Professional Documents

Culture Documents

C1 - Control of Parallel Connected Inverters...

Uploaded by

Manjunath KallamadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C1 - Control of Parallel Connected Inverters...

Uploaded by

Manjunath KallamadiCopyright:

Available Formats

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 29, NO.

1, JANUARYIFEBRUAKY 1993

136

Control of Parallel Connected Inverters

in Standalone ac Supply Systems

Mukul C. Chandorkar, Student Member, IEEE, Deepakraj M.

Divan, Member, IEEE, and Rambabu Adapa, Senior Member, IEEE

Abstract-A scheme for controlling parallel-connected invertJnvener

ers in a standalone ac supply system is presented in this paper.

This scheme is suitable for control of inverters in distributed

source environments such as in isolated ac systems, large and

distributed uninterruptible power supply (UPS) systems, photovoltaic systems connected to ac grids, and low-voltage dc power

""

transmission meshes. A key feature of the control scheme is that

Fig. 1. Inverter connected to stiff ac system.

it uses feedback of only those variables that can be measured

locally at the inverter and does not need communication of control

signals between the inverters. This is essential for the operation

of large ac systems, where distances between inverters make for power transmission have traditionally been current sourced,

communication impractical. It is also important in high-reliability in recent years, voltage source inverters (VSI) have been

UPS systems where system operation can be maintained in the increasingly used for high-power applications like electric

face of a communication breakdown. Real and reactive power traction and mill drives, photovoltaic power systems, and

sharing between inverters can be achieved by controlling two battery storage systems. Control schemes for VSI's in power

independent quantities-the power angle, and the fundamental

inverter voltage magnitude. Simulation results obtained with the system environments have formed the topic of recent work

[2]. Further, with inverter topologies like the neutral-point

control scheme are also presented.

I. INTRODUCTION

S DC TO AC power converters feeding power to ac supply systems become more numerous, the issues relating

to their control need to be addressed in greater detail. Inverters

connecting dc power supplies to ac systems occur in numerous

applications. Photovoltaic power plants and battery storage

installations are examples of such applications. In either case,

the inverter interfaces could be connected to a common ac

system. Distributed uninterruptible power supply (UPS) systems feeding power to a common ac system are also possible

examples. In addition, over the past several years, there has

been considerable interest in applying inverter technology to

low voltage dc (LVDC) meshed power transmission systems.

The feasibility from the control viewpoint of an LVDC mesh

has been demonstrated in [l]. The transmission system could

typically consist of inverters connected at several points on

the LVDC mesh, providing power to ac systems that could

be interconnected as well. Multiple inverters connected to a

common ac system essentially operate in parallel and need to

be controlled in a manner that ensures stable operation and

prevents inverter overloads. Although inverter topologies used

Paper IPCSD 92-16, approved by the Industrial Power Converter Committee

of the IEEE Industry Applications Society for presentation at the 1991 Industry

Applications Society Annual Meeting, Dearborn, MI, September 28-October

4. This work was supported by NSF grant 8 818 339 and EPRI Agreement

RP7911-12. Manuscript released for publication April 25, 1992.

M. C. Chandorkar and D. M. Divan are with the Department of Electrical

and Computer Engineering, University of Wisconsin, Madison, WI 53706.

R. Adapa is with the Electric Power Research Institute, Palo Alto, CA

94303.

IEEE Log Number 9204199.

clamped (NPC) inverter [3], it is possible to achieve substantial harmonic reduction at reasonably low PWM switching

frequencies.

A standalone ac system may be described as one in which

the entire ac power is delivered to the system through inverters.

In a standalone ac system, there are no synchronous alternators

present in the system that would provide a reference for the

system frequency and voltage. All inverters in the system need

to be operated to provide a stable frequency and voltage in the

presence of arbitrarily varying loads. This paper first develops

a control method for an inverter feeding real and reactive

power into a stiff ac system with a defined voltage, as shown

in Fig. 1. This forms the basis of a control method suitable for

standalone operation. The inverter is a VSI with gate turn-off

(GTO) thyristor switches, operating from a dc power source,

and feeding into the ac system through a filter inductor. In

a standalone system, a filter capacitor is needed to suppress

the voltage harmonics of the inverter. The requirements for

controlling such an interface are described in the next section.

Later sections describe the development of an effective control

scheme to meet these requirements and present simulation

results obtained from the study of a power distribution system

with parallel-connected inverters.

11. REQUIREMENTS OF THE CONTROL SYSTEM

The control of inverters used to supply power to an ac

system in a distributed environment should be based on

information that is available locally at the inverter. In typical

power systems, large distances between inverters may make

communication of information between inverters impractical.

Communication of information may be used to enhance system

0093-9994/93$03.00 0 1993 IEEE

CHANDORKAR er al.: CONTROL OF PARALLEL-CONNECTED INVERTERS

137

P = X!L sin6

Q=

Lf

Lf

- =cos6

w Lf

Fig. 2. Real and reactive power flows.

performance but must not be critical for system operation. This

essentially implies that inverter control should be based on

terminal quantities.

It is well known that stable operation of a power system

needs good control of the real power flow P and the reactive

power flow Q. The P and Q flows in an ac system are

decoupled to a good extent [4]. P depends predominantly on

the power angle, and Q depends predominantly on the voltage

magnitude. This is illustrated in Fig. 2. It is essential to have

good control of the power angle and the voltage level by means

of the inverter. Control of frequency dynamically controls

the power angle and, thus, the real power flow. To avoid

overloading the inverters, it is important to ensure that changes

in load are taken up by the inverters in a predetermined manner

without communication. This is achieved in conventional

power systems with multiple generators by introducing a droop

in the frequency of each generator with the real power P

delivered by the generator [4]. This permits each generator to

take up changes in total load in a manner determined by its

frequency droop characteristicsand essentially utilizes the system frequency as a communication link between the generator

control systems. In this paper, the same philosophy is used to

ensure reasonable distribution of total power between parallelconnected inverters in a standalone ac system. Similarly, a

droop in the voltage with reactive power is used to ensure

reactive power sharing.

An important aspect of the control methodology developed

here is that it is highly modular in nature. Thus, the basic

control scheme can be very easily adapted to meet variations in

the configuration of the power system, as shown in Sections 111

and IV. This modularity is achieved by choosing the controlled

quantities of the slow, outer control loops to meet the dictates

of the power system configuration while maintaining the same

fast, inner inverter control structure. The controller for an

inverter connected to a stiff ac system, which is detailed

in Section 111, is easily modified for the control of parallelconnected inverters feeding a standalone ac system, which is

detailed in Section IV.

111. CONTROL OF SINGLE INVERTER

FEEDINGINTO A STIFF SYSTEM

The power schematic of Fig. 1 shows a single inverter

connected to a stiff ac system through a filter inductor.

The inverter is assumed to be a six-pulse GTO VSI. This

section details the control of the inverter based on feedback

of quantities measured locally at the inverter. The real and

reactive power fed into the ac system are the two variables that

are controlled by the inverter. Given set points for the real and

V

d

1 :Inverter Voltage Vwtor 1

0:

S e I For Choice of Inverter Voltage Vector

(a)

(b)

Fig. 3. (a) Inverter output voltage vectors; (b) inverter switch positions.

reactive power P* and Q*, the real and reactive power P and

Q fed by the inverter into the ac system can be controlled by

a method that controls the time integral of the inverter output

voltage space vector. This concept has previously been applied

extensively to ac motor drives [ 5 ] , [6]. The entire control of

the inverter is performed in the stationary d-q reference frame

and is essentially vector control. The transformation from the

physical a-b-c reference frame to the stationary d-q-n reference

frame is described by the following equations [7].

In these equations, the quantity f generically denotes a

physical quantity, such as a voltage or a current. In the absence

of a neutral connection, the quantity fn is of no interest. For

a six-pulse VSI, the inverter output voltage space vector can

take any of seven positions in the plane specified by the d-q

coordinates. These are shown in Fig. 3 as the vectors 0-6.

The time integral of the inverter output voltage space vector

is called the inverter flux vector for short. The flux vector

does not have the same significance as in motor applications.

Rather, it is a fictitious quantity related to the volt-seconds in

the filter inductor. The d and q axis components of the inverter

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 29, NO. 1, JANUARY/FEBRUARY 1993

138

PI

L o w Pass

Filter

Regulator

P' & Q* : Set Points for Real & Reactive Power

Fig. 4. Inverter control scheme-stiff

flux vector

are defined as

1

t

$du

Vddr

(4)

ac system.

In (9), e, and e d are the q- and d-axis components, respectively, of the ac system voltage vector E. In addition, i, and i d

are the components of the current vector 7. When i , and i d are

expressed in terms of the fluxes, the equation is expressed as

--CO

/

t

$,U

(5)

--CO

The magnitude of

& is

Taking into account the spatial relationships between the

two flux vectors and assuming the ac system voltage to be

sinusoidal, (10) can be expressed as

3

p = - w$,$, sin 6,.

2L.f

The angle of

5with respect to the y axis is

In this expression,

and

are the magnitudes of the ac

system and the inverter flux vectors, respectively, and 6, is the

6, = tan-' (7) spatial angle between the two flux vectors. w is the frequency

of rotation of the two flux vectors. The expression for reactive

The d and y axis components of the ac system voltage flux power transfer for Fig. 1 can be derived in a similar manner.

vector

its magnitude, and angle are defined in a similar This is

and

is defined as

manner. The angle between

3 w

(12)

Q = - -[$U$, COS - 7 / 5 3 .

6, = 6, - Se.

2 L.f

(8)

.I::(

5,

Control of the flux vector has been shown to have good

dynamic and steady-state performance [5],[6]. It also provides

a convenient means to define the power angle since the inverter

voltage vector switches position in the d - y plane, whereas

there is no discontinuity in the inverter flux vector. It is useful

to develop the power transfer relationships in terms of the

flux vectors. The basic real power transfer relationship for the

system of Fig. 1 in the d-q reference frame is

3

P = -(eqi,

2

+edid).

(9)

Equations (11) and (12) indicate that P can be controlled

by controlling S,, which can be defined as the power angle,

and Q can be controlled by controlling &,. The cross coupling

between the control of P and Q is also apparent from these

equations.

The control system for the inverter is given in Fig. 4. The

two variables that are controlled directly by the inverter are

is controlled to have a specified

and 6,. The vector

magnitude and a specified position relative to the ac system

This control forms the innermost control loop

flux vector

and is very fast. It is noted that both the inverter and the

6.

CHANDORKAR et al.: CONTROL OF PARALLEL-CONNECTED INVERTERS

139

"

TABLEI

CHOICEOF SWITCHINGVECTOR

Sector No. (Location of

I

z)

I I m r v v v 1

Increase

Decrease &

(The zero vector is chosen to decrease 4,)

.ii

33

N

ac system voltage space vectors ,are obtained by measuring

instantaneous voltage values that are available locally. The set

points for the controller are P* and Q*, and the set points for

the innermost control loop $: and 6; are derived from these.

The actual values of P and Q calculated from the feedback are

compared with the set values. The error drives a proportionalintegral (P-I) regulator, which generates the set points $; and

6; for the innermost control loop. The control of the inverter

to generate the specified $, and 6, is detailed in the next

subsection.

0

10

c>

LIU 0

- 6 00

-2.011

2 00

h v

In

6 00

11

VS

Fig. 5. Inverter flux vector.

0

A. Control of $, and 6,

The control of 4, and 6, forms the first level of control

and directly controls the inverter switching. The choice of

the inverter switching vector is made on the basis of the

deviations of $,, and 6, from the set values $: and 6;

and the position of the inverter flux vector in the d-q plane

given by 6,. If the deviation of 6, from 6; is more than

a specified limit, a zero switching vector is chosen. If this

deviation is less than a specified limit or if $, deviates from

$: by more than a specified amount, a switching vector that

increases 6, and changes $, in the correct direction is chosen.

This is essentially accomplished by hysteresis comparators for

the set values and then using a look-up table to choose the

correct inverter output voltage vector. The considerations for

developing the look-up table are dealt with in [ 5 ] . The choice

' 1.694

1l.727

1l.760

1'.794

1l.827

s 1'.860

T *10-1

of inverter switching vector is dictated by the value of 6,.

Fig. 6. Inverter voltage and current waveforms.

The d-q plane is divided into six sectors for 6, as shown in

Fig. 3(a), which also shows the inverter switching vectors.

The inverter switch positions for the vectors are shown in Fig. the power system of Fig. 1 are presented in Figs. 5-7. The dc

3(b). The value of 6, determines the choice of two possible bus voltage is taken to be 10 kV, and the line-to-line voltage

inverter switching vectors apart from the zero vector. One of the ac system is taken to be 3.3 kV rms. The inductor L

vector increases the magnitude $,, and the other decreases is 17 mH. Fig. 5 gives the plot of the locus of the inverter

it, whereas both tend to increase 6,. Thus, to decrease 6,, the flux vector

The locus is seen to be close to a circle since

zero switching vector is chosen. To correct the value of $,,, the magnitude $, is very tightly controlled. Fig. 6 shows the

one of the two active switching vectors is chosen, depending inverter line-to-line voltage ?& and the inverter line current iu

on the sign of the correction required. Table I gives the choice for P* = 1MW and Q* = 500 kvar. Fig. 7 shows the response

of active vectors for given positions of the inverter flux vector, of the inverter to step changes in Q* and P*, successively. It

which is specified by 6,. In this manner, $, and 6, are tightly is noted that there is a disturbance in P when Q* is changed

controlled to lie within specified hysteresis bands by means and a disturbance in Q when P* is changed. In each case, the

of inverter switching. The tip of the inverter flux vector is P-I regulators modify the set values of :

6 and 4,: to main

guided along an almost circular path. Control of $, and 6, the P and the Q at the set values. In addition, the tight contro

in this manner results in a PWM voltage waveform at the of P and Q within limits is apparent from Fig. 7.

inverter output.

I v . CONTROL OF INVERTERS IN A STANDALONE SYSTEM

B. Simulation Results

The control of a single inverter feeding a stiff ac system

-

6.

Simulation results of the control scheme of Fig. 4 applied to

based only on instantaneous measurement of terminal quanti-

140

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 29, NO. 1, JANUARYFEBRUARY 1993

frequency of

are obtained from the outermost loop, which

implements specified droop characteristics for the frequency

with P and magnitude with Q, as mentioned in Section 11. The

entire control is, thus, a three-level structure. The innermost

control level controls

and 6, and is the same as that

described in the previous section. The second level controls

the ac side frequency and the voltage at each inverter and

6 and $: for the innermost level. The

provides set points :

third level computes the set points for frequency and voltage

for each inverter. The two outer control levels are described

below.

A. Control of Frequency and Voltage

ol

0.02

0.06

0.11

0.15

0.20

0.25

Fig. 7. Inverter real and reactive power.

The frequency controller determines the setpoint 6; that is

needed to attain the specified frequency. The structure of the

frequency controller is given in Fig. 10. The frequency setting

w* is integrated to obtain a reference for the position 6:c of

the ac system voltage vector across the filter capacitor. This

is compared with the actual position Sa, of E. The error is

used to drive a P-I regulator, which produces the setpoint

a,: which is given to the innermost control loop described

previously. This scheme achieves a very tight control of the

output frequency since the regulator attempts to control the

output voltage vector angle at every instant.

The voltage controller determines the setpoint $: that is

needed to attain the specified ac system voltage magnitude.

The voltage controller needs to take care of the filter dynamics

to determine the exact value of $:. The structure of the voltage

controller is given in Fig. 11. The controller command input

is E*, which is the specified value of the magnitude of F.

The controller consists of a command feedforward term and a

voltage magnitude feedback term. The command feedforward

term is given by

Fig. 8. Standalone ac system.

ties now forms the basis of the control scheme for multiple

inverters in standalone system environments. The essential

difference in the control scheme is that in the standalone

system, there is no ac side voltage available for reference. The

inverters themselves produce the ac system voltage, which is

fed back to control the inverters. There is thus a possibility

of controlling the voltage and the frequency of the ac system

by inverter control. Fig. 8 shows two inverters feeding into

a standalone ac system. The inverters are interfaced to the ac

system through LC filters. The two inverters are connected by

a tie line, and each inverter has a local load. The dc power

source represents a 10-kV dc power transmission mesh. The

nominal voltage on the ac system is 3.6 kV rms line to line, and

the nominal frequency is 60 Hz. Each inverter is a six-pulse

VSI made up of GTO switches.

Fig. 9 shows the block diagram of the control of inverters

in a standalone system. As in the single inverter case, the two

and 6, for each

variables that are directly controlled are

inverter. Middle control loops are then used to control the

magnitude and angular frequency of the ac system voltage

vector E. The set points f o r the magnitude and angular

The command feedforward gives the value of $: needed to

achieve the specified E* with an unloaded filter and is intended

to speed up the voltage control loop. The voltage magnitude

feedback term is used to generate an error signal that actuates

a P-I controller. The resultant value of $: is used as a setpoint

for the innermost control loop described previously.

The ac system frequency w is computed six times in one

cycle. For this purpose, six axes are defined in the d-q plane.

The time taken by the vector E to cross from one axis to

the next consecutive axis is used to compute the frequency.

For parallel operation of multiple inverter units, the setpoints

w* and E* need to be chosen to ensure the correct P and

Q sharing between the inverters in response to arbitrary load

changes. This has to be done without communication of the

setpoints between the two inverter systems. The next subsection describes the outermost control loop, which determines the

setpoints w* and E* for each inverter system independently

without any signal communication. This is done on the basis

of the real andreactive power loading of the inverter systems.

CHANDORKAR

et

al.: CONTROL OF PARALLEL-CONNECTED INVERTERS

Outer hop: Droop Characteristics

---

I - - -

---

--

Middle Loop: E and o

--

I

I

J

,

Feedback ' PandQ &E*=f(Q)

Voltage

Innerbop:

---

Droops

AC System

141

SYStelll

Voltage

Vector

_--

--T--

E*

Inverter

oand

+ Flux

Control

Calc.

Vector

vvand

_--

Sp

---

WV

vv*

Inverter

-1

I

I

Vector

Control

+Inverter

Switches

1-

I

AC System Voltage

Feedback

Inverter Voltage

Feedback

E

Fig. 9. Inverter control scheme-standalone

ac system.

slopes m, for different inverters are chosen such that

*

0'

mlPo2 = maPo2 = ... = mnPon

sx

From Filter Output

Fig. 10. Frequency controller for standalone system.

(14)

then for a total power P , the load distribution between the

inverters satisfies the relationships

mlP1 = mzP2 = ... = mnPn

(15)

By choosing the slopes according to (14), it can be ensured

that load changes are taken up by the inverters in proportion

to their power ratings. The power-sharing mechanism can

Fig. 11. Voltage controller for standalone system.

be best understood by considering the two-inverter system

shown in Fig. 8. An increase in power drawn by the load

B. Computing w* and E* for Parallel Operation

near Inverter 2 results in increased power from both inverters.

The outermost loop determines the setpoints for w* and If the magnitude of m2 is larger than that of m l , w; would

E* to ensure correct real and reactive power sharing between tend to drop lower than w:. Hence, the vector Fz would lag

the parallel connected inverters. This action is similar to that the vector El, and the power flow in the tieline from Inverter

used in conventional power systems to ensure the correct load 1 to Inverter 2 would increase. Thus, Inverter 1 would take

sharing between generators feeding to a common ac system up a larger proportion of the load. It is possible to define

[4].For the frequency set point, a droop is defined for the P- a composite power-frequency curve for all the inverters in

w* characteristic of each inverter. The frequency set point is the system. The composite load curve is likewise defined.

thus made to decrease with increasing real power supplied by At the steady-state operating point on the composite loadthe inverter. The P-U* droop characteristic can be described frequency curve, the total power delivered by the inverters

matches the power consumed by the loads. Depending on the

by

stiffness of the composite power-frequency curve, the steadywt = W O - m,(Po; - P,) = g,(P).

(13)

state system frequency will change on changing loads. The

frequency may then be restored to its nominal value by a

In this expression, i = 1 for inverter 1, and i = 2 for slower outer loop. To restore the frequency, the value of Po;,

inverter 2 (Fig. 8). W O is the nominal operating frequency of (13) has to be modified for the inverters. This is equivalent to

the ac system and is taken to be 377 rads (60 Hz). Po, is the shifting the power-frequency curve vertically. The restoration

power rating of the ith inverter, and P, is its actual loading. of the frequency may be done in a slow, coordinated manner

The slope of the droop characteristic is m, and is numerically by a master controller, using a slow communication channel

negative. The values of m; for different inverters determine between the inverters.

In a similar manner, the setpoints E,* for the ac system

the relative power sharing between the inverters. In typical

systems, the P-w* characteristics are stiff, and the frequency voltages at the inverter systems can be determined from

change from no load to full load is extremely small. If the drooping reactive power-voltage characteristics (Q-E) for

Regulator

From Filter

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 29, NO. 1, JANUARYIFEBRUARY 1993

142

the inverters. This droop ensures the desired reactive power

sharing between the inverter systems and is described by

Ef = Eo

- n;(Qoi - Q;) = f ; ( P ) .

(17)

In (17), EOis the nominal voltage on the ac system, Qo; is

the nominal reactive power supplied by the ith inverter, and

n; is the slope of the droop characteristic.

The control system described above has been applied to the

standalone system of Fig. 8. The results of simulation studies

are presented below.

C. Simulation Results

For the simulation studies, the droops of the two inverter

systems are characterized by the following parameters:

Pol = 0.75 MW

ml = -1.4 x

Po2 = 0.6

(radls)/W

0.28

U. 24

U.32

U.4U

U.36

MW

mz = -1.75 x

Qol = 0.2 Mvar

Qo2 = 0.1 MVU

n1 = -1.0 x 10-4 V/VX

n2

= -2.0 x

(radls)/W

V/var.

The nominal voltage is 3.6 kV rms line to line, and the

nominal frequency is 60 Hz. The filter components for the

two inverter systems are identical as are the initial load

components. The component values are typical for a lowpower ac system. With reference to Fig. 8, the component

values are

O.ZI1

11.24

0.28

0.32

0.36

U.40

Fig. 12. Inverter real and reactive power (standalone system).

Fig. 12 shows the response of the inverters when the

resistance RE^ (Fig. 8) is decreased suddenly to half its value.

Fig. 12 shows the real and reactive powers supplied by the two

inverter systems to the load. The figure shows that Inverter 1

carries a larger share of the real power since it has a stiffer

slope. Fig. 13 shows the line-to-line voltage across the filter

capacitor of Inverter 1. The plot for the reactive powers in

Fig. 12 shows oscillations. These oscillations are the result of

filter interactions and occur in the absence of active damping

of the loop formed by the two filter capacitors and the tie-line

inductance. These oscillations are not uncommon in power

systems and can be damped by the inverters, given sufficient

inverter bandwidth. One effective means of damping these

oscillations is the introduction of a series active filter [8]

between the capacitor and the ac system bus. As mentioned in

[8], this method presents a low resistance to the fundamental

and a high resistance to harmonics, thus effectively limiting

the harmonic current injection into the ac system. The series

active filter inverter is not expected to handle real power and

can have a reasonably low rating.

' I - L'

U.2U

U.24

0.28

0.32

0.36 S

0.40

Fig. 13. Voltage across Inverter 1 filter capacitor.

V. CONCLUSIONS

This paper has described a method to effectively control

inverters in a standalone ac supply system without any form of

signal communication. The control methodology has a highly

modular structure. This feature enables easy modification of

the controls to meet the requirements of different ac system

structures. The simulation results presented indicate that the

scheme effectively achieves the goals of power sharing in

the presence of arbitrarily changing loads. Active damping in

the loop formed by the filter capacitors and the tieline would

enhance the performance further. The scheme described in this

paper uses P-I regulators to determine the set points for 6;

CHANDORKAR ef al.: CONTROL OF PARALLEL-CONNECTED INVERTERS

and $:. However, the dynamic performance of the system can

be substantially improved if an observer structure is used to

determine the frequency. The position of the ac system voltage

vector can be determined very accurately at any time. This

information can be used to set up a frequency observer, the

output of which would be an estimated frequency. The time

integral of the estimated frequency can be compared with the

actual position of the voltage vector, and the estimated frequency can be modified accordingly. Feedback of the observer

states results in a system with very good dynamic response and

disturbance rejection properties.

In summary, this paper has

discussed control system requirements for inverters interfaced to an ac system, with emphasis on a standalone ac

system

developed a modular control scheme that meets these

requirements without control signal communication between parallel-connected inverters

presented simulations for the control scheme as applied

to an inverter connected to a strong ac system and to two

inverters connected in parallel to a standalone ac system

briefly discussed the issue of filter interaction in the case

of parallel-connected inverters and suggested a method

for minimizing these interactions.

REFERENCES

[ I ] B. K. Johnson, R. H. Lasseter, and R. Adapa, Power control applica[2]

[3]

[4]

[5]

[6]

[7]

[8]

tions on a superconducting LVdc mesh, IEEE Trans. Power Delivery,

vol. 6, no. 3, pp. 1282-1288, July 1991.

L. Angquist and L. Lindberg, Inner phase angle control of voltage

source converter in high power applications, in IEEE PESC Con$ Rec.,

1991, pp. 293-298.

A. Nabae, I. Takahashi, and H. Akagi, A neutral-point-clamped PWM

inverter, IEEE Trans. Industry Applicaitons, vol. IA-17, pp. 518-523,

Sept./Oct. 1981.

A. R. Bergen, Power System Analysis. Englewood Cliffs, NJ: PrenticeHall, 1986.

I. Takahashi and T. Noguchi, A new quick-response and high-efficiency

control strategy of an induction motor, IEEE Trans. Industry Applications, vol. IA-22, pp. 820-827, Sept./Oct. 1986.

M. Depenbrock, Direct self-control (DSC) of inverter-fed induction

machine, IEEE Trans. Power Electron., vol. 3, pp. 420-429, Oct 1988.

T. A. Lipo, Analysis of synchronous machines, course notes, Univ.

of Wisconsin-Madison, 1990.

S. Bhattacharya, D. M. Divan, and B. Banerjee, Synchronous frame

harmonic isolator using active series filter, in Proc. 4th Euro. Con5

Power Electron. Applications (Florence, Italy), 1991, vol. 3, pp. 30-35.

Mukul C. Chandorkar (S90) received the B.Tech.

degree in electrical engineering from the Indian

Institute of Technology, Bombay, India, in 1984 and

the M. Tech. degree in electrical engineering from

the Indian Institute of Technology, Madras, India, in

1987. Since 1989, he has been working on the Ph.

D. program in Electrical and Computer Engineering

at the University of Wisconsin, Madison

From 1984 to 1986, he was with Larsen and

Toubro Limited, Bombay, India, working on the

engineering of cement and chemical plants. He

worked as a design engineer in the power electronics industry in India

during 1988-1989. His primary technical interests are in power electronics

applications to electric machines and to power systems.

143

Deepakraj M. Divan (M83) received the B. Tech

degree in electrical engineering from the Indian

Institute of Technology, Kanpur, India, in 1975. He

also received the M.Sc and Ph.D degrees in electrical engineering from the University of Calgary,

Canada.

He has worked for two years as a Development

Engineer with Philips India Ltd. After finishing his

Masters program in 1979, he started his own concem in Pune, India, providing product development

and manufacturing services in the power electronics

and instrumentation areas. In 1983, he joined the Depa&ent of Electrical

Engineering at the University of Alberta as an Assistant Professor. Since 1985,

he has been with the Department of Electrical and Computer Engineering at

the University of Wisconsin, Madison, where he is presently an Associate

Professor. He is also an Associate Director of the Wisconsin Electric Machines

and Power Electronics Consortium (WEMPEC). His primary areas of interest

are in power electronic converter circuits and control techniques. He has over

30 papers in the area as well as many patents. He is also a consultant for

various industrial concems.

Dr. Divan was a recepient of the Killam Scholarship while in the Ph.D

program and has won various prize papers including the IEEE-US Best Paper

Award for 1988-89, first prize paper for the Industrial Drives and Static Power

Converter Committee in 1989, third prize paper in the Power Semiconductor

Committee and the 1983 third prize paper award of the Static Power Converter

Committee of the IEEE Industry Applications Society. He has been the

Program Chairman for the 1988 and 1989 Static Power Converter Committee

of the IEEE-IAS, Program Chairman for PESC 91, and a Treasurer for PESC

89. He is also a Chairman of the Education Committee in the IEEE Power

Electronics Society.

Rambabu Adapa (S81-M786-SM90) was bom

in Andhra Pradesh, India, on Sept. 2, 1956. He

received the B.S. degree in electrical engineering

from Jawaharlal Nehru Technological University,

Kakinada, India, in 1979. He received the M.S.

degree in electrical engineering from the Indian

Institute of Technology, Kanpur, India, in 1981. He

received the Ph.D. degree in electrical engineering

from the University of Waterloo, Canada, in 1986.

He joined the Power System Planning and Operations urogram of the Electrical Svstems Division

of the Electric Power Research I n & & (EPRI), Palo Ako, CA, in June

1989. Prior to joining EPRI, he was Staff Engineer in the Systems Engineering department of McGraw-Edison Power Systems, Franksville, WI. At

McGraw-Edison, he was involved in several digital and analog studies, which

included transient, harmonic, and insulation coordination studies performed

for electric utilities. At EPRI, he manages the Electro-Magnetic Transients

Program (EMTP) development and maintenance project, commercialization

of the Harmonic Analysis Software (HARMFLO) endeavor, and several

other EPRUNSF-funded projects. His interests include EMTP, power system

planning and operations, HVDC transmission, harmonics, and expert systems.

Dr. Adapa is a Senior Member of the IEEE Power Engineering Society,

a member of the DC Transmission subcommittee of the Transmission and

Distribution Committee, a member of CIGRE and of the local IEEE Santa

Clara chapter. He is a Registered Professional Engineer in the State of

Wisconsin.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Test On ElectrostaticsDocument4 pagesTest On ElectrostaticsHemendra PrasannaNo ratings yet

- Tan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDocument10 pagesTan Delta Test - Loss Angle Test - Dissipation Factor Test - Electrical4U PDFDan AndreiNo ratings yet

- 02 IRIS2 - NV - Controller-ENDocument36 pages02 IRIS2 - NV - Controller-ENAhmedNo ratings yet

- Kalka Public School: Holiday HomeworkDocument18 pagesKalka Public School: Holiday HomeworkMohammad UmarNo ratings yet

- MP EM Ass 21: LR, LC, LRC CircuitsDocument16 pagesMP EM Ass 21: LR, LC, LRC CircuitsBlueAstro100% (6)

- Question Bank 1st YearDocument45 pagesQuestion Bank 1st YearAbhishekNo ratings yet

- Design of A Large Area Rectenna For Energy Harvesting Using Ambient RF EnergyDocument24 pagesDesign of A Large Area Rectenna For Energy Harvesting Using Ambient RF EnergyGAUTI2212No ratings yet

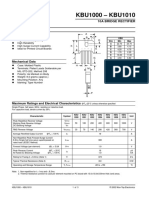

- KBU1000 - KBU1010: FeaturesDocument3 pagesKBU1000 - KBU1010: FeaturesTRUNG Lê ThànhNo ratings yet

- WSC IomDocument36 pagesWSC IomArief100% (2)

- Energy Harvesting Through Dance Floor Using Piezoelectric DeviceDocument5 pagesEnergy Harvesting Through Dance Floor Using Piezoelectric DeviceBelayneh TadesseNo ratings yet

- Intelligent Pressure Transmitter With Control Capability: Operation and Maintenance Instruction / ManualDocument110 pagesIntelligent Pressure Transmitter With Control Capability: Operation and Maintenance Instruction / Manualvembrietto_harsNo ratings yet

- MS 3000 Standard Kit 3 - Technical Data Sheet V 1.0Document3 pagesMS 3000 Standard Kit 3 - Technical Data Sheet V 1.0lxd.hepNo ratings yet

- Lab E1 RLC CircuitDocument11 pagesLab E1 RLC CircuitChing Wai Yong100% (1)

- IC Control Thy - TCA 785Document5 pagesIC Control Thy - TCA 785apriliaa ayuuNo ratings yet

- Chemical Sensors Volume 1: Fundamentals of Sensing Material: General ApproachesDocument74 pagesChemical Sensors Volume 1: Fundamentals of Sensing Material: General ApproachesMomentum Press0% (1)

- Areva Battery MonitorDocument4 pagesAreva Battery MonitorJoseph SumpaicoNo ratings yet

- Capacitance and Inductance of A Parallel Plate Transmission LineDocument2 pagesCapacitance and Inductance of A Parallel Plate Transmission LineBabasrinivas GuduruNo ratings yet

- ch1 Introductiontopq Bev40603Document46 pagesch1 Introductiontopq Bev40603Nur DaniaNo ratings yet

- RC Phase Shift Oscillator Full DerivationDocument12 pagesRC Phase Shift Oscillator Full DerivationPranav Itraj0% (1)

- Magnetiser Range 1 2Document5 pagesMagnetiser Range 1 2api-314773820No ratings yet

- Electric Arc Furnace Power Modeling For STATCOM Controller ApplicationDocument6 pagesElectric Arc Furnace Power Modeling For STATCOM Controller Applicationteektak1No ratings yet

- PAPER 11 EDATool-BasedMethodologyfor ChandrasekarDocument20 pagesPAPER 11 EDATool-BasedMethodologyfor ChandrasekarReynaldo LOERANo ratings yet

- SolutionDPP 3capacitor Kirchhoffs1st2ndLawDocument57 pagesSolutionDPP 3capacitor Kirchhoffs1st2ndLawprachuryaNo ratings yet

- q615 Electrical Electronics and Control EngineeringDocument36 pagesq615 Electrical Electronics and Control Engineeringjustooln2No ratings yet

- Series Resonance Circuits PDFDocument16 pagesSeries Resonance Circuits PDFnpavankNo ratings yet

- AC CircuitsEE 03 01 To EE 03 04 QuestionnaireDocument3 pagesAC CircuitsEE 03 01 To EE 03 04 QuestionnaireCelina RoxasNo ratings yet

- Life ELNA Technical NoteDocument9 pagesLife ELNA Technical NotejohnNo ratings yet

- Safety Precautions in ElectronicsDocument16 pagesSafety Precautions in ElectronicsChezzzzyNo ratings yet

- Capacitance Cheat CodeDocument13 pagesCapacitance Cheat CodeADITYA UPADHYAYNo ratings yet

- (IEEE Format) Design Consideration A Low-Cost Capacitive Sensor For Plantar Pressure Insole - R1Document5 pages(IEEE Format) Design Consideration A Low-Cost Capacitive Sensor For Plantar Pressure Insole - R1WAHYU DWI LESTARINo ratings yet