Professional Documents

Culture Documents

7 Methods To Improve Forecasting Accuracy

Uploaded by

rafazel hardyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Methods To Improve Forecasting Accuracy

Uploaded by

rafazel hardyCopyright:

Available Formats

L O G I L I T Y V O YA G E R S O L U T I O N S

A Logility Demand Optimization White Paper

Seven Methods That

Improve Forecast Accuracy

Forecasting Best Practices for Varying Supply

Chain Scenarios

L O G I L I T Y V O YA G E R S O L U T I O N S

A Logility Demand Optimization White Paper

Table of Contents

Seven Methods That Improve Forecast

Accuracy

Three Basic Categories of

Forecasting Methods........................................3

Forecasting Best Practices for Varying Supply Chain Scenarios

Seven Forecasting Methods that Improve

Supply chain Performance...............................4

Introduction

Typically, a variety of forecasting methods are applicable to any particular

type of supply chain scenario. Smart supply chain planners use multiple

methods tuned to perform well at different phases of the product life

cycle, chosen to best exploit the available historical data and degree of

market knowledge. The key is to pick the most effective and flexible

models, blend their best features, and shift between them as needed to

keep forecast accuracy at its peak.

In this paper we will take a brief look at seven methods that have

produced superior results for Logilitys many clients in a variety of

industries and market conditions around the world.

Best fit Statistical Modeling.............................5

Derived Modeling............................................6

Modeling for Intermittent Demand.................6

Attribute-Based Modeling...............................7

Causal Event Modeling....................................7

Summary.........................................................8

Table of Figures

Basic Forecasting Models.................................3

Seven Methods for More Accurate

Forecasting......................................................4

www.logility.com 2

L O G I L I T Y V O YA G E R S O L U T I O N S

Three Categories of Forecasting Models

Forecasting models classically fall into three

categories: qualitative, quantitative and hybrid. The

primary differences between them include the type

of input data and the mathematical and statistical

methods employed to generate forecasts.

Qualitative models are experience-driven,

relying on subjective inputs from knowledgeable

personnel, such as salespeople, account

managers, and the like.

Quantitative models are statistically driven,

drawing heavily on historical performance data

as the basic data input. The calculating logic is

defined and operations are purely mathematical.

Forecasting models

Hybrid models typically draw on historical

demand information as a starting point, then use

empirical data to further refine the forecast.

qualitative, quantitative

classically fall into

three categories:

and hybrid.

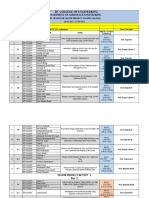

Three Categories: Forecasting Models

Category

Qualitative

Experience driven

Sub

Description

Subjective

Relies on subjective inputs from knowledgeable personnel, such as salespeople,

account managers, and the like. This approach typically sets up formal procedures for

data review, and requires a consensus to determine the value of various forms of

information.

Consensus among forecasters may be obtained by aggregating individual estimates or

through structured polling methods.

Time Series

Quantitative

Employs a time-ordered sequence of observations of a particular variable, and uses only the

history of that variable to determine future values.

For example, if monthly sales volumes of lawnmowers sold in the Southeast display a linear

pattern, a linear trend model would provide the best basis for the forecast.

Creates a new forecast based on an existing forecast.

Statistically driven

Derived

When a new items forecast is thought to be fundamentally the same as an existing items,

characteristics can be used in creating the new forecast, which may be factored up or down

by a percentage.

This preserves the overall trend and seasonal characteristics of the item, providing a good

starting point for the new item.

Attribute-based

Hybrid

Employs user-defined attributes to model new product introductions, seasonal or fashion

driven products, and product end-of-life retirement based on a demand profile.

Uses a causal relationship between a particular time series variable and other time series

factors to calculate the forecast.

Historical demand

plus empirical data

Causal

Causal techniques are useful in forecasting lift during promotional campaigns, where

demand caused by promotional factors has an established relationship to base demand.

Additional factors can be used, such as end-cap displays, seasonality of the product, etc.

Factors are not additive but are used together to calculate the expected lift for your product.

3 www.logility.com

L O G I L I T Y V O YA G E R S O L U T I O N S

A best practices

approach also must

include the ability to

incorporate personal

expertise and weight

the various factors in

generating forecasts.

Seven Forecasting Methods that Improve Supply Chain

Performance

For many supply chain scenarios, its typically best

to employ a variety of methods to obtain optimal

forecasts. Ideally, managers should take advantage

of several different methods and build them into

the foundation of the forecast.

The best practice is to use automated method

switching to accommodate selection and

deployment of the most appropriate forecast

method for optimal results.

In order to ensure optimal demand forecasting,

managers must employ the forecasting methods

that best serve the unique dynamics of their

business at a specific moment in time.

Advanced demand planning and forecasting

systems automate many of the functions required

to select, model and generate multi-echelon

forecasts, lifting the burden of manually intensive

approaches and accelerating sensitivity to model

changes as market conditions evolve. A best

practices approach also must include the ability

to incorporate personal expertise and weight the

various factors in generating forecasts.

In Logilitys experience working with over 1,000

organizations ranging across dozens of industries,

seven specific forecasting methods stand

out. Their unique strengths combine to deliver

powerful, flexible, and accurate results..

Seven Methods for More Accurate Forecasting

Type

The 7 Methods

Description

Modified Holt /

Holt-Winters

Use Holt when demand is trended, but does not vary by the time of the year. Use

Holt-Winters when demand is often higher or lower during particular times of the

year.

Moving Average

Use for products with demand histories that have random variations, including no

seasonality or trend, or a fairly flat demand.

Inhibited

Use to produce a zero forecast.

Modified Parent-Child

Use to forecast products as a percent of the forecast for another product (dependent

demand).

Intermittent

Demand

Modified Croston

Use for products with low demand or for some zero demand periods, such as

slow-moving parts.

Attribute-based

Demand Profile

Employs user-defined attributes to model new product introductions, seasonal or

fashion driven products, and product end-of-life retirement.

Causal

Promotions

Use to calculate lift from promotions in addition to the normal forecast.

Best-Fit

statistical

Derived

www.logility.com 4

L O G I L I T Y V O YA G E R S O L U T I O N S

Best-fit Statistical Modeling

For most levels of management within an

organization, aggregated demand history for

product family, brand category, country and/

or selling region are good predictors of future

performance. Such demand history also serves as

a baseline for effectively forecasting Stock Keeping

Units (SKUs.) When there are more than four-to-six

periods of sales history, SKUs can be effectively

forecast with moving average and basic trend

methods. SKUs with at least one year of sales

history offer sufficient information to incorporate a

seasonal profile into the projected trend.

A modified Holt-Winters decomposition model

with best-fit analysis can generate forecasts based

on demand history that incorporate trends and

seasonal information. The method senses the

amount of history available for each time series

or segment to create a basic model that best fits

the history. Then it uses the best combination of

smoothing factors to enable the model to react

to changing conditions going forward without

overreacting to anomalies in demand (such

as unplanned seasonal events, transportation

disruptions, and so on).

For factors relating to seasonality, planners need

the ability to weight the historical demand. Under

the assumption that the previous year is the best

indicator of what will happen next year, most

forecast systems apply a higher weighting factor to

the previous years demand, less to the year before

and even less to the years before that. But if the

previous year was unusual in any significant way,

the planner must have the capability to change the

historical weighting factors (so that the history two

years ago has more impact on the current forecast

than last year, for instance) so as not to under- or

over-forecast the business.

5 www.logility.com

Seasonal methods can be effective with less than

24 months of history; the minimum required is

12 months. An effective approach for expected

seasonal items with less than 12 months of

history is to assign a seasonal curve that has been

captured from a similar item or item group.

A powerful best-fit statistical method should

include flexible features such as trend, seasonalwith-trend, moving average and low-level pattern

fitting, as well as trend models for products with

sporadic, low-volume demand.

The method should provide limiting and damping,

as well as seasonal smoothing, demand filtering,

reasonability tests, tracking signals and tests for

erratic nature that evaluate the validity of each

element, determining which are anomalous and

should be filtered. These parameters give the

planner the flexibility to tune the process to best fit

conditions at any element of the organization.

Best fit refers to the ability to change forecast

methods as a product evolves. The process may

start out as a demand profile method, evolve to

a modified Holt-Winters method as the product

becomes stable, and ultimately transition to a

demand profile method again as the product life

cycle comes to an end.

Capabilities that will automatically change the

forecast method are important features of a

comprehensive forecasting solution.

Forecast models

change as a product

evolvesperhaps

starting out with

a demand profile

model, then

evolving to another

as the product

becomes stable and

transitioning back

to a demand profile

model again at the

end of the life cycle.

L O G I L I T Y V O YA G E R S O L U T I O N S

Derived Modeling

Logility Voyager

Solutions products

provide a variety of

forecasting models

to suit commonly

encountered supply

chain planning

scenarios across many

industries. Logilitys

automated model

switching ensures that

the most appropriate

forecast model is

applied, given the

type of scenario under

consideration.

One method of generating new product forecasts

is to use demand variations or extensions

from existing products, families or brands.

Consequently, they draw on the historical data of

existing products or families. When combined with

causal effects or management-selected overrides

to accommodate introductory promotions, derived

modeling can provide a realistic and dynamic

forecast for new products.

Using this approach, new products are assigned

a percentage of the parent, family and/or brand,

enabling them to proportionately inherit a forecast

that contains the base, trend and seasonal

elements of the associated category. As the

forecast for the associated category is adjusted to

reflect changing conditions over time, so too is the

derived products forecast. If the derived products

point-of-sales (POS) or demand levels deviate

from the forecast and exceed a user-defined

tolerance, the system can generate a performance

management alert to notify forecast analysts to

take corrective action.

Once the product has accumulated sufficient

demand history of its own, the link to the derived

models source model is severed and the product

is then forecasted on its own using multiple best-fit

statistical methods.

Modeling for Intermittent

Demand

Slow-moving parts typically exhibit irregular

demand that may include periods of zero or

excessively lumpy demand. A Modified Croston

Method handles low and lumpy demand that

exhibits either a patterned variation or no pattern.

The patterned variation looks at available history

and classifies each demand element relative to

those around it. It classifies the periods into peaks,

valleys, plains, plateaus, up-slopes and downslopes. It measures the duration of plateaus and

plains, as well as the severity of peaks and valleys.

It then conducts pattern-fitting analysis to find

regularity over time, attempting to fit the pattern to

the history and averaging for low and high points.

The patterned forecast is put in context of future

periods with the average trend, and the pattern is

re-evaluated using demand history of subsequent

periods.

If no pattern is present, the unpatterned variation

method attempts to use averaged highs and

lows to create a step-change forecast for future

demand.

Both techniques permit zero demand to reside

in the history, and will acknowledge such in the

future demand forecast. In forecasting for spare

parts, for example, the demand is frequently

low-level and spotty, containing many periods of

zero demand interspersed with low-level demand.

This forecasting technique allows patterns of zero

demand to be forecast into the future.

Attribute-Based Modeling

What if lack of data, short life cycle, or other

mitigating factors make it difficult to forecasts

using time series or qualitative techniques?

Forecast creation for new product introductions,

short-life or seasonal products, and end-of-life

products calls for attribute-based modeling

techniques.

The attribute-based model provides a wide variety

of demand profiles by which to characterize

the product, and can adjust the products plan

dynamically in response to early demand signals.

The method will analyze historical sell-in and/

or sell-through data to develop a wide variety of

demand and seasonal profiles. These profiles are

assigned to individual planning records. Then, as

actual demand information is captured, the current

profile is validated or alternate profiles identified to

dynamically adjust the products plan.

www.logility.com 6

L O G I L I T Y V O YA G E R S O L U T I O N S

Four Unique Processes

Attribute-based modeling consists of four unique

processes:

1. Creation of Demand Profiles

Creation of demand profiles is based on

mathematical concepts known as Chi-squared

analysis. The demand planner selects products

to be included based on attributes such as

color, fabric type, region of the country, etc.,

and multiple attributes can be used at once.

Planners can efficiently realign history for events

like Easter, which does not occur during the

same period each year.

2. Assigning Demand Profiles

New, seasonal, and end-of-life products can

now be assigned to Demand Profiles.

Advanced attribute-based models offer user defined attribute matching capabilities, allowing

the planner to set criteria for how a new

products attributes must match the attributes

of a demand profile.

3. Automatic Revision of the Forecast Based

on Demand Signals

Forecast accuracy must be monitored

continually. One way of monitoring the accuracy

of the forecast is through the use of POS data,

which is the demand signal that most

accurately reflects customer buying patterns.

POS or other demand signals such as

syndicated data is used to check the accuracy

of the forecast. Correctness-of-fit modeling

adjusts the forecast to reflect what is happening

in the marketplace, quickly reacting to realworld changes.

Causal Event Modeling

Causal modeling can specifically address the

effects of promotional elements such as price

discounts, coupons, advertising and product

placements. It supports input from multiple

marketing groups, and aids the identification and

reconciliation of potential conflicts or overlaps in

promotional planning proposals.

Logility Voyager

Demand Planning

employs a Modified

Holt Model, Modified

Holt-Winters, Moving

Causal modeling enables planners to quickly

simulate marketing program options and refine

forecasts. Using pre-trained neural network

technology in causal-based modeling is a unique

best practice that lets planners quickly start to

model the cause-and-effect relationship of different

promotional elements.

Average, as well as

Backcasting is a technique in which past

promotional events are entered into the neural

network, which then learns the relationship of

various elements. The pre-trained network takes

on customized characteristics and behaviors

quickly, rather than requiring 1218 months

to build from scratch. Using pre-trained neural

network technology, planners can incorporate

marketing activities into supply chain forecasts

much more quickly.

Croston Model offers

two types of Derived

models. To handle

low and lumpy

demand, a Modified

versions for patterned

and unpatterned

variation.

Logility Voyager Life

Cycle Planning

uses a Demand

Profile Model to

forecast items where

there is a lack of data

or other mitigating

4. Assess Accuracy of Demand Profile Based

on Demand Signals

factors. Logility

Voyager Event

In a perfect world, demand profiles, once set,

would never need adjustingnew products

would sell just like other products with similar

attributes. Unfortunately, we dont live in a

perfect world. But by utilizing point-of-sale

or other demand signals, the accuracy of the

assigned curve can be checked against other

demand profiles that have similar attributes.

Through Relative-Error-Index (REI) calculations

the planner can quickly see which demand

profile now has the most accurate fit based

on current demand trends and can change the

current demand profile to the profile that has

the lowest REI.

7 www.logility.com

Planning employs

a Causal Model to

calculate lift from

promotions in

addition to the normal

forecast.

L O G I L I T Y V O YA G E R S O L U T I O N S

Summary: Flexibility and Ease of Use are Vital to

Good Forecasting

Optimal demand planning and forecasting requires comprehensive modeling capabilities plus

the flexibility and ease-of-use to shift methods as life cycles progress and market conditions

change. Advanced forecasting systems (such as the Logility Voyager Solution) use a

combination of qualitative and quantitative techniques to generate reliable forecasts.

As we have seen, Attribute-based methods that use demand profiles are often suited to new

product introduction and end of product life cycles, at times when reliable historical demand

data is lacking or the available data is less relevant.

At the more mature stages of the product life cycle, five different time-series statistical models

come into play, including modified Holt, Holt-Winters, moving average, and intermittent for low

demand, whether patterned or unpatterned. These models are used to create retrospective

forecasts that cover prior periods (typically three years) of documented demand. The forecasts

are then matched to actual demand history to determine which one best fits the real-world

data. The best-fit winner is used to create an objective base forecast. At this point, planners

may include more qualitative calculations based on personal knowledge and experience with

intangible market factors.

Causal methods are used throughout the life cycle to adjust forecasts in anticipation of

promotional events. Causal methods allow planners to predict how discounting and other

promotional factors will affect volume, and layer the impact of these events on top of the

underlying base forecast.

Finally, Derived models can be used to create a Parent-Child relationship in which forecasts for

closely related products are driven as a percentage of the forecast for a leader product. This

ensures that when the forecast is modified for the parent all the child forecasts would be

updated accordingly.

About Logility

With more than 1,250

customers worldwide,

Logility is a leading provider

of collaborative, bestof- breed supply chain

solutions that help small,

medium, large, and Fortune

1000 companies realize

substantial bottom-line

results in record time.

Logility Voyager Solutions

is a comprehensive supply

chain management solution

that features a performance

monitoring architecture

and provides supply

chain visibility; demand,

inventory and replenishment

planning; sales and

operations planning (S&OP);

To prevail in a business economy shaped by uncertain demand and rapid market changes, all

of these forecasting methods must be harnessed within one practical, comprehensive solution

suite. Advanced demand management software can automate much of the selection and

switching of methods as a product moves through its life cycle. A best-in-class forecasting

system is one that provides flexibility for users to weight elements and override key parameters

in the forecast calculation based on their intuitive knowledge and market expertise.

supply and inventory

Logilitys powerful software solutions help planners pick the best method, spot trends and

forecast demand signal changes more quickly, and sense the best time to change methods

when a more appropriate approach is indicated. Superior predictive power and real-time

reflexes are the keys to coming out ahead of the competition during uncertain business cycles.

warehouse management.

optimization; manufacturing

planning and scheduling;

transportation planning

and management; and

Leading apparel companies

such as VF Corp, Polo Ralph

Lauren, Hanes Brands,

New Balance, Brown Shoe,

Williamson-Dickie and more

rely on Logility Voyager

Solutions to drive excellence

across their supply chains.

www.logility.com

Logility, Inc. 2011. All rights reserved. Logility is a registered trademark and Logility Voyager Solutions, Voyager Demand Planning,

Voyager Life Cycle Planning, and Voyager Event Planning are trademarks of Logility, Inc.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptDocument6 pagesUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- Leadership DefinitionsDocument4 pagesLeadership Definitionsrafazel hardyNo ratings yet

- Managing Resistance To Change and Holding The GainsDocument32 pagesManaging Resistance To Change and Holding The Gainsrafazel hardyNo ratings yet

- Academic Search Engines: Online Searching For Professional or Academic Purposes - Part IiDocument15 pagesAcademic Search Engines: Online Searching For Professional or Academic Purposes - Part Iirafazel hardyNo ratings yet

- Master Production ScheduleDocument21 pagesMaster Production Schedulerafazel hardyNo ratings yet

- Logistik 1Document49 pagesLogistik 1rafazel hardyNo ratings yet

- Strategic Planning Forecasting FundamentalsDocument33 pagesStrategic Planning Forecasting Fundamentalsrafazel hardyNo ratings yet

- Master Production ScheduleDocument18 pagesMaster Production Schedulerafazel hardyNo ratings yet

- Harvard Business Review - Operation ManagementDocument4 pagesHarvard Business Review - Operation Managementrafazel hardyNo ratings yet

- Six Essential Strategies For Selecting A Global 3PL - Inbound LogisticsDocument3 pagesSix Essential Strategies For Selecting A Global 3PL - Inbound Logisticsrafazel hardyNo ratings yet

- An Overview of Third Party Logistics Industry: Chrisoula Papadopoulou, PHDDocument54 pagesAn Overview of Third Party Logistics Industry: Chrisoula Papadopoulou, PHDrafazel hardyNo ratings yet

- Project Scheduling and TrackingDocument47 pagesProject Scheduling and TrackingArun VinodhNo ratings yet

- FM 2030Document18 pagesFM 2030renaissancesamNo ratings yet

- Acute Coronary SyndromeDocument30 pagesAcute Coronary SyndromeEndar EszterNo ratings yet

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNo ratings yet

- Chapter 1 ClassnotesDocument35 pagesChapter 1 ClassnotesAllison CasoNo ratings yet

- .Urp 203 Note 2022 - 1642405559000Document6 pages.Urp 203 Note 2022 - 1642405559000Farouk SalehNo ratings yet

- Week 7Document24 pagesWeek 7Priyank PatelNo ratings yet

- HirePro Video Proctored Online-Instruction Sheet - Bain IndiaDocument1 pageHirePro Video Proctored Online-Instruction Sheet - Bain Indiaapoorv sharmaNo ratings yet

- Assignment#10 Global Strategy and The Multinational CorporationDocument1 pageAssignment#10 Global Strategy and The Multinational CorporationAnjaneth A. VillegasNo ratings yet

- Ito Na Talaga Yung FinalDocument22 pagesIto Na Talaga Yung FinalJonas Gian Miguel MadarangNo ratings yet

- BNF Pos - StockmockDocument14 pagesBNF Pos - StockmockSatish KumarNo ratings yet

- LM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Document2 pagesLM74680 Fasson® Fastrans NG Synthetic PE (ST) / S-2050/ CK40Nishant JhaNo ratings yet

- AIA1800 Operator ManualDocument184 pagesAIA1800 Operator ManualZain Sa'adehNo ratings yet

- Origami Oso HormigueroDocument9 pagesOrigami Oso HormigueroRogelio CerdaNo ratings yet

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusDocument7 pagesArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesNo ratings yet

- QP December 2006Document10 pagesQP December 2006Simon ChawingaNo ratings yet

- Activity # 1 (DRRR)Document2 pagesActivity # 1 (DRRR)Juliana Xyrelle FutalanNo ratings yet

- Agco Serie 800 PDFDocument24 pagesAgco Serie 800 PDFJohnny VargasNo ratings yet

- MGMT Audit Report WritingDocument28 pagesMGMT Audit Report WritingAndrei IulianNo ratings yet

- Aptitude Number System PDFDocument5 pagesAptitude Number System PDFharieswaranNo ratings yet

- Tetralogy of FallotDocument8 pagesTetralogy of FallotHillary Faye FernandezNo ratings yet

- Analizador de Combustion Kigaz 310 Manual EngDocument60 pagesAnalizador de Combustion Kigaz 310 Manual EngJully Milagros Rodriguez LaicheNo ratings yet

- Gemini Dollar WhitepaperDocument7 pagesGemini Dollar WhitepaperdazeeeNo ratings yet

- Famous Russian PianoDocument10 pagesFamous Russian PianoClara-Schumann-198550% (2)

- SMC 2D CADLibrary English 1Document590 pagesSMC 2D CADLibrary English 1Design IPGENo ratings yet

- Functional DesignDocument17 pagesFunctional DesignRajivSharmaNo ratings yet

- Review1 ScheduleDocument3 pagesReview1 Schedulejayasuryam.ae18No ratings yet

- Sam Media Recruitment QuestionnaireDocument17 pagesSam Media Recruitment Questionnairechek taiNo ratings yet

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDocument42 pages15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaNo ratings yet