Professional Documents

Culture Documents

Nano 02

Uploaded by

Deepak Raj ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nano 02

Uploaded by

Deepak Raj RCopyright:

Available Formats

Effect of Nano-Technology in Hydrogen Storage

A new era of Hydrogen fuel storage

R.Siva kumar1, T.Vijayprathap2.

B.E.Mechanical(III-Year), Sona College of Technology,Salem-5.

Contact no: 8526899442, Email id: kumarrsiva35@gmail.com1

Email id: nationvijayprathap@gmail.com2.

ABSTRACT

Hydrogen is the lightest of the

Hydrogen is the most abundant

elements with an atomic weight of 1.0.

element is the universe on the Earth its

Liquid hydrogen has a density of 0.07

mostly found as water. Hydrogen can

grams per cubic centimeter, whereas

easily separated from Oxygen in water

water has a density of 1.0 g/cc. and

via Electrolysis. This process is about

gasoline about 0.75 g/cc.

67% efficient. The alternative is to

When hydrogen is burned in air the

store hydrogen in a solid metal by

main product is water. Some nitrogen

forcing it into the gaps between the

compounds may also be produced and

atoms.

may have to be controlled.

By a strange property of

physics this actually holds more

Recent Development:

hydrogen in a smaller volume than

Japanese scientists are working on a

possible in liquid form. For this

method of splitting water using laser

purpose the lightest element Titanium

light beamed from a satellite in orbit.

is used in our study.

The alternative is to store hydrogen in

a solid metal by forcing it into the gaps

between the atoms.

Properties:

As a liquid its energy density per unit

volume is 1000 times higher.

By a strange

property of physics this actually holds

more hydrogen in a smaller volume

than possible in liquid form. For this

purpose the lightest element Titanium

compared with, for ex, Gasoline with equal

is used in our study.

energy content- about 30 times bigger volume

at 100 atm gas pressure. Condensed hydrogen

is about ten times denser but is much too

expensive to produce and maintain. There are

also obvious safety concerns with the use of

pressurized or liquefied hydrogen in vehicles.

Metal hydrides as Hydrogen storage devices:

Literature Review

Metals can absorb hydrogen in atomic

Use of Hydrogen as Fuel:

form and thereby act as hydrogen sponges.

It is believed that hydrogen will within

Around 50 metallic elements of the periodic

a few years become the fuel that powers most

table can absorb hydrogen in a great quantity

vehicles and portable devices. The reason is

and the possible choices of hydrogen storage

the depletion of oil and the relatively facile

materials are, therefore, enormous. Many

production

various

scientific and engineering studies have been

renewable source of energy- hydroelectric,

carried out of the absorption/desorption of

wind, solar, geothermal- with water being the

hydrogen in metals and development of such

only raw material needed. To release the

hydrogen storage devices. Daimler-Benz, for

energy, hydrogen can be burned in an efficient

example, produced in the early 1980s a car

and clean way in a fuel cell to form water

fuelled by hydrogen where the storage tank

again, or made to drive an electrochemical cell

was a chunk of Fe-Ti metal alloy. The volume

as in the commonly used nickel hydride

of this storage device is less than a factor of

battery. As concerns over air pollution and

two greater than the equivalent gasoline tank,

global warming increase, the incentive to

but the problem is that hydride is 20 times

switch to clean and efficient hydrogen

heavier. The only successful commercial large

economy becomes grater and the transition

scale

may occur well before oil reserves are

hydrogen storage so far is the metal hydride

depleted. While hydrogen has many inherent

battery, which has supplied battery power to

advantages, there remains a problem with

many small electrical appliances such as

storage

Pressurized

mobile phones and portable computers. Metal

hydrogen gas takes a great deal of volume

hydrides have so far not become useful as

of

and

hydrogen

from

transportation.

application

of metal

hydrides

as

storage devices for hydrogen gas even though

the first patent on this process. The process

they have some distinct advantages over

was initially referred to as milling/mixing.

pressurized hydrogen gas, both improved

The term mechanical alloying was actually

safety and reduced volume.

coined by Ewan C. McQueen.

Mechanical Alloying;

Experimental work

Mechanical Alloying (MA) is a high-

TiH2 in the powder form is taken as the

energy ball milling technique; in which

starting material and is milled in a ball mill

elemental blends are tend to achieve alloying

under dry conditions for various time intervals

at the atomic level. In addition to elemental

(2h, 5h, 7h and 10h) with Ball to Powder ratio

blends, pre-alloyed powders and ceramics,

of 20:1. Heat treatment is carried out in a

such as oxides, nitrides, etc., can also be used

muffle type furnace for 1h in each case.

to produce alloys and composites by these

Characterisation of the metal hydride is done

techniques. This technique was developed

using XRD and DSC.

around 1996 by Benjamin and his co-workers

X-ray diffraction results of as received

as a part of the program to produce oxide

and milled samples are shown in figure 1.

dispersion strengthened (ODS) NI-base super

XRD results confirmed the as received sample

alloys for gas turbine applications. The initial

as TiH2 as in Fig 1. Even up to 10h of milling

experiments by Benjamins group were aimed

at BPR ratio of 20:1 there is no formation of

at coating the oxide particles with Ni by ball

new phase except the decrease in the intensity

milling. Such a process was known 40 years

of TiH2 peaks with the addition of tungsten

earlier from the work of Hoyt, who reported

carbide peaks as impurity. Hence DSC is

coating of WC with Co by ball milling. In

carried out with the milled and the as received

1966, Benjamins group to the production of

samples. XRD plot of unmilled and milled

alloy turned attention by high-energy ball

heat-treated samples are shown in figure 2,

milling. The first experiments on this direction

which

were on the production of thoria dispersed

dehydrogenation

nickel (commonly known as TD nickel) and

process. TiHx forms at lower temperatures and

NI-Cr-Al-Ti alloy with Thoria dispersions.

the formation of Ti shows the end of the

The success of both these experiments led to

dehydrogenation

clearly

indicates

process

process.

is

that

a

The

the

two-step

peak

transformation

temperatures

are

well

Figures

separated in milled samples when compare to

unmilled samples and the separation increases

with milling time. The peak temperatures

decrease with increase in the milling time.

The observed effects of milling of the

are

due

to

the

decrease

in

dehydrogenation temperatures and separation

between the peak temperatures. The separation

in the peak transformation temperatures is

Intensity (A.U)

hydride

TiH2

0h

2h

5h

clearly observed from the DSC plots shown in

7h

10h

Figure 3. The peak transformation temperature

20

30

40

50

60

70

80

90

2 (degree)

for the -Ti transformation and the TiHx

transformation is given in Table 1. Table 1

indicates

that

the

peak

transformation

temperature for -Ti transformation in the

unmilled and 10h milled powder differs by

65C

whereas

the

peak

transformation

TiH

2

TiH

x

-Ti

a margin of 170C. The TiHx thus formed as a

result of the first stage dehydrogenation is

Intensity(A.U)

temperature for TiHx transformation differs by

550 C

more stable when compared to TiH2.

A possible explanation for the decrease

in the first transformation temperature in the

20

30

40

750 C

50

60

70

80

90

2 (degree)

ease of decomposition of the high hydrogen

containing TiH2 phase due to decrease in the

particle size, increase in the specific surface

area and increase in the defect concentration

due to cold work.

Fig 1. XRD plot of milled TiH2 without

Fig 2.a.XRD plot of unmilled TiH2

Heat treatment

heat

treated at diff. temp.

TiH

2

TiH

x

-Ti

Intensity(A.U)

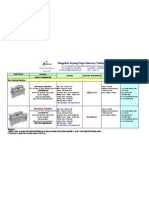

Table 1 Peak transformation temperatures for

TiHx and -Ti formation

0h

10 h

o

400 C

20

30

40

50

Hours

Peak

Peak

of

Temperatures of

Temperatures of

Milling

TiHx

-Ti

Transformation

Transformation

(C)

528

440

366

360

355

(C)

625

602

591

582

560

600 C

60

70

80

90

2 (degree)

10h

Discussion

7h

5h

2h

Heat Flow Exothermic

0

2

5

7

10

Nano TiH2 used as fuel should be first

0h

ignited to 355C and the exothermic reactions

thus produced will ignite the remaining TiH2. It

functions as an auto catalytic mechanism. This

100

200

300

400

500

600

700

800

Temperature ( C)

Fig 2.b. XRD plot of milled TiH2

(10h)

Fig 3. DSC plot of TiH2

heat treated at diff. temp

ignition can be brought about very easily by

the passage of electricity because Hydrogen

can be easily dissociated from Titanium. This

dissociated hydrogen is immediately used for

propulsion of the engine and hence the safety

hazard is eliminated.

Why TiH2 and why not cheaper MgH2?

The automobile industry has set 5% by

hydrogen

(i.e.,

weight as a target for efficient hydrogen

formation

of

storage in metals. The hydride, MgH2 can store

depending

upto 7% by weight (approx.) and TiH 2 can

dissociation process)

store upto 5% by weight of hydrogen

after

the

TiH0.7-1.1

upon

the

Why TiH2 and why not cheaper AlH2?

(approx.). Hence it is apparent that both TiH2

In case of Aluminium the formation of

and MgH2 can store hydrogen for automobile

hydride is too difficult comparing with the

industries. But the problems encountered with

hydride formation in Titanium. Because the

MgH2 are that

rate of formation aluminium hydride

The rate of absorption and

from aluminium and hydrogen is lower than

desorption of hydrogen is too

that of TiH2. Again the dissociation of

low

hydrogen is difficult in the case of aluminium.

donot

Oxide formation is more facilitated in

readily dissociate at the surface

Aluminium, than the formation of hydride. As

of Mg

oxygen will be deposited at the surface of

Hydrogen

molecules

Hydrogen

atoms

strongly

with

too

aluminium, the reactivity of aluminium is

magnesium

minimum at the surface than at the core

bind

portion and hence hydride formation is more

atoms

The above problems can be overcome by

Hence by comparing TiH2with light

using TiH2.

The

enthalpy

of

formation of TiH2 from Ti and

hydrogen

is

lower

when

compared to Magnesium.

Hydrogen

materials, it is shown that TiH2 is well suited

for hydrogen storage. This serves as a big

break through in the usage of hydrogen as a

potential source of fuel.

molecules

readily dissociate at the surface

of Titanium, being an active

metal

difficult.

Bonding of hydrogen

with Titanium is strong only

after dissociation of 50% of

Conclusion

Present situation requires immediate

care to be taken for the problem of

environmental

pollution

caused

by

the

combustion of fuels. Using of Hydrogen gives

a major advantage of creating a greener

environment

since

the

end

product

of

combustion is water that can be used to

produce hydrogen again.

Major results of this research work reveal the

following datas.

1) TiH2 dissociation occurs at some 200C

earlier for nano particles when compared with

conventional particles which facilitates the use

of TiH2 in the storage of hydrogen.

2) The dissociation oh hydrogen is easier in

the nano level when it is produced by

mechanical milling because of the two

following reasons.

a) A part of the energy is supplied by

the process of mechanical activation.

b)

Enthalpy

formation

is

also

facilitated by the process of mechanical

activation.

Hence TiH2 can be used as a good source of

hydrogen storage device which facilitates the

usage of hydrogen as a fuel.

Reference

www.nano.org.uk

www.nanowerk.com

www.hydrogen.energy.gov

www.interscience.willy.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Alternate FuelsDocument9 pagesAlternate FuelsDeepak Raj RNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Final Project Report Foot Step (With Out Footer)Document47 pagesFinal Project Report Foot Step (With Out Footer)Deepak Raj R100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cit Sandwich Polytechnic College COIMBATORE-641 014. Department of Mechanical EngineeringDocument3 pagesCit Sandwich Polytechnic College COIMBATORE-641 014. Department of Mechanical EngineeringDeepak Raj RNo ratings yet

- Address: To The Manager, Eltex Super Casting, Periyanaickenpalayam, Coimbatore-641020, South IndiaDocument1 pageAddress: To The Manager, Eltex Super Casting, Periyanaickenpalayam, Coimbatore-641020, South IndiaDeepak Raj RNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- KeyDocument5 pagesKeyDeepak Raj RNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Microsoft ISA Server 2006 - Certificate Troubleshooting - Part IIDocument7 pagesMicrosoft ISA Server 2006 - Certificate Troubleshooting - Part IIKhodor AkoumNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CMR900Document6 pagesCMR900Time To Use BrainNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Sony CR1220 PDFDocument2 pagesSony CR1220 PDFdiego742000No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Brochure A35g A40g t4f en 22 20050840 DDocument20 pagesBrochure A35g A40g t4f en 22 20050840 DRengga PratamaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TPMS - A Learning GuideDocument14 pagesTPMS - A Learning GuideOrangeElectronicUsaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Chapter 3 - Well Completion Practices PDFDocument138 pagesChapter 3 - Well Completion Practices PDFchft100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Acoples Hidraulicos Serie 60 ParkerDocument2 pagesAcoples Hidraulicos Serie 60 ParkerAntonio MoralesNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- ERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaDocument9 pagesERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaiacikgozNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- d350 Taper Lock End Anchor Tech Data SheetDocument2 pagesd350 Taper Lock End Anchor Tech Data SheetEdsantadNo ratings yet

- UntitledDocument32 pagesUntitledAnimeFreak930901No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- White BoxDocument9 pagesWhite BoxAmitsonu222No ratings yet

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Document1 pageQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargNo ratings yet

- How To Size Hydropneumatic TankDocument3 pagesHow To Size Hydropneumatic TankfelipeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 7ML19981GC61 1Document59 pages7ML19981GC61 1Andres ColladoNo ratings yet

- SWIFT Case Study Accord EADS 200808Document3 pagesSWIFT Case Study Accord EADS 200808maheshbendigeri5945No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Binthen Motorized Curtain Price List Rev1.0 Jan 2022Document4 pagesBinthen Motorized Curtain Price List Rev1.0 Jan 2022Emil EremiaNo ratings yet

- Surge Arresters PP 7Document9 pagesSurge Arresters PP 7gabriela69sNo ratings yet

- Bhopal Gas TragedyDocument25 pagesBhopal Gas TragedyHarry AroraNo ratings yet

- Phase ShifterDocument7 pagesPhase ShifterNumanAbdullahNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ISMSBrochure 2011Document19 pagesISMSBrochure 2011Benw005No ratings yet

- Pre-Stressed Elective EngineeringDocument7 pagesPre-Stressed Elective EngineeringJonas FernandezNo ratings yet

- U-Joint Shaft PDFDocument5 pagesU-Joint Shaft PDFAdrian SantosNo ratings yet

- A Modified Vince Gingery PlasticDocument13 pagesA Modified Vince Gingery PlasticgeppaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Syllabus 330C SystemsDocument1 pageSyllabus 330C SystemsDANIEL VARGAS RODRIGUEZNo ratings yet

- Infineon IKFW50N65DH5Document15 pagesInfineon IKFW50N65DH5nithinmundackal3623No ratings yet

- Camsco Breaker PDFDocument12 pagesCamsco Breaker PDFMichael MaiquemaNo ratings yet

- Don't Just Lead, Govern: Implementing Effective IT GovernanceDocument20 pagesDon't Just Lead, Govern: Implementing Effective IT GovernanceWahyu Astri Kurniasari100% (1)

- Micronta 12VDC Power Adapter 273-1653A InstructionsDocument2 pagesMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNo ratings yet

- Serial NumberDocument3 pagesSerial NumberNidal Nakhalah67% (3)

- BOB SO Information HandoutDocument5 pagesBOB SO Information HandoutKabya SrivastavaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)