Professional Documents

Culture Documents

Security Specifications and Maintenance: Fig.110 Fig.120

Uploaded by

bobisaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Security Specifications and Maintenance: Fig.110 Fig.120

Uploaded by

bobisaCopyright:

Available Formats

Fig.

100

100

20

10

Fig.100 Press the nipple (10) in axial way as indicated form the arrow and

get the head (100) of the nipple (10) on the rim (20).With this operation the

gasket enter in the seating,and so must be done by naked hand with extreme

lightness. After that the head (100) of the nipple (10) will be on the rim (20) it

will be possible to continue the rotation of teh nipple (10) in ordero to srew it

on the spoke (70).

Continue the gradual traction of the nipple (10) handle from the special square section (50). For these operations pliers cant be used , but its necessary

to use special operation key with suitable section.The use of other tools

could ruin irreparably the surfaces of key-position.

Attention:The recommended tightening torque is 4-7 Nm. Dont exceed the

maximum limit. Eventual tampering on high torque could damage the rim

and compromise the pressure tightness of the system.

50

70

STS

SECURITY SPECIFICATIONS

AND MAINTENANCE

Short user manual

1. Stock nipples in non-transparent bags in a clean place. The light (natural or artificial) causes untimely obsolescence of sealings, and the light film of lubricating grease could be a dirt trap (please follow accurately the

instruction on page 2, Fig. 10-30)

2. Before the assembly of the wheel or substitution of a nipple you have to assure that all parts of the wheel and

the area of assembly are perfectly clean. The sealing will be supplied with a light film of lubricating grease that

could encourage the contamination of impurities and so penalize the efficiency of the tubeless system. (please

follow accurately the instruction on page 2, Fig. 10-30)

3. The most delicate phase of the wheel assembly is when, during the insert of the nipple in the rim, the O-ring

has to be introduced in the rim hole. Turning and forcing laterally the nipple could provoke pinches and compromise the pressure tightness. (please follow accurately the instruction on page 5, Fig. 100)

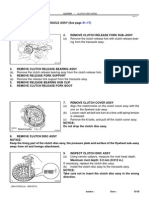

Fig.120

Fig.110

10

4. Remember to check the correct positioning of the security ring. Its function is to limit the axial amplitude of the

nipple during the driving operation (please follow accurately the instruction on page 6, Fig. 120)

5. Referring the CARBONMATRIX wheels (carbon rim) you have to pay full attention during the assembly of the

tires. A leverage that is not well rounded or badly employed could provoke the chipping of the carbon coat.

110

110

30

30

10

70

Fig.110 When the wheel is completed assemble again the security ring

(30) on the nipple (10), inserting it in a radial way as indicated form the

arrow.

The action can be done pointing the ring (30) in the seating (110) of the

nipple (10) and then insert with a standard with tapered nose pliers.

If not executed correctly, during this action, the rim could be scratched.

Fig.120 Be sure that the security ring (30) is completely placed in the seating (110) of the nipple (10).

The task of the ring (30) is to maintain the nipple

(10) in position during the wheel working or in case

of breaking of the spoke (70),so the loss of this ring

may generate a dangerous situation .

DONT USE THE WHEEL EVEN IF ONLY ONE

RING MISS .

ALPINA RAGGI S.p.A. - Via Piave, 10 - 23871 LOMAGNA (Lecco) Italia - Tel. + 39 039 92281 Fax + 39 039 9220294

www.alpinaraggi.it - info@alpinaraggi.it

1) The friction between the O-ring seal of the STS nipple and the calibrated rim hole makes the loosening of nipple very difficult (which normally is a classical phenomenon and typical for tube type wheels with air chamber) . For

that it is not necessary to retighten the wheels screwing the nipples each time. As a precaution please check by

hand if a spoke becomes loose and only in this case provide for screwing the nipple carefully, paying attention that

2-3 mm of the spoke will remain always visible.

2) The STS nipple is blind (not passing as a traditional nipple) and for that the spoke cannot pass on the other

side of the nipple head if overtorqued. This causes a blocking of the spoke in the nipple and torsions consequently

the fibres of the spoke that becomes brittle and provokes the breakage of the spoke.

3) The non respect of the instructions specified under 1) and 2) provokes an overload and brittleness due to the

torsion of spokes (sometimes until breakage). This causes damages without remedies at nipples, hubs and rims

(cracks and breakage of the dimples).

Fig.10 Disassemble the nipples (10) in case this will be necessary from the rim (20) follow these instructions. The operations

showed require manual ability , so only qualified and expert

personal in mechanical field can do that .Working without

any ability could be dangerous for themselves and for other

people. ALPINA RAGGI SpA wont be in charge for any tamperings or wrong operations that will damage person,object or

invalidate the tyre holding system. The components that will

guarantee the holding are and must be opportunely lubricated

,so,all the maintenance stages must be done in clean and

powderless habitat.

Fig.10

10

20

40

STS

30

SECURITY SPECIFICATIONS AND MAINTENANCE

Fig.20

Fig.20, 30 Clean properly with a moist

brush (with water) the intersection zone

nipples/rim . Remove the security ring

(30) pressing in orthogonal way (see the

arrow) on one or both surfaces (40) of the

ring (30) through a thin pointed screwdriver.The ring will come out in the direction

showed in (Fig.30). Pay attention : dont

lose the ring.

Fig.

30

40

30

30

Fig.40

Fig.

ATTENTION

1 :Avoid to clean the

wheel with washing system with high pressure both with warm and cold water ( like Puli30

vapor).If you want to use in any case a washing system with high pressure , keep a distance of 50cm at least

between the jet source and the intersection source nipple/rim ( see Pos.30 of Fig.20).Getting closer facilitate the

dirty intrusion , compromising the holding of the tire,and the damaging of the same gasket too.

2 : If you dont manage correctly and with care the screwdriver used to remove the ring , this could cause injures or ruin the rim .

50

30

Fig.40 Unscrew the nipple

(10) and the spoke (70)

making the nipples rotate

in anticlockwise sense

(see arrows).First operate

using the portion square

section (50), and then

through the hexagonal

hold (60). For these operations pliers cant be used

, but its necessary to use

special operation keys with

suitable section.The use

of other tools could ruin

irreparably the surfaces of

key-position.

Fig.50

Fig.40

60

80

10

Fig.60 Everytime that the nipple (10) will be disassembled its

necessary to check carefully through a standard magnifying

glass the aspect of the gasket(90). This must not have any

pinch,crushing or irregular deformations.

If the gasket is undamaged its necessary (before assembling the

nipple) , to clean it carefully ( without moving it from the seating )

through a little brush with soft bristles soaked in a standard clean

hydrocarbon ( pethrol, gas oil or similar ) . Verify that after cleaning any bristles of the brush will not remain.Oil the gasket (Alpina

recommend grease RASSINT PTFE from LOCHIM )

In case it would be necessary to change the gasket (90) its

necessary to clean adequately the seating before assembling

the new gasket.About the cleaning of the seating use a little

brush with soft bristles soaked in a standard clean hydrocarbon (

pethrol,gas oil or similar ) Verify that after the cleaning any bristles

of the brush will not remain.The gasket (90) is a standard OR2025-NBR ( American Norm AS 568 A Cod. 010). Oil the seating

and gasket with a standard grease P.T.F.E. (ALPINA raccomend

grease RASSINT - PTFE from LOCHIM).

20

90

10

50

Fig.70

Fig.70 Everytime that the nipple will be disassembled (10 Fig.60)

it will be necessary to clean carefully the seating (80) of the rim

(20). About the cleaning of the seating use a little brush with soft

bristles soaked in a standard clean hydrocarbon ( pethrol, gas oil

or similar ) . Verify that after cleaning any bristles of the brush will

not remain.Oil the seating (Alpina recommend grease RASSINT

PTFE from LOCHIM )

Fig.90

10

50

100

The introduction of the gasket (90) will be from the head side

(100) of the nipples (10) and not form the side of the square

key (50).

Fig.80

10

Fig.60

90

70

80

Fig.50

20

80

70

10

80

10

70

Fig.50 Remove the nipple (10) from the seating (80) of the ring (20) unthreading it in the direction of the arrow . If

necessary remove the spoke (70) unthreading it from the hub following the direction indicated with the arrow.

20

70

20

70

80

20

Fig.80 Introduce (not completely ) the

nipple (10) in the seating (80) of the rim

(20). Drawing up the spoke (70) to the

nipple (10) following the direction of the

arrow .

NB If the system of axial tightness of

the nipple should be with spiral spring,

remember to put it on the spoke before

screwing the spoke on the nipple. As

the ring is closed, it wont be possible

to assemble it once the wheel has

been preassembled or in any consecutively phase.

Fig.90 Screw clockwise as indicated

with the arrow , the nipple (10) on the

spoke (70),until drawing up the gasket

(90) to the seating entrance (80) of the

rim (20).

STOP THE NIPPLE ROTATION (10)

You might also like

- 1971 Johnson 60HP Outboards Service Manual PDFDocument5 pages1971 Johnson 60HP Outboards Service Manual PDFChrisStainton0% (1)

- ENCO Automatic Boring and Facing HeadDocument2 pagesENCO Automatic Boring and Facing Headbill100% (1)

- Yanmar 4tne88 TNE Series PDFDocument15 pagesYanmar 4tne88 TNE Series PDFluna281068No ratings yet

- Caterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)Document23 pagesCaterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)kfmuseddkNo ratings yet

- Fox Shocks Float and Float 2 RebuildDocument22 pagesFox Shocks Float and Float 2 RebuildJules De MontignyNo ratings yet

- 4G63 SOHC Timing Belt Removal and Installation GuideDocument8 pages4G63 SOHC Timing Belt Removal and Installation GuideRex Loreto67% (3)

- QB78 DisassemblyDocument8 pagesQB78 Disassemblysjdarkman1930100% (2)

- T 176Document9 pagesT 176ashkansoheylNo ratings yet

- 1uz Fe EngineDocument28 pages1uz Fe EngineAnas AlaaNo ratings yet

- Remove & Install Bucket CylinderDocument8 pagesRemove & Install Bucket CylinderchanlinNo ratings yet

- Ferguson Loader 100 Loader Service Manual MH S mf100ldrDocument9 pagesFerguson Loader 100 Loader Service Manual MH S mf100ldrOscarNo ratings yet

- Wilroy: Conversion Kit Instruction ManualDocument4 pagesWilroy: Conversion Kit Instruction ManualrudrakrNo ratings yet

- Ir10,20 Ir12,22 en 1025972Document9 pagesIr10,20 Ir12,22 en 1025972Steven FryeNo ratings yet

- Remo TBDocument5 pagesRemo TBTyler MacNo ratings yet

- Amarillo Gear Repair ManualDocument32 pagesAmarillo Gear Repair Manualfazzlie100% (1)

- 6.0L Turbo Rebuild Instructions PDFDocument5 pages6.0L Turbo Rebuild Instructions PDFW MoralesNo ratings yet

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- Maintenance For Model Master Rotary TableDocument7 pagesMaintenance For Model Master Rotary Tablejdk3dNo ratings yet

- R&I Track Roller MenDocument5 pagesR&I Track Roller MenDanNo ratings yet

- 2012 Fork Service ManualDocument36 pages2012 Fork Service ManualFer SabidongNo ratings yet

- 199-538A KitDocument10 pages199-538A KitcarlosNo ratings yet

- Circle Clearances - Check/Adjust: Manual de Operación y MantenimientoDocument7 pagesCircle Clearances - Check/Adjust: Manual de Operación y MantenimientoTaller HeavytechNo ratings yet

- Samsung SC X 4200 TonerDocument6 pagesSamsung SC X 4200 TonerMarcus RamosNo ratings yet

- Group 3 Disassembly and AssemblyDocument5 pagesGroup 3 Disassembly and AssemblyAndré TarginoNo ratings yet

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoNo ratings yet

- Roller Circle - Check and AdjustDocument3 pagesRoller Circle - Check and AdjustGilney FreitasNo ratings yet

- 2012 Dorado Pro Service ManualDocument29 pages2012 Dorado Pro Service ManualSea RidersNo ratings yet

- Cylinderipiston: System Components 10-2 Cylinderipiston Removal 10-4 10-3 Cylinderipiston Installation....... 10-9Document118 pagesCylinderipiston: System Components 10-2 Cylinderipiston Removal 10-4 10-3 Cylinderipiston Installation....... 10-9poiufdsapuroiqNo ratings yet

- Repair Information: Mitre SawDocument14 pagesRepair Information: Mitre Sawusmanghani17201No ratings yet

- Sjannualservicev1.1 190Document39 pagesSjannualservicev1.1 190antoineNo ratings yet

- Drive Shaft & Propeller ShaftDocument21 pagesDrive Shaft & Propeller ShaftMusat Catalin-MarianNo ratings yet

- Hx2k Wire RopeDocument3 pagesHx2k Wire RopeAnandha PadmanabhanNo ratings yet

- REVE Dorado Service ManualDocument32 pagesREVE Dorado Service ManualHéctor Alberto LaioloNo ratings yet

- Towing and Suspension Solutions: Falcon 5250 Complete Repair KitDocument6 pagesTowing and Suspension Solutions: Falcon 5250 Complete Repair KitLawrence KucharekNo ratings yet

- TCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UpDocument8 pagesTCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UphidraulicNo ratings yet

- XL Series Actuators 1: Installation, Operating and Maintenance InstructionsDocument8 pagesXL Series Actuators 1: Installation, Operating and Maintenance InstructionsFranco M. CaverzanNo ratings yet

- Qb78 Co Pellet Rifle: Text and Photos by George Fox LangDocument8 pagesQb78 Co Pellet Rifle: Text and Photos by George Fox LangLaszlo CsokNo ratings yet

- Clutch Unit2Document4 pagesClutch Unit2Cristiano BruschiniNo ratings yet

- Toyota Corolla Repair ManualDocument24 pagesToyota Corolla Repair ManualOlrac AgairdamNo ratings yet

- Renk SNDocument4 pagesRenk SNrpichoNo ratings yet

- Parilla x30 Overhaul ManualDocument38 pagesParilla x30 Overhaul ManualCarolina MatosNo ratings yet

- Tapping ChucksDocument14 pagesTapping ChucksDHAMODHARANNo ratings yet

- Removal/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Document7 pagesRemoval/installation Recommendations: Identification of NTN-SNR Wheel Bearing KIT R140.77Ioan PascaNo ratings yet

- 2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXDocument36 pages2013-2015 FIT CTD Cartridge Rebuild - Bike Help Center - FOXYadi RomaNo ratings yet

- Ydr CSSN 06Document2 pagesYdr CSSN 06siddik.s2582No ratings yet

- Remove Front IdlersDocument12 pagesRemove Front IdlersAnonymous 2JhNPknvNo ratings yet

- 011 - FlywheelDocument12 pages011 - Flywheelmax_simonsNo ratings yet

- Axle Shafts - Front: Description & OperationDocument4 pagesAxle Shafts - Front: Description & OperationYeremi MatthewNo ratings yet

- For Volvo850GLT Front Axle ShaftsDocument4 pagesFor Volvo850GLT Front Axle ShaftsYeremi MatthewNo ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- CLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DDocument6 pagesCLEVELAND 199-512 Repair Kit For Master Cylinder 10-30, 10-30A, 10-30C & 10-30DBrunoNo ratings yet

- Accent Cylinder Head AssemblyDocument30 pagesAccent Cylinder Head Assemblyflash_24014910No ratings yet

- Pentax Spotmatic Service ManualDocument51 pagesPentax Spotmatic Service Manualmamamojo100% (1)

- Ec10d 1Document9 pagesEc10d 1Guido Leonardo EnriqueNo ratings yet

- Series 51 Motor Repair ManualDocument20 pagesSeries 51 Motor Repair ManualAngel Dlsg100% (4)

- Lubrication Specifications Universal JointsDocument6 pagesLubrication Specifications Universal Jointsmohammed barghothiNo ratings yet

- DR Service InstructionsDocument4 pagesDR Service InstructionsCentral HydraulicsNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- 495 SERIES™, 4195 SERIES™: Cast Iron Construction Motor Speed Product LineDocument2 pages495 SERIES™, 4195 SERIES™: Cast Iron Construction Motor Speed Product Lineandres peraltaNo ratings yet

- SS IM S241.564.en-01Document68 pagesSS IM S241.564.en-01Lucky OkoteNo ratings yet

- Fiche de Composition Du Manuel PR: TF C 34/45 (F CH55) - REF. Q 20440 - 93Document2 pagesFiche de Composition Du Manuel PR: TF C 34/45 (F CH55) - REF. Q 20440 - 93gsrNo ratings yet

- List Unit Terprogres Pt. Mas 16 - 07 - 2022 - 084603Document6 pagesList Unit Terprogres Pt. Mas 16 - 07 - 2022 - 084603Ar JunaNo ratings yet

- Su Type Twin Carburetor PDFDocument13 pagesSu Type Twin Carburetor PDFDaffa Farhan AhmadNo ratings yet

- T28 Beretta DepliantDocument8 pagesT28 Beretta DepliantJ RivkinNo ratings yet

- Washing Machine SWMA612EGZ GuideDocument8 pagesWashing Machine SWMA612EGZ Guidesabitavabi100% (1)

- Training Program Guide 2013 PDFDocument52 pagesTraining Program Guide 2013 PDF2791957No ratings yet

- 2019 Ford Ranger Quick Reference GuideDocument10 pages2019 Ford Ranger Quick Reference GuideCharles MutetwaNo ratings yet

- 4881 - Tower Wagon - Four Wheeler - 240 HP - 10 T - Make Ovis EqptsDocument10 pages4881 - Tower Wagon - Four Wheeler - 240 HP - 10 T - Make Ovis EqptsTHANGAVEL PNo ratings yet

- Controler AddressDocument4 pagesControler Addressfrancismci92No ratings yet

- 2017 VW BeetleDocument2 pages2017 VW BeetlecbNo ratings yet

- Pharma Project DetailsDocument2 pagesPharma Project DetailsSenthil PeriasamyNo ratings yet

- Hydreco V3A4013 Brochure 2014Document8 pagesHydreco V3A4013 Brochure 2014Montes JorgeNo ratings yet

- RV Accessories - Spare Parts: 2017 Price List 2017 Liste de Prix 2017 Prijslijst 2017 PreislisteDocument99 pagesRV Accessories - Spare Parts: 2017 Price List 2017 Liste de Prix 2017 Prijslijst 2017 PreislistepabloNo ratings yet

- CAM RIT: Three Phase S ConstructionalDocument30 pagesCAM RIT: Three Phase S ConstructionalJay Prakash MandalNo ratings yet

- Manual Del Estudiante d7r 2pdf PDF FreeDocument106 pagesManual Del Estudiante d7r 2pdf PDF FreehaiderNo ratings yet

- QSK 50 Fan Pully & Fan Idler EX2500-6 & EX5500-6Document5 pagesQSK 50 Fan Pully & Fan Idler EX2500-6 & EX5500-6Bambang DwiantoNo ratings yet

- 3406 Crankshaft Main Bearings PDFDocument5 pages3406 Crankshaft Main Bearings PDFmanu luvunga100% (1)

- Chaste House Air HandlerDocument14 pagesChaste House Air HandlerLisa TerzoNo ratings yet

- Spare-Parts Book: C-Service 3Document130 pagesSpare-Parts Book: C-Service 3RobertNo ratings yet

- 4143.020.073 2 HL 270 PDF Transmission (Mechanics) Mechanical EngineeringDocument1 page4143.020.073 2 HL 270 PDF Transmission (Mechanics) Mechanical EngineeringАртурNo ratings yet

- TM 1 1740 204 13 and PDocument149 pagesTM 1 1740 204 13 and PpavannnNo ratings yet

- Maintenance Alat BeratDocument3 pagesMaintenance Alat BeratPeralatan Divisi3No ratings yet

- 3/2 Direct Acting High Orifice Universal Solenoid ValveDocument18 pages3/2 Direct Acting High Orifice Universal Solenoid ValveNico RoisnerNo ratings yet

- Audi Q2 No. 6 / 1: Airbag Systems, (L0L)Document9 pagesAudi Q2 No. 6 / 1: Airbag Systems, (L0L)acb . bNo ratings yet

- UntitledDocument2 pagesUntitledOmar MohammedNo ratings yet

- V60-V62 Series: Directional Control ValvesDocument12 pagesV60-V62 Series: Directional Control ValvesIrfan AhmedNo ratings yet