The

HydroCOM-System

Edition 2.01

General Description

HydroCOM 2.0

makes compressor control

and monitoring

an easy job

�1 INTRODUCTION ......................................................................................................3

2 ABBREVIATIONS ....................................................................................................4

3 GENERAL FUNCTION.............................................................................................5

3.1 What is HydroCOM? .....................................................................................................................................5

3.2 Functional Description HydroCOM .............................................................................................................6

3.3 The reverse flow regulation .........................................................................................................................7

3.4 Control Strategy ...........................................................................................................................................9

3.5 Admissions .................................................................................................................................................10

3.5.1 Electromagnetic Compatability (EMC) ...................................................................................................10

3.5.2 Safety of low voltage devices.................................................................................................................10

3.5.3 Explosion protection ..............................................................................................................................11

4 THE COMPONENTS OF THE HYDROCOM SYSTEM..........................................12

4.1 HydroCOM Actuators .................................................................................................................................12

4.1.1 Task.......................................................................................................................................................12

4.1.2 Design ...................................................................................................................................................12

4.2 Compressor Interface Unit CIU .................................................................................................................14

4.2.1 Duty .......................................................................................................................................................14

4.2.2 Design ...................................................................................................................................................14

4.3 External power supply ...............................................................................................................................14

4.3.1 Duty .......................................................................................................................................................14

4.3.2 Design ...................................................................................................................................................14

4.4 Isolation Amplifier ......................................................................................................................................14

4.4.1 Duty .......................................................................................................................................................14

4.5 TDC-sensor .................................................................................................................................................15

4.5.1 Duty .......................................................................................................................................................15

4.6 Hydraulic Unit HU .......................................................................................................................................15

4.6.1 Duty .......................................................................................................................................................15

4.6.2 Design ...................................................................................................................................................15

4.7 Service Unit SU ...........................................................................................................................................16

4.7.1 Duty: ......................................................................................................................................................16

4.8 The Compressor Condition Monitoring (CCM) Software Package.........................................................17

4.9 Measuring Module TIM ...............................................................................................................................18

4.9.1 Duty: ......................................................................................................................................................18

4.9.2 Design ...................................................................................................................................................18

General Description 201

00-01-19

Introduction

The present version of the General Description Handbook shall describe in

short the function of the HydroCOM System. This manual is designed for

general information on the function of the system. Minor technical details of

the delivered version may slightly deviate.

General Description 201

00-01-19

Abbreviations

The following abbreviations will be used throughout this manual

Actuator

CAoff

CAon

CIU

DCS

EPS

GIM

HU

IA

IPS

IVD

PLC

SU

TDC

TIM

General Description 201

unit for the actuation of the suction valves

switching point of the solenoid valve, at which the suction

valve opens

switching point of the solenoid valve, at which the suction

valve closes

Compressor Interface Unit

Control System: either Distributed Control System,

programmable logical control or programmable loop

controller

External Power Supply

General Interface Module

Hydraulic Unit

Isolation Amplifier

Internal Power Supply

Intelligent Valve Driver

programmable logical controller

Service Unit

Top Dead Center

Transmitter Interface Module

00-01-19

General function

3.1

What is HydroCOM?

The reliable, efficient, flexible compressor control system for optimal use of

resources.

HydroCOM is a hydraulically acutated computerised compressor control

system.

HydroCOM is a system for the stepless capacity control of reciprocating

compressors in a range between 0 -100 %. It is based on components of the

injection technology for large Diesel engines, enhanced by state of the art

digital computing and control technology. Hydraulically actuated unloaders

keep the suction valves open during part of the compression cycle. Thus

part of the gas induced into the cylinder during the suction cycle is pushed

back into the suction plenum. In this way the gas volume per working stroke

can be controlled in the full range.

As the energy consumption of a compressor is essentially proportional to the

quantity of gas compressed per compression cycle, this system realizes an

energy saving compressor control method.

The capacity control is driven either by a distributed control system or by a

loop controller optionally supplied by HOERBIGER. Therefrom 4 .. 20mA

signals must be sent to the HydroCOM system (CIU).

Additional to this control function HydroCOM facilitates the monitoring of all

valve nest temperatures. They are transmitted via 4..20mA signals to the

distributed control system.

The new generation HydroCOM 2.0 offers further the possibility when using

TIM measuring modules to install transmitters in the field and to transfer the

measured values via the HydroCOM bus to the control unit CIU. All the

measured values and status reports, as well as all control signals can

optionally also be transferred via MODBUS between the CIU and the

distributed control system.

General Description 201

00-01-19

�3.2

Functional Description HydroCOM

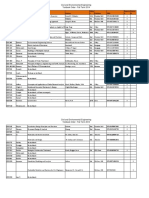

The drawing below shows the typical configuration of the HydroCOM-system

in a plant.

Field

Field

DCS

DCS//PLC

PLC

Control

Control

Room

Room

48 Vdc

TDC

BUS

4..20 mA,

binary contacts

HOERBIGER HOERBIGER HOERBIGER

Valve

Cod e

#

#

Scroll /

Reset

SIM 1

Valve

Code

#

#

Scroll /

Reset

SIM 2

V alve

C ode

HOERBIGEHOERBIGEHOERBIGE

P ower

R

R

R

TDC

En able

Ext.Sim.

P

Sensor

hy

Error

d

L

S M

o

U O

D

B

U

S

#

#

S cro ll /

R eset

SIM 3

GIM

CIU

5V

15V

IPS

HYD

ROCO

M

Maintenance

Maintenance

Oil

HU

TIM

SU

CCM

Fig. 1.: principle sketch HydroCOM system

HydroCOM actuators are installed on top of the suction valves of the

compressor. They perform the essential control activity, i.e. keeping the

valves open during part of the compression cycle. They are supplied with the

necessary energy via hydraulic lines from a hydraulic unit (HydroCOM-HU).

The actuators are driven via a data line and a power supply line by a

compressor interface unit (HydroCOM-CIU). This CIU-unit serves as the

interface between the HydroCOM system and the overriding distributed

control system (DCS/PLC/loop controller). The compressor control task is

solved in the distributed control system.

The communcation between the DCS and the HydroCOM system is

exchanged via 4..20mA analogue signals (compressor capacity, valve nest

temperatures) and via binary signals (warning, error, simulation,

enable).HydroCOM 2.0 further offers the possibility to transfer the above

mentioned analogue and digital signals between PLS and CIU via

MODBUS. In this case the communication goes via MODBUS-interface, no

wiring between CIU and PLS is necessary.

A TDC-sensor informs the control unit CIU about the actual position of the

piston in the cylinder. The conversion to the exact opening and closing time

of the suction valves is done by the CIU. The capacity output of the

compressor thus becomes a simple analogue control variable for the plant

operator. By using digital control technology the HyroCOM system can react

within 2-3 turn of the crank shaft to changes of the required volume, thus

minimizing dead times.

The compressor interface unit CIU can be connected to a service unit SU

(IBM compatible PC) via an RS-232 interface. By means of the SU the CIU

can be configured using a Windows based program. Threshold values for

alarms can be adapted to the actual operation parameters. In case of

malfunction a detailed analysis of the CIU can be made via the SU.

General Description 201

00-01-19

�3.3

The reverse flow regulation

The capacity control method is based on the so called reverse flow regulation

principle. A part of the gas which has been taken into the cylinder during the

suction cycle is conveyed back to the suction chamber during the

compression cycle.

2

Saved energy

at part load

Fig. 2.: The principle of reverse flow regulation

The above indicator diagram shows the function principle of the control

system. The cylinder pressure is a function of the actual position of the

piston inside the cylinder. In Pos.1 (bottom dead center, BDC) the

compression cycle starts. Without the HydroCOM system, under full load

operation, the gas is compressed immediately after passing the BDC. When

the cylinder pressure reaches pos.2 the discharge valve starts opening. The

gas is pushed out of the cylinder. When the piston reaches pos.3 (top dead

center, TDC) the re-expansion starts. The gas which is still in the cylinder

due to the cylinder clearance, re-expands. When the cylinder pressure

reaches the suction pressure (pos.4) the suction valve opens and gas is

induced into the cylinder. The power necessary for the operation of the

compressor is proportional to the area enclosed by the indicator pressure

curve.

Check

CheckValve

Valve

Solenoid

Solenoid

Valve

Valve

M

Hydraulic

HydraulicUnit

Unit

Hydraulic

Hydraulic

Cylinder

Cylinder

Unloader

Unloader

Suction

SuctionValve

Valve

Fig. 3.: HydroCOM actuator - function

General Description 201

00-01-19

�By means of the HydroCOM system the suction valve of the compressor

which is actuated by a fast-switching hydraulic solenoid, is kept open during

a part of the compression cycle by an unloader. Thus the indicator pressure

does not follow the curve pos.1 to pos.2 ,but the line of pos.1 to pos.5. The

required power input is therefore much lower than in the previously

described case. The slight pressure increase (1-5) is due to pressure losses

in the valves. As the gas flows back from the cylinder chamber into the

suction line, the quantity of gas in the cylinder available for compression is

reduced. At pos.5 a solenoid valve in the HydroCOM actuator is switched,

thus the unloader which keeps the suction valve open is released and the

suction valve closes. The compression follows the line from pos.5 to pos.6.

One can see from the diagram that for this load case (approx. 50%) actually

only half the power input is required. Thus the principle of reverse flow

regulation saves energy.

General Description 201

00-01-19

�3.4

Control Strategy

The compressor is either controlled by the distributed control system or by

an external loop controller provided optionally by HOERBIGER.

One of the process variables (e.g. discharge pressure, suction pressure,

flow volume..) is selected as control variable. The user defines a setpoint for

this variable. A PI controller is assigned to each stage of the compressor.

The first stage is controlled according to the process variable. The output of

the first controller operates primarily the first stage. The interstage suction

pressures are selected as control variables for the higher stages. In order to

avoid instabilities the controller output of the first stage is fed forward to the

higher stage loop controllers. The capacity delivered by each stage is varied

by 4..20mA = appr. 0..100% controller signals which are sent to the CIU.

The enclosed basic sketch shows this principle. A start-up function for the

start-up phase may be provided in the DCS configuration. It includes a startup unloading function and a start-up ramp in order to obtain smooth loading

of the compressor after start-up.

Optionally HOERBIGER can either give assistance with the configuration of

the DCS or HOERBIGER can deliver a programmed H&B loop controller.

Hy: Hydraulic Fault

Wa: Warning

DCS

En: Enable

Control Variable

Setpoint

CIU

Er: Error

PI-Controller

1st stage

Sim: Simulation

Y1: 4..20 mA=ca. 0..100%

Suction pressure 2nd stage

4...20 mA = 0-100 bar

Setpoint

Feedforward

HOERBIGER

Startup

ramp

Y2: 4..20 mA =ca. 0..100%

T1: 4..20 mA = -25..+125

PI-Controller

2nd stage

100%

T2: 4..20 mA = -25..+125

Controller Output

HOERBIGER

HOERBIGER

Valve

Valve

Valve

Code

Code

Code

HOERBIGER

Power

TDC

Enable

Ext.Sim.

P hyd Lo

Sensor

Error

S

U

Scroll /

Reset

SIM 1

Scroll /

Reset

SIM 2

HOERBIGER

15V

HYDROCOM

Scroll /

Reset

SIM 3

GIM

HOERBIGER

5V

MODB

US

IPS

T3: 4..20 mA = -25..+125

T4: 4..20 mA = -25..+125

0%

t

TDC-Sensor

HydroCOM Bus

48 VDC

Actuators

Compressor

Hydraulic-Unit

Fig 4.: basic control scheme

General Description 201

00-01-19

�3.5

Admissions

The legal provisions of the different countries prescribe the observance of

regulations and directives concerning mainly safety matters. In the EEA and

the CENELEC countries (Belgium, Denmark, Germany, Finland, France,

Greece, Great Britain, Ireland, Iceland, Italy, Luxemburg, The Netherlands,

Norway, Austria, Portugal, Sweden, Switzerland and Spain ) these

regulations are standardized. Other countries have often quite different

regulations, sometimes the European ones may be applied.

Certain properties have to be certified by a homologation with an authorized

institution, while for others a producers declaration will do. In future the CEsign will serve to attest compliance with all the directives in the EEA. At the

time being the CE-sign attests accordance with the machine safety directive,

the EMC directive, and the low voltage device directive, whereas for

explosion protection there is a transient time until July 1st, 2003.

3.5.1 Electromagnetic Compatability (EMC)

Standards:

EN 50081-1

electromagnetic compatibility

Generic emission standard

Part 1: residential environment

EN 50082-2

electromagnetic compatibility

Generic immunity standard

Part 2: Industrial environment

and basic standards (e.g. EN 55011 and others)

The EMC-directive and their conversions into national law (e.g. Austrian

electrotechnical law with EMC regulation or German EMC law) define the

conditions necessary to place electrical units on the market.

At one hand the functioning of the unit in an environment of electromagnetic

interference must be guaranteed, on the other hand the unit must not cause

harmful interference with its environment.

With ISM-units (Industrial, Scientific, Medical) among which the HydroCOM

system can be counted, no homologation is necessary, the compliance with

the applicable regulations has to be testified by a manufacturer's declaration

and the CE-sign.

HOERBIGER had HydroCOM tested at a competent body and can therefore

issue the manufacturer's declaration.

3.5.2 Safety of low voltage devices

Standards:

EN 61010-1 safety requirements for electrical

equipment for measurement, control and

laboratory use, Part 1: General requirements

Those parts of HydroCOM which are supplied by mains voltage (essentially

the CIU unit) are subject to the low voltage device directive. Examinations

are made and a technical documentation is kept available for authorities.

General Description 201

10

00-01-19

�3.5.3 Explosion protection

Standards:

Electrical apparatus for potentially

explosive atmospheres

EN 50014

General requirements

EN 50018

Flame proof enclosures d

EN 50019

Increased safety e

additional for the TIM module:

EN 50020

intrinsic safety b

As most of the HydroCOM installations will be in potentially explosive

atmospheres, all units will be produced explosion proof.

Protection class EEx-d will be applied to the housing where the valve

electronics, the solenoid which drives the hydraulic valve and the sensors

are placed. EEx-e is applied to the terminal chamber and the construction of

the solenoid.

With module TIM the housing containing the electronics is made in

protection class EEx-d, the terminal chamber for mains supply and bus in

class EEx-e, the terminal chamber for the transmitter lines in class EEx-ib.

The accordance with the European regulations is guaranteed by a

homologation with a testing laboratory as well as the required sample tests

and it is certified by a mark of conformity on the unit.

HOERBIGER have received FM Approval for the USA (The approval for the

measuring module TIM is still pending).

In case further admissions become necessary the respective lead time and

expenditure have to be considered.

General Description 201

11

00-01-19

The Components of the HydroCOM system

SU

RS 232

CIU

MODBUS

DCS

Wa: Warning

Er: Error

Hy: Hydraulic Fault

HOERBIGER

En: Enable

HOERBIGER

HOERBIGER

Valve

Valve

Valve

C ode

Code

Code

HOERBIGER

Power

TDC

Enable

Ext.Sim.

P hyd Lo

Sensor

Error

S

U

Sim: Simulation

Scroll /

Reset

Scroll /

Reset

SIM 2

SIM 1

Y1: 4...20 mA =appr. 0...100%

HOERBIGER

MODB

US

GIM

230 VAC or

110 VAC

15V

HYDROCOM

Scroll /

Reset

SIM 3

HOERBIGER

5V

IPS

Y2: 4...20 mA =appr. 0...100%

Suction pressure 1st stage

4...20 mA = 0-50 bar

T1: 4...20 mA = -25...+125

T2: 4...20 mA = -25...+125

T3: 4...20 mA = -25...+125

Suction pressure 2nd stage

4...20 mA = 0-100 bar

EPS

T4: 4...20 mA = -25...+125

I

IA

A

TDC-Sensor

HU

analogue signal lines

Actuators

binary signal lines

3*500VAC

48 VDC lines

VAC lines

Compressor

hydraulic lines

Flare Gas

flare lines

Fig 5.: General view HydroCOM system

The above example shows (for a two-stage compressor) all the components

and lines the HydroCOM system consists of. The following section will

explain the individual components in a general way.

These are

4.1

the HydroCOM Actuators

Compressor Interface Unit

External Power Supply

Isolation Amplifier

TDC-sensor

the HydroCOM HU (hydraulic unit)

the HydroCOM SU (service unit)

Measuring module TIM (optional, not shown)

HydroCOM Actuators

4.1.1 Task

The HydroCOM actuators are those elements which act upon the valves via

the unloaders. The hydraulic pressure necessary for this purpose is supplied

by the hydraulic unit (HU). The actuators are controlled by the Compressor

Interface Unit (CIU) and get their electrical power supplied by the EPS

(External Power Supply).

4.1.2 Design

The actuators consist of a valve housing, a seal housing and an electronic

control unit (IVD i. e. Intelligent Valve Driver).

In the valve housing there is a 3/2 way valve which is actuated by a solenoid

and a retracting spring.. Depending on the position of the 3/2 way valve the

actuator piston is either exposed to the pressure maintained by the

General Description 201

12

00-01-19

�hydraulic unit or to the atmospheric pressure (tank). A check valve is located

upstream of this 3/2 way valve. During the phase of reverse flow through the

suction valve the fluid gets trapped. The pressure in the volume downstream

of the check valve and upstream of the pressure relief port of the switching

valve may exceed the pressure of the hydraulic unit. Thus the system

requires minimum auxiliary energy to drive the hydraulic unit.

In order to protect the moving parts of the unloading system as well as the

valve sealing elements against excessive impact stress a two stage throttle

is installed in the actuator. It consists of a start bypass volume and an

orifice. The bypass volume is filled during the first phase of the closing

operation ( 50% to 90% of the valve lift). Then when flowing through the

orifice a high pressure is built up which dampens the valve plate motion

considerably before it hits the seat.

The actuator piston acts on a push rod, which actuates the valve unloader.

Sealing of this push rod is reached by a wiper element, sealing rings and

guide bands which are installed in the sealing housing. This packing works

up to a pressure of 100 bars. Between the upper and lower guide there is a

ring chamber which has to be connected to flare.

A temperature sensor is located within this seal housing with the sensing

point very close to the suction valve. Thus it is exposed directly to any

potential suction temperature changes caused by valve failure or extended

idling of the compressor.

Valve

ValveHousing

Housing

Oil

Oilinin

Oil

pressure

sensor

Oil pressure sensor

Valve

Valvecartridge

cartridge

Soft

touch

Soft touchdamper

damper

Oil

Oilout

out

Piston

cartridge

Piston cartridge

High

Highpressure

pressurepiston

piston

Electric

ElectricHousing

Housing

Connection

Connectionbox

box

Printed

Printedcircuits

circuitsincl.

incl.

Microcontroller

Microcontrollerand

and

Safety

Safetybarriers,

barriers,

Fuses,

Fuses,Bus

BusInterface

Interface

Seal

SealHousing

Housing

Leakage

Leakageout

out

Wiper

Wiperrings

rings

Guiding

Guidingrings

rings

Sealing

Sealingrings

rings

Flare

Flareconnection

connection

Temperature

Temperaturesensor

sensor

Unloader

UnloaderRod

Rod

Fig 6.: construction HydroCOM Actuator

In case hydraulic oil leaks into the seal housing it is led off by a leakage oil

connection into a collecting tank. The collecting volume for the leakage oil is

connected to atmosphere by two venting bores. Immediately below the

venting bores there are the leakage oil connections.

The valve electronics (IVD) are located in a flameproof housing (EEx-d).

They control the solenoid, monitor the hydraulic pressure and measure the

valve nest temperature. Each actuator is equipped with a microprocessor for

the fulfillment of these tasks. This microprocessor solves drive, monitoring,

and communication functions by means of a special program. The electrical

lines are connected to the CIU via a terminal chamber

(EEx-e).

General Description 201

13

00-01-19

�4.2

Compressor Interface Unit CIU

4.2.1 Duty

The HydroCOM-CIU (Compressor Interface Unit) serves as an interface

between the HydroCOM-system and the distributed control system. The

controller output defined for each compressor stage is translated into the

opening and closing signals for the suction valves. The valve nest

temperatures, which are fed back by the actuators, are transferred to the

DCS via the CIU. Further the transmission of enable-, warning-, error- , and

simulation signals is effected via the CIU. An IBM compatible PC (RS-232Interface) can be connected to the CIU. Via this interface the CIU can be

configured and checked. In order to open and close the suction valves with

respect to the crank-angle a TDC-sensor sends the TDC-pulses to the CIU

which calculates the valve actuation timing.

Data exchange to the DCS need not be effected via parallel wiring but can

alternatively by carried out via MODBUS.

4.2.2 Design

The Compressor Interface Unit consists of up to six Stage Interface Modules

(SIM), the General Interface Module (GIM) and the Internal Power Supply

(IPS). The modules are placed in a 19" sub-rack. Up to eight valves as well

as up to two Transmitter Interface Modules TIM can be controlled per SIM.

Head-end and crank end valves can be driven independently. There must be

one data line to the compressor per SIM (For an exact specification of the

data line see the assembly and installation manual).

HOERBIGER

HOERBIGER

HOERBIGER

HOERBIGER

HOERBIGER

HOERBIGER

Power

Valve #

Valve #

Valve #

Code #

Code #

Code #

Scroll /

Reset

Scroll /

Reset

Scroll /

Reset

SU

SIM 1

SIM 2

TDC

Enable

5V

Ext.Sim.

Phyd Lo

Sensor

Error

15V

MODBUS

HYDROCOM

SIM 3

GIM

IPS

Fig. 7.: Front view HydroCOM-CIU

4.3

External power supply

4.3.1 Duty

The External Power Supply (EPS) serves for providing power to the IVD

and the solenoids of the actuators. The solenoids require a supply voltage of

48 VDC. A supply line has to be laid from the EPS to each valve (for exact

specification of the lines see the assembly and installation manual).

4.3.2 Design

Depending on the number of actuators three different models of EPS-units

are available which differ in their power rating.

4.4

Isolation Amplifier

4.4.1 Duty

The Isolation Amplifier interfaces the digital signal of the TDC sensor in the

hazardous area (intrinsically safe circuit) to the safe area. A proximity switch

acc. to NAMUR or DIN 19234 can be connected at the input. The output is

General Description 201

14

00-01-19

�connected to the CIU. Input, output and supply voltage are electrically

isolated from each other.

4.5

TDC-sensor

4.5.1 Duty

The TDC-sensor synchronizes the CIU with compressor speed. CIU and

TDC-sensor are electrically separated by the isolation amplifier IA. The

TDC-Sensor is a cylindrical, inductive proximity switch according to DIN

19234 (NAMUR).

4.6

Hydraulic Unit HU

4.6.1 Duty

The Hydraulic Unit serves to supply the actuators with oil in order to open

the suction valves. A pump pressurizes - depending on the suction pressure

of the highest controlled compressor stage - oil from atmospheric pressure

up to 150 bar. The oil is fed to the actuators via lines that can be shut-off.

There are pulsation dampers close to inlet and outlet of the valves.

The oil is led back unpressurized. Besides the oil supply lines a leakage oil

line has to be connected to a separate collector tank. (The specification of

the piping system can be found in the assembly and installation manual).

4.6.2 Design

The following drawing shows the basic design of the hydraulic unit.

Hydraulic oil is pumped via a gear pump into the system. The oil is

connected to the circuits of each stage via redundant high-pressure-filters

with check valves (visual blocking indication).

For each compressor stage one circuit is used. The maximum operating

pressure is maintained through a pressure control valve. Any overflowing oil

is cooled down in a cooler and is sent via a return filter to the tank.

Depending on the customers demand the following options can be

integrated into the hydraulic unit:

signal for warning of tank oil level to DCS

signal for warning of tank oil temperature to DCS

drip pan

oil heating (Stand by units during cold seasons)

If the customer wishes to purchase other options than these standardized

options we kindly advise to purchase the hydraulic unit by a local supplier.

General Description 201

15

00-01-19

�Fig .8.: principle design hydraulic unit

4.7

Service Unit SU

4.7.1 Duty:

The service unit consists of an IBM-compatible PC (not supplied with the

HydroCOM-system) and the respective service software based on Microsoft

Windows. It serves for configuration of the CIU and for analyzing the system.

It is used for adapting the CIU to the special application. Limit values of

warning and malfunction can be adapted. In case of damage, a detailed

error analysis of the CIU can be established by means of the SU. Further it

is possible to set the optimal switching time of unloader action in order to

obtain a very soft opening of the suction valves.

General Description 201

16

00-01-19

�4.8

The Compressor Condition Monitoring (CCM) Software Package

The optional HydroCOM CCM (Compressor Condition Monitoring) software

package can be used for online monitoring and smart alarm handling: e.g.

deviation of theoretical and measured value.

Compared to conventional alarm handling much more sensitive alarm limits

can be set without insignificant alarms.

This CCM software runs on a PC which can be linked to the CIU using a

RS232/485 data cable.

Fig.9: Alarm screens and trend diagram HydroCOM CCM

General Description 201

17

00-01-19

�4.9

Measuring Module TIM

4.9.1 Duty:

The measuring module TIM serves to use the already existing data line

between the field and the control room for additional measuring tasks.

This especially concerns data relevant for machine diagnosis like discharge

valve temperatures, pressures, etc.

Standard transmitters in 2-wire execution can be used (4 ... 20 mA). The

explosion protection requirements have to be observed.

Terminal compartment

like actuator

Flameproof

housing

Terminal compartment

for transmitter circuits

Fig.10: Measuring Module TIM

4.9.2 Design

Similar to the actuator the TIM is installed in the field. Therefor the

electronics are installed in a flameproof housing. The electrical connection is

similar to that of the actuator. Further there is a terminal compartment for 8

intrinsically safe circuits. Power supply and safety barriers (EExib) for the

intrinsically safe circuits are within the flameproof housing.

Windows is a trademark of Microsoft Corporation

General Description 201

18

00-01-19