Professional Documents

Culture Documents

Us 20040158969

Uploaded by

dgfhjsdg hfsdhyjOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20040158969

Uploaded by

dgfhjsdg hfsdhyjCopyright:

Available Formats

US 20040158969A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2004/0158969 A1

(43) Pub. Date:

Ortmann et al.

(54)

METHOD FOR PRODUCING A SHEATHED

PENETRATOR

(30)

Aug. 19, 2004

Foreign Application Priority Data

Feb. 12, 2003

(DE) ................................... .. 103 05 721.8

(75) Inventors: Helmut Ortmann, Duisburg (DE);

Publication Classi?cation

Stefan Thiesen, Willich (DE); Dieter

J ungbluth, Herschbach (DE)

Correspondence Address:

VENABLE, BAETJ ER, HOWARD AND

CIVILETTI, LLP

PO. BOX 34385

WASHINGTON, DC 20043-9998 (US)

(73)

Assignee: Rheinmetall W & M GmbH, Unterluss

(22)

Filed:

Int. Cl? .................................................... ..B23P 17/04

Us. 01. .............................................................. .. 29/592

(57)

ABSTRACT

A method is provided for producing a sheathed penetrator

having a steel sheath and a heavy-metal core With a smooth

surface. The method includes heating the steel sheath to a

temperature betWeen 70 and 350 C.; inserting the heavy

metal core into the heated steel sheath; and allowing the steel

sheath to cool doWn. An inside diameter of the steel sheath

(DE)

(21) Appl. No.:

(51)

(52)

and an outside diameter of the heavy-metal core are such

that an interference ?t exists betWeen the steel sheath and the

heavy-metal core after the steel sheath has cooled doWn.

10/776,169

Feb. 12, 2004

l.

7

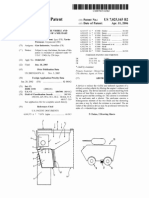

Patent Application Publication Aug. 19, 2004 Sheet 1 0f 2

US 2004/0158969 A1

FiC.\

Patent Application Publication Aug. 19, 2004 Sheet 2 0f 2

I.n

US 2004/0158969 A1

Aug. 19, 2004

US 2004/0158969 A1

METHOD FOR PRODUCING A SHEATHED

PENETRATOR

CROSS REFERENCE TO RELATED

APPLICATION

[0001] This application claims the priority of German

Patent Application, DE 103 05 721.8 ?led Feb. 12, 2003 and

Which is incorporated herein by reference.

BACKGROUND OF THE INVENTION

[0002] The invention relates to a method for producing a

sheathed penetrator, comprising a steel sheath and a heavy

results in an interference ?t due to the shrinkage of the steel

sheath. In addition, the steel sheath and the heavy-metal core

can also be glued together.

[0009] The sensitivity to breakage of the heavy-metal core

is reduced considerably When a smooth heavy-metal core is

used because of the reduction in the notching effect.

[0010] The sheathed penetrator that is produced according

the inventive method has the advantage that it can be

disassembled easily at a later date. To disassemble, the

penetrator sheath is heated up again and, once it has suf?

ciently eXpanded, is removed from around the heavy-metal

core, so that the individual parts can be reused in other

metal core.

applications. In particular, it is possible to insert a different

core into the eXisting sheath (a replacement core). This can

[0003]

German patent publication DE 22 34 219 C1 is

be advantageous, for eXample, if correspondingly improved

directed to a method for producing a sheathed penetrator,

Wherein a tubular steel sheath and a tungsten carbide core

that is sensitive to breakage are connected by means of a

in penetrator technology or if the penetrator is to be used for

different purposes, for eXample if the threat situation has

cores are to be inserted as a result of further developments

threaded connection. The disadvantage of this method is that

changed.

on the one hand it is very cost intensive and, on the other

[0011] It has been proven that it is advantageous if the

steel sheath is produced With the poWder metallurgy method

hand, installing the eXternal thread on the brittle heavy

metal core considerably increases sensitivity to breakage of

this core.

[0004]

German patent publication DE 39 11 575 A1 is

directed to ?tting the steel sheath onto the heavy-metal core

through surface Welding. Apart from the fact that this

method also involves a long and cost-intensive production

process, it has turned out that When attaching the steel sheath

through surface Welding, the resulting heat negatively

effects the mechanical values and structure of the heavy

metal core.

[0005] German patent publication DE 40 16 051 C2 is

directed to af?Xing the steel sheath With the aid of pressure

rolling. HoWever, this method also has not succeeded in

practical operations because of a number of disadvantages.

since this is a very economical method. The poWder-based

material makes it possible to produce the required geometric

dimensions in essentially one operating step, Without requir

ing additional mechanical processing. In addition, a particu

larly precise coaXial positioning of core and sheath can be

achieved. Sheathed penetrators of this type therefore have a

particularly trouble-free and non-oscillating ?ight phase.

[0012] HoWever, the steel sheath can also be produced

through further processing of a respective solid material.

[0013] Additional details and advantages of the invention

folloW from the exemplary embodiment that is eXplained in

the folloWing With the aid of the Figures.

BRIEF DESCRIPTION OF THE DRAWINGS

In particular, the mechanical deformation process can lead to

required for carrying out this method are very cost-intensive.

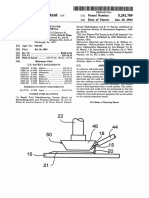

[0014] FIG. 1 shoWs a schematic representation of an

eXample of a ?rst embodiment of the invention; and

SUMMARY OF THE INVENTION

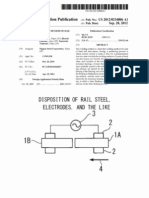

[0015] FIG. 2 shoWs a schematic representation of an

eXample of a second embodiment of the invention.

[0006] It is an object of the invention to provide a simple

and loW-cost method for producing a sheathed penetrator,

Wherein the structure of the heavy-metal core and/or its

breaking strength is not, or not essentially, in?uenced.

DETAILED DESCRIPTION OF THE

INVENTION

damage to the components. In addition, the machines

[0007] This and other objects are achieved according to

the invention, in Which a method is provided for producing

a sheathed penetrator having a steel sheath and a heavy

metal core With a smooth surface. The method includes

heating the steel sheath to a temperature betWeen 70 and

350 C.; inserting the heavy-metal core into the heated steel

sheath; and alloWing the steel sheath to cool doWn. An inside

[0016] FIG. 1 shoWs a schematically draWn, ?n-stabiliZed

sheathed penetrator 1. The penetrator 1 has, in this eXample,

a tungsten heavy-metal core 2, a steel sheath 3 produced

With the poWder-metallurgical method, Which consists of a

tubular main part 4 and, in this eXample, a solid material rear

part 5 onto Which a guide assembly 6 is screWed, as Well as

a ballistic cap 7.

[0017] To produce this sheathed penetrator 1, the tubular

diameter of the steel sheath and an outside diameter of the

main part 4 of the steel sheath 3 is initially heated to a

heavy-metal core are such that an interference ?t eXists

temperature betWeen 70 and 350 C., preferably 150 C.

FolloWing this, the heavy-metal core 2 that is provided With

betWeen the steel sheath and the heavy-metal core after the

steel sheath has cooled doWn.

[0008] The invention is based on the idea of initially

heating the steel sheath to a temperature betWeen 70 and

350 C., preferably 150 C., and subsequently inserting the

heavy-metal core With smooth surface into the heated steel

sheath. The steel sheath is then alloWed to cool doWn, Which

an extremely smooth surface 8 is inserted into the heated

steel sheath 3.

[0018] To permit an easier and faster insertion of the

heavy-metal core into the steel sheath, it has proven advan

tageous if the inside diameter of the steel sheath 3 and the

outside diameter of the heavy-metal core 2 have a conical

Aug. 19, 2004

US 2004/0158969 A1

shape that opens up slightly toward the front of the penetra

inserting the heavy-metal core into the heated steel

tor 1. FIG. 2 shows an example of the invention in Which the

inside diameter of the steel sheath 3 and the outside diam

eter of the heavy-metal core 2 have a conical shape that

alloWing the steel sheath to cool doWn,

opens up slightly toWard the front of the penetrator 1.

[0019]

The steel sheath 3, 3 is then alloWed to cool doWn,

so that it shrinks to ?t onto the heavy-metal core 2, 2. The

inside diameter of the steel sheath 3, 3 and the outside

diameter of the heavy-metal core 2, 2 in this case are

selected such that the interference ?t betWeen the steel

sheath 3, 3 and the heavy-metal core 2, 2 is suf?ciently

strong.

[0020] Finally, the guide assembly 6 is attached to the rear

part 5 of the steel sheath 3, 3 and the ballistic cap 7 is

attached With its inside surface 9 that ?ts against the pro

jectile body, for eXample With the aid of glue or friction

Welding.

sheath; and

Wherein an inside diameter of the steel sheath and an

outside diameter of the heavy-metal core are such that

an interference ?t eXists betWeen the steel sheath and

the heavy-metal core after the steel sheath has cooled

doWn.

2. The method according to claim 1, Wherein the steel

sheath is heated to a temperature of approximately 150 C.

3. The method according to claim 1, Wherein the steel

sheath and the heavy-metal core are additionally connected

by glue.

4. The method according to claim 1, Wherein the steel

sheath is produced With the aid of a poWder-metallurgical

method.

5. The method according to claim 1, Wherein the steel

sheath is produced through processing of a respective solid

of ordinary skill in the art that many changes and modi?

material.

6. The method according to claim 1, Wherein the inside

diameter of the steel sheath and the outside diameter of the

heavy-metal core have a conical shape that has a larger

diameter at a front end of the penetrator.

7. The method according to claim 2, Wherein the steel

sheath and the heavy-metal core are additionally connected

cations can be made to the invention Without departing from

by glue.

[0021]

The invention is not limited to the above-described

eXemplary embodiment. For eXample, it is possible to fash

ion a tip onto the front of the heavy-metal core and ?t the cap

over this tip.

[0022]

It Will be apparent, based on this disclosure, to one

the spirit and scope thereof.

What is claimed is:

1. Amethod for producing a sheathed penetrator having a

steel sheath and a heavy-metal core, the heavy metal core

having a smooth surface, the method comprising:

heating the steel sheath to a temperature betWeen 70 and

350 C.;

8. The method according to claim 2, Wherein the steel

sheath is produced With the aid of a poWder-metallurgical

method.

9. The method according to claim 2, Wherein the steel

sheath is produced through processing of a respective solid

material.

10. The method according to claim 2, Wherein the inside

diameter of the steel sheath and the outside diameter of the

heavy-metal core have a conical shape that has a larger

diameter at a front end of the penetrator.

*

You might also like

- Piping Spool Fabrication ProcedureDocument14 pagesPiping Spool Fabrication ProcedureMiky Andrean100% (6)

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- Overheated and Burnt SteelDocument10 pagesOverheated and Burnt SteelBhavikRawalNo ratings yet

- Ladle Nozzle Filling CompoundDocument2 pagesLadle Nozzle Filling CompoundRam Deo Awasthi75% (4)

- Instruction Manual-Turning RollersDocument13 pagesInstruction Manual-Turning RollersRomaldoNo ratings yet

- United States Patent (191: Merz Et A1. Date of PatentDocument13 pagesUnited States Patent (191: Merz Et A1. Date of Patentbonmarche28No ratings yet

- United States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Document4 pagesUnited States Patent 1191 1111 3,956,085: Haas (45) May 11, 1976Alejandro Saravia AlcócerNo ratings yet

- 1931 6834 1 SMDocument12 pages1931 6834 1 SMchpinto10% (1)

- Flash Butt WeldingDocument20 pagesFlash Butt WeldingRakesh SrivastavaNo ratings yet

- European Patent Specification: Steel - A Low Alloy High Strength CompositionDocument12 pagesEuropean Patent Specification: Steel - A Low Alloy High Strength CompositionDa DdeNo ratings yet

- New Welding Tubular Joint Used For JacketDocument6 pagesNew Welding Tubular Joint Used For JacketTien Hong DoNo ratings yet

- 6.study FullDocument8 pages6.study FullTJPRC PublicationsNo ratings yet

- Welding and Joining Process: Basic Concept of WeldingDocument7 pagesWelding and Joining Process: Basic Concept of WeldingNaresh kumarNo ratings yet

- United States Patent: Noveske (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Noveske (10) Patent N0.: (45) Date of Patentduffy5555No ratings yet

- Principles of WeldingDocument13 pagesPrinciples of WeldingMadhurimaMitraNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- Method of Ladle Steelmaking and Product Produced Thereby - A. Finkl & Sons CoDocument9 pagesMethod of Ladle Steelmaking and Product Produced Thereby - A. Finkl & Sons ComanikannanNo ratings yet

- Shot PeeningDocument11 pagesShot Peeningdnageshm4n244No ratings yet

- A Study of The Scale Structure of Hot-Rolled SteelStrip by Simulated Coiling and CoolingDocument22 pagesA Study of The Scale Structure of Hot-Rolled SteelStrip by Simulated Coiling and CoolingbraneworldNo ratings yet

- Centrifugal Casting (8-20)Document20 pagesCentrifugal Casting (8-20)Rabindra DashNo ratings yet

- THE EFFECTS OF STEEL MILL PRACTICE ON PIPE AND TUBE MAKING-nichols PDFDocument13 pagesTHE EFFECTS OF STEEL MILL PRACTICE ON PIPE AND TUBE MAKING-nichols PDFAntonioNo ratings yet

- R 02 Danieli Corus - Blast Furnace Cast HouseDocument11 pagesR 02 Danieli Corus - Blast Furnace Cast HouseSaptarshi SenguptaNo ratings yet

- Advantages of ForgingDocument14 pagesAdvantages of Forgingrehan RNNo ratings yet

- Continuous Casting PracticesDocument5 pagesContinuous Casting Practicesbhauvik0% (1)

- Journal of Materials Processing TechnologyDocument8 pagesJournal of Materials Processing TechnologyHARIMETLYNo ratings yet

- Cs Project ReportDocument24 pagesCs Project Reportharika mandadapuNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Presentation Chp30 2Document31 pagesPresentation Chp30 2azemmmNo ratings yet

- Heat Plat ApplicationDocument6 pagesHeat Plat ApplicationJDC - Export ManagerNo ratings yet

- Steel Esr CernDocument11 pagesSteel Esr Cernfarchipmm58No ratings yet

- Determination of Necessary Preheating Temperature in Steel WeldingDocument7 pagesDetermination of Necessary Preheating Temperature in Steel WeldingKelvin LabarezNo ratings yet

- Welding by Roop Lal RanaDocument21 pagesWelding by Roop Lal Ranaanmolmahajan1234No ratings yet

- Tailormade Course For Bhel - J&K Trainees (Tech)Document5 pagesTailormade Course For Bhel - J&K Trainees (Tech)Yuvaraj ChinthNo ratings yet

- BS 4449 PDFDocument20 pagesBS 4449 PDFAnonymous 8Lfqtc100% (1)

- Principles of WeldingDocument19 pagesPrinciples of WeldingAekJayNo ratings yet

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocument7 pagesNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNo ratings yet

- United States Patent 1191: Suzi, Gallo, Turin, My Foreign Patent DocumentsDocument3 pagesUnited States Patent 1191: Suzi, Gallo, Turin, My Foreign Patent DocumentsAbhinav BhargavNo ratings yet

- Friction Stir Welding of SteelDocument4 pagesFriction Stir Welding of SteelInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Laboratory 5Document10 pagesLaboratory 5Andy BirdieNo ratings yet

- Metal Mould-Casting Processes: Unit Iv Moulding ProcessesDocument26 pagesMetal Mould-Casting Processes: Unit Iv Moulding ProcessesMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- Metal Casting Technology: Digital Assignment 2Document11 pagesMetal Casting Technology: Digital Assignment 2Sanket GandhiNo ratings yet

- Billets ProcessDocument5 pagesBillets ProcessWewey NuestroNo ratings yet

- Heat Treatment of SteelDocument7 pagesHeat Treatment of SteelmaadNo ratings yet

- US Patent For Dredger Teeth MaterialDocument6 pagesUS Patent For Dredger Teeth MaterialathiyanindyaNo ratings yet

- Key Words: Primary Steelmaking, Ladle Metallurgy, Ingot Casting, Continuous Casting ConceptDocument4 pagesKey Words: Primary Steelmaking, Ladle Metallurgy, Ingot Casting, Continuous Casting ConceptAbhijeet BhagavatulaNo ratings yet

- Uzi/M6417, M 71 W75': Aug. 12, 1941-P. R. SeemillerDocument7 pagesUzi/M6417, M 71 W75': Aug. 12, 1941-P. R. SeemillerRadnumNo ratings yet

- United States Patent (19) : (73) Assignee: NKK Corporation, Tokyo, JapanDocument7 pagesUnited States Patent (19) : (73) Assignee: NKK Corporation, Tokyo, JapanErin GokNo ratings yet

- Metal ForgingDocument17 pagesMetal ForgingcemekaobiNo ratings yet

- Effects of The Casting Temperature On Microstructure and Mechanical Properties of The Squeeze-Cast Al-Zn-Mg-Cu AlloyDocument4 pagesEffects of The Casting Temperature On Microstructure and Mechanical Properties of The Squeeze-Cast Al-Zn-Mg-Cu AlloyDhanashekar ManickamNo ratings yet

- 2001 - Casting of Aluminum Alloy Ingots For Thixoforming Using A Cooling SlopeDocument4 pages2001 - Casting of Aluminum Alloy Ingots For Thixoforming Using A Cooling SlopeSpandana AchantaNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level Controlsalvador2meNo ratings yet

- 4 Harden AbilityDocument12 pages4 Harden AbilityFadlin QisthiNo ratings yet

- THE Working of Steel: Page V Preface To Second EditionDocument207 pagesTHE Working of Steel: Page V Preface To Second EditionGutenberg.org100% (2)

- Brazing and Soldering 1.0 Basics of Brazing and SolderingDocument4 pagesBrazing and Soldering 1.0 Basics of Brazing and SolderingDhananjay ParasharNo ratings yet

- Final Metal CastingDocument38 pagesFinal Metal CastingishanNo ratings yet

- Study of Forging Process Equipemnts-Practical-3Document12 pagesStudy of Forging Process Equipemnts-Practical-3prashantNo ratings yet

- Metallography of Welds - ASM International PDFDocument5 pagesMetallography of Welds - ASM International PDFJoseph Alexander BorgNo ratings yet

- Exothermic Welding: HistoryDocument3 pagesExothermic Welding: HistoryPratap VeerNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Us 3292539Document3 pagesUs 3292539dgfhjsdg hfsdhyjNo ratings yet

- Us 5610365Document5 pagesUs 5610365dgfhjsdg hfsdhyjNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,038,955: 2 I J J E '7" OperationDocument4 pagesUlllted States Patent (19) (11) Patent Number: 6,038,955: 2 I J J E '7" Operationdgfhjsdg hfsdhyjNo ratings yet

- Us 6019217Document5 pagesUs 6019217dgfhjsdg hfsdhyjNo ratings yet

- Us 3345945Document3 pagesUs 3345945dgfhjsdg hfsdhyjNo ratings yet

- Us 7025165Document5 pagesUs 7025165dgfhjsdg hfsdhyjNo ratings yet

- Us 6131519Document4 pagesUs 6131519dgfhjsdg hfsdhyjNo ratings yet

- Us 1530692Document2 pagesUs 1530692dgfhjsdg hfsdhyjNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 8,291,806 B2Document12 pagesUnlted States Patent (10) Patent N0.2 US 8,291,806 B2dgfhjsdg hfsdhyjNo ratings yet

- Aazzzs 2112291252:: Ulllted States Patent (19) (11) Patent Number: 6,048,379Document45 pagesAazzzs 2112291252:: Ulllted States Patent (19) (11) Patent Number: 6,048,379dgfhjsdg hfsdhyjNo ratings yet

- STP780 Eb.1415051 1 PDFDocument191 pagesSTP780 Eb.1415051 1 PDFhayderlin navaNo ratings yet

- The Power HandbookDocument96 pagesThe Power HandbookVictor HaraujoNo ratings yet

- Adhesive Transfer Tapes With Adhesive 300Document6 pagesAdhesive Transfer Tapes With Adhesive 300Tommy JonceNo ratings yet

- Geberit HDPE Catalogue Installation 2014Document120 pagesGeberit HDPE Catalogue Installation 2014Patricio AcuñaNo ratings yet

- Chapter 5 - Water Pollution. English VersionDocument11 pagesChapter 5 - Water Pollution. English VersionBijay MridhaNo ratings yet

- Plantation of Teak WoodsDocument11 pagesPlantation of Teak WoodsTochi Krishna AbhishekNo ratings yet

- PHARMACEUTICAL PRODUCT DEVELOPMENT INC 10-K (Annual Reports) 2009-02-24Document156 pagesPHARMACEUTICAL PRODUCT DEVELOPMENT INC 10-K (Annual Reports) 2009-02-24http://secwatch.com100% (2)

- Metronidazole AssyDocument2 pagesMetronidazole AssysaiNo ratings yet

- Fl4274en MKDocument2 pagesFl4274en MKbichojausenNo ratings yet

- HydrogenationDocument18 pagesHydrogenationSpandana ReddyNo ratings yet

- Flexonyl Blue WF 153Document2 pagesFlexonyl Blue WF 153Leandro EsvizaNo ratings yet

- Cat Delta ConectoresDocument90 pagesCat Delta ConectoresArgenis TRNo ratings yet

- INTRODUCTION TO ORGANIC CHEMISTRY XXXDocument6 pagesINTRODUCTION TO ORGANIC CHEMISTRY XXXadritaNo ratings yet

- Assal's PatentsDocument11 pagesAssal's PatentsAnwar AssalNo ratings yet

- Grundfosliterature 5235678Document104 pagesGrundfosliterature 5235678Adriana SandruNo ratings yet

- Tilapia Production Using Biofloc TechnologyDocument3 pagesTilapia Production Using Biofloc TechnologyYousaf JamalNo ratings yet

- ActionTypes LookupDocument2 pagesActionTypes LookupRohitKumarNo ratings yet

- Design SedimentPonds PDFDocument17 pagesDesign SedimentPonds PDFkalaiNo ratings yet

- JBM A 31162 PDFDocument9 pagesJBM A 31162 PDFAndrew makramNo ratings yet

- ADECO English PDFDocument28 pagesADECO English PDFpabulumzengNo ratings yet

- Zeta Plus™ A Series Filters - (316.6 K)Document4 pagesZeta Plus™ A Series Filters - (316.6 K)georgadam1983No ratings yet

- NETAFIM Drip Irrigation System HandbookDocument96 pagesNETAFIM Drip Irrigation System HandbookCarlos Rovello GandoNo ratings yet

- Wastewater Treatment Final ReportDocument247 pagesWastewater Treatment Final Reporthiyogs0% (1)

- Application of Ion Exchange Processes For The Treatment of Radioactive Waste....Document124 pagesApplication of Ion Exchange Processes For The Treatment of Radioactive Waste....Nguyen DungNo ratings yet

- DS59 - (1980) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of 12 To 27 Percent Chromium Steels PDFDocument338 pagesDS59 - (1980) Evaluations of The Elevated Temperature Tensilde and Creep-Rupture Properties of 12 To 27 Percent Chromium Steels PDFJacques StrappeNo ratings yet

- Caradol Sa36 23Document2 pagesCaradol Sa36 23AL NDOYENo ratings yet

- f1 Series Fluid Mechanics Data Sheets Web PDFDocument15 pagesf1 Series Fluid Mechanics Data Sheets Web PDFAtheerAlmosawi0% (1)