Professional Documents

Culture Documents

CadWeld

Uploaded by

HansLopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CadWeld

Uploaded by

HansLopezCopyright:

Available Formats

CADweld Experiences

Page 1 of 5

Bob Applegate's Boring Page

Boring the web since 1994

What is CADweld?

Technically, it's called exothermic welding, but the name CADweld is a

registered trademark of Erico, which manufactures the product line. On

their web site, look on the left for Online Catalogs and then choose

"CADweld - Americas".

It's a pretty cool method to weld electrical conductors together. I'm sure

it can do a lot more, but the most common use for hams is to weld

ground cables to ground rods. For instance, I use #4 stranded copper

wire for all my ground connections outside, and have 10 ground rods in

my grounding system so far. Most of those rods are literally welded to

Welcome > Ham Radio > CADweld Experiences >

the ground wire using CADweld.

Here is a sample weld, which was later buried in my yard:

Why Would I Use It?

The traditional method of doing ground rods is pretty flaky, often isn't

done right, and requires frequent inspections and touch-ups. The ground

rods normally stick out above the ground, and use compression

connectors to squeeze the ground wire for a "good" joint. Can you say

"corrosion?" That exposed connection WILL deteriorate, no matter how

much Penetrox you slop on it. And, since it needs to be inspected, you

have to keep the connections above ground. Yuck!

With a couple little kids running around the yard, and with poor soil that

needs lots of ground rods, I needed something better. Besides, I want to

make QSOs, not spend time checking/cleaning ground connections. Enter

http://www.k2ut.org/cadweld.html

12/1/2014

CADweld Experiences

Page 2 of 5

exothermic welding.

CADweld basically melts a metal around the joint where the ground rod

and wire meet. It's a molecular bond, which means no corrosion between

the wire and rod. It's a solid joint, a blob of metal. All of my ground rods

are buried, so there is nothing to see except from the base of the tower

to where the wires go under ground. The copper will rot before the

CADweld connection fails.

What Do I Need?

First, there are two basic groups of these things: one-shot and re-usable.

Their names describe them well. I have the most experience with oneshot molds.

No matter what type you use, you'll always use some sort of mold (either

ceramic or graphite), a "shot" (some sort of powdered metal) an ignitor

(a fine powder that burns like crazy) and a flint igniter (to ignite the

whole thing).

Here's the best part... you get the mold set up, pour in the shot, and

then ignite it... WHOOOSH! A flame shoots out for about 1/2 second,

then inside the mold it'll glow bright red as the molten metal forms

around the wire/rod. It takes only about 10 to 15 seconds for a solid

weld, but the mold will be brutally hot for quite a while.

One Shot

This consists of a kit to do one weld. Included in the small cardboard box

are the mold, the mold top, the metal thingy, and the shot. If you look at

the picture below, you'll see a typical one-shot mold. The mold is in the

upper right. The metal disc goes into the bottom of the mold, then the

shot (the powdery stuff being poured out of the blue container) gets

poured on top. Finally, the disc with the hole in the middle goes on top.

Reusable

I need another picture here. Below is a picture of the XXXX clamp that

http://www.k2ut.org/cadweld.html

12/1/2014

CADweld Experiences

Page 3 of 5

you'll definitely need to hold the mold in place. The clamp is used to hold

the mold in place; you need to buy the appropriate mold for you

application. You'll then need one shot per weld. When you're done, the

mold and clamp can be re-used, although there is a limited life of the

mold.

Here's a picture of the reusable clamp and mold, ready for the shot to be

poured in:

After the magic, the mold is released and this is the end result:

http://www.k2ut.org/cadweld.html

12/1/2014

CADweld Experiences

Page 4 of 5

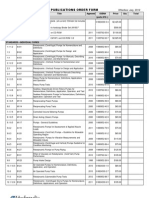

Where Can I Get It?

I'm sure there are a number of places that sell it, but I found the R. F.

Connection first. They stock the CADweld one-shot molds, and can order

other products for you. They've gotten me shots, re-usable molds, etc.

Advice

Information

I screwed up a few molds, and had a pretty poor success rate at first. I

kept bugging the folks at R. F. Connection until they got me in touch with

the experts at Erico. Erico has a few products that I would highly

recommend to anyone consideringthis product:

How to CADWELD, An Easy Connection to Make (videotape)

CADWELD ONE-SHOT Connections (videotape)

Booklet: Installers and Inspectors Guide for CADweld Electrical

Connections

Booklet: Contractor Tips for the Use of CADweld Products

Contact a dealer or Erico for pricing on these. I had fouled up a number

of one-shots before getting this material, then had a 100% success rate

after looking at the data.

http://www.k2ut.org/cadweld.html

12/1/2014

CADweld Experiences

Page 5 of 5

Products

Reusable molds are expensive (about $90 each) and you need the XXXX

clamp (shown above, another $40). Keep in mind that molds don't last

forever, so you might get 50 welds from one. Assuming you get 40 welds

and each shot is $3 (about right), that's about $6.25 per weld. One-shots

are $7-$9 each, so this still works nicely.

Tips

For one-shot molds, there is a rubber gasket on the bottom that fits

around the ground rod. If your ground wires are pulling up on the mold,

it'll be a disaster. The molten metal will cause the rubber to pull away

from the mold, and it'll ignite. Molten metal pours out the bottom,

setting almost anything on fire. When I did my rods, they were all down

in holes so the whole thing could be under ground. This really was a case

of "fire in the hole!"

So, make sure the mold is pressing down on the ground rod. Easy to do

with little effort. This makes every weld a perfect one.

Use an Erico flint igniter. There's a long explanation for why, but trust

me, it does work better than a torch.

Storage, Handling, Etc

The boxes with the shots and one-shot molds are marked which end has

to be kept up. Pay attention to that! If you toss them around, the igniter

material will mix with the shot and won't light.

Keep them in a dry place for obvious reasons.

Common Problems

It Won't Ignite!

My biggest problem, but it was easy to solve with a few steps. First,

when you dump out the shot, the igniter at the bottom probably won't

come out. I use a little screwdriver to just scrape loose the material, and

then pour it out.

If you're using a reusable mold, make sure you put some of the igniter

on the lip of the mold. Get that started and the rest of the shot will ignite

without a problem.

1994-2011 Bob Applegate Contact Me

http://www.k2ut.org/cadweld.html

12/1/2014

You might also like

- Dimension Book For FlangesDocument18 pagesDimension Book For FlangesHansLopezNo ratings yet

- Engineering Work Package Rules of Credit PresentationDocument21 pagesEngineering Work Package Rules of Credit PresentationHansLopezNo ratings yet

- Pipeline Equipment and ConstructionDocument16 pagesPipeline Equipment and ConstructionHansLopezNo ratings yet

- Cott Manufacturing Big FinkDocument1 pageCott Manufacturing Big FinkHansLopezNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Module1 - EV TechnologyDocument40 pagesModule1 - EV TechnologyThiruvenkadam SrinivasanNo ratings yet

- Blasting Vibration 1989Document84 pagesBlasting Vibration 1989Alejandra ArmentaNo ratings yet

- Single Wire Earth Return (SWER) : Course Instructor: Peter ArmstrongDocument16 pagesSingle Wire Earth Return (SWER) : Course Instructor: Peter ArmstrongnambaccucNo ratings yet

- Heat Exchange PDFDocument3 pagesHeat Exchange PDFmunhNo ratings yet

- DPS Phy - Set - ADocument3 pagesDPS Phy - Set - AscNo ratings yet

- Thermoelectric Modules Assemblies For Medical Laser ApplicationsDocument8 pagesThermoelectric Modules Assemblies For Medical Laser Applicationsricardo.barredo7464No ratings yet

- Sheer Driving PleasureDocument25 pagesSheer Driving Pleasuremst317No ratings yet

- Power Electronics in Motor DrivesDocument7 pagesPower Electronics in Motor DrivesAlfredo Brumnić Fredo0% (1)

- Design and Implementation of Multiple Output Switch Mode Power SupplyDocument6 pagesDesign and Implementation of Multiple Output Switch Mode Power SupplyseventhsensegroupNo ratings yet

- Thick-Walled P.V.Document23 pagesThick-Walled P.V.Erick PalladaNo ratings yet

- Raku Kei Reiki MudrasDocument4 pagesRaku Kei Reiki Mudrasmajadb100% (1)

- Xylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsDocument4 pagesXylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsAtiqNo ratings yet

- Ansi-Hi Pump StandardsDocument2 pagesAnsi-Hi Pump StandardsAndrés Eduardo100% (1)

- PID Temperature Control: Proportional GainDocument5 pagesPID Temperature Control: Proportional Gainvamsikumar reddyNo ratings yet

- 2022 AJSO Exam With AnswersDocument24 pages2022 AJSO Exam With AnswersWelly Boss HwiNo ratings yet

- Wireless Pump Control With Water Level Monitoring System: June 2018Document7 pagesWireless Pump Control With Water Level Monitoring System: June 2018amitNo ratings yet

- Metravi: Digital Ac/Dc Clamp MeterDocument1 pageMetravi: Digital Ac/Dc Clamp MeterSAEL SOLARNo ratings yet

- 25 HP & 20 HP Solar Pump QuatationDocument5 pages25 HP & 20 HP Solar Pump QuatationAmodNo ratings yet

- Live Line Insulator WashingDocument8 pagesLive Line Insulator WashingWjdan Al ZwaiNo ratings yet

- Signature RedactedDocument49 pagesSignature RedactedG Pavan KumarNo ratings yet

- Integration of Nonlinear Crude Distillation Unit Models in RefineryDocument11 pagesIntegration of Nonlinear Crude Distillation Unit Models in RefineryNông DânNo ratings yet

- Trident Tech LabDocument16 pagesTrident Tech LabkrcdewanewNo ratings yet

- Simufact BR Rolling 2015 E Web PDFDocument2 pagesSimufact BR Rolling 2015 E Web PDFSamir KhNo ratings yet

- 4D Seminar ReportDocument41 pages4D Seminar ReportChandu Sunag0% (1)

- Experiment Procedure: Description of The Experiment Components and Measuring EquipmentsDocument14 pagesExperiment Procedure: Description of The Experiment Components and Measuring EquipmentsMuhammad Ali Khan AwanNo ratings yet

- Quick Reference GC Detectors 5994 4919en AgilentDocument2 pagesQuick Reference GC Detectors 5994 4919en AgilentSasan FaniNo ratings yet

- PneumaticACtuator Masoneilan - Linear Setpoint PDFDocument63 pagesPneumaticACtuator Masoneilan - Linear Setpoint PDFAnonymous e7DNMZ100% (1)

- Panolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly BiodegradableDocument1 pagePanolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly Biodegradablerobertoalfaro492023No ratings yet

- Monitoring System SettingDocument4 pagesMonitoring System Settinglinkangjun0621No ratings yet

- Vdocuments - MX - Cummins Parts Mag Diesel Parts Cummins Engine CumminsDocument283 pagesVdocuments - MX - Cummins Parts Mag Diesel Parts Cummins Engine CumminsBonifasius LgaolNo ratings yet