Professional Documents

Culture Documents

Batching Asphalt Materials For Design (Binder Course) : A. Grading

Uploaded by

Golam MasudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batching Asphalt Materials For Design (Binder Course) : A. Grading

Uploaded by

Golam MasudCopyright:

Available Formats

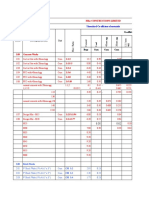

BATCHING ASPHALT MATERIALS FOR DESIGN (BINDER COURSE)

A. GRADING

Date: 23/03/2015 >> 20/05/2015

Material

Percent

25mm

19mm

12.5mm

9.5mm

4.75mm

2.36mm

1.18mm

0.600mm

0.300mm

0.150mm

0.075mm

S.G.

15-20 mm Agg

0.23

10-15 mm Agg

0.10

5-10 mm Agg

0.25

CRS

0.31

Nat. Sand

0.07

Filler(Produced)

0.04

23

Contribution

10

Contribution

25

Contribution

31

Contribution

7

Contribution

4

Contribution

100.0

23.0

100.0

10.0

100.0

25.0

100.0

31.0

100.0

7.0

100.0

4.0

88.6

20.4

100.0

10.0

100.0

25.0

100.0

31.0

100.0

7.0

100.0

4.0

10.1

2.3

90.7

9.1

100.0

25.0

100.0

31.0

100.0

7.0

100.0

4.0

1.4

0.3

17.2

1.7

94.7

23.7

100.0

31.0

100.0

7.0

100.0

4.0

0.0

0.0

0.1

0.0

17.4

4.4

99.9

31.0

100.0

7.0

100.0

4.0

0.0

0.0

0.0

0.0

0.3

0.1

79.8

24.7

90.3

6.3

100.0

4.0

0.0

0.0

0.0

0.0

0.0

0.0

61.2

19.0

81.9

5.7

100.0

4.0

0.0

0.0

0.0

0.0

0.0

0.0

45.0

14.0

71.3

5.0

100.0

4.0

0.0

0.0

0.0

0.0

0.0

0.0

29.9

9.3

36.6

2.6

99.8

4.0

0.0

0.0

0.0

0.0

0.0

0.0

14.2

4.4

15.2

1.1

99.0

4.0

0.0

0.0

0.0

0.0

0.0

0.0

3.9

1.2

3.8

0.3

98.6

3.9

2.660

SUM (%)

100

100.0

97.4

78.4

67.7

46.3

35.1

28.7

22.9

15.8

9.4

5.4

River

SAND

Filler

Bitumen

Total

Combined Grading

Weight in GM

15-20

mm Agg

2.649

2.625

2.579

2.627

Gsb=

B. BATCHING BY WEIGHT OF TOTAL MIX

Bitumen Content, %

2.659

10-15 mm 5-10 mm Crushed

Agg

Agg

SAND

23

10

25

31

100

3.5

2220

965

2413

2992

676

386

350

10000

2208

960

2400

2976

672

384

400

10000

4.5

2197

955

2388

2961

669

382

450

10000

2185

950

2375

2945

665

380

500

10000

5.5

2174

945

2363

2930

662

378

550

10000

2.639

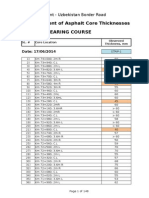

Ayni-Panjakent-Uzbekistan Border Road

Combined gradation on Particle Size Distribution of Aggregate and Filler for BC

Km 46 Batching Plant

Location :

Sampled by :

Date of Sampling :

Sample :

Engineer's Test / Joint Test

Particle Size Distribution Plot

100

90

80

70

Percentage Passing

60

50

40

30

20

1000

Particle Size, microns

19.0 mm

9.5 mm

4.75 mm

10

2.36mm

0.075 mm

0.150 mm

10

1000

TEST DATA FOR SIEVE ANALYSIS

Sieve

Size, mm

Mass Retained

Fract.-1

Fract.-2

Fract.-3

Total Mass

Fract.-4

Ret.

25

19.0

12.5

9.50

4.75

2.360

1.180

0.6

NOT SHOWING IN THE GRAPH

Cu. Mass

Retained

%

Retained

oad

and Filler for BC

Date of Testing :

Engineer's

Low er

Upper

Actual

100000

%

Finer

100.0

97.4

78.4

67.7

46.3

35.1

28.7

22.9

BATCHING ASPHALT MATERIALS FOR DESIGN (WEARING COURSE)

A. GRADING

KM 46 PLANT

Date: 27/03/2015 >> 15/05/2015

Material

Percent

25mm

19mm

12.5mm

9.5mm

4.75mm

2.36mm

1.18mm

0.600mm

0.300mm

0.150mm

0.075mm

15-20 mm Agg

99.8

84.7

9.3

0.6

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Contribution

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

10-15 mm Agg

0.21

5-10 mm Agg

0.28

CRS

0.39

Nat. Sand

0.09

Filler(Produced)

0.03

21

Contribution

28

Contribution

39

Contribution

9

Contribution

3

Contribution

100.0

21.0

100.0

28.0

100.0

39.0

100.0

9.0

100.0

3.0

100.0

21.0

100.0

28.0

100.0

39.0

100.0

9.0

100.0

3.0

90.7

19.0

100.0

28.0

100.0

39.0

100.0

9.0

100.0

3.0

17.2

3.6

94.7

26.5

100.0

39.0

100.0

9.0

100.0

3.0

0.1

0.0

17.4

4.9

99.9

39.0

100.0

9.0

100.0

3.0

0.0

0.0

0.3

0.1

79.8

31.1

90.3

8.1

100.0

3.0

0.0

0.0

0.0

0.0

61.2

23.9

82.1

7.4

100.0

3.0

0.0

0.0

0.0

0.0

45.0

17.6

71.3

6.4

100.0

3.0

0.0

0.0

0.0

0.0

29.9

11.7

36.6

3.3

99.8

3.0

0.0

0.0

0.0

0.0

14.2

5.5

15.2

1.4

99.0

3.0

0.0

0.0

0.0

0.0

3.9

1.5

3.8

0.3

98.6

3.0

SUM (%)

100

Combined Grading

2.659

2.649

2.625

2.579

2.627

Gsb =

100.0

100.0

98.0

81.1

55.9

42.3

34.3

Filler

Bitumen

Total

B. BATCHING BY WEIGHT OF TOTAL MIX

Weight in gm

Bitumen Content, %

S.G.

2.660

10-15 mm 5-10 mm Crushed

15-20 mm Agg

Agg

Agg

Sand

River

Sand

21

28

39

0.0

2016.0

2688.0

3744.0

864.0

288.0

400.0

10000

100

4.5

0.0

2005.5

2674.0

3724.5

859.5

286.5

450.0

10000

0.0

1995.0

2660.0

3705.0

855.0

285.0

500.0

10000

5.5

0.0

1984.5

2646.0

3685.5

850.5

283.5

550.0

10000

0.0

1974.0

2632.0

3666.0

846.0

282.0

600.0

10000

27.0

17.9

9.9

4.8

2.635

Ayni-Panjakent-Uzbekistan Border Road

Combined gradation on Particle Size Distribution of Aggregate and Filler for WC

Km 46

Location :

Sampled by :

Date of Sampling :

Sample :

Engineer's Test / Joint Test

Particle Size Distribution Plot

100

90

80

70

Percentage Passing

60

50

40

30

20

1000

Particle Size, microns

19.0 mm

9.5 mm

12.5 mm

4.75 mm

10

2.36mm

0.075 mm

0.150 mm

10

1000

TEST DATA FOR SIEVE ANALYSIS

Sieve

Size, mm

25

19.0

12.5

9.50

4.75

2.360

1.180

0.6

Mass Retained

Fract.-1

Fract.-2

Fract.-3

Total Mass

Fract.-4

Ret.

Cu. Mass

Retained

%

Retained

oad

and Filler for WC

Date of Testing :

Engineer's

Low er

Upper

Actual

100000

%

Finer

100.0

100.0

98.0

81.1

55.9

42.3

34.3

27.0

WC(12.5mm) Tested in May, 2015

Binder Content

4.0

4.5

5.0

5.5

6.0

Corrected

Gmm

2.486

2.474

2.459

2.440

2.420

Gmm

Actual

2.486

2.465

2.459

2.458

2.420

Gmm

2.500

2.480

2.460

Gmm

2.440

2.420

2.400

2.380

3.0

4.0

5.0

6.0

7.0

BC(19mm) Tested in May, 2015

Binder Content

3.5

4.0

4.5

5.0

5.5

Accepted

Gmm

2.478

2.462

2.451

2.444

2.438

1

2.478

2.459

2.456

2.447

2.415

Gmm (actual)

2

2.478

2.464

2.451

2.441

2.417

AVG

2.478

2.462

2.454

2.444

2.416

Gmm

2.490

2.480

2.470

2.460

Gmm

2.450

2.440

2.430

2.420

2.410

3.0

4.0

5.0

6.0

1)

Km 29+830 ~ Km 29+900

(70m, R/S)

Measurement : 70m x 3.1m x 0.5m

2)

Km 30+700 ~ Km 30+820

(120m, L/S)

Measurement : 120m x 5.0m x 0.5

3)

Km 33+260 ~ Km 34+000

t : 70m x 3.1m x 0.5m = 109m3

t : 120m x 5.0m x 0.5m = 300m3

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Analisa Saringan: Lab Tech PT. Bumi Indah, MahasiswaDocument12 pagesAnalisa Saringan: Lab Tech PT. Bumi Indah, MahasiswaLeonardo SemeNo ratings yet

- JMF Ac Binder CourseDocument57 pagesJMF Ac Binder Courseusman towoliuNo ratings yet

- S.No Description Unit Rate AmountDocument4 pagesS.No Description Unit Rate AmountSirajoddin PatelNo ratings yet

- Ministry of Transportation - Field Services, PavingDocument12 pagesMinistry of Transportation - Field Services, PavingukruegerNo ratings yet

- Item Description Quantity Unit Materials Labor Unit Cost Total Cost Unit Cost I. Concrete Works 2.50 Cu.m Item NoDocument2 pagesItem Description Quantity Unit Materials Labor Unit Cost Total Cost Unit Cost I. Concrete Works 2.50 Cu.m Item NoKim Javier EstaNo ratings yet

- SDBC Without FillerDocument9 pagesSDBC Without Fillerer_kenedyNo ratings yet

- Week 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensityDocument27 pagesWeek 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensitySamantha NamzugNo ratings yet

- Item Description Unit Times Length WidthDocument33 pagesItem Description Unit Times Length WidthAhamed Manazir HazzaanNo ratings yet

- Recommended Fitting Pratice BearingsDocument6 pagesRecommended Fitting Pratice BearingsNguyễn Văn HưngNo ratings yet

- DBM With FillerDocument8 pagesDBM With Fillerer_kenedy100% (1)

- Grading of Commercially Available Mineral AggregateDocument4 pagesGrading of Commercially Available Mineral AggregateSunil BoseNo ratings yet

- Vo - 33-1Document61 pagesVo - 33-1Ahamed Manazir HazzaanNo ratings yet

- Mfar Constructions Limited: SL - No Description of Item UnitDocument12 pagesMfar Constructions Limited: SL - No Description of Item UnitNaveen TibbaNo ratings yet

- ACbC Blend Class B - RevisedDocument1 pageACbC Blend Class B - RevisedKhaliq Ur RehmanNo ratings yet

- AV Industrial Products LTD Catalogue Anti Vibration MountsDocument52 pagesAV Industrial Products LTD Catalogue Anti Vibration MountsAV Industrial Products LtdNo ratings yet

- Normal MixesDocument18 pagesNormal MixesInhinyero SibilNo ratings yet

- 1-) 20 MM Limestone Sieve AnalysisDocument6 pages1-) 20 MM Limestone Sieve AnalysisYasin AykanatNo ratings yet

- THDFRM 3Document1 pageTHDFRM 3AS BaizidiNo ratings yet

- Light GaugeDocument2 pagesLight GaugeMomayKradookkradicNo ratings yet

- S.O.R For Building Ahmedabad District 2015-16Document694 pagesS.O.R For Building Ahmedabad District 2015-16Kunal Mandalaywala100% (1)

- Tamiz Diametro (MM) Masa de Suelo Retenido (G)Document6 pagesTamiz Diametro (MM) Masa de Suelo Retenido (G)Ignacio TrujjilloNo ratings yet

- Bulk Oil Storage Aliaabad, Daulatpur.Document17 pagesBulk Oil Storage Aliaabad, Daulatpur.sameerpecNo ratings yet

- 2.63 Viton Sponge Sheeting TdsDocument1 page2.63 Viton Sponge Sheeting TdsSachin AherNo ratings yet

- Avl PDFDocument52 pagesAvl PDFAhmet HamamcıoğluNo ratings yet

- Civil Engineering Basics: Concrete GradeDocument9 pagesCivil Engineering Basics: Concrete GradevamsiNo ratings yet

- Basic Points For Civil EngineersDocument9 pagesBasic Points For Civil Engineersshamsullah samarNo ratings yet

- Sieve Analysis-08.08Document4 pagesSieve Analysis-08.08ASHOKKUMARNo ratings yet

- Technobots - Co.uk Spur Gear Dimensions MOD 1.0 MOD 1.5Document1 pageTechnobots - Co.uk Spur Gear Dimensions MOD 1.0 MOD 1.5741852963aaaNo ratings yet

- Building Material Rate AnalysisDocument13 pagesBuilding Material Rate AnalysisChirag Bhavsar100% (1)

- Centro Comercial El Reloj Malvinas Plaza R.M.Britania S.A.C. Contratistas GralesDocument12 pagesCentro Comercial El Reloj Malvinas Plaza R.M.Britania S.A.C. Contratistas GralesCristy ReateguiNo ratings yet

- Breakdown of Project Estimated Cost by AdminDocument4 pagesBreakdown of Project Estimated Cost by AdminorualsalocinNo ratings yet

- Valve Pits Estimate 2014-15Document15 pagesValve Pits Estimate 2014-15Sasidhar KatariNo ratings yet

- Plain Tube Dimension: OD Wall Thickness ID Outside SurfaceDocument2 pagesPlain Tube Dimension: OD Wall Thickness ID Outside SurfaceLim DongseopNo ratings yet

- All in Aggregate M-45 (PQC) : For The Contractor For The Engineer / ConsultantDocument5 pagesAll in Aggregate M-45 (PQC) : For The Contractor For The Engineer / ConsultantImran KhanNo ratings yet

- Trial Job Mix Formula24.07.0201115Document1 pageTrial Job Mix Formula24.07.0201115Marwa AlasheebiNo ratings yet

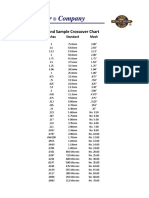

- Sand Sample Crossover ChartDocument2 pagesSand Sample Crossover ChartLEONARDO ARZUZANo ratings yet

- Daily Drilling Operation RecordDocument19 pagesDaily Drilling Operation RecordArief TAnkziNo ratings yet

- Design Mix PCC BlockDocument8 pagesDesign Mix PCC Blockvikrant987No ratings yet

- Rate Analysis160511Document17 pagesRate Analysis160511kaustubhp9875% (8)

- Dgar 1Document22 pagesDgar 1Moses KaswaNo ratings yet

- Assignment: Client:India Cements Limited Tandur, Ap Contractor: L&T Ecc DivisionDocument13 pagesAssignment: Client:India Cements Limited Tandur, Ap Contractor: L&T Ecc DivisionkonkashivaNo ratings yet

- BRKT Brake PedalDocument8 pagesBRKT Brake PedalSanjayNo ratings yet

- Steel Received To DABS-015 ProjectDocument6 pagesSteel Received To DABS-015 ProjectSovan PramanickNo ratings yet

- Summary of Construction SpecificationDocument11 pagesSummary of Construction SpecificationShafiqullah GowharyNo ratings yet

- Sagian Brick Masonry RWDocument26 pagesSagian Brick Masonry RWmumarbsc7244No ratings yet

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Document37 pagesSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarNo ratings yet

- SDBC With FillerDocument8 pagesSDBC With Fillerer_kenedyNo ratings yet

- Rebar Cutting ListDocument31 pagesRebar Cutting ListJona PajilaNo ratings yet

- Civil Rate ExcelDocument81 pagesCivil Rate Excelyo5208100% (2)

- Aci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpDocument6 pagesAci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpEulogio JameroNo ratings yet

- Project 8th SemDocument21 pagesProject 8th Semamish rajNo ratings yet

- Steel Rolling and MarginDocument26 pagesSteel Rolling and MarginSatya kaliprasad vangaraNo ratings yet

- Sieve Analysis-05.07.2018 Coarse & FineDocument3 pagesSieve Analysis-05.07.2018 Coarse & FineASHOKKUMARNo ratings yet

- Lect. Suspens Rsuspcorr ZRC (CM) D (MM) %pasa Tiempo (Min) Patron. Agua Temperatu Ra CDocument3 pagesLect. Suspens Rsuspcorr ZRC (CM) D (MM) %pasa Tiempo (Min) Patron. Agua Temperatu Ra CDamian Morocho MillerNo ratings yet

- Classification - ROCK - FILL 5384 (Version 1)Document5 pagesClassification - ROCK - FILL 5384 (Version 1)geo ghallabNo ratings yet

- Calculation of Mix Design (10260 2009)Document24 pagesCalculation of Mix Design (10260 2009)aayushagarwal123100% (1)

- Catalog SculeDocument820 pagesCatalog SculeMarinas Darius-IonutNo ratings yet

- ACI Mix-Design-8-2Document6 pagesACI Mix-Design-8-2Aboalmaail AlaminNo ratings yet

- Mix Design 8 2Document6 pagesMix Design 8 2Eulogio JameroNo ratings yet

- C2/JMBP (Spec Extract From P.85) : Grading Requirement For Rock Used For Slope Protection of Jamuna RiverDocument1 pageC2/JMBP (Spec Extract From P.85) : Grading Requirement For Rock Used For Slope Protection of Jamuna RiverGolam MasudNo ratings yet

- Can Id MassDocument12 pagesCan Id MassGolam MasudNo ratings yet

- ASTM Grooving ToolDocument2 pagesASTM Grooving ToolGolam MasudNo ratings yet

- SPT and CPTDocument57 pagesSPT and CPTGolam MasudNo ratings yet

- SPT and CPTDocument57 pagesSPT and CPTGolam MasudNo ratings yet

- Can Id MassDocument12 pagesCan Id MassGolam MasudNo ratings yet

- Borehole Logging Procedures: in ReviewDocument9 pagesBorehole Logging Procedures: in ReviewGolam MasudNo ratings yet

- GI ParagraphsDocument36 pagesGI ParagraphsGolam MasudNo ratings yet

- Geotechnical Investigation PresentationDocument2 pagesGeotechnical Investigation PresentationGolam MasudNo ratings yet

- 1.0 What Is Geotechnical InvestigationDocument13 pages1.0 What Is Geotechnical InvestigationGolam MasudNo ratings yet

- QA GuidelinesDocument1 pageQA GuidelinesGolam MasudNo ratings yet

- Learning For Writers and EditorsDocument297 pagesLearning For Writers and EditorsGolam MasudNo ratings yet

- 1 Test Requests: /conversion/tmp/scratch/383298889Document43 pages1 Test Requests: /conversion/tmp/scratch/383298889Golam MasudNo ratings yet

- ToR - Qaisar-Laman PDFDocument22 pagesToR - Qaisar-Laman PDFGolam MasudNo ratings yet

- Widening and Improvement of Road and Construction of Flyover at Mirpur Cantt. Estimation For Soil InvestigationDocument5 pagesWidening and Improvement of Road and Construction of Flyover at Mirpur Cantt. Estimation For Soil InvestigationGolam MasudNo ratings yet

- The Effect of Warm Mix Asphalt Additive (Sasobit®) On Determination of Optimum Bitumen ContentDocument7 pagesThe Effect of Warm Mix Asphalt Additive (Sasobit®) On Determination of Optimum Bitumen ContentGolam MasudNo ratings yet

- Measurement of Asphalt Core Thicknesses in The Field Wearing CourseDocument148 pagesMeasurement of Asphalt Core Thicknesses in The Field Wearing CourseGolam MasudNo ratings yet

- AC-19asphalt Con. Mix Design PDFDocument11 pagesAC-19asphalt Con. Mix Design PDFGolam MasudNo ratings yet

- Why A Failed Relationship IsnDocument7 pagesWhy A Failed Relationship IsnGolam Masud0% (1)

- On Road Marking Paint: Ayni-Panjakent-Uzbekistan Border RoadDocument2 pagesOn Road Marking Paint: Ayni-Panjakent-Uzbekistan Border RoadGolam MasudNo ratings yet

- Data Mining ToolsDocument9 pagesData Mining Toolspuneet0303No ratings yet

- Coerver Training DrillsDocument5 pagesCoerver Training Drillsburvi200111860% (1)

- Report Documentation Page: Major James R. VanceDocument26 pagesReport Documentation Page: Major James R. VanceQazma RarajNo ratings yet

- Alessandro Albanese - All Season CollectionDocument29 pagesAlessandro Albanese - All Season CollectionWilliam BourneNo ratings yet

- Collection DunodDocument2 pagesCollection DunodBrahim Boutjbirine50% (4)

- Strategic Cost ManagementDocument12 pagesStrategic Cost ManagementvionysusgoghNo ratings yet

- Grlweap 2005Document3 pagesGrlweap 2005José RuizNo ratings yet

- MILLER Testable ConceptsDocument109 pagesMILLER Testable ConceptsMohammedGooda100% (1)

- Zulfia Karimova - ENGLISHDocument13 pagesZulfia Karimova - ENGLISHtncj664sp6No ratings yet

- Table of Specifications With Test in Science - Quarter 4 - (Week 3 and Week 4)Document4 pagesTable of Specifications With Test in Science - Quarter 4 - (Week 3 and Week 4)Sarah Jane Lagura Rele50% (2)

- Periodic Trends Lesson PlanDocument6 pagesPeriodic Trends Lesson PlanWadé AzuréNo ratings yet

- Mvo 1965Document113 pagesMvo 1965younisNo ratings yet

- Stochastic Epidemic ModellingDocument15 pagesStochastic Epidemic ModellingIRJMETS JOURNALNo ratings yet

- How Fractions, Decimals and Percentages Work TogetherDocument9 pagesHow Fractions, Decimals and Percentages Work TogetherjohnteecubeNo ratings yet

- Dokumen - Tips Strength of Materials 5691845f3ea8eDocument13 pagesDokumen - Tips Strength of Materials 5691845f3ea8eJay GeeNo ratings yet

- Surigao Del Sur State University: Mathematics in The Modern World Module Number 2Document11 pagesSurigao Del Sur State University: Mathematics in The Modern World Module Number 2TOP ERNo ratings yet

- How To Product ManualDocument250 pagesHow To Product ManualAmith M DNo ratings yet

- Practical 9: Enthalpy Change of ReactionDocument4 pagesPractical 9: Enthalpy Change of ReactionJulia QistinaNo ratings yet

- Front PageDocument5 pagesFront PageAnas AloyodanNo ratings yet

- Best Freight Forwarding ERP Software - CargoNet PDFDocument19 pagesBest Freight Forwarding ERP Software - CargoNet PDFGo cargonetNo ratings yet

- Article 2 - NOVEMBER - Thermage PDFDocument3 pagesArticle 2 - NOVEMBER - Thermage PDFPey EsperasNo ratings yet

- Service Manual: Diva Avr200 Surround Sound ReceiverDocument61 pagesService Manual: Diva Avr200 Surround Sound Receiver王军No ratings yet

- CC W3 AWS Basic InfraDocument57 pagesCC W3 AWS Basic InfraMuhammad Tehseen KhanNo ratings yet

- List of RAs UpdatedDocument12 pagesList of RAs UpdatedThe SuperstarNo ratings yet

- Ecosystem ScriptDocument7 pagesEcosystem ScriptGeraldine Co TolentinoNo ratings yet

- Data Structures and Problem Solving Using JavaDocument20 pagesData Structures and Problem Solving Using JavaBrent Xavier AgnoNo ratings yet

- Exercises For Functional AnalysisDocument10 pagesExercises For Functional AnalysisEDU CIPANANo ratings yet

- Smart Goals Unit 2 BiologyDocument2 pagesSmart Goals Unit 2 Biologyapi-330056366No ratings yet

- The Sniper - Storey PDFDocument177 pagesThe Sniper - Storey PDFJose Luis95% (19)

- Abu Ibrahim Al-Hashimi Al-Qurashi: Abū Ibrāhīm Al-Hāshimi Al-Qurashi Mawli Al-SalbiDocument12 pagesAbu Ibrahim Al-Hashimi Al-Qurashi: Abū Ibrāhīm Al-Hāshimi Al-Qurashi Mawli Al-SalbiJosué Barrón GonzálezNo ratings yet