Professional Documents

Culture Documents

Epsilone Vea Control

Uploaded by

manil_5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epsilone Vea Control

Uploaded by

manil_5Copyright:

Available Formats

1/3

VEA

HIGHLY EFFICIENT VISCOSITY ENHANCING AGENT

PRODUCT

EPSILONE VEA is a highly efficient and robust liquid

admixture based on macro-copolymers designed to

enable the production of highly cohesive and

pumpable HPC or SCC.

EPSILONE VEA improves the stability and the

segregation resistance of various type of concrete. It

enhances the thixotropic properties of cement based

materials.

WORKING MECHANISM

EPSILONE VEA first dissolves in the cement paste and

adsorb free water molecule. Therefore, active

macro-copolymer swells. Adjacent polymer chains

develop attractive forces, resulting in the formation of

a gel like network. At low shear rate and especially at

high concentration, the polymer strangles causing an

increase in the apparent plastic viscosity. Moreover,

active copolymers will adsorb on the neighborhood

particles forming a three dimensional bridge

structure.

The rheology of fresh concrete can be mainly

described by its yield point and plastic viscosity:

The yield point describes the force needed to start

the concrete moving. Yield point is related to the

workability of the concrete and may be assessed by

tests such as the slump or flow value.

Plastic Viscosity describes the resistance of a

concrete to flow under external stress. Viscosity is

caused by internal friction. The speed of flow of

concrete is related to its plastic viscosity and may be

assessed by the T500 time during a slump flow test

or by the time to flow through a V Funnel.

The balance between the yield point and the plastic

viscosity is the key to obtaining the appropriate

concrete rheology. EPSILONE VEA changes the

rheological properties of concrete by increasing the

plastic viscosity but usually cause only a small increase

in the yield point. HRWR Admixtures which decrease

the yield point are used in conjunction with EPSILONE

VEA to optimize the yield point.

PROPERTIES

EPSILONE VEA is designed for specific applications. It

is used to:

Reduced segregation in highly owable/self

compacting concrete

Reduced washout in underwater concrete

Reduced friction and pressure in pumped concrete

Compensates for poor aggregate grading, especially

a lack of fines in the sand

Allows reductions in powder content in self

compacting concrete

Reduced bleeding in concrete

Improves green strength in semi-dry concrete

Less sensitive to variations in the moisture content

of the aggregate Improves concrete robustness

Provides stability to more uid mixes without the

risk of segregation Reduced formwork pressure by

thixotropic effect

Better surface appearance

A more durable concrete

Reduces environmental risk caused by the wash out

of cement particles

Prevents blockages by allowing the concrete to

remain fluid, homogeneous and resistant to

segregation, even under high pumping pressures

SCOPE OF USE

EPSILONE VEA is recommended for all areas of use of

high-performance concrete in the concrete industry:

Standard concrete

Self-Compacting Concrete

High Performance/High Strength Concrete

2/3

VEA

High Durability Concrete

Precast Concrete

Mass Concrete

Underwater concrete

Pervious Concrete

Lightweight aggregate concrete

Sprayed concrete

Shotcrete

Manufactured Concrete Products

Semi-Dry Concrete

Screeds & Renders

Repair Mortar

Sustainable concrete

HVFA concrete

Architectural concrete with exposed coarse

aggregate surfaces.

Low cementituous SCC concrete mix designs.

Light Grey

1.02 0.02

NIL BS 5075/EN 934-2

STANDARDS

EFNARC - VMA Guidelines 2006

CAA VMA for SCC Guidelines

BS EN 480

BS EN 934-2

ISO 649-2

INSTRUCTION FOR USE

EPSILONE VEA should be dispensed and well mixed at

the end of the batching sequence after all other

ingredients have been thoroughly mixed.

For the best efficiency, it is highly recommended to

deduct the added amount of VEA from the total

water. It is preferable to stir, shake or agitate the

product before usage especially when kept intact in

the store for a long period.

DOSAGE RATES

EFFECT OF OVERDOSE

Overdose of EPSILONE VEA may result in the

following:

Loss of initial workability

Increase in concrete mix cohesiveness

Slowing the placing rate

This effect can usually be overcome by increasing the

superplasticizer content.

COMPATIBILITY

EPSILONE VEA can be used in mixtures containing:

CHARACTERISTICS

Appearance

Specific gravity @ 25C

Chloride content

components.

At optimum dosage a right balance between fluidity,

passing ability and resistance to segregation is

achieved.

Range of dosage rates: from 400 to 2000 ml per 100

kg of cementituous content.

Various concrete materials, slump, ambient air

temperature, additions of pozzolanic materials,

mixing time, and type and brand of cement will affect

dosage rates. It is suggested that trial mixes be

conducted in order to determine the required dosage

for optimum performance with available concrete

Silica fume

Fly Ash

GGBFS

Pozzolanic Binders

EPSILONE VEA is compatible with all types of

SODAMCOs concrete admixture.

Consult SODAMCO's technical dept. for advice.

PACKAGING

EPSILONE VEA is supplied in:

1000 liters containers.

200 liters drum.

20 liters Jeriken

STORAGE

EPSILONE VEA can be stored up to 6 months from

manufacturing date under cover, out of direct

sunlight and protected from extreme temperatures.

In case of frost, the product recovers its properties

after progressive thawing and homogenizing by

agitation.

HEALTH & SAFETY

IIn case of contact with skin or eyes, rinse thoroughly

with water. If irritation persists, seek medical

attention.

If swallowed, do not induce vomiting and seek

medical attention.

3/3

VEA

QUALITY STATEMENT

All our products are manufactured to comply with our

internal QA/QC program and quality management

system to ensure consistency and quality

DISCLAIMER

While the company guarantees its products against defective

materials, the use and application of these products are made

without guarantee since the conditions of their applications are

beyond its control. It is recommended to verify with the company

that the product is suitable for the intended use, and that the Data

Sheet version is the latest one. The company may modify it without

prior notice. Technical characteristics are listed for guidance only.

For more information, please contact the companys office in your

location.

NOTE

The information included on this Technical Data Sheet is the sole

property of SODAMCO Holding. The unauthorized disclosure, use,

dissemination or copying (either whole or partial) of this data sheet

or any information it contains, is prohibited and subject to legal

pursuit.

Edition: 02/13-A

T +961 1 510863/4 M +961 3 380748 F +961 1 510862 sodamco@sodamco.com www.sodamco.com

Lebanon . UAE . Syria . Qatar . KSA . Jordan . Kuwait . Oman

You might also like

- Audit Report-2 SignedDocument12 pagesAudit Report-2 Signedmanil_5100% (2)

- Effective Use of Bonding AgentsDocument4 pagesEffective Use of Bonding Agentsrenee100% (2)

- TDS-103 Dispersion Techniques Carbopol PolymersDocument5 pagesTDS-103 Dispersion Techniques Carbopol PolymersMostofa RubalNo ratings yet

- Adapt Formula SheetDocument6 pagesAdapt Formula SheetUngoliant101No ratings yet

- PST Questions Types Explainations v2Document6 pagesPST Questions Types Explainations v2Nikhil Kasat50% (2)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Audit Report 2 - ClientDocument10 pagesAudit Report 2 - Clientmanil_5No ratings yet

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5No ratings yet

- Admix Load CellDocument6 pagesAdmix Load Cellmanil_5No ratings yet

- Coalesce RDocument4 pagesCoalesce Rrieza_fNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- Antifoam Solutions Brochure InddDocument0 pagesAntifoam Solutions Brochure Inddhisham_00No ratings yet

- C88 2013Document5 pagesC88 2013manil_5No ratings yet

- Ceraproof Iwp Liquid: Liquid Integral Water Proofing Compound For Cement Mortar and ConcreteDocument2 pagesCeraproof Iwp Liquid: Liquid Integral Water Proofing Compound For Cement Mortar and ConcreteGuru RajaNo ratings yet

- MasterPolyheed 8177 v3Document3 pagesMasterPolyheed 8177 v3Rajesh NairNo ratings yet

- Cebex 100 Non-Shrink Grout AdmixtureDocument19 pagesCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobNo ratings yet

- Glenium 27Document3 pagesGlenium 27Ct TanNo ratings yet

- Cebex 112 Mortar Plasticiser Improves Workability & YieldDocument2 pagesCebex 112 Mortar Plasticiser Improves Workability & YieldMel AdNo ratings yet

- Sika Cemflex: Acrylic Polymer For Making Flexible Cementitious Waterproofing SlurryDocument4 pagesSika Cemflex: Acrylic Polymer For Making Flexible Cementitious Waterproofing Slurryankur dasNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- TDS - Emaco S68 PlusDocument3 pagesTDS - Emaco S68 PlusVenkata RaoNo ratings yet

- PDS Sika ViscoCrete-8100 enDocument3 pagesPDS Sika ViscoCrete-8100 enimeldaturualloNo ratings yet

- TDS - Glenium Ace 415Document3 pagesTDS - Glenium Ace 415Alexi ALfred H. TagoNo ratings yet

- Sika® Viscocrete®-3006 Es: Product Data SheetDocument2 pagesSika® Viscocrete®-3006 Es: Product Data SheetShihab AhamedNo ratings yet

- Epsilone HP 504Document2 pagesEpsilone HP 504John PaulsyNo ratings yet

- TDS - Glenium Ace 340Document3 pagesTDS - Glenium Ace 340Alexi ALfred H. TagoNo ratings yet

- Cebex 100 PDFDocument4 pagesCebex 100 PDFAnonymous IwqK1NlNo ratings yet

- Glenium 105 Suretec TdsDocument2 pagesGlenium 105 Suretec TdsGabriel LimNo ratings yet

- Glenium - Ace - 6 - Suretec - v4Document2 pagesGlenium - Ace - 6 - Suretec - v4Kuldeep ChakerwartiNo ratings yet

- Masterseal 550Document4 pagesMasterseal 550Haresh BhavnaniNo ratings yet

- Masterglenium Sky 8705Document2 pagesMasterglenium Sky 8705usenuyaNo ratings yet

- En - Mca Pds - Cqs-1hp - V.2.0Document2 pagesEn - Mca Pds - Cqs-1hp - V.2.0Roland Rojas VilchezNo ratings yet

- SmartCare TechnoPlast S 300Document2 pagesSmartCare TechnoPlast S 300raviteja036100% (1)

- Cebex 100Document2 pagesCebex 100didonkimurayahooNo ratings yet

- Masterseal 521 TdsDocument3 pagesMasterseal 521 Tdsraafat ibrahimNo ratings yet

- Duconmix WS ES 860 RbsDocument3 pagesDuconmix WS ES 860 RbsmasudNo ratings yet

- Conplast AEA: Air Entraining AdmixtureDocument4 pagesConplast AEA: Air Entraining AdmixtureVenkata Raju KalidindiNo ratings yet

- Sikacim Latex Pds enDocument3 pagesSikacim Latex Pds enMuhammad AzharNo ratings yet

- High Range Water Reducer Maintains Workability & DurabilityDocument4 pagesHigh Range Water Reducer Maintains Workability & DurabilitymaxlehenerNo ratings yet

- AdmixturesDocument27 pagesAdmixturesShubham ParmarNo ratings yet

- SikacimDocument2 pagesSikacimCHETTIKULAM NATHAM projectNo ratings yet

- TDS - Bronco Cemgrout SP75Document4 pagesTDS - Bronco Cemgrout SP75Jignessh JoshiNo ratings yet

- TDS Cebex 200 India2 PDFDocument2 pagesTDS Cebex 200 India2 PDFKamal KumarNo ratings yet

- Delvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteDocument2 pagesDelvo Crete Stabiliser: Liquid Hydration Inhibitor For ConcreteShoyeeb AhmedNo ratings yet

- Plastiment 2001 NSDocument2 pagesPlastiment 2001 NSjeevendraNo ratings yet

- 14.penecoat Stabilizer ENG PDS 19.11.2019Document2 pages14.penecoat Stabilizer ENG PDS 19.11.2019Bilal HodžićNo ratings yet

- Alccofine 1108SR : Description Typical PropertiesDocument2 pagesAlccofine 1108SR : Description Typical Propertiesravi100% (1)

- Cebex 100Document2 pagesCebex 100Riyan Aditya NugrohoNo ratings yet

- Tds - Emaco s66 CPDocument2 pagesTds - Emaco s66 CPVenkata RaoNo ratings yet

- Silres BS 4004: Silane EmulsionsDocument3 pagesSilres BS 4004: Silane EmulsionsVaittianathan MahavapillaiNo ratings yet

- Cebex 112: Mortar PlasticiserDocument2 pagesCebex 112: Mortar PlasticiserBalasubramanian AnanthNo ratings yet

- Sika Plast 257Document3 pagesSika Plast 257HasithaNo ratings yet

- Cebex 200Document2 pagesCebex 200Anonymous XVEucVMsENo ratings yet

- Cebex 100Document2 pagesCebex 100manil_5No ratings yet

- Readyplast M Super Ready Mix Plastering MortarDocument2 pagesReadyplast M Super Ready Mix Plastering MortarPritpal SinghNo ratings yet

- Elotex Seal 80 PDFDocument2 pagesElotex Seal 80 PDFRajuNSanaboinaNo ratings yet

- Masterlife Sra 50: Description Expanding PropertiesDocument2 pagesMasterlife Sra 50: Description Expanding PropertiesSavalia HardikNo ratings yet

- Cebex 112Document2 pagesCebex 112End EndNo ratings yet

- Adhere Mix-700: High Grade Super PlasticizerDocument2 pagesAdhere Mix-700: High Grade Super PlasticizerAbdur RazzaqNo ratings yet

- ShaliPlast IW CIDocument2 pagesShaliPlast IW CISunil Kumar GiriNo ratings yet

- MateriDocument3 pagesMateriTeuku Rahmad MauliddinNo ratings yet

- (Excipient) Memantine SR - SureleaseDocument2 pages(Excipient) Memantine SR - SureleaseByunghoon LeeNo ratings yet

- Atmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionFrom EverandAtmospheric Pressure Plasma Treatment of Polymers: Relevance to AdhesionNo ratings yet

- CBGMDocument16 pagesCBGMmanil_5No ratings yet

- C115C115M. 2010Document8 pagesC115C115M. 2010manil_5No ratings yet

- Norma ASTM C117.1589619-1Document3 pagesNorma ASTM C117.1589619-1Mónica ZúñigaNo ratings yet

- C87C87M 2010Document4 pagesC87C87M 2010manil_5No ratings yet

- Admix ComparisonDocument1 pageAdmix Comparisonmanil_5No ratings yet

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument5 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method Formanil_5No ratings yet

- C70. 2013Document3 pagesC70. 2013manil_5No ratings yet

- Waste AuditDocument47 pagesWaste Auditmanil_5No ratings yet

- Light Weight DesignDocument12 pagesLight Weight Designmanil_5No ratings yet

- Excel Stats Nicar2013Document6 pagesExcel Stats Nicar2013yaktamerNo ratings yet

- Alkali Aggregate ReactionDocument26 pagesAlkali Aggregate Reactionmanil_5No ratings yet

- Admix ComparisonDocument1 pageAdmix Comparisonmanil_5No ratings yet

- Waste AuditDocument47 pagesWaste Auditmanil_5No ratings yet

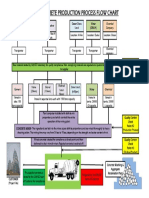

- Process Flow ChartDocument1 pageProcess Flow Chartmanil_5No ratings yet

- WP Message From DM.Document1 pageWP Message From DM.manil_5No ratings yet

- 1Document8 pages1manil_5No ratings yet

- Basic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)Document9 pagesBasic Concrete Technology (BCT) : Examination Questions - January, 2016 (Total Marks 50, Max Time 2 Hours)manil_5No ratings yet

- Load Cell KAUDocument4 pagesLoad Cell KAUmanil_5No ratings yet

- Load Cell 46-23Document2 pagesLoad Cell 46-23manil_5No ratings yet

- NDT 1Document126 pagesNDT 1manil_5No ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Accelerated C TankDocument1 pageAccelerated C Tankmanil_5No ratings yet

- Environmental Impact AssessmentDocument7 pagesEnvironmental Impact Assessmentmanil_5No ratings yet

- ChemistryDocument31 pagesChemistryjochiman100% (1)

- Feature Selection Using Kernel Based Local Fisher Discriminant Analysis For Hyperspectral Image ClassificationDocument4 pagesFeature Selection Using Kernel Based Local Fisher Discriminant Analysis For Hyperspectral Image ClassificationVarun BhardwajNo ratings yet

- Esp IndahDocument10 pagesEsp IndahandreaNo ratings yet

- MK300 - Catalogue Relay bảo vệ dòng rò (Earth Leakage Relay) MK300 của MikroDocument2 pagesMK300 - Catalogue Relay bảo vệ dòng rò (Earth Leakage Relay) MK300 của MikroconmavtvnNo ratings yet

- SRD 1813576Document7 pagesSRD 1813576Sazzad Reza Durlov 1813576630No ratings yet

- DS-PDSMK-4 (BAR) Wired Smoke Sensor 20190917Document2 pagesDS-PDSMK-4 (BAR) Wired Smoke Sensor 20190917jose paredesNo ratings yet

- Final Report - HVACDocument10 pagesFinal Report - HVACBenny BennyNo ratings yet

- Tyre Curing GuideDocument6 pagesTyre Curing GuideMALAY GUPTANo ratings yet

- 434-II 435-II 437-II BrochureDocument6 pages434-II 435-II 437-II BrochureLukmanKpNo ratings yet

- Alia AUF790 Ultrasonic Open Channel FlowmeterDocument4 pagesAlia AUF790 Ultrasonic Open Channel FlowmeterRexCrazyMindNo ratings yet

- OverTheWire Bandit Level 0 WalkthroughDocument28 pagesOverTheWire Bandit Level 0 WalkthroughAdib DfNo ratings yet

- Solar PV Modules Technical Specifications SheetDocument1 pageSolar PV Modules Technical Specifications SheetHannan AhmadNo ratings yet

- Grade 9 and 10 Exam Dmmhs With No AnswerDocument4 pagesGrade 9 and 10 Exam Dmmhs With No AnswerRonnel SingsonNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- Optimization of Logistics and Warehouse Operations Using Operations Research TechniquesDocument10 pagesOptimization of Logistics and Warehouse Operations Using Operations Research Techniquessahil singhNo ratings yet

- Practice 2.8 A: Sketch The Graph of Each Linear InequalityDocument4 pagesPractice 2.8 A: Sketch The Graph of Each Linear InequalityKadi SantanaNo ratings yet

- Delmar Unit 4 Magnetism Sept 2022Document51 pagesDelmar Unit 4 Magnetism Sept 2022Williams UgazNo ratings yet

- 5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilityDocument12 pages5 Optimising The Speed Potential of Curves - Increase in Permissible Cant Deficiency - FeasibilitydevidattairsmeNo ratings yet

- TM841S-L, TM861S-L: TO-220F 8A TriacDocument2 pagesTM841S-L, TM861S-L: TO-220F 8A TriacEulerMartinsDeMelloNo ratings yet

- Applied Thermodynamics by Onkar Singh.0003 14-16Document3 pagesApplied Thermodynamics by Onkar Singh.0003 14-16ZeenathulFaridaAbdulGaniNo ratings yet

- 3rd-grading-physics-2022-summative-quizDocument2 pages3rd-grading-physics-2022-summative-quizOdessa SantosNo ratings yet

- CE 352 - Groundwater HydrologyDocument59 pagesCE 352 - Groundwater HydrologyPamela MadeloNo ratings yet

- Mathematics of 3D PrintingDocument41 pagesMathematics of 3D PrintingHabtamu GeremewNo ratings yet

- Manual Testing - Common Interview QuestionsDocument31 pagesManual Testing - Common Interview QuestionsSravanthi AylaNo ratings yet

- Maxtor Hard DriveDocument64 pagesMaxtor Hard DriveKondwani AndreahNo ratings yet

- D77003 enDocument57 pagesD77003 enzliangNo ratings yet

- Chem 123 Problem Set 1Document4 pagesChem 123 Problem Set 1Stuart BrookesNo ratings yet

- Sharp Lc-32ad5e-Bk LCD TV SMDocument92 pagesSharp Lc-32ad5e-Bk LCD TV SMsabre504No ratings yet