Professional Documents

Culture Documents

Dielectric Behaviour of PZT Ceramics at Microwave Frequencies

Uploaded by

theijesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dielectric Behaviour of PZT Ceramics at Microwave Frequencies

Uploaded by

theijesCopyright:

Available Formats

The International Journal Of Engineering And Science (IJES)

|| Volume || 4 || Issue || 1 || January - 2015 || Pages || 21-26||

ISSN (e): 2319 1813 ISSN (p): 2319 1805

Dielectric Behaviour of Pzt Ceramics at Microwave Frequencies

1,

B.K. Bongane , 2,N.P. Pawar , 3,U.B. Tumberphale, 4,R.S. Kawale ,

5,

P.G.Gawali

1.

Department of Physics, B. S. College, Basmathnagar, Dist: Hingoli- 431 512, India.

-----------------------------------------------------ABSTRACT ----------------------------------------------------The dielectric behavior of PbZr0.52Ti0.48O3 have been carried out at the X-band microwave frequency. The

composite material was prepared by using solid state reaction method. The dielectric constant (), dielectric

loss (), quality factor (

), relaxation time () and conductivity () of PZT having particle sizes 500,

250,176.5and125 microns have been studied at different temperatures i.e. -100,+100,+300 and +500c. The

experimental dielectric values have been verified by using correlation formulaes of Landau-Lifshitz-Looyenga

and Bottcher. It founds the good agreement with experimental values.

KEYWORDS: Dielectric properties, pzt, ferroelectric ceramics

----------------------------------------------------------------------------------------------------------------------------- ---------Date of Submission: 18 December 2014

Date of Accepted: 20 January 2015

----------------------------------------------------------------------------------------------------------------------------- ----------

I.

INTRODUCTION:

Perovskite PbZr1-xTixO3 ceramics are the most widely used Ferroelectric materials because & their

excellent properties. The highest piezoelectric and electromechanical coupling co-efficient have been obtained

for compositions nears the morpho tropic phase boundary (MPB) between rhombohedra and tetragonal phase.

Piezoelectricity was first discovered by Jacques and Pierce Curie in 1880, and other materials later discovered

included Rochelle salt, BaTio3, PbTio3, (PbzR0.52 Ti0.48o3), etc. Since lead zircon ate titanate (PZT) her excellent

piezoelectric properties, a high curies temperature, high spontaneous polarization and high electromechanical

coupling co-efficient it has become an important industrial product.

The compound Pb (Zr0.52 Ti0.48)O3 (PZT) has great piezoelectric properties which can apply in

transducer applications [1]. The optimized PZT thin film was also to successfully fabricate an acoustic device.

The device could be used as a transmitter or as a receiver [2]. PZT is one of the best know Ferroelectric material

due to its remarkable ferroelectric and piezoelectric properties in polycrystalline from [3-5]. It is most widely

used piezoelectric ceramic materials in devices like actuators, ultrasonic, transducers, sensors, resonators,

ferroelectric memory, optoelectronic, piezoelectric transformers [6-8]. Study of dielectric materials in

microelectronics devices gave rise to a new generation of microelectronic devices, such as

microelectromechanical systems, non-volatile random access memory microwave integrated circuits [9]. The

dielectric, elastic and piezoelectric properties of Ferroelectric materials are dependent on frequency and

amplitude of the driving field. Materials exhibiting piezoelectricity as well as nonlinear dielectric behavior are

named as Ferroelectric materials. These types of materials have wide range of applications as sound wave

detector, phonograph, pickups, microphones, accelerometers, biomedical field, capacitors etc.[10]. The main

objective of this work is to prepare the PZT material and to study its dielectric parameters for various grain sizes

and temperatures. The similar work has been done by other researchers [11-14].

II.

EXPERIMENTAL PROCEDURE:

Synthesis of material : PZT composite material was prepared for microwave studies by using solid state

reaction method. In SSR method, the solid reactants react chemically without presence of any solvent at high

temperatures yielding a product which is stable. The advantage of SSR method is that final product in solid

form is structurally pure with the desired properties depending on the final sintering temperatures. This method

is environment friendly and no toxic an unwanted waste is produced after the SSR is complete. The steps

involved in SSR are

[1] Take weighed appropriate high purity starting materials, fine grain powders in stoichiometric properties.

[2] Mix them together, thoroughly using agate mortar and pestle or ball milling.

[3] Heat the solid powder mixture (calcinations) at elevated temperatures in air using muffle furnace.

[4] Report the calcinations process twice with intermittent grinding.

[5] Final powder is ready.

www.theijes.com

The IJES

Page 21

Dielectric Behaviour Of Pzt Ceramics

The high purity AR grade Pb3O4 ZrO2TiO2 were used as starting materials for the solid state reaction.

[15]. These constituents were weighed and mixed thoroughly. The composite material was prepared for 50gm.

Pb3O4 ZrO2 & TiO2 are estimated as per Pb Zr0.52Ti0.48 O3 so that total molecular wt.is 318.424gm. Then after

estimating the samples of weights Pb3O4 ZrO2 & TiO2 had taken as 212.536, 73.932 and 31.956 gms respectively

out of 50 gms. Then this was mixed in stoichiometric proportion has been grinded about 3 hours continuously

using agate mortar for first calcinations. This mixture was initially sintered at temp 8000c for a time about 4

hours in a muffle furnace. Then after first calcinations the sample was again grinded or 1 hrs and kept about 4

hrs. at 12000c for final sintering. The chemical reaction at high temperature take place, through solid state

reaction giving a stable sample product free of residual reactants.

Material preparation for Dielectric studies :For the determination of dielectric parameters of PZT were

prepared by using sieves of different sizes. Like 500, 250, 176.5, 125 microns particle sizes. All the samples

transferred into the glass bottles and labeled according to their particle size. To determine the relative packing

factor (r) densities for each powder sample is measured, measurement of dielectric parameters () and () for

these powder samples were carried out using reflectometer technique at 9.85 GHz [10 to 13] microwave

frequency and at temperatures (-100c, +100c, +300c & +500c).For the accurate measurement of wavelength in

dielectric (d), sample is introduced in the dielectric cell in steps. Applying constant force of 98N on the

sample, and for each time the corresponding output power is measured by using crystal pick in the directional

coupler. The relationship between reflected power and sample height is approximately given by a sinusoidal

curve. The distance between two adjacent minima of the curve gives half the dielectric wavelength (d).

Determination of molecular parameters: The dielectric constant () and loss factor () for PZT powder at

microwave frequency are determined by using relations [16].

........ (1)

........ (2)

Where

is the free space wavelength

is the wavelength in dielectric

is the cutoff wavelength of waveguide

is the guide wavelength

The conductivity ( ) and relaxation time ( ) are obtained by using following relations.

......(3)

......(4)

Where w = 9.85 GHz angular frequency of measurement 0 is the permittivity of free space.

The values of

and

for bulk materials can be co-related by using the relations given by Bottcher

and Landau Lifshitz Looyenga.

III.

RESULTS AND DISCUSSION :

Table 1 shows values of permittivity ( ) and loss factor ( ) along with values of relative packing

fraction (r) for different particle sizes and temperatures. There is systematic increase in

and

with

increasing r. and systematic decrease in

and

with increasing temperature. This is expected because at

higher values of r the interparticle hindrance offered to the dipolar motion for a compact medium is much

higher than less bounded particles. The calculations of quality factor (Qxf) where f is resonant microwave

frequency are also mentioned in table 1. It is found decrease in Q x f values for decreasing particle size and by

increasing temperature the Q x f values increases. The values of relaxation time (p) and conductivity (p) are

increases systematically by increasing r and decreases by increasing of temp. It is due to, when polar

molecules are very large, then under the influence of high frequency the rotary motion of polar molecules of a

system is not sufficiently rapid to attain equilibrium with field. The increase in p by increasing r is due to

increasing hindrance to the process of polarization. The increase in p suggests that at higher compaction, no

micro cracks develop in sample due to high mechanical pressure. As temp increases, p decreases may be due to

increase in the effective length of dipole. Again increase in temp, causes an increase in energy loss due to the

large number of collisions and thereby decreasing p.

Table 2 indicates the measured and computed values of

and

for bulk from powder

measurements. The results reported at r = 1 are those measured on the finest crushed powder sample packed at

very closely in a sample holding dielectric cell at 98N force, so minimum voids between the particles. The

smallest particle size 125 micron or less assumed this system as solid bulk for getting correlation between

www.theijes.com

The IJES

Page 22

Dielectric Behaviour Of Pzt Ceramics

powder and solid bulk. The correlation formulae of Landau Lifshitz Looyenga and Bottcher was used. The

bulk values

and

are very much closer to measured values.

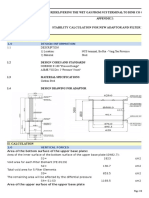

Table 1. Values of

Temperature

(oc)

-10

10

30

50

, Q x f, p and p of PZT at different temperatures and particle sizes.

Relative

packing

factor (r)

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

Q=

32.35

44.41

53.18

64.87

25.45

37.66

46.38

55.78

23.16

33.56

40.82

50.76

20.56

27.17

34.85

40.82

4.08

6.60

8.67

11.71

2.83

5.14

7.05

9.32

2.45

4.31

5.81

8.08

2.04

3.13

4.57

5.81

7.93

6.73

6.13

5.54

8.99

7.33

6.58

5.98

9.45

7.78

7.03

6.28

10.07

8.68

7.63

7.03

QxF

GHz

p

(P.S.)

78.11

66.33

60.43

54.60

88.58

72.16

64.80

58.95

93.10

76.65

69.22

61.87

99.19

85.58

75.13

69.22

2.04

2.40

2.64

2.92

1.78

2.21

2.45

2.71

1.71

2.07

2.30

2.57

1.60

1.86

2.11

2.30

2.23

3.61

4.71

6.41

1.55

2.81

3.85

5.10

1.34

2.36

3.17

4.42

1.11

1.71

2.50

3.17

Table 2. Measured and calculated Values of

and

, for solid bulk from PZT at different

temperatures and packing fractions.

Temperature

(oc)

- 10

+ 10

+ 30

+ 50

www.theijes.com

Relative

packing

factor

(r)

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

0.86

0.90

0.94

1.00

Measured

value

32.35

44.41

53.18

64.87

25.45

37.66

46.38

55.78

23.16

33.56

40.82

50.76

20.56

27.17

34.85

40.82

Calculated

from

Bottchers

Calculated

from

L-L-L

40.52

51.19

58.28

64.87

31.79

44.03

50.82

55.78

28.89

39.20

44.70

50.76

25.60

31.69

38.14

40.82

39.74

50.68

56.66

64.87

31.78

44.02

50.81

55.78

28.50

38.48

43.75

49.14

25.30

31.22

37.22

40.03

The IJES

Measured

value

4.08

6.60

8.67

11.71

2.83

5.14

7.05

9.32

2.45

4.31

5.81

8.08

2.04

3.13

4.57

5.81

Calculated

from

Bottchers

Calculated

from

L-L-L

5.51

8.14

9.80

11.71

3.81

6.33

7.97

9.32

3.30

5.31

6.56

8.08

2.74

3.85

5.16

5.81

5.16

7.76

9.52

11.71

3.58

6.04

7.74

9.32

3.1

5.07

6.38

8.08

2.58

3.68

5.02

5.81

Page 23

Dielectric Behaviour Of Pzt Ceramics

www.theijes.com

The IJES

Page 24

Dielectric Behaviour Of Pzt Ceramics

IV.

CONCLUSION:

It is found there is fair agreement of values dielectric constant between values obtained experimentally

and theoretically given by Landau Litshitz Looyenga and Bottcher between powder and solid bulk works

well.

www.theijes.com

The IJES

Page 25

Dielectric Behaviour Of Pzt Ceramics

V.

ACKNOWLEDGEMENT

Authors are very thankful to Dr. G.M. Kalamse for providing microware Research laboratory and

making fruitful discussion.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

Wanwilai Chaisan et al., Dielectric and ferrolectric properties of lead zirconate titanate caramics prepared by modified mixed oxide

method, Material Chemistry and Physics, 104, 2007, 113-118.

Chung-Cheng Chang et al., The Farbication and characterization of PZT Thin film Acoustic devices for Application in underwater

Rototic system. Proc. Natl. Sci. Counc. Roc.(A), 24(4), 2000, 287-292.

Y. Xu, Ferroelectric materials and their applications, (North Holland, Amsterdon, 1991).

G. Saghi-Szabo and R.E. Cohen, First principles study of piezoelectricity in tetragonal P bTiO3 and PbZr1/2Ti1/2O3. Phys. Rev. A, 59(20)

Z. Zhang, P. We, K.P. Ong, L. Lu and C. Shu, Electronic properties of A-site substituted lead zirconate fitanate; density functional

calculations, Phys. Rev. B, 76 (125102), 2007.

R.C. Buchanan, Ceramic materials for electronics, (Marcel Dekker, New York, 1991).

G.H. Haexptling, Ferroelectric ceramics : History and technology, J. Am. Ceram. Soc., 82, 1999, 797.

P. Muralt, J. Micromech, Microeng, 10, 2000, 136.

J.F. Scott, Ferroelectric Review, 1, 1998, 1-129.

P.G Gawali and B.K Bongane, Dielectric behavior & some pulses using reflectmetric technique at 9.85 CH3, Indian Journal &

applies research, 3, 2003.

B.S Narawade, P.G Gawali & G.M Kalmse, Dielectric studies & Binary mixture of n-propyl alcohol ethylenediamine, Journal of

Chemical Sciences & India Academy of Sciences, 117(6), 2005, 673-677.

P.G. Gawali and B.K Bongane, Microwave dielectric properties of (Bao.5Pbo.5)Tio3 with wave various temperature and particle sizes,

Bio-nano Frontier (Communicated).

B.K Bongane and P.G Gawali. Effect of particle size and temperature on dielectric parameters of PLZT ceramics at 9.85 GH3,

International Journal of Physics and Mathematical Sciences (Accepted MS NO. IJPMS 2014/04/011).

N.S Gajbhiye et al., Dielectric properties of nanostructure PZT synthesized by chemical methods, Defense Science Journal, 57(1),

2007, 61-68.

Mridula Kumari, Arun Singh, Jagdhar Mandal, Structural and Dielectric properties of PZT ceramics prepared by solid state reaction

route. International Journal of Scientific & Engineering Research, 5(4) 2014, 404-406.

Yadav J.S. and Gandhi J.M., Simple microwave technique for measuring the dielectric parameters and their powders, Indian Journal

of Pure and Applied Physics, 30, 1992, 427.

www.theijes.com

The IJES

Page 26

You might also like

- The Effect of Firm Size and Diversification On Capital Structure and FirmValue (Study in Manufacturing Sector in Indonesia Stock Exchange)Document12 pagesThe Effect of Firm Size and Diversification On Capital Structure and FirmValue (Study in Manufacturing Sector in Indonesia Stock Exchange)theijesNo ratings yet

- Defluoridation of Ground Water Using Corn Cobs PowderDocument4 pagesDefluoridation of Ground Water Using Corn Cobs PowdertheijesNo ratings yet

- Gating and Residential Segregation. A Case of IndonesiaDocument7 pagesGating and Residential Segregation. A Case of IndonesiatheijesNo ratings yet

- Literacy Level in Andhra Pradesh and Telangana States - A Statistical StudyDocument8 pagesLiteracy Level in Andhra Pradesh and Telangana States - A Statistical StudytheijesNo ratings yet

- A Statistical Study On Age Data in Census Andhra Pradesh and TelanganaDocument8 pagesA Statistical Study On Age Data in Census Andhra Pradesh and TelanganatheijesNo ratings yet

- Analytical Description of Dc Motor with Determination of Rotor Damping Constant (Β) Of 12v Dc MotorDocument6 pagesAnalytical Description of Dc Motor with Determination of Rotor Damping Constant (Β) Of 12v Dc MotortheijesNo ratings yet

- Multimedia Databases: Performance Measure Benchmarking Model (PMBM) FrameworkDocument10 pagesMultimedia Databases: Performance Measure Benchmarking Model (PMBM) FrameworktheijesNo ratings yet

- Data Clustering Using Autoregressive Integrated Moving Average (ARIMA) Model For Islamic Country Currency: An Econometrics Method For Islamic Financial EngineeringDocument10 pagesData Clustering Using Autoregressive Integrated Moving Average (ARIMA) Model For Islamic Country Currency: An Econometrics Method For Islamic Financial EngineeringtheijesNo ratings yet

- Means of Escape Assessment Procedure For Hospital's Building in Malaysia.Document5 pagesMeans of Escape Assessment Procedure For Hospital's Building in Malaysia.theijesNo ratings yet

- A Study For Applications of Histogram in Image EnhancementDocument5 pagesA Study For Applications of Histogram in Image EnhancementtheijesNo ratings yet

- Industrial Installation Skills Acquired and Job Performance of Graduates of Electrical Installation and Maintenance Works Trade of Technical Colleges in North Eastern NigeriaDocument8 pagesIndustrial Installation Skills Acquired and Job Performance of Graduates of Electrical Installation and Maintenance Works Trade of Technical Colleges in North Eastern NigeriatheijesNo ratings yet

- Big Data Analytics in Higher Education: A ReviewDocument8 pagesBig Data Analytics in Higher Education: A ReviewtheijesNo ratings yet

- Development of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencyDocument9 pagesDevelopment of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencytheijesNo ratings yet

- Impact of Sewage Discharge On Coral ReefsDocument5 pagesImpact of Sewage Discharge On Coral ReefstheijesNo ratings yet

- Improving Material Removal Rate and Optimizing Variousmachining Parameters in EDMDocument5 pagesImproving Material Removal Rate and Optimizing Variousmachining Parameters in EDMtheijesNo ratings yet

- Experimental Study On Gypsum As Binding Material and Its PropertiesDocument15 pagesExperimental Study On Gypsum As Binding Material and Its PropertiestheijesNo ratings yet

- Studio of District Upgrading Project in Amman - Jordan Case Study - East District WahdatDocument5 pagesStudio of District Upgrading Project in Amman - Jordan Case Study - East District WahdattheijesNo ratings yet

- Design and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatorDocument5 pagesDesign and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatortheijesNo ratings yet

- The Effect of Organizational Culture On Organizational Performance: Mediating Role of Knowledge Management and Strategic PlanningDocument8 pagesThe Effect of Organizational Culture On Organizational Performance: Mediating Role of Knowledge Management and Strategic PlanningtheijesNo ratings yet

- Short Review of The Unitary Quantum TheoryDocument31 pagesShort Review of The Unitary Quantum TheorytheijesNo ratings yet

- Performance Evaluation of Calcined Termite Mound (CTM) Concrete With Sikament NN As Superplasticizer and Water Reducing AgentDocument9 pagesPerformance Evaluation of Calcined Termite Mound (CTM) Concrete With Sikament NN As Superplasticizer and Water Reducing AgenttheijesNo ratings yet

- Status of Phytoplankton Community of Kisumu Bay, Winam Gulf, Lake Victoria, KenyaDocument7 pagesStatus of Phytoplankton Community of Kisumu Bay, Winam Gulf, Lake Victoria, KenyatheijesNo ratings yet

- A Lightweight Message Authentication Framework in The Intelligent Vehicles SystemDocument7 pagesA Lightweight Message Authentication Framework in The Intelligent Vehicles SystemtheijesNo ratings yet

- Energy Conscious Design Elements in Office Buildings in HotDry Climatic Region of NigeriaDocument6 pagesEnergy Conscious Design Elements in Office Buildings in HotDry Climatic Region of NigeriatheijesNo ratings yet

- Marginal Regression For A Bi-Variate Response With Diabetes Mellitus StudyDocument7 pagesMarginal Regression For A Bi-Variate Response With Diabetes Mellitus StudytheijesNo ratings yet

- Mixed Model Analysis For OverdispersionDocument9 pagesMixed Model Analysis For OverdispersiontheijesNo ratings yet

- Evaluation of Tax Inspection On Annual Information Income Taxes Corporation Taxpayer (Study at Tax Office Pratama Kendari)Document5 pagesEvaluation of Tax Inspection On Annual Information Income Taxes Corporation Taxpayer (Study at Tax Office Pratama Kendari)theijesNo ratings yet

- The Effect of Varying Span On Design of Medium Span Reinforced Concrete T-Beam Bridge DeckDocument4 pagesThe Effect of Varying Span On Design of Medium Span Reinforced Concrete T-Beam Bridge DecktheijesNo ratings yet

- Fisher Theory and Stock Returns: An Empirical Investigation For Industry Stocks On Vietnamese Stock MarketDocument7 pagesFisher Theory and Stock Returns: An Empirical Investigation For Industry Stocks On Vietnamese Stock MarkettheijesNo ratings yet

- Integrated Approach To Wetland Protection: A Sure Means For Sustainable Water Supply To Local Communities of Nyando Basin, KenyaDocument6 pagesIntegrated Approach To Wetland Protection: A Sure Means For Sustainable Water Supply To Local Communities of Nyando Basin, KenyatheijesNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- How To Design Multi KW Converters For Electric Vehicles Part 1 Ev System OverviewDocument8 pagesHow To Design Multi KW Converters For Electric Vehicles Part 1 Ev System OverviewSROTRIYA TRIPATHINo ratings yet

- Newton's Law of Accelerated Motion: Complete The ChartDocument2 pagesNewton's Law of Accelerated Motion: Complete The Chartlaurenq2030No ratings yet

- Design A Squirrel-Cage Induction Motor. Design A 2-hp 3-Phase 440-VoltDocument17 pagesDesign A Squirrel-Cage Induction Motor. Design A 2-hp 3-Phase 440-VoltLester MuscaNo ratings yet

- Electrical Diagrams1Document55 pagesElectrical Diagrams1Youssef BoulaghlaNo ratings yet

- Bushing 2099 PDFDocument40 pagesBushing 2099 PDF8085roNo ratings yet

- Capacitance TheoryDocument31 pagesCapacitance TheoryNiteshNo ratings yet

- Diode 2A01-2A07 (Data Sheet)Document3 pagesDiode 2A01-2A07 (Data Sheet)Dimitris DimitriadisNo ratings yet

- Prac-6 - Ideal GasesDocument18 pagesPrac-6 - Ideal GasesCristiano PassarelliNo ratings yet

- Stability Calculation for New Adapter and Filter ElementsDocument8 pagesStability Calculation for New Adapter and Filter ElementsSally LuciaNo ratings yet

- PN Junction Diode ExplainedDocument16 pagesPN Junction Diode ExplainedHarry WinstonNo ratings yet

- Current Electricity Latest 2023 - 17aa175d 3382 4a65 9ad5 Bad8694c983aDocument9 pagesCurrent Electricity Latest 2023 - 17aa175d 3382 4a65 9ad5 Bad8694c983asnigdha varshaNo ratings yet

- Dometic RM 2612 RV Ref Ridge Rat orDocument20 pagesDometic RM 2612 RV Ref Ridge Rat orgoldminer4No ratings yet

- Exp 1Document2 pagesExp 1JJ Sean CruzNo ratings yet

- E31404 Interlock List - FieldUpdates 291210 DCSDocument4 pagesE31404 Interlock List - FieldUpdates 291210 DCSrgonzalezmunozNo ratings yet

- MC-300 CD - Service ManualDocument28 pagesMC-300 CD - Service ManualMilorad Pajovic100% (1)

- SPI2016 Tutorial SlidesDocument112 pagesSPI2016 Tutorial SlidesJerry LiaoNo ratings yet

- 1A Bipolar Linear Regulator AMS1117 Technical Reference GuideDocument7 pages1A Bipolar Linear Regulator AMS1117 Technical Reference GuideFelipe silva santanaNo ratings yet

- Experiment N O - 1 8: Shunt Motor Characteristics PurposeDocument7 pagesExperiment N O - 1 8: Shunt Motor Characteristics PurposeMaranNo ratings yet

- Wave OpticsDocument15 pagesWave Opticspropeg 19No ratings yet

- Autonics TCN Manual PDFDocument2 pagesAutonics TCN Manual PDFArturo ValentinNo ratings yet

- Mathematical Description of a WaveDocument3 pagesMathematical Description of a WaveSubhash DhungelNo ratings yet

- Mcv110 Valve PilotDocument8 pagesMcv110 Valve PilotJose Manuel Bautista Martinez100% (1)

- Magnetic Monopole - A Complete Bibliography 1889 - 2000Document573 pagesMagnetic Monopole - A Complete Bibliography 1889 - 2000135753150% (2)

- Week 7 & 8 Wind LoadsDocument43 pagesWeek 7 & 8 Wind Loadsmuhammad nuruddin che ab malikNo ratings yet

- Statistical power prediction method revised formulasDocument4 pagesStatistical power prediction method revised formulasHieu100% (1)

- Basic Range: BI1-Time Overcurrent RelayDocument2 pagesBasic Range: BI1-Time Overcurrent RelayMidhun Varghese100% (1)

- 4 BuoyancyDocument5 pages4 BuoyancyDaniel Vasquez0% (1)

- 1 EXP Mechanical Vibration (Corrected)Document4 pages1 EXP Mechanical Vibration (Corrected)AbhiNo ratings yet

- EP19209582NWA1Document13 pagesEP19209582NWA1VAIBHAV36No ratings yet

- Datasheet Motor PM55L 048 HPG9Document1 pageDatasheet Motor PM55L 048 HPG9Geziany Fernandes100% (4)