APACT04, Bath

April 26-28, 2004

Model Predictive Control:

A Success Story Continues

Frank Allgwer *

Institute for Systems Theory in Engineering

University of Stuttgart

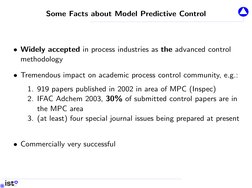

�Some Facts about Model Predictive Control

Widely accepted in process industries as the advanced control

methodology

Tremendous impact on academic process control community, e.g.:

1. 919 papers published in 2002 in area of MPC (Inspec)

2. IFAC Adchem 2003, 30% of submitted control papers are in

the MPC area

3. (at least) four special journal issues being prepared at present

Commercially very successful

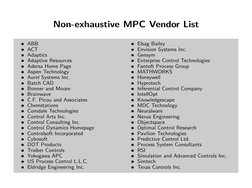

�Non-exhaustive MPC Vendor List

ABB

ACT

Adaptics

Adaptive Resources

Adersa Home Page

Aspen Technology

Aurel Systems Inc.

Batch CAD

Bonner and Moore

Brainwave

C.F. Picou and Associates

Chemstations

Comdale Technologies

Control Arts Inc.

Control Consulting Inc.

Control Dynamics Homepage

Controlsoft Incorporated

Cybosoft

DOT Products

Trieber Controls

Yokogawa APC

US Process Control L.L.C.

Eldridge Engineering Inc.

Elsag Bailey

Envision Systems Inc.

Gensym

Enterprise Control Technologies

Fantoft Process Group

MATHWORKS

Honeywell

Hyprotech

Inferential Control Company

IntellOpt

Knowledgescape

MDC Technology

Neuralware

Nexus Engineering

Objectspace

Optimal Control Research

Pavilion Technologies

Predictive Control Ltd.

Process System Consultants

RSI

Simulation and Advanced Controls Inc.

Simtech

Texas Controls Inc.

�Structure of Presentation

A short introduction to theory and practice of MPC

Linear vs. nonlinear MPC

Efficient nonlinear MPC formulation

Conclusion of presentation:

Nonlinear model predictive control of realistically sized chemical

processes possible, if

(i) state of the art NMPC formulations,

(ii) specialized NMPC optimizers

are used.

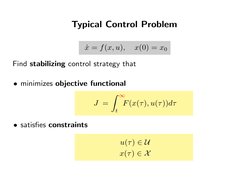

�Typical Control Problem

x = f (x, u),

x(0) = x0

Find stabilizing control strategy that

minimizes objective functional

Z

J =

F (x( ), u( ))d

t

satisfies constraints

u( ) U

x( ) X

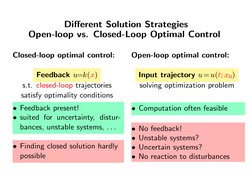

�Different Solution Strategies

Open-loop vs. Closed-Loop Optimal Control

Closed-loop optimal control:

Open-loop optimal control:

Feedback u=k(x)

s.t. closed-loop trajectories

satisfy optimality conditions

Feedback present!

suited for uncertainty, disturbances, unstable systems, . . .

Finding closed solution hardly

possible

Input trajectory u = u(t; x0)

solving optimization problem

Computation often feasible

No feedback!

Unstable systems?

Uncertain systems?

No reaction to disturbances

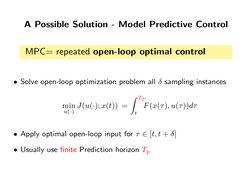

�A Possible Solution - Model Predictive Control

MPC= repeated open-loop optimal control

Solve open-loop optimization problem all sampling instances

min J(u(); x(t)) =

u()

TP

F (x( ), u( ))d

Apply optimal open-loop input for [t, t + ]

Usually use finite Prediction horizon Tp

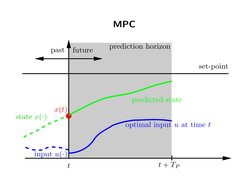

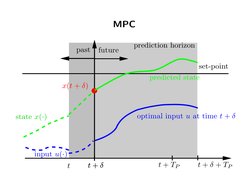

�MPC

past

future

prediction horizon

set-point

predicted state

x(t)

state x()

optimal input u at time t

input u()

t

t + TP

�MPC

past

future

prediction horizon

set-point

predicted state

x(t + )

optimal input u at time t +

state x()

input u()

t

t+

t + TP

t + + TP

�Characteristics of MPC

Moving horizon implementation

Performance oriented time domain formulation

Incorporation of constraints

Explicit system model used to predict future plant dynamics

�Linear MPC - Nonlinear MPC

Linear MPC

Uses linear model: x = Ax + Bu

Quadratic cost function F = xT Rx + uT Ru

Linear constraints Hx + Gu < 0

Quadratic program

Nonlinear MPC (NMPC)

Nonlinear model: x = f (x, u)

Cost function can be nonquadratic F (x, u)

Nonlinear constraints h(x, u) < 0

Nonlinear program

�A Brief History of MPC

Idea is rather old:

One technique for obtaining a feedback controller synthesis

from knowledge of open-loop controllers is to measure the

current control process state and then compute vary rapidly for

this the open-loop control function. The first portion of this

function is then used during a short time interval, after which

a new value of the function is computed for this measurement,

The process is then repeated.

(Lee & Marcus, 1967)

�A Brief History of MPC

cont.

Early industrial MPC applications:

Model Predictive Heuristic Control (IDCOM)

Richalet et al. 1976 . . .

Adersa

Dynamic Matrix Control (DMC)

Cutler & Ramaker 1979 . . .

Shell Oil

Academic research:

Few early theoretical investigations:

Kleinmann 1970, Thomas 1975, Chen & Shaw 1982, . . .

Predictive control theory:

Keerthi & Gilbert 1988, Mayne & Michalska 1990, . . .

�Linear MPC: Commercial Products

By now linear MPC is a fully established

advanced control method:

Already in 1995 over 2200 applications reported

First, mainly applications in refining/petrochemical sector

By now much broader scope

Large applications (603 x 283, DMC Corp.)

Significant benefits reported

Virtually all MPC applications up to mid 90s use

linear step or impulse response models

Models found by suitable identification

MPC Software often includes identification modules

Online computations require solution of QP

�Linear MPC Applications

Area

Refining

Petrochemicals

Chemicals

Pulp and Paper

Air and Gas

Utility

Mining/Metallurgy

Food Processing

Polymer

Furnaces

Aerospace/Defense

Automotive

Unclassified

Total

Aspen Honeywell Adersa PCL SGS Total

Tech

Hi-Spec

1200

480

280

25

1985

450

80

20

550

100

20

3

21

144

18

50

10

10

6

7

41

4

16

10

17

42

13

40

1833

40

696

UT/ TWMCC/AspenTech 1

1045

1438

3

7

26

125

450

450

68

10

14

37

51

17

45

13

7

1601

4542

S. Joe Qin and T. A. Badgwell

�Possible Benefits of NMPC

Improved controller performance due to the ability to use better

(=nonlinear) models

Enlargement of application field

regulation problems with

highly nonlinear processes

large disturbances

servo control problems with frequently changing operation

points

control of batch processes

...

�Application of NMPC to a Chemical Reactor

Cyclopentenol Production

V, A, Tf

Klatt/Engell/Kremling/Allgower 93

Van der Vusse reaction scheme:

A

2

1

B

C

VR

V, A, B, C, D

QK

3

2A

D

controlled variables:

manipulated variables:

disturbances:

concentration cB

flow rate V

feed temperature Tf , cA0

2

c A = V (cA0 cA) k1()cA k3()cA ,

c B = V cB + k1() cA k2()cB ,

1

= V (0 )

k1()cAHRAB + k2()cB HRBC

Cp

�

k w AR

2

+k3()cA HRAD +

(K )

CpVR

�

�

1

K =

QK + kw AR ( K )

mK CP K � �

Ei

ki() = ki0exp

, i = 1, 2, 3

�Operation at Point of Optimal Yield

1.1

2

Yield:

�

cBs ��

s =

cA �

0

at optimum:

�

=

u opt

Kopt

0

=0

y �

=

u opt

1

1.0

Ks

-1

0.9

5

10

15

us

gain changes sign at optimal operating point

strong nonlinearity

not integral controllable

20

25

30

35

�NMPC of the Chemical Reactor

V, A, Tf

Control task:

VR

V, A, B, C, D

rejection of disturbances in Tf , cA0

setpoint changes in cBs

input constraints in V

control tolerance 0.02 mol

l

QK

NMPC setup:

performance index: J =

R t+Tp

t

output feedback case (EKF)

(cB cBs)2dt

�Performance of NMPC-controller

1.2

Output

� mol �

cB

1.1

setpoint

1

0.9

30

Input

� 1 �

V h

20

10

0

0

x

scenario

500

1000

1500

Tf = 100o C

2000

Time[s]

2500

3000

3500

4000

Tf = 115o C

|

{z

}|

{z

}

model/plant mismatch

model/plant mismatch

case 1

case 2

�Control for Optimal Yield

task: on-line optimization of yield J =

1.3

Output

� mol �

cB

R t+Tp

t

c2B ( )d

1.2

1.1

1

0.9

40

30

Input

� 1 �

V h

20

10

0

0

x

cA0

h mol i

l

Tf [o C]

500

1000

1500

2000

2500

Time[s]

3000

3500

4000

4500

5.1

4.5

4.5

5.7

4.5

104.9

100

115

5000

�Comparison to Set-point Control

setpoint control

yield optimization

0.22

yield

0.21

0.2

0.19

production

rate

� mol �

V cB h

NT $

x.

h

i

cA0 mol

l

400

300

200

0

5.1

500

1000

1500

2000

Time[s]

2500

5.7

production rate doubled

3000

3500

4000

�Linear vs. Nonlinear MPC

Reasons for present dominance of LMPC:

Linear models can be straightforwardly identified from

process test data

Efficient implementation of LMPC possible

LMPC QP has to be solved

NMPC NLP has to be solved

Tuning for stability easy for LMPC

�Issues in Nonlinear MPC

System theoretic formulation and investigation:

stability, performance, robustness, ...

Implementation issues:

efficient and reliable real-time optimization, modeling, ...

�Efficient Numerical Solution of the Open-Loop

Optimal Control Problem

Typically solved by finite dimensional input parameterization

Can, for example be solved by: direct multiple shooting method

u

6

xu *i

xi

u

u

u

u

u

u

sN

sN1

x0 uu u u

t t1 t2

u

u

u-

tN1 tN

x0 uu us1 u

t t1 t 2

u

u

tN1 tN

Optimization problem shows special sparse structure

Consecutive optimization problems are similar

use efficient hot starting/embedding strategy

State of the art solution strategy, specially tailored to NMPC

allows real-time solution for realistically sized problems

(based on MUSCOD II, [Diehl et al.] )

�Approximate Solution: Real-time Iteration Scheme

Question:

Is it really necessary to solve optimal control problem exactly?

Often sufficient to perform only one SQP subiteration per sampling time if:

special update is used

close to optimal solution

Can be performed fast

Rigorous stability proof available

[Diehl/Findeisen/Allg

ower/Bock/Schl

oder 03]

Real-time iteration scheme

Expands range of applicability (faster systems, ...)

Utilizes inherent robustness of NMPC

�Issues in Nonlinear MPC

System theoretic formulation and investigation:

stability, performance, robustness, ...

Implementation issues:

efficient and reliable real-time optimization, modeling, ...

�An Important Issue in (N)MPC Theory

Even in nominal case:

no model plant mismatch

no disturbances

Predicted open-loop

trajectories

6=

Closed-loop trajectories

x(t) x(t + ) finite horizon

t + TP

t + + TP

�An Important Issue in (N)MPC Theory

x(t)

Even in nominal case:

no model plant mismatch

no disturbances

x(t + 2)

x(t + 3)

Predicted open-loop

trajectories

6=

Closed-loop trajectories

R

Performance? Goal: min 0 F (x( ), u( ))d . What is achieved

R t+Tp

by repeatedly minimizing t F (x( ), u( ))d ?

Stability? Why should the closed-loop be stable?

Schemes that guarantee stability?

�Dilemma of NMPC

Guaranteed Stability versus Performance

good performance

Large horizon

closed loop stability

computationally

not feasible

Need for short horizon formulations that achieves

good performance and stability

2 possible approaches:

choose Tp, F , . . . s.t. closed loop is stable

design NMPC scheme, s.t. closed loop is stable independent of

choice of Tp, . . . guaranteed stability NMPC scheme

�Zero Terminal Constraint NMPC

[Keerthi, Gilbert 88, Mayne, Michalska 90]

Simplest NMPC scheme with guaranteed stability

min J(x(t), u)

u

Z t+Tp

J()=

F (x( ), u( ))d

x(t)

subject to: x = f (x, u),

system dynamics

x(t) given

state feedback

u( ) U

input constraints

x( ) X

state constraints

x(t + Tp) = 0 zero terminal const.

+ stability

- feasibility, performance for short horizons?

- computationally not feasible

x(t + TP ) = 0

�NMPC Schemes with guaranteed stability

Avoid ZTC, instead use

terminal region constraint

virtual local control law inside of terminal region that allows

infinite prediction approximation via E(x(t + Tp))

min J(x(t), u)

u

Z

J()=

t+Tp

F (x( ), u( ))d+E(x(t + Tp))

x(t)

subject to: x = f (x, u),

system dynamics

x(t) given

state feedback

u( ) U

input constraints

x( ) X

state constraints

x(t + Tp) terminal constraint

x(t + TP )

E(t + TP )

Terminal penalty term E(x(t + Tp)) approximates

infinite horizon cost in terminal region

i.e. Quasi-infinite horizon NMPC [Chen, Allg

ower 1997]

�Guaranteed Stability

[Chen&Allg

ower 98], [Mayne et.al. 00], [Fontes 01]

min J(x(t), u)

u

Z

with: J()=

t+Tp

F (x( ), u( ))d +E(x(t + Tp))

and: x(t + Tp)

Nominal Stability: If

a) E() and s.t.:

x u U with

E

f (x, u) + F (x, u) < 0

x

b) optimization feasible for t = 0

R

x(t)

E(x(t + TP ))

Asymptotic Stability

Guaranteed Region of Attraction:

Set R of states satisfying b)

horizon performance approx. even for small TP

Advantages: guaranteed stability

�Comments

Many schemes fit into this setup:

Quasi-infinite horizon NMPC

Simulation-approximated infinite horizon NMPC

CLF approaches

[Jadbabaie et. al.

...

How to determine E, ?

[Chen&Allg

ower 97]

[De Nicolao et.al.97]

99, Primbs et.al. 00]

Exemplatory quasi-infinite horizon NMPC:

Jacobian linearization stabilizable

quadratic cost function

F (x, u) = xT( )Qx( ) + uT( )Ru( )

E(x) = xT P x

:= {x Rn|xT P x }

P is solution of Lyapunov equation

is solution semi-infinite optimization

�NMPC Theory in the 90s:

Instantaneous State Feedback NMPC

Assumptions:

On-line computation of optimal input trajectory u? requires

no computation time

(instantaneous solution)

Continuous application of

optimal input u = u?(x), i.e. 0

(instantaneous implementation)

predicted state

x(t + )

input u

x(t)

state x()

input u()

t+

Unrealistic assumptions, however

(i) allows to develop system theoretic understanding

(ii) lays basis for development of methodological tools

key focus on stability issue

t + TP t + TP +

�Sampled-Data Output Feedback NMPC: Wrap Up

Under certain conditions it is possible to extend the state feedback

stability results to the sampled-data output-feedback case

Problems:

When are the assumptions satisfied?

Value function uniformly continuous in R?

Separation requires fast enough error convergence of observer

I measurement noise?

Present results must be seen as a first step towards

a practical output feedback NMPC scheme

�Application of NMPC to a Distillation Column

Separation of liquid mixtures

into its components

xD

40

D

28

T28

F, XF

21

14

V

1

Q

xB

B

T14

�Application of NMPC to a Distillation Column

xD

40

D

28

T28

Objective: keep xD , xB at setpoints

inferential control: T14, T28 controlled variables

Disturbances: F , xF

Manipulated variables: L, V

F, XF

21

14

Sampling time = 30s

T14

V

1

Models of different sizes available:

5th, 42nd, 164th, 204th order

States estimated from T14, T28

Quadratic weights on deviation from set-points

xB

B

Methanol/n-Propanol

High purity separation

Performance?

Computational feasibility?

�Simulations: Performance + Computation

3

x 10

x28x28s

1

0

1

6

VVs [kmol/s]

x 10

2

1

0

CPU time [s]

164th order model

42nd order model

5th order model

0

0

500

1000

1500

2000

time [s]

2500

3000

3500

Feed concentration disturbances (+10, 15, +5 %)

Quasi-infinite horizon NMPC

Efficient dynamic optimization approach (multiple shooting, MUSCOD-II)

Only Simulations. How about real application?

�Pilot Plant for Experiments

Located at Institute for System Dynamics and Control, University of Stuttgart

�Experimental Results

NMPC

PI Controller

T28 [oC]

71

204th order model

70.5

2 PI control loops:

T14 L, T28 Q

70

Q [kW]

feed flow increase by

20% at t = 1000s

2.5

2

0

1000 2000 3000

time [s]

1000 2000 3000

time [s]

NMPC is computationally feasible and delivers good performance

�Conclusions

Gave a short introduction to NMPC

Linear MPC is a well established advanced control technology

Nonlinear MPC is generally seen to hold much promise

In the past decade a NMPC control theory was developed based

on instantaneous considerations

Current research focuses on extensions to realistic scenarios

output feedback

sampled-data implementation

robustness

computational issues

Showed experimental results that prove feasibility of methodology

for industrially sized problems

NMPC will have a significant impact in nonlinear

control applications over the next five years