Professional Documents

Culture Documents

Dev Low-Cost Arsenic DWFSOM94

Uploaded by

vaglohrdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dev Low-Cost Arsenic DWFSOM94

Uploaded by

vaglohrdCopyright:

Available Formats

PUBLISHED BY THE NATIONAL ENVIRONMENTAL SERVICES CENTER

Development of Low-Cost Treatment Options for

Arsenic Removal in Water Treatment Facilities

Summary

Illinois State Water Survey and University of Illinois researchers experimented with different combinations of chemical additives and steps along the treatment process. They found that the addition of

hydrogen peroxide combined with iron that was already present in the groundwater (approximately

2 milligrams per liter [mg/L]) to the Danvers water system produced a significant reduction in

arsenic (III) levels to below 3 micrograms per liter (ug/L). To accomplish this reduction, they added

as much as 30 micro molar (uM) hydrogen peroxide to the water treatment system before the water

was aerated. This procedure reduced arsenic (III) levels but did not decrease the dissolved arsenic

indicating that no arsenic was being absorbed to the iron or other oxidants. To correct this problem,

they implemented an additional experiment to determine if hydrogen peroxide combined with additional iron would provide active sites for the dissolved arsenic to combine with and, therefore, be

removed in the iron removal step. They found that the addition of iron (II) or iron (III) at a concentration of 5 to 6 mg/L along with the addition of hydrogen peroxide at a concentration of 20uM,

would indeed remove 83 to 97 percent of the dissolved arsenic.

Arsenic Found in Groundwater

The arsenic rule is one of the most controversial regulations in the history of the Safe

Drinking Water Act. Intended to protect

public health, focus has been on the rules

cost to implement rather than the beneficial

health effects the public would receive from

reduced exposure.

Arsenic is typically found in groundwater,

the source that many small communities

rely upon for their drinking water supplies.

Until recently, water systems had to comply

with a maximum contaminant level (MCL)

of 50 parts per billion (ppb). But the U.S.

Environmental Protection Agency did not

believe that level was low enough to protect

people from long-term, chronic exposure to

arsenic in drinking water, which can cause

serious dermatological conditions such as

blackfoot disease* and cancer of the skin,

bladder, lung, liver, and kidney, and other

ailments.

*Blackfoot disease is a severe form of peripheral vasculardisease in which the blood vessels in the lower limbs are severely

damaged, eventually resulting in progressive gangrene.

Download all of our

Tech Briefs at

Although arsenic composes only two parts per

million (ppm) of the Earths crust, there are

regions where higher concentrations occur in

the mineral strata. Groundwater in the deep

levels of such strata has been exposed to and

has absorbed arsenic over a greater period of

time and contains high levels. Shallow levels

of mineral strata contain groundwater that

has not had as long of a residence time and

as such has not absorbed as much and consequently contains less arsenic. Arsenic that

occurs in high levels in the U.S. is in the

Southwest and Northwest and other areas

that may be in close proximity to geothermal

activity. Other areas that may have higher

than average concentrations include parts of

Michigan, Illinois, and Minnesota.

What is the new level?

Because of public health concerns, EPA

researched what it believed to be a safer

arsenic consumption level. The agency set

the new MCL at 10 ppb.

www.nesc.wvu.edu/ndwc/ndwc_tb_available.htm

Unfortunately, drinking water from

many small water systems continues

to exceed this MCL. Problems arise

because many of these systems do

not have the funds to pay for additional treatment costs. Because of

this situation, the Midwest

Technology Assistance Center

(MTAC) for Small Public Water

Systems funded research to help

small communities meet the new

standard.

Free

Available

Residual

Team Researches Removal Method

A research team at the Illinois State Water

Survey and the University of Illinois

proposed to develop an inexpensive

treatment option for arsenic removal,

suitable particularly for small community water systems. The team came

up with some very interesting

results. By extending and optimizing

a reaction that already occurs during

iron removal at many drinking water treatment plants, they remarkably improved

arsenic removal, while increasing chemical

costs only slightly and requiring no large

capital equipment costs.

The premise of this project was that 1) the

iron already present in the water could be

used in conjunction with hydrogen peroxide

to produce a strong agent to oxidize arsenic

to a form that is easier to remove, and 2) that

by manipulating the chemistry, the process

could be optimized for arsenic removal.

The Fenton reaction, in which hydrogen peroxide and iron combine to form a strong oxi-

dizing agent called hydroxyl radical, was discovered by H.J.H. Fenton in 1894. This reaction occurs naturally during aeration

treatment of groundwater containing iron,

and forms hydrogen peroxide as an intermediate. Hydroxyl radical reacts quickly with

arsenic (III) changing it to arsenic (V), which is

much less toxic and adsorbs more completely

to iron as it precipitates during iron removal.

When the iron precipitate is removed by filtration, the arsenic is removed with it.

Many water systems already have such treatment procedures in place for iron removal

because of aesthetic issues such as taste and

laundry staining. Typically, systems that

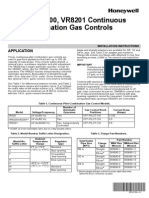

Figure 1

Aeration/Sand Filtration Unit,

Cation Exhange Softening,

and Chlorination

OF FOUR

a

PAGE

two

Tech Brief Development of Low-Cost Treatment Options for Arsenic Removal in Water Treatment Facilities, Fall 2006, Vol. 6, Issue 3

How does arsenic affect humans?

Arsenic exists in groundwater in two forms, arsenic (III) and arsenic (V). Studies have shown that the

toxicity of arsenic (III) is several times greater than arsenic (V). The bodys gastrointestinal tract will

absorb arsenic in either form. The arsenic enters the bloodstream and initially accumulates in the liver,

spleen, kidney, and gastrointestinal tract. Clearance or detoxification from these tissues is rapid via a

series of oxidative-reduction reactions that terminates in the arsenic being methylated or changed into

dimethylarsenoic acid. This methylation process is the bodys principal mechanism for detoxification.

The methylated arsenic form is less toxic and easily excreted via the kidneys as urine. Two to four

weeks following exposure any remaining arsenic found in the body is found in kinetin-rich tissues such

as the skin, hair, and nails.

Methylation efficiencies in humans appear to decrease at high doses of arsenic or if exposed to chronic

doses. The body has a limited capacity to detoxify a quantity of arsenic that enters the body. When the

body reaches that point arsenic is retained and is stored in soft tissues and in the cellular components

of those tissues. One of the most striking effects of this accumulation is the significant interference that

arsenic causes with enzyme reaction systems, especially with the cells energy production mechanisms

that occur in the mitochondria.

Cell respiration or the breakdown of cellular glucose to form carbon dioxide, water and adenosine triphosphate (ATP is a high energy producing compound) occurs in a cell component called the mitochondria. The process of respiration is performed by many enzymatic reactions and arsenic toxicity interferes with this process. Arsenic (III) has the propensity to bind to sulfur containing enzymes. In doing

so, the arsenic-sulfur binding site results in a structural deformation that incapacitates the enzyme. This

binding can occur with any number of enzymes along the pathway, which contain sulfur and once incapacitated, the pathway process will not go forward and high-energy compounds are no longer formed.

Arsenic (V) will substitute for phosphorus (P) ion in many biochemical reactions, especially in the formation of high- energy ATP. This results in a breakdown of high-energy compounds and an overall loss of cellular energy. This disruption of the high-energy pathways limits the availability of cellular energy. Without

the energy to allow the cell to perform its functions, the tissue composed of these cells slowly becomes

nonfunctional over time, resulting in the neurological and physiological impairments and disabilities attributed to arsenic poisoning.

have high concentrations of iron can remove

up to 25 percent of total arsenic during standard aeration processes. However, previous

research had shown that more of the

hydroxyl radical is produced using hydrogen

peroxide than with aeration alone, which

would be helpful to arsenic removal.

three

OF FOUR

NATIONAL ENVIRONMENTAL SERVICES CENTER

The researchers set up a pilot plant that

simulated the treatment plant at Danvers,

Illinois, to use as an example, because this

municipal system was already set up to

remove iron, and used water that was

expected to be difficult to treat, providing a

more difficult challenge for the treatment

process. Danvers is a small community of

about 1,100 people in central Illinois, near

Bloomington, that draws its raw water from

the Mahomet Aquifer.

PAGE

Hydrogen peroxide had been tried as a

treatment chemical prior to this study, but

usually at levels that were too high to be

cost-effective for a small system. This experiment showed, however, that the combination of low doses of hydrogen peroxide and

iron added to groundwater before it was

aerated was capable of oxidizing most of the

arsenic (III) in Danvers, Illinois, groundwater and reducing total arsenic from approximately 40 ppb to less than 5 ppb in batch,

laboratory flow, and pilot-scale flow experiments (compared to 30 ppb remaining after

normal iron removal) in groundwater with a

high level of dissolved organic carbon. The

estimated chemical costs for this treatment

totaled about 7 cents per one thousand gallons of treated water.

What they found in this study was that not

only was the iron/arsenic ratio critical to

arsenic removal, but the hydrogen peroxide

concentration was as well. In addition, the

researchers found that supplementing the

iron already in the water increased the

adsorption of arsenic to iron. They also

found that arsenic removal is more efficient

when hydrogen peroxide is added to the

anoxic groundwater. The researchers

wanted to be careful not to expose the water

to oxygen, because oxygen could use up the

dissolved iron before it could react with

hydrogen peroxide.

Figure 2 - Danvers Pilot Plant Diagram

a

Danvers Plant Experiment

The Danvers plant treatment train consists

of an aeration/sand filtration unit, cation

exchange softening, and chlorination. (See

Figure 1, page two.) During pilot experiments the researchers connected their pilot

plant directly to a sample tap at the wellhead, allowing them to add various doses of

hydrogen peroxide and iron to this sidestream of raw water in parallel with the

actual water treatment system. The connection consisted of a check valve and a gasliquid separator that physically divided it

from the water in the supply pipe.

OF FOUR

In their pilot plant, the researchers added iron

and hydrogen peroxide dosing solutions while

the water was still anoxic. (See Figure 2.)

Next, the water was pushed through a static

mixer and through a plug-flow reactor to give

the iron and peroxide time to react. The plugflow reactor provided a 1.5-minute reaction

time for the peroxide. Preliminary laboratory

experiments had indicated that the complete

reaction between hydrogen peroxide and iron

required less than 22 seconds.

PAGE

four

Following the plug-flow reactor, iron was

added before the water was introduced into

the bottom of the aeration basin, where it

would be completely aerated before flowing

to a bed of sand for filtration. The space

above the sand served as a flocculation

basin with a detention time of approximately

30 minutes. The finished water was collected

in a large basin, which was used for backwashing the sand filter between experiments.

For More Information

Development of Low-Cost Treatment Options

for Arsenic Removal in Water Treatment

Facilities by Gary R. Peyton, Thomas R.

Holm, and John Shim, June 2005, was

funded by the Midwest Technology

Assistance Center. The University of Illinois

at Urbana-Champaign and the Illinois State

Water Survey sponsored the report. Copies

of the final report are available by calling

(217) 333-9321.

MTAC provides technical assistance to small

public water systems as well as water systems serving Native American communities.

Their mission is to provide small system

administrators and operators with the information necessary to make informed decisions about planning, financing, and

selecting and implementing technological

solutions to address needs.

Midwest Technology Assistance Center

2204 Griffith Dr.

Champaign, Il 61820-7495

Phone: (217) 333-9321

Fax: (217) 244-3054

mtac.sws.uiuc.edu

If you would like to receive any or all of our free Tech

Briefs, send a request with your name, address, item

numbers, your phone number, and number of copies to

info@ mail.nesc.wvu.edu.

You also may call NESC at (800) 624-8301.

An Equal Opportunity/Affirmative Action Institution

Published by The National Environmental Services Center at West Virginia University, P.O. Box 6064, Morgantown, WV 26506-6064

Tech Brief Development of Low-Cost Treatment Options for Arsenic Removal in Water Treatment Facilities, Fall 2006, Vol. 6, Issue 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Enterprise Social Listening Platforms, Q1 2016Document16 pagesEnterprise Social Listening Platforms, Q1 2016DuDu Smile100% (1)

- Lustick Polity Taking Evol Seriously Pol201026a PDFDocument31 pagesLustick Polity Taking Evol Seriously Pol201026a PDFLuis Gonzalo Trigo SotoNo ratings yet

- 69-2480ef ADocument68 pages69-2480ef AvaglohrdNo ratings yet

- 68 0282Document12 pages68 0282vaglohrdNo ratings yet

- 69 1960Document4 pages69 1960vaglohrdNo ratings yet

- 69 2815efsDocument36 pages69 2815efsvaglohrdNo ratings yet

- HoneywellDocument24 pagesHoneywellmartinariel79750100% (1)

- W 50-1376 PDFDocument2 pagesW 50-1376 PDFvaglohrdNo ratings yet

- Product Guide and SpecificationsDocument2 pagesProduct Guide and SpecificationsvaglohrdNo ratings yet

- 50 1194Document8 pages50 1194vaglohrdNo ratings yet

- 69 0234Document12 pages69 0234vaglohrdNo ratings yet

- 50 9693Document2 pages50 9693vaglohrdNo ratings yet

- Modulo de EncendidoDocument24 pagesModulo de EncendidoIsrael Perales PalaciosNo ratings yet

- System Installation GuideDocument48 pagesSystem Installation GuidevaglohrdNo ratings yet

- 68 3088 01Document2 pages68 3088 01vaglohrdNo ratings yet

- Installation Guide: Non-Programmable Digital ThermostatDocument16 pagesInstallation Guide: Non-Programmable Digital ThermostatBojan BjelajacNo ratings yet

- Honeywell Gas Valve ReplacementDocument16 pagesHoneywell Gas Valve Replacementstamos990No ratings yet

- 69 2012Document20 pages69 2012vaglohrdNo ratings yet

- 69 1922esDocument16 pages69 1922esvaglohrdNo ratings yet

- Honeywell ST9120 Fan Control Board Installation PDFDocument12 pagesHoneywell ST9120 Fan Control Board Installation PDFbandihootNo ratings yet

- 68 0312Document140 pages68 0312vaglohrdNo ratings yet

- 03 00005Document3 pages03 00005vaglohrdNo ratings yet

- 69 2285Document64 pages69 2285vaglohrdNo ratings yet

- 50 1324Document8 pages50 1324vaglohrdNo ratings yet

- 68 3088 01Document2 pages68 3088 01vaglohrdNo ratings yet

- 69 2070 01Document16 pages69 2070 01vaglohrdNo ratings yet

- Honeywell 7b722Document24 pagesHoneywell 7b722Non AragonNo ratings yet

- 68 0311Document160 pages68 0311vaglohrdNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- STP at Karamsara Nala Malaj KhandDocument1 pageSTP at Karamsara Nala Malaj KhandDanish JavedNo ratings yet

- KWI Sea Water DesalinationDocument2 pagesKWI Sea Water DesalinationUmutNo ratings yet

- Industrial Water Treatment ProcessDocument28 pagesIndustrial Water Treatment Processlintang cahyaniNo ratings yet

- DR - Mohamed Rabee GhazyDocument6 pagesDR - Mohamed Rabee Ghazymoh_rabee27No ratings yet

- Water Treatment PlantDocument28 pagesWater Treatment PlantVuthpalachaitanya Krishna0% (1)

- Activated SludgeDocument26 pagesActivated SludgeNoshaba NoreenNo ratings yet

- Designing An Integrated Wastewater-Treatment SystemDocument6 pagesDesigning An Integrated Wastewater-Treatment SystemBramJanssen76No ratings yet

- Baffling Factor Manual Provides Disinfection Tank Design GuidanceDocument65 pagesBaffling Factor Manual Provides Disinfection Tank Design Guidance조기현No ratings yet

- Nkusip Package-Ii, Belgaum Gokak CMC - Sewerage and SanitationDocument4 pagesNkusip Package-Ii, Belgaum Gokak CMC - Sewerage and SanitationraajuannaNo ratings yet

- CV NirbhayDocument4 pagesCV NirbhayShiv GovindNo ratings yet

- Small Waste Water Treatment Plant ReportDocument57 pagesSmall Waste Water Treatment Plant Reportraviswm180100% (2)

- Draft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei DarussalamDocument13 pagesDraft Policy Recommendation On Domestic Was Tewater Management and Potential Project Prop Osal in Brunei DarussalamHaqeem HNo ratings yet

- Unit 1 (C.Shah)Document40 pagesUnit 1 (C.Shah)siddharthaNo ratings yet

- Bibliography of Categorized For Technical ContentDocument32 pagesBibliography of Categorized For Technical Contentdalton2003No ratings yet

- Ceramic Membranes. MBR. Likuid NanotekDocument4 pagesCeramic Membranes. MBR. Likuid NanotekAntonio SempereNo ratings yet

- Week 7-CHEM4015-CIVE4140-2023-2024Document21 pagesWeek 7-CHEM4015-CIVE4140-2023-2024Nitin RautNo ratings yet

- Thesesaastu 2019 175Document76 pagesThesesaastu 2019 175Zemenu PiltoNo ratings yet

- Hamann - Sewage Treatment Plants - HL Cont CompactDocument5 pagesHamann - Sewage Treatment Plants - HL Cont CompactAbrham B. GMNo ratings yet

- Wastewater ExamDocument9 pagesWastewater ExamSanti PoNo ratings yet

- Sedimentation in Water TreatmentDocument27 pagesSedimentation in Water TreatmentTruc Nguyen Lai ThanhNo ratings yet

- Listado de libros sobre desalación de aguasDocument5 pagesListado de libros sobre desalación de aguaseleuterio poncepancaNo ratings yet

- Nijhuis High Rate I-Daf: DAF Systems For Larger VolumesDocument4 pagesNijhuis High Rate I-Daf: DAF Systems For Larger VolumesSuresh DNo ratings yet

- MD Shahadat Hossan (Du) (3848)Document5 pagesMD Shahadat Hossan (Du) (3848)MD Shahadat HossanNo ratings yet

- Point of use and point of entry WaterPOD water treatment systems explainedDocument13 pagesPoint of use and point of entry WaterPOD water treatment systems explainedlouryNo ratings yet

- WWI 20091201 Dec 2009 PDFDocument44 pagesWWI 20091201 Dec 2009 PDFDavid FergusonNo ratings yet

- WWE Full-Time Ramchunder NevilDocument7 pagesWWE Full-Time Ramchunder NevilNevil NevNo ratings yet

- Comparison of Aerob N AnaerobDocument14 pagesComparison of Aerob N Anaerobyuki_akitsuNo ratings yet

- Concept of Settling PDFDocument25 pagesConcept of Settling PDFkasara sreetejNo ratings yet

- Method Statement: Chilled Water TreatmentDocument10 pagesMethod Statement: Chilled Water TreatmentNIDHILNo ratings yet

- The Effectiveness of Musa Acuminata Colla Banana Peels As Purifying Agents For WaterDocument19 pagesThe Effectiveness of Musa Acuminata Colla Banana Peels As Purifying Agents For WaterVanessa FloresNo ratings yet