesRevised Full Paper - Opportunities and Challenges of BitcoinREKHA V.No ratings yet

- Presentation - 02 Reliability in Computer SystemsDocument24 pagesPresentation - 02 Reliability in Computer Systemsvictorwu.ukNo ratings yet

- Lezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityDocument26 pagesLezione Argiolu - Master Roma3!3!12-2010 - Test Di Application SecurityWB_YeatsNo ratings yet

- Puch Moped Horn Wiring Diagram (Chrome Oval Switches)Document1 pagePuch Moped Horn Wiring Diagram (Chrome Oval Switches)MopedgalNo ratings yet

- Unilift de DGDDocument36 pagesUnilift de DGDLove SemsemNo ratings yet

- Saraswathi 2018Document4 pagesSaraswathi 2018Daniel CoronelNo ratings yet

- Chapter 9 CompensationDocument24 pagesChapter 9 CompensationSophie CheungNo ratings yet

- Sample Rubrics MakingDocument4 pagesSample Rubrics MakingKerstmis “Scale” NataliaNo ratings yet

- FIN323 Project 2021-2022Document6 pagesFIN323 Project 2021-2022saleem razaNo ratings yet

- Ems Accounting Term 2Document39 pagesEms Accounting Term 2Paballo KoopediNo ratings yet

- Guide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCDocument12 pagesGuide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCLennike SantosNo ratings yet

- BPV ApproachDocument13 pagesBPV ApproachfwfsdNo ratings yet

- Vol II - PIM (Feasibility Report) For Resort at ChorwadDocument42 pagesVol II - PIM (Feasibility Report) For Resort at Chorwadmyvin jovi denzilNo ratings yet

- Invoice SummaryDocument2 pagesInvoice SummarymuNo ratings yet

- Lower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & AboveDocument2 pagesLower Gasket Kit (S/N E/ 9Fz999 & Below) : Model Number: 335 Serial Number: A9KA11001 & Above, AAD111001 & Abovezeeshan tanveerNo ratings yet

- Ranbaxy Acquisition by DaiichiDocument9 pagesRanbaxy Acquisition by Daiichirupe59No ratings yet

- My Linux Attack Commands-ADocument51 pagesMy Linux Attack Commands-Aapogee.protectionNo ratings yet

- Regulator With NRVDocument2 pagesRegulator With NRVBiswanath LenkaNo ratings yet