0% found this document useful (0 votes)

605 views2 pagesLiquid Jet Mixers: Circulate Liquids

Liquid jet mixers are jet pumps that use a motive liquid to mix and circulate other liquids in vessels and storage tanks. They have no moving parts, are simple and reliable. Jet mixers should be installed at the lowest point in a tank to ensure effective mixing at various liquid levels. The number of mixers needed depends on factors like tank geometry and size, liquid properties, required mixing time, and liquid level ranges. Mixing time can be calculated based on tank volume and total flow delivered by the jet mixers. Pump selection depends on required pressure and flow.

Uploaded by

aravindCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

605 views2 pagesLiquid Jet Mixers: Circulate Liquids

Liquid jet mixers are jet pumps that use a motive liquid to mix and circulate other liquids in vessels and storage tanks. They have no moving parts, are simple and reliable. Jet mixers should be installed at the lowest point in a tank to ensure effective mixing at various liquid levels. The number of mixers needed depends on factors like tank geometry and size, liquid properties, required mixing time, and liquid level ranges. Mixing time can be calculated based on tank volume and total flow delivered by the jet mixers. Pump selection depends on required pressure and flow.

Uploaded by

aravindCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

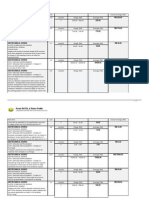

- Liquid Jet Mixers

- Standard Constructions

- Connections, Dimensions and Weights