Professional Documents

Culture Documents

Oxe Poster1

Uploaded by

ohsnap1017Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxe Poster1

Uploaded by

ohsnap1017Copyright:

Available Formats

KINETIC BASED PROCESS MODELING OF THE ISOBUTYLENE

POLYMERIZATION PROCESS

Yongtai Li, Michael Fidell, Paul Anthony, Omar M. Basha and Badie I. Morsi*

Reactor and Process Engineering Laboratory

Department of Chemical and Petroleum Engineering, Unviersity of Pittsburgh, Pittsburgh, PA 15261

* Corresponding author: morsi@pitt.edu

INTRODUCTION

MODEL DEVELOPMENT

Polymers and co-polymers derived from isobutylene (IB) could be produced in a wide range

of molecular weights and could be used in numerous applications. For instance, low

molecular weight liquid polybutenes are used as adhesives, sealants, coatings, lubricants,

and plasticizers, and for the impregnation of electrical cables. Medium molecular weight

polyisobutylene was the first viscosity-index modifiers for lubricants; and high molecular

weight polyisobutylene is used in the production of uncured rubbery compounds and as an

impact additive for thermoplastics. Unfortunately, despite the importance and wide

applications of the isobutylene polymerization process, only its kinetics have been heavily

investigated, whereas efforts towards developing comprehensive reactor models, which can

The final reactor model is expected to predict the reactor performance at various operating

conditions and to optimize the isobutylene polymerization process. It should be

remembered that the overall performance of any reactor is governed by the reaction

kinetics, hydrodynamics and transport parameters. The reaction kinetics are fundamentally

independent of the reactor type and size, however, the hydrodynamics and transport

parameters are strongly affected not only by them, but also by the operating conditions

(Figure 2 (A)).

Thermodynamic

quantities

Stoichiometry

Kinetics

reactor model for the isobutylene polymerization reaction, in continuous agitated reactors.

The final reactor model is expected to predict the reactor performance at various operating

conditions and to optimize the isobutylene polymerization process.

POLYMERIZATION MECHANISM

The carbocationic polymerization of isobutylene Figure 1. (A) AlCl3 (B) TiCl4 (C) Lewis Acid

initiated IB polymerization

and its copolymerization with viable comonomers

is

Figure 2. (A) Interplay among the parameters required for reactor modeling, (B) Algorithm for

reactor modeling

The reactor model equations include material balance for all phases, energy balance and

balance.

These

isobutylene

as highlighted in Table 1.

C6H5C(CH3)2Cl/BCl3

initiating system

1,4-bis(1-chloro-1methylethy1)benzene

(DiCumC1)/BC1

Blocked Bifunctional

Initiators in the Presence of

Di-tert-butylpyridine as a

Proton Trap

Diisobutylene hydrochloride

or triisobutylene

hydrochloride in the presence

of BCl3 and

benzyltriethylammonium

tetrachloroborate

t-Bu-m-DCC/TiCl4/2,4-DMP

Cumyl chloride/TiCl4/2,4dimethylpyridine system

Reference

Norrish and Russell

(1951) [26]

Wichterle et al. (1961)

[27]

= .

= . .

= +

= . ;

5-tert-butyl-1,3-bis(2-chloro2-propyl)benzene (t-Bu-mDCC) or 2-chloro-2,4,4trimethylpentane (TMPCl) in

conjunction with TiCl4

2-chloro-2,4,4trimethylpentane

(TMPCl)/TiCl4 and AlCl3

= .

TiCl4, Me2AlCl, and BCl3

= . ; =

Where is the total concentration of chain

ends

= +

=

Methylaluminum

Bromide Coinitiators

AlBr3

such

as

reactor

investigated. Simulations were carried out

Paulo et al. (2000)

[36]

Bahadur et al. (2000)

[37]

the

overall

X-PIB

X-IB

PIB production (kg/hr)

Schlaad et al. (2000)

[21]

0.5

0.4

0.3

0.45

0.4

0

0.2

reactor

= . .

Chmelir et al. (2007)

[41]

References:

[1] R. Norrish, K. Russell, Transactions of the Faraday Society 48 (1952) 91-98.

[2] O. Wichterle, M. Marek, I. Trekoval, Journal of Polymer Science 53 (1961) 281-287.

[3] R.B. Taylor, F. Williams, Journal of the American Chemical Society 91 (1969) 3728-3732.

[4] S.C. Guhaniyogi, J.P. Kennedy, W.M. Ferry, J. of Macromolecular Science: A 18 (1982) 25-37.

[5] B. Ivan, J.P. Kennedy, Macromolecules 23 (1990) 2880-2885.

[6] M. Gyor, H.-C. Wang, R. Faust, Journal of Macromolecular Science, Part A 29 (1992) 639-653.

.

0.4

0.6

Time (hr)

ko-Initiation (1/hr)

10

0.8

1

100

0.5

0.45

0.9

0.4

0.8

0.35

0.7

0.3

0.6

0.25

0.5

0.2

0.4

0.15

0.3

incorporating mass transfer phenomena

0.1

0.2

0.05

0.1

into the model, moreover optimization

results are shown in Figure 3.

Future model improvements, include the

investigation of impeller design on the

overall performance of the polymerization

Sipos et al.(2003)[22]

De and Faust (2006)

[40]

0.55

0.5

and a sensitivity analysis was conducted

on

370

0.6

0.1

to investigate the effect of different kinetic

320

0.7

0.2

process inside the CSTR, in addition to

Storey and Donnalley

(2000) [11]

the

0.6

performance, some sample simulation

Storey et al.(1998)

[25]

representing

Temperature (K)

220

270

170

Roth et al. (1997) [34]

Storey and Choate

(1997) [13]

parameters

0.8

under both steady and transient states,

parameters

= +

Ivan and Kennedy

(1990) [24]

P-tCl is the tert-chloride chain

[P-tCl]0 is the total number of polymer chains

parameters

pressures and initializing systems were

Guhaniyogi et al.

(1982)[28]

= +

Where is the concentration of

instantaneously active growing chains

Conventional tertiary alkyl

chloride initiators

ASPEN Plus V 7.2, and the effect of

0.9

dimensions, operating temperatures and

Balogh et al. (1994)

[32]

Gyor et al. (1991) [29]

[ ]

=

TiCl4

The simulation was implemented in

various

Taylor andWilliams

(1969)[19]

, + ,

=

BCl3 and CH3Cl

ZnO

many

120

Table 1. Proposed IB Polymerization kinetics

TiCl4

include

SIMULATION RESULTS

models have been proposed for each of these steps

Stannic Chloride

equations

representation of the reactor behavior, the algorithm for the model is shown in Figure 2 (B).

various kinetic

Kinetic Investigation

Conversion

parameters were integrated using a FORTRAN code to allow for a more representative

involves an initiation, propagation, chain transfer

Initiator

Steam quality

Yield

all side reactions and oligomers produced, as well as hydrodynamics and mass/heat transfer

TiCl4, etc. (Figure 1). Generally, the liquid phase

and chain termination steps,

Results

thermodynamic models were programmed into Aspen Plus. The reaction kinetics, incorporating

coinitiators include AlCl3, (alkyl)AlCl2, BF3, SnCl4,

of

Heat produced

relevant components were entered into Aspen Properties, and the polymerization

and a Lewis acid coinitiator. Typical Lewis acid

polymerization

Phsyico-chemical

properties

YES

Concentration and

Temperature profiles

Operating

Conditions

Geometry

NO

hydrodynamics, heat and mass transfer and reaction kinetics. The physical properties of all

typically composed of two components: an initiator

electrophillic

Convergence?

Hydrodynamics and

mass transfer

momentum

mechanistically complex. The initiating system is

Empirical

correlation

s

schemes for energy and mass and mass

integration would also be investigated .

[7] L. Balogh, Z. Fodor, T. Kelen, R. Faust, Macromolecules 27 (1994) 4648-4651.

[8] M. Roth, M. Patz, H. Freter, H. Mayr, Macromolecules 30 (1997) 722-725.

[9] R.F. Storey, K.R. Choate, Macromolecules 30 (1997) 4799-4806.

[10] R.F. Storey, C.L. Curry, L.B. Brister, Macromolecules 31 (1998) 1058-1063.

[11] C. Paulo, J.E. Puskas, S. Angepat, Macromolecules 33 (2000) 4634-4638.

[12] M. Bahadur, T.D. Shaffer, J.R. Ashbaugh, Macromolecules 33 (2000) 9548-9552.

[13] R.F. Storey, A.B. Donnalley, Macromolecules 33 (2000) 53-59.

0

104

105

106

107

Ea (J/kmol)

108

109

Figure 3. Sample Simulation results (Top), Sensitivity

Analysis (Bottom)

[ [14] H. Schlaad, Y. Kwon, L. Sipos, R. Faust, B. Charleux, Macromolecules 33 (2000) 8225-8232.

[15] L. Sipos, P. De, R. Faust, Macromolecules 36 (2003) 8282-8290.

[16] P. De, R. Faust, Macromolecules 39 (2006) 7527-7533.

[17] M. Chmel, M. Marek, O. Wichterle, Journal of Polymer Science Part C: Polymer Symposia 16 (1967) 833-839.

Acknowledgement: The authors would like to thank Lubrizol for the financial support of this project.

Steady State Polyisobutylene Production (kg/s)

p-methylstyrene

Hydrodynamic models

/ Trubulence theory

ko-Initiation Effect on PIB conversion

and

Variables

Model equations

solved numerically

Ea Effect on PIB conversion

isoprene

Reactor

Model

Experiment

Hydrodynamic

and Transport

Parameters

Absorptionreaction theory

Polyisobutylene Conversion

like

Guess initial

values

Inputs

be used to describe and optimize the process have been very limited. Therefore The overall

objective of this project aims at the development of a rigorous kinetic based Aspen Plus

Pressure, Temperature,

Mixing speed, reactor size,

Kinetics, thermodynamic

data..

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Joy To The WorldDocument1 pageJoy To The WorldShantika Luciana SinuratNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Resting in God's GraceDocument7 pagesResting in God's Graceohsnap1017100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

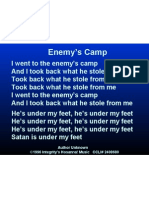

- Enemy's CampDocument1 pageEnemy's Campspiffy1000No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Joy To The WorldDocument1 pageJoy To The WorldShantika Luciana SinuratNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Aspen Polymers DatasheetDocument2 pagesAspen Polymers DatasheetSyed Ubaid AliNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Malaguena PianoDocument2 pagesMalaguena PianoKristine Maglupay0% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Modeling Falling RaindropsDocument8 pagesModeling Falling Raindropsohsnap1017No ratings yet

- Example Plan With CalculationsDocument33 pagesExample Plan With Calculationsohsnap1017No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Autumn PianoDocument2 pagesAutumn Pianoohsnap1017No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Midterm SolutionDocument11 pagesMidterm Solutionohsnap1017No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- HW1Document25 pagesHW1ohsnap1017No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chemical Engineering Exam PracticeDocument14 pagesChemical Engineering Exam Practiceohsnap1017100% (3)

- CDE F GA B CDE F GA: Notes On The Lines Notes in The SpacesDocument1 pageCDE F GA B CDE F GA: Notes On The Lines Notes in The Spacesohsnap1017No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Let Us SingDocument1 pageLet Us Singohsnap1017No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Note PageDocument1 pageNote Pageohsnap1017No ratings yet

- Autumn PianoDocument2 pagesAutumn Pianoohsnap1017No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Scan 0005Document1 pageScan 0005ohsnap1017No ratings yet

- Psa DiagramDocument1 pagePsa Diagramohsnap1017No ratings yet

- CoopEdBrochure SSOEDocument8 pagesCoopEdBrochure SSOEohsnap1017No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Let It GoDocument1 pageLet It Goohsnap1017No ratings yet

- C Major ScaleDocument1 pageC Major Scaleohsnap1017No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Process EngineeringDocument1 pageProcess Engineeringohsnap1017No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hall of FameDocument4 pagesHall of Famelittleredribbons83% (12)

- 2021santos REVIEW Nanofibrillatedcelluloseincement BasedcompositesDocument17 pages2021santos REVIEW Nanofibrillatedcelluloseincement BasedcompositesPaloma GuardeziNo ratings yet

- 1kb Plus LadderDocument4 pages1kb Plus LadderPedro SoaresNo ratings yet

- Quiz 4Document44 pagesQuiz 4Juba W Allen50% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- MethodsXDFTB PDFDocument10 pagesMethodsXDFTB PDFDIEGO FERNANDO TRIVINO BOLANOSNo ratings yet

- CBSE Class 12 Physics Surface Chemistry Important QuestionsDocument4 pagesCBSE Class 12 Physics Surface Chemistry Important Questionsbhavishyat kumawatNo ratings yet

- Bacteria Morphology GuideDocument38 pagesBacteria Morphology GuideFuad Hasan Pranto 1921147049No ratings yet

- Unit 5: Moles & StoichiometryDocument39 pagesUnit 5: Moles & StoichiometryNico Theodorus SimamoraNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument12 pagesCambridge International Advanced Subsidiary and Advanced LevelHafiza Sikder AnishaNo ratings yet

- Experiment 5Document24 pagesExperiment 5monico3950% (2)

- Nylon Textiles Processing AuxiliariesDocument3 pagesNylon Textiles Processing AuxiliariesKetan GandhiNo ratings yet

- Enzyme Inhibition Types and MechanismsDocument29 pagesEnzyme Inhibition Types and MechanismsDarshan DSSNo ratings yet

- Surface ModificationDocument4 pagesSurface ModificationLuthfi AbdillahNo ratings yet

- Ultra High Strength ConcreteDocument29 pagesUltra High Strength ConcreteShahab Sadqpur88% (8)

- FINAL Chapter 9 - AcroDocument29 pagesFINAL Chapter 9 - AcroaissaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sikadur 31 CF Normal PDS (CE)Document5 pagesSikadur 31 CF Normal PDS (CE)Satria AdityaNo ratings yet

- Carborane Synthesis MethodsDocument17 pagesCarborane Synthesis MethodsJulienne Stephanie Fabie100% (1)

- Synthesis and Characterization of Tin Oxide: A ReviewDocument4 pagesSynthesis and Characterization of Tin Oxide: A ReviewkannanNo ratings yet

- Stoichiometry CalculationsDocument8 pagesStoichiometry CalculationsAmro DyabNo ratings yet

- Graphene Based Coatings For Corrosion Protection: Yu, FengDocument193 pagesGraphene Based Coatings For Corrosion Protection: Yu, FengHong Giang LeNo ratings yet

- A Periodic Table Logic ProblemDocument2 pagesA Periodic Table Logic Problemkjj7760No ratings yet

- Analysis Nitrite HIGHDocument3 pagesAnalysis Nitrite HIGHvandrake10No ratings yet

- CSEC P2 Titration CalculationsDocument14 pagesCSEC P2 Titration CalculationsDeneil WalkerNo ratings yet

- G41363046476 Specs SheetDocument4 pagesG41363046476 Specs SheetsercanworkNo ratings yet

- FIITJEE Computer Based JEE Test Series & Concept ClassesDocument2 pagesFIITJEE Computer Based JEE Test Series & Concept ClassesR,guruchandranNo ratings yet

- Guidelines for Establishing Solar Salt Facilities from Various SourcesDocument119 pagesGuidelines for Establishing Solar Salt Facilities from Various SourcesZubair Khan100% (2)

- 2008 Effect of Salinity and PH On Pickering Emulsion StabilityDocument17 pages2008 Effect of Salinity and PH On Pickering Emulsion StabilityLuis Carlos Patiño LagosNo ratings yet

- KVPY SA Hints and Solutions for Model Test Paper 1Document65 pagesKVPY SA Hints and Solutions for Model Test Paper 1VamsiMadupuNo ratings yet

- The Chemistry of A Welding RodDocument2 pagesThe Chemistry of A Welding RodsabbiNo ratings yet

- IntroductionDocument3 pagesIntroductionMohsen MohammadNo ratings yet

- Determining Lithium Using Flame Emission PhotometryDocument2 pagesDetermining Lithium Using Flame Emission PhotometryPenelope MeloNo ratings yet