Professional Documents

Culture Documents

Engine Coding: 1988 Mazda 626 1988 Mazda 626

Uploaded by

lopezdestructionOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Coding: 1988 Mazda 626 1988 Mazda 626

Uploaded by

lopezdestructionCopyright:

Available Formats

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

2.2L 4-CYL & 2.2L 4-CYL TURBO

1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

ENGINE CODING

ENGINE IDENTIFICATION

Engine can be identified by engine code number stamped on pad located in front of exhaust manifold.

ENGINE IDENTIFICATION CODES

Application

B2200, MX-6 & 626: 2.2L 4-Cylinder & 2.2L 4-Cylinder Turbo

Engine Code

F2

REMOVAL & INSTALLATION

ENGINE

Removal (B2200)

1. Remove hood. Drain engine oil and coolant. Disconnect negative battery cable. Remove air cleaner

assembly and dipstick. Disconnect all coolant hoses. Remove cooling fan, radiator shroud and radiator.

Disconnect accelerator and cruise control cables. Disconnect fuel hoses.

2. Disconnect all vacuum hoses and electrical connections. Remove 3-way solenoid valve, vacuum sensor

assembly, duty solenoid valve assembly and vacuum switch.

3. Remove secondary air pipe assembly. Disconnect exhaust pipe from manifold. Remove A/C compressor

and power steering pump with hoses attached.

4. Remove starter motor. Remove gusset plates near engine mounts. Remove rear cover. Support

transmission. Remove transmission-to-engine bolts and engine mount bolts. Remove engine.

Installation (All Models)

To install, reverse removal procedure. Adjust all control cables. Adjust all fluid levels.

Removal (MX-6 & 626)

CAUTION: Fuel pressure must be released prior to removing fuel lines.

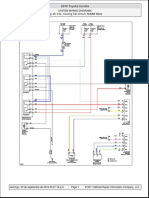

1. Engine and transaxle are removed as an assembly. Fuel pressure must be released. Start engine and

disconnect circuit opening relay. Relay is located near clutch pedal area. See Fig. 1. Operate engine until

it stalls. With ignition off, reinstall circuit opening relay.

domingo, 04 de octubre de 2015 10:10:31

10:10:00 a.m.

Page 1

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Fig. 1: Circuit Opening Relay Location

Courtesy of MAZDA MOTORS CORP.

2. Remove hood. Drain engine oil, transaxle fluid and coolant. Disconnect negative battery cable. Remove

battery and battery carrier. Remove air cleaner and intake hoses.

3. Disconnect all coolant, vacuum and fuel hoses, and electrical connections. Cover fuel lines with shop

towel prior to removal as lines may retain pressure. Remove all control cables. Remove radiator and

cooling fan. On turbo models, disconnect intercooler hoses.

4. Disconnect speedometer cable, clutch release cylinder and shift rods (M/T), or control cable (A/T) and

electrical connectors at transaxle. Remove A/C compressor and power steering pump with hoses attached.

5. Remove front wheels, splash shields and stabilizer bar. Remove drive axles. See appropriate article in

DRIVE AXLES section. Disconnect exhaust pipe from manifold. Remove engine and transaxle mounting

nuts. Remove engine and transaxle as an assembly.

Installation (All Models)

To install, reverse removal procedure. Adjust all control cables. Adjust all fluid levels.

CYLINDER HEAD & MANIFOLDS

Removal (B2200)

1. Disconnect negative battery cable. Drain cooling system. Rotate crankshaft and position No. 1 piston at

TDC of compression stroke. Remove air cleaner, cooling fan and radiator shroud. Disconnect accelerator

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 2

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

cable.

2. Disconnect fuel hoses and remove fuel pump (M/T). Disconnect all coolant, vacuum and fuel hoses, and

electrical connections. Remove 3-way solenoid valves and vacuum sensor assembly.

3. Remove duty solenoid valve assembly. Remove spark plug wires, spark plugs and distributor. Remove

secondary air pipe assembly. Remove intake manifold and carburetor as an assembly. Remove exhaust

manifold heat shield and manifold. Remove timing belt. See TIMING BELT.

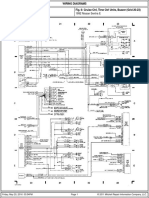

4. Remove valve cover and gasket. Gradually remove cylinder head bolts in proper sequence. See Fig. 2.

Remove cylinder head and gasket.

CAUTION: Cylinder head bolts must be loosened in proper sequence to prevent

cylinder head warpage or cracking.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 3

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 4

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Fig. 2: Cylinder Head Bolt Removal & Installation Sequence

Courtesy of MAZDA MOTORS CORP.

Inspection

Check cylinder head height and warpage. Resurface head if warpage exceeds specification. See CYLINDER

HEAD SPECIFICATIONS table. Replace cylinder head if not within specification after resurfacing.

CYLINDER HEAD SPECIFICATIONS

Application

Height

Maximum Grind Limit

Maximum Warpage

In. (mm)

3.620-3.624 (91.95-92.05)

.008 (.20)

.006 (.20)

Installation

1. Ensure proper gasket application. See Fig. 3. Install cylinder head. Apply oil to head bolt threads and

seating surface. Using proper sequence, tighten bolts to specification using 2 steps. See Fig. 2. See

TORQUE SPECIFICATIONS.

2. Apply silicone sealant to designated area prior to valve cover installation. See Fig. 4. Coat distributor "O"

ring with oil and install on distributor. Coat distributor blade or drive gear with oil prior to installation.

3. Install timing belt. To install remaining components, reverse removal procedure. Tighten bolts to

specification.

CYLINDER HEAD & MANIFOLDS

CAUTION: Fuel pressure must be released prior to removing fuel lines.

Removal (MX-6 & 626)

1. Engine and transaxle are removed as an assembly. Fuel pressure must be released. Start engine and

disconnect circuit opening relay. Relay is located near clutch pedal area. See Fig. 1. Operate engine until

it stalls. With ignition off, reinstall circuit opening relay.

2. Disconnect negative battery cable. Drain cooling system. Remove air intake pipe. Disconnect all lines for

turbo (if equipped). Disconnect all coolant, vacuum and fuel hoses, and electrical connections. Cover fuel

lines with shop towel prior to removal as lines may retain pressure. Remove all control cables at throttle

body.

3. Remove 3-way solenoid valves, EGR solenoid assembly and EGR pipe. Remove insulator from exhaust

manifold. Disconnect exhaust pipe at manifold. Remove exhaust manifold and turbo (if equipped).

Remove distributor. Remove rear housing.

4. Remove intake manifold. Remove timing belt. See TIMING BELT. Remove valve cover and gasket.

Gradually remove cylinder head bolts in proper sequence. See Fig. 2. Remove cylinder head and gasket.

CAUTION: Cylinder head bolts must be loosened in proper sequence to prevent

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 5

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

cylinder head warpage or cracking.

Inspection

Check cylinder head height and warpage. Resurface head if warpage exceeds specification. See CYLINDER

HEAD SPECIFICATIONS table. Replace cylinder head if not within specification after resurfacing.

CYLINDER HEAD SPECIFICATIONS

Application

Height

Maximum Grind Limit

Maximum Warpage

In. (mm)

3.620-3.624 (91.95-92.05)

.008 (.20)

.006 (.20)

Installation

1. Ensure proper gasket application. See Fig. 3. Install cylinder head. Apply oil to head bolt threads and

seating surface. Using proper sequence, tighten bolts to specification using 2 steps. See Fig. 2. See

TORQUE SPECIFICATIONS.

2. Apply silicone sealant to designated area prior to valve cover installation. See Fig. 4. Coat distributor "O"

ring with oil and install on distributor. Coat distributor blade or drive gear with oil prior to installation.

3. Install timing belt. To install remaining components, reverse removal procedure. Tighten bolts to

specification.

Fig. 3: Head Gasket Identification

Courtesy of MAZDA MOTORS CORP.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 6

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Fig. 4: Applying Valve Cover Sealant

Courtesy of MAZDA MOTORS CORP.

TIMING BELT

Removal

1. Disconnect negative battery cable. On B2200 models, drain cooling system. Radiator removal may be

required. Remove cooling fan and shroud. Remove distributor from front housing. Remove cooling fan

pulley and bracket. Remove secondary air pipe assembly.

2. On all models, remove all accessory drive belts. Remove crankshaft pulley. Remove timing belt covers.

Remove baffle plate located in front of crankshaft sprocket. Note direction of baffle plate installation.

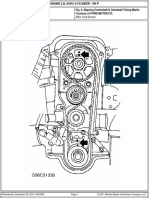

3. Rotate crankshaft to align crankshaft sprocket with timing mark. Ensure No. 1 mark on camshaft sprocket

is aligned with timing mark on front housing. See Fig. 5.

4. If timing belt is to be reused, place arrow on belt to indicate belt rotation. Remove tensioner lock bolt,

tensioner and spring. Remove timing belt.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 7

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Fig. 5: Aligning Timing Marks

Courtesy of MAZDA MOTORS CORP.

5. If camshaft sprocket requires removal, remove retaining bolt and remove sprocket. Remove crankshaft

sprocket if required.

Inspection

Inspect timing belt for wear on rounded edges of drive teeth. Inspect belt for signs of oil contamination. Replace

belt if damaged or contaminated. Inspect belt tensioner for smoothness or abnormal noise. Replace damaged

components.

Installation

1. Install sprockets with timing mark toward front of engine. Align camshaft and crankshaft sprocket timing

marks. See Fig. 5.

2. Install belt tensioner, lock bolt and tensioner spring. Position belt tensioner to limit of travel toward intake

manifold side and partially tighten lock bolt.

3. Install timing belt. If used belt is installed, ensure belt is installed in proper direction of rotation. Loosen

tensioner lock bolt to apply tension. Rotate crankshaft 2 revolutions in direction of rotation. Tighten

tensioner lock bolt. Ensure timing marks are properly aligned.

4. On MX-6 and 626 models, check for proper belt tension by measuring amount of deflection midway

between idler pulley and camshaft sprocket. Belt deflection should be .30-.33" (7.6-8.4 mm) when force

of 22 lbs. (10 kg) is applied. Repeat adjustment if deflection is not within specification.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 8

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

NOTE:

Belt deflection specification not available on B2200 models.

5. To install remaining components, reverse removal procedure. Ensure baffle plate is installed with flat side

against crankshaft sprocket. Reverse removal procedure to complete installation.

6. On B2200 models, ensure distributor housing and drive gear marks are aligned. Rotate crankshaft until

No. 1 piston is at TDC of compression stroke. Lubricate distributor gear with oil. Install distributor into

housing with marks facing upward.

CAMSHAFT & FRONT OIL SEAL

Removal

1. Remove timing belt and camshaft pulley. On B2200 models, remove fuel pump (M/T models), distributor

and front housing. On MX-6 and 626 models, remove distributor and rear housing.

2. On all models, check camshaft end play. Replace camshaft or cylinder head if not within specification.

See CAMSHAFT.

3. Remove rocker arm shaft assembly. See ROCKER ARM SHAFT ASSEMBLY. Remove camshaft. On

B2200 models, remove rear seal cap from cylinder head.

Inspection

1. Inspect camshaft lobes for scoring or wear. Measure camshaft bearing journals, runout and fuel pump

cam lobe height (B2200 models).

2. Measure camshaft bearing-to-journal oil clearance. Replace components if not within specification. See

CAMSHAFT SPECIFICATIONS table.

Installation

1. Apply engine oil to camshaft journals and bearings. Install camshaft with dowel pin facing upward.

Apply a thin coat of engine oil to camshaft oil seal and front housing. Press oil seal into housing.

2. Install new "O" ring on distributor. Coat "O" ring and distributor drive gear or blade with engine oil prior

to installation. On B2200 models, apply sealant to seal cap prior to installation.

3. On all models, to install remaining components, reverse removal procedure using new gaskets. Tighten

bolts to specification.

VALVE ARRANGEMENT

Intake Manifold Side: Intake Valves.

Exhaust Manifold Side: Exhaust Valves.

ROCKER ARM SHAFT ASSEMBLY

Removal

Remove valve cover and gasket. Loosen rocker arm bolts gradually in proper sequence. See Fig. 6. Remove

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 9

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

camshaft bearing cap bolts, rocker arms and rocker shafts as an assembly. DO NOT allow components to

separate during removal. Mark component location for reassembly reference.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 10

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 11

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Fig. 6: Rocker Arm Bolt Removal & Installation Sequence

Courtesy of MAZDA MOTORS CORP.

CAUTION: Rocker arm component location must be marked for reassembly

reference.

Disassembly & Inspection

Disassemble rocker arm and shaft assemblies. Mark components for location. Inspect rocker arm and shaft for

damage or flaking. Measure rocker arm I.D. and rocker arm shaft O.D. Determine oil clearance. Replace

components if not within specification. See ROCKER ARM & SHAFT SPECIFICATIONS table.

ROCKER ARM & SHAFT SPECIFICATIONS

Application

Rocker Arm Bore

B2200

All Others

Shaft Diameter

B2200

All Others

Rocker Arm-to-Shaft Clearance

In. (mm)

.6300-.6310 (16.000-16.027)

.748-.749 (19.00-19.03)

.6286-.6293 (15.966-15.984)

.746-.747 (18.95-18.97)

B2200 (1)

.0006-.0024 (.016-.061)

All Others (1)

(1) Maximum clearance is .004" (.10 mm)

.0008-.0029 (.020-.074)

Reassembly & Installation

1. If hydraulic lash adjuster was removed from rocker arm, fill reservoir of rocker arm with oil. Coat

hydraulic lash adjuster with oil and install in rocker arm. Reassemble rocker arms and shafts.

CAUTION: On B2200 models, intake rocker arm shaft is the long shaft. Ensure

oil holes in center bearing cap face each other. On all other models,

intake rocker arm shaft contains twice as many oil holes as exhaust

side. The stepped ends of shaft must be installed at rear of cylinder

head. Ensure No. 3 bearing cap contains oil passage from cylinder

head.

2. To install, reverse removal procedure. Prior to installing rocker shaft assembly, apply silicone sealant to

front and rear bearing cap-to-cylinder head contact areas.

3. On MX-6 and 626 models, ensure No. 3 bearing cap contains the oil passage from cylinder head. On all

models, tighten bolts to specification in 2 steps using proper sequence. See Fig. 6.

VALVE SERVICE

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 12

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Disassemble cylinder head. Measure valve stem diameter, valve margin and length. Replace valves not within

specification. See VALVES.

VALVE GUIDE INSPECTION

Inspection

Measure valve guide bore, height and valve stem clearance. Replace guide if not within specification. See

VALVE GUIDE SPECIFICATIONS table.

VALVE GUIDE SPECIFICATIONS

Application

Guide Bore

B2200

All Others

Guide Installed Height

B2200

All Others

Valve Stem-To-Guide Clearance

In. (mm)

.3177-.3185 (8.070-8.090)

.2760-.2768 (7.010-7.030)

.752-.772 (19.10-19.60)

.780-.799 (19.81-20.29)

Exhaust (1)

.0012-.0026 (.030-.066)

Intake (1)

(1) Maximum clearance is .008" (.20 mm).

.0010-.0024 (.025-.061)

VALVE GUIDE

Removal & Installation (B2200)

1. To remove valve guide, use Valve Guide Remover/Installer (49 0221 251A) and drive valve guide from

combustion chamber side of cylinder head. Note length of valve guides.

2. To install, install clip on valve guide. Using valve guide remover/installer, drive guide into head from

side opposite combustion chamber. Drive valve guide in until clip contacts cylinder head. Ensure stem-toguide clearance and installed height are within specification. See VALVE GUIDE SPECIFICATIONS

table.

NOTE:

Although design of intake and exhaust valve guides are different, use exhaust

valve guides on both sides for replacement.

VALVE GUIDE

Removal & Installation (MX-6, 626)

1. To remove valve guide, heat cylinder head to approximately 190F (90C). Using Valve Guide

Remover/Installer (49 0221 251A), drive valve guide from combustion chamber side of cylinder head.

Note length of valve guides.

domingo, 04 de octubre de 2015 10:10:01 a.m.

Page 13

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

2. To install, heat cylinder head to approximately 190F (90C). Using valve guide remover/installer, drive

guide into head from side opposite combustion chamber. Install guide to proper installed height. See

VALVE GUIDE SPECIFICATIONS table.

VALVE SEATS SERVICE

Inspection

1. Valve seat sinkage should be checked after valve and valve seat have been reconditioned and lightly

lapped. With valve installed, measure distance between end of valve stem and cylinder head.

2. Standard installed height is 1.831" (46.50 mm) for B2200 models and 1.976" (50.19 mm) for all others. If

installed height is within 1.831-1.850" (46.50-47.00 mm) for B2200 models and 1.976-2.008" (50.1951.00 mm) for all other models, valve can be used as is.

3. Spacer plate must be installed between spring seat and cylinder head to adjust if height is 1.8501.890" (47.00-48.00 mm) for B2200 models or 2.008-2.035" (51.00-51.70 mm) for all other models.

Replace cylinder head if height exceeds 1.890" (48.00 mm) for B2200 models or 2.035" (51.69 mm) for

all other models.

VALVE STEM OIL SEALS SERVICE

With valves removed, remove oil seals from cylinder head. Coat seals with oil. Using Valve Stem Oil Seal

Installer (49 G030 222) for B2200 models or (49 H012 009) for all other models, install valve stem oil seal.

VALVE SPRINGS SERVICE

Measure free length of valve springs. Replace springs if not within specification. See VALVE SPRING

SPECIFICATIONS table. Check valve spring for squareness. Replace spring if out-of-square

exceeds .06" (1.5 mm) for inner springs or .07" (1.8 mm) for outer spring on B2200 models or .067" (1.7 mm)

on all other models.

CAUTION: Large valve spring must be installed with closer pitch area toward cylinder

head.

VALVE CLEARANCE ADJUSTMENT

No adjustment is required. Preload of hydraulic lifter is automatically adjusted.

CYLINDER BLOCK ASSEMBLY SERVICE

Inspection

1. Inspect cylinder block for cracks, warpage, cylinder bore taper and out-of-round. Replace or repair

cylinder block if not within specification. See CYLINDER BLOCK SPECIFICATIONS table.

2. Measure cylinder bore and piston skirt diameter. Piston skirt diameter should be measured at 90 degree

angle to piston pin approximately .71" (18.0 mm) below oil ring groove. Clearance between piston and

cylinder bore must be within specification. See PISTONS, PINS & RINGS SPECIFICATIONS table.

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 14

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

CYLINDER BLOCK SPECIFICATIONS

Application

Bore Diameter: Standard

Grinding Limit

Maximum Warpage

In. (mm)

3.3859-3.3866 (86.000-86.019)

.008 (.20)

.006 (.15)

.0007 (.019)

Taper & Out-of-Round Limit (1)

(1) Specification not listed on B2200 models.

OVERHAUL

OIL PAN

Removal

1. Disconnect negative battery cable. Drain engine oil. On B2200 models, remove engine splash shield and

engine crossmember. Disconnect steering linkage at idler arm. Remove 2 gussets and flywheel inspection

cover.

2. On MX-6 and 626 models, remove front exhaust pipe. Remove clutch housing cover and gussets on M/T

models. Remove right sub-frame. On all models, remove oil pan. Oil strainer must be removed to remove

oil baffle plate.

Installation

1. On B2200 models, apply sealant on one side of baffle plate and on oil pan in rear seal case and oil pump

joining areas.

2. On MX-6 and 626 models, apply sealant on entire surface of oil baffle plate and oil pan. On all models,

install baffle plate and oil strainer. Install oil pan.

PISTON & ROD ASSEMBLY

Removal

1. Remove cylinder head. See CYLINDER HEAD. Remove oil pan. Ensure cylinder ridge is removed.

Mark connecting rod and cap for cylinder identification.

2. Note direction of "FRONT" mark on piston located near piston pin area. See Fig. 7. This mark is

positioned toward timing belt side of engine. Remove rod cap. Remove piston assembly.

Installation

1. Ensure piston ring end gap and side clearance are within specification. Install rings on piston with ring

code identification marks toward top of piston. Lubricate piston, rings and cylinder bore with engine oil.

2. Properly space ring end gaps on piston. See Fig. 7. Install piston and rod into cylinder bore. Ensure piston

is installed with "Front" mark toward timing belt side of engine. See Fig. 7.

3. Check bearing clearance using Plastigage method. Tighten rod cap nuts to specification. See TORQUE

SPECIFICATIONS. Ensure rod moves freely on crankshaft. Check connecting rod side play. Repair or

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 15

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

replace connecting rod if not within specification. See MAIN & ROD BEARINGS SPECIFICATIONS

table.

CAUTION: Piston and rod assembly must be installed with "Front" mark toward

timing belt side of engine.

Fig. 7: Piston & Ring Alignment

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 16

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Courtesy of MAZDA MOTORS CORP.

FITTING PISTONS

Measure cylinder bore and piston skirt diameter. Piston skirt diameter should be measured at 90 degree angle to

piston pin approximately .71" (18.0 mm) below oil ring groove. Clearance between piston and cylinder bore

must be within specification. See PISTONS, PINS & RINGS SPECIFICATIONS table.

PISTON PIN REPLACEMENT

Removal

Note connecting rod oil hole and "Front" mark on piston. See Fig. 7. Using press and Piston Pin

Remover/Installer (49 G030 042), remove pin.

Inspection

1. Inspect piston for cracks or damage in ring areas. Check ring side clearance. Replace piston if not within

specification. See PISTONS, PINS & RINGS SPECIFICATIONS table.

2. Check connecting rod for bend or twist and center-to-center length. Replace components if not within

specification See CONNECTING ROD SPECIFICATIONS table.

3. Measure piston pin outer diameter. Outer diameter should be .8651-.8654" (21.974-21.980 mm). Replace

if not within specification.

CONNECTING ROD SPECIFICATIONS

Application

Center-to-Center

Maximum Twist or Bend

In. (mm)

6.238-6.242 (158.45-158.55)

.0024 (.060)

Installation

1. Ensure connecting rod oil hole is opposite "F" mark on piston. See Fig. 7. Apply engine oil to piston pin

and to connecting rod bore.

2. Insert piston pin from piston side marked "F". Force required to install pin should be 1100-3300 lbs. (5001500 kg). Replace components if force required is not within specification. Ensure connecting moves

smoothly.

CRANKSHAFT & MAIN BEARINGS

Removal

1. Remove flywheel or drive plate. Remove rear seal case. Remove oil pump and oil pan. Ensure connecting

rods and main bearing cap are marked for location.

2. Remove connecting rod caps and bearings. Note direction of arrow on main bearing caps. Remove main

bearing caps. Ensure all components are placed in correct order. Remove crankshaft. Remove main

bearings from cylinder block. Mark bearings for location.

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 17

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Inspection

Inspect crankshaft for cracks, damaged gear or threads. Check crankshaft for runout, out-of-round and taper.

Replace or repair crankshaft if not within specification. See MAIN & ROD BEARINGS SPECIFICATIONS

table.

Installation

1. Install upper main bearings in cylinder block. Ensure oil hole is aligned and bearing is properly seated.

Lubricate bearings with engine oil.

2. Install crankshaft in block. Install main bearing caps in original location with arrow toward front of

engine.

CAUTION: Main bearing cap must be installed in original location with arrow

facing toward front of engine.

3. Check oil clearance using Plastigage method. Tighten bolts to specification. Remove main bearing cap.

Clearance must be within specification. If oil clearance exceeds specification, replace bearings or

crankshaft.

4. Ensure crankshaft rotates freely with main bearing caps installed. Check crankshaft end play. See

CRANKSHAFT END PLAY.

5. Install connecting rod caps and bearings. Ensure components are installed in original location. Tighten

rod nuts to specification. Ensure connecting rods move freely on crankshaft.

6. To install remaining components, reverse removal procedure. Clean sealant from flywheel or drive plate

bolts. Apply sealant on flywheel or drive plate bolts and install. Tighten bolts to specification.

CONNECTING ROD BEARINGS

Removal & Installation

1. Mark bearing cap and connecting rod for location. Remove connecting rod cap and bearing.

2. Install replacement bearing. Ensure reference marks on rod cap and connecting rod are aligned. Check

bearing clearance using Plastigage method. Tighten nuts to specification.

3. Ensure connecting rod moves freely on crankshaft. Check connecting rod side clearance. Clearance must

be within specification. See MAIN & ROD BEARINGS SPECIFICATIONS table.

CRANKSHAFT END PLAY

End play must be within specification. See MAIN & ROD BEARINGS SPECIFICATIONS table. If not

within specification, crankshaft must be ground and undersized main bearing installed.

REAR CRANKSHAFT OIL SEAL

Removal & Installation

1. Remove flywheel or drive plate. Remove rear oil seal case. Pry seal from seal case.

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 18

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

2. To install, coat seal lip with oil. Press seal in seal case. Install seal case and gasket. Trim gasket even with

oil pan mounting surface. Install flywheel or drive plate. Clean sealant from flywheel or drive plate bolts.

Apply sealant on flywheel or drive plate bolts and install. Tighten bolts to specification.

ENGINE OILING SYSTEM

Oil pressure is provided by a rotor-type pump driven by the timing belt. Pressure relief valve is located in the oil

pump body. Oil cooler, used on turbo models, is mounted between oil filter and cylinder block.

OIL PUMP & OIL SEAL

Removal

Disconnect negative battery cable. Drain engine oil. Remove timing belt and crankshaft sprocket. See TIMING

BELT. Remove oil pan, oil strainer and baffle plate. See OIL PAN. Remove oil pump.

Disassembly & Inspection

1. Disassemble pump. Note location of rotor alignment marks. With rotors in pump body, check clearance

between outer rotor and pump body. Place straightedge across pump body to check rotor side clearance.

2. Check clearance between straightedge and both rotors. Check clearance between tip of both rotors.

Replace gear set or pump assembly if not within specification. See OIL PUMP SPECIFICATIONS table.

Ensure relief valve slides freely in pump body bore. Inspect relief valve spring for damage.

OIL PUMP SPECIFICATIONS

Application

Outer Rotor-to-Pump Body

Standard

Maximum

Rotor Side Clearance

Standard

Maximum

Rotor Tip Clearance

Standard

Maximum

In. (mm)

.0035-.0069 (.090-.176)

.008 (.20)

.0012-.0035 (.030-.090)

.004 (.10)

.0017-.0033 (.044-.084)

.007 (.18)

Reassembly & Installation

1. Coat all components with oil. To reassemble, reverse disassembly procedure. Install rotors with alignment

marks aligned and positioned toward pump cover. Apply Loctite to oil pump cover bolts and tighten.

2. To install, reverse removal procedure. Apply a thin coat of grease to "O" ring and install on pump. Apply

engine oil to new oil seal and install. Apply sealant to pump sealing surfaces and install. Ensure sealant

does not enter oil passage.

OIL COOLER

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 19

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Removal & Installation

Drain cooling system. Disconnect hoses at oil cooler. Remove oil filter. Remove oil cooler retaining nut.

Remove oil cooler. To install, reverse removal procedure. Tighten nut to specification.

WATER PUMP

Removal

1. Disconnect negative battery cable. Rotate crankshaft so No. 1 piston is at TDC of compresssion stroke.

Drain coolant. On B2200 models, remove cooling fan, pulley and radiator shroud.

2. On all models, remove timing belt, idler pulley and belt tensioner. See TIMING BELT. On B2200

models, remove coolant inlet pipe and gasket. On all models, remove water pump, "O" ring and rubber

seals.

Installation

To install, reverse removal procedure using new "O" rings, rubber seals and gaskets. Coat "O" rings with

petroleum jelly prior to installation. Fill cooling system.

NOTE:

For further information on cooling systems, see appropriate article in the

ENGINE COOLING section.

ENGINE SPECIFICATIONS

CRANKCASE CAPACITY

Crankcase capacity is 4.9 qts. (4.6L) with filter replacement.

NORMAL OIL PRESSURE

Oil pressure should be 43-57 psi (3-4 kg/cm2 ) at 3000 RPM.

GENERAL ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

Application

B2200

Displacement

Cubic Inches

Liters

Fuel System

HP @ RPM

Torque Ft. @ RPM

Compression Ratio

domingo, 04 de octubre de 2015 10:10:02 a.m.

In. (mm)

133.2

2.2

2-Bbl

85 @ 4500

118 @ 2500

8.6:1

Page 20

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Bore

Stroke

MX-6 & 626 (Non-Turbo)

Displacement

Cubic Inches

Liters

Fuel System

HP @ RPM

Torque Ft. @ RPM

Compression Ratio

Bore

Stroke

MX-6 & 626 (Turbo)

Displacement

Cubic Inches

Liters

Fuel System

HP @ RPM

Torque Ft. @ RPM

Compression Ratio

Bore

Stroke

3.39 (86.1)

3.70 (94.0)

133.2

2.2

Fuel-Injection

110 @ 4700

130 @ 3000

8.6:1

3.39 (86.1)

3.70 (94.0)

133.2

2.2

Fuel-Injection

145 @ 4300

190 @ 3500

7.8:1

3.39 (86.1)

3.70 (94.0)

VALVE SPECIFICATIONS

VALVE SPECIFICATIONS

Application

In. (mm)

B2200 (1)

Intake

Head Diameter

Face Angle

Seat Angle

Seat Width

1.732 (43.99)

45

45

.047-.063 (1.19-1.60)

.3161-.3167 (8.030-8.045)

Stem Diameter (2)

Stem Clearance (3)

Valve Lift

Exhaust

Head Diameter

Face Angle

Seat Angle

Seat Width

domingo, 04 de octubre de 2015 10:10:02 a.m.

.0010-.0024 (.025-.060)

n/a

1.417 (35.99)

45

45

.047-.063 (1.19-1.60)

Page 21

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Stem Diameter (4)

.3159-.3165 (8.025-8.040)

Stem Clearance (3)

Valve Lift

.0012-.0026 (.030-.067)

n/a

(1) (5)

MX-6 & 626

Intake

Head Diameter

Face Angle

Seat Angle

Seat Width

Stem Diameter

1.276-1.283 (32.41-32.59)

45

45

.047-.063 (1.19-1.60)

.2744-.2750 (6.970-6.985)

.0010-.0024 (.025-.060)

Stem Clearance (3)

Valve Lift

Exhaust

Head Diameter

Face Angle

Seat Angle

Seat Width

Stem Diameter

n/a

1.335-1.343 (33.91-34.12)

45

45

.047-.063 (1.19-1.60)

.2742-.2748 (6.965-6.980)

.0012-.0026 (.030-.067)

Stem Clearance (3)

Valve Lift

(1) Minimum valve margin on intake valves is .02" (.5 mm) and .04" (1.0 mm) on exhaust valves.

(2) Minimum

diameter is .3142" (7.980 mm)

(3) Maximum

clearance is .008" (.20 mm).

(4) Minimum

diameter is .3140" (7.975 mm).

n/a

(5) Minimum

valve length is 4.534" for (115.16 mm) for intake valves and 4.555" (115.70 mm) for

exhaust valves.

PISTONS, PINS & RINGS SPECIFICATIONS

PISTONS, PINS & RINGS SPECIFICATIONS

Application

Pistons: Clearance

Pins

Piston Fit

In. (mm)

.0014-.0030 (.036-.075)

(1)

(2)

Rod Fit

Rings

Ring No. 1

End Gap

Press

.008-.014 (.20-.35)

.0012-.0028 (.030-.070)

Side Clearance (1)

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 22

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Ring No. 2

End Gap

Side Clearance

Oil Ring

.006-.012 (.15-.30)

.0012-.0028 (.030-.070)

End Gap (3) (4)

Side Clearance

(1) Maximum clearance is .006" (.15 mm).

(2) Interference fit

.012-.035 (.30-.89)

n/a

is .0005-.0015" (.013-.038 mm) on B2200 models and .0003-.0009" (.008-.023 mm)

on all others.

(3) On turbo models clearance is .008-.028" (.020-.071 mm).

(4) Wear

limit is .04" (1.0 mm).

MAIN & ROD BEARINGS SPECIFICATIONS

MAIN & ROD BEARINGS SPECIFICATIONS

Application

Main Bearings

In. (mm)

Journal Diameter (1)

2.3597-2.3604 (59.93659.956)

.0012-.0019 (.031-.049)

Clearance (2)

Thrust Bearing

No. 3

.0031-.0071 (.079-.180)

Crankshaft End Play (3)

Connecting Rod Bearings

Journal Diameter (1)

2.0056-2.0061 (50.94050.955)

.0010-.0026 (.027-.067)

Clearance (4)

.004-.010 (.10-.25)

Side Play (5)

(1) Maximum journal out-of-round and taper is .002" (.05 mm). Maximum crankshaft runout

is .0012" (.031 mm).

(2) On MX-6 and 626 models, all except No. 3 journal standard clearance is .0010-.0017" (.025-.043

mm). No. 3 standard clearance is .0012-.0019" (.031-.049 mm). Maximum clearance on all models

is .003" (.08 mm).

(3) Maximum end play is .012" (.30 mm).

(4) Wear

limit is .004" (.10 mm).

(5) Maximum

side play is .012" (.30 mm).

VALVE SPRING SPECIFICATIONS

VALVE SPRING SPECIFICATIONS

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 23

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Application

B2200

Inner

In. (mm)

Free Length (1)

Installed Height

Pressure: Lbs. @ In. (Kg @ mm)

Valve Closed

Valve Open

Outer

1.73 (44.0)

Free Length (2)

Installed Height

Pressure: Lbs. @ In. (Kg @ mm)

Valve Closed

Valve Open

MX-6 & 626

Intake

2.05 (52.0)

Free Length (3)

Installed Height

Pressure: Lbs. @ In. (Kg @ mm)

Valve Closed

Valve Open

Exhaust

1.95 (49.5)

Free Length (4)

Installed Height

Pressure: Lbs. @ In. (Kg @ mm)

Valve Closed

Valve Open

(1) Limit is 1.68" (42.7 mm).

1.98 (50.3)

(2) Limit is

1.98" (50.4 mm).

(3) Limit is

1.90" (48.3 mm).

(4) Limit is

1.94" (49.3 mm).

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

n/a

CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS (1) (2) (3)

Application

Front & Rear

In. (mm)

Journal Diameter (4)

domingo, 04 de octubre de 2015 10:10:02 a.m.

1.2575-1.2584 (31.94031.965)

Page 24

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Clearance (5)

Lobe Lift

Center

.0014-.0033 (.035-.085)

n/a

Journal Diameter (4)

1.2563-1.2573 (31.91031.935)

.0026-.0045 (.066-.115)

Clearance (2)

Lobe Lift

(1) Maximum camshaft runout is .0012" (.031 mm).

(2) Standard

n/a

end play is .003-.006" (.08-.15 mm) and limit is .008" (.20 mm).

(3) On

B2200 models, fuel pump lobe height is 1.478-1.482"(37.54-37.64 mm) with wear limit of

1.465" (37.21 mm).

(4) Maximum out-of-round is .002" (.05 mm).

(5) Maximum

oil clearance is .006" (.15 mm).

VALVE TIMING SPECIFICATIONS

VALVE TIMING SPECIFICATIONS

Application

B2200

Intake

Open (BTDC)

Close (ABDC)

Exhaust

Open (BBDC)

Close (ATDC)

MX-6 & 626

Intake

Open (BTDC)

Close (ABDC)

Exhaust

Open (BBDC)

Close (ATDC)

Specification

25

59

64

20

10

49

55

12

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

Application

Camshaft Pulley Bolt

Connecting Rod Cap Nut

Coolant Inlet Pipe Bolt

domingo, 04 de octubre de 2015 10:10:02 a.m.

Ft. Lbs. (N.m)

35-48 (47-65)

48-51 (65-69)

14-19 (19-26)

Page 25

2011 Mitchell Repair Information Company, LLC.

1988 Mazda 626

2.2L 4-CYL & 2.2L 4-CYL TURBO 1988 ENGINES Mazda - 2.2L & 2.2L Turbo 4-Cylinder

Cylinder Head Bolt (1)

Drive Plate Bolt (A/T)

End Plate Bolt

Exhaust Manifold Nut

Flywheel Bolt (M/T)

Front Housing Bolt

Fuel Pump Bolt

Intake Manifold Nut

Main Bearing Cap Bolt

Oil Cooler Nut

Oil Pump Bolt

M8

M10

Rear Housing Bolt

59-64 (80-87)

71-76 (96-103)

14-19 (19-26)

16-21 (22-29)

71-76 (96-103)

14-19 (19-26)

14-19 (19-26)

14-19 (19-26)

61-65 (83-88)

22-29 (30-39)

14-19 (19-26)

27-38 (37-52)

14-19 (19-26)

13-20 (18-27)

Rocker Arm Shaft Bolt (2)

Thermostat Cover Bolt

Timing Belt Crankshaft Bolt

Timing Belt Idler

Timing Belt Tensioner Bolt

Water Pump Bolt

14-22 (19-30)

116-123 (157-167)

27-38 (37-52)

28-38 (38-52)

14-19 (19-26)

INCH Lbs. (N.m)

109-152 (13-17)

69-104 (8-12)

61-104 (7-12)

69-104 (8-12)

61-87 (7-10)

Crankshaft Pulley Bolt

Oil Strainer Bolt

Oil Pan Bolt

Rear Seal Case Bolt

Timing Belt Cover

Valve Cover

B2200

All Others

(1) Tighten in sequence. See Fig. 2.

(2) Tighten

26-35 (3-4)

52-69 (6-8)

in sequence. See Fig. 6.

domingo, 04 de octubre de 2015 10:10:02 a.m.

Page 26

2011 Mitchell Repair Information Company, LLC.

You might also like

- s10 2.2l Engine PDFDocument25 pagess10 2.2l Engine PDFdedMazai100% (1)

- Engine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Document49 pagesEngine Identification: 1998-2000 ENGINES 3.0L V6 1998-2000 ENGINES 3.0L V6Rafael Enrique Grijalva GarciaNo ratings yet

- Motor KA24E PDFDocument32 pagesMotor KA24E PDFJose Pichinte100% (2)

- Ranger 2000-2001 4.0Document47 pagesRanger 2000-2001 4.0testNo ratings yet

- 4.2L Engine PDFDocument28 pages4.2L Engine PDFIvanov Hernandez Freire67% (3)

- 4.2L EngineDocument28 pages4.2L Engineadnmb100% (6)

- Engine Identification: Grand Vitara 6Document45 pagesEngine Identification: Grand Vitara 6David VásquezNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Engine Identification: Vitara 5Document35 pagesEngine Identification: Vitara 5Saulo RodriguesNo ratings yet

- 4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationDocument19 pages4.0L V8 - VINS (K, U) Selected Block: Removal & InstallationsixdownNo ratings yet

- 3.3L 6-Cyl VinDocument28 pages3.3L 6-Cyl VingypsyshortNo ratings yet

- 7.5L EngineDocument32 pages7.5L EngineSalvador Gasca100% (1)

- s10 2.2l EngineDocument25 pagess10 2.2l EngineRaul Ramirez100% (1)

- Cutlas Motor ReparaciónDocument24 pagesCutlas Motor ReparaciónfeaaNo ratings yet

- 1995 Toyota T100 DX 1 TON 2.7L 3RZ-FE PDFDocument60 pages1995 Toyota T100 DX 1 TON 2.7L 3RZ-FE PDFManuel TerrazaNo ratings yet

- Manual de Servicio Isuzu 2.2lDocument24 pagesManual de Servicio Isuzu 2.2lChino PlagaNo ratings yet

- ISACA Fact SheetDocument2 pagesISACA Fact SheetSilviaHerreraNo ratings yet

- 24L FourDocument28 pages24L FourIqbal NugrohoNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Ingles PDFtrastornadojhonNo ratings yet

- Focus RS Cylinder Head RemovalDocument20 pagesFocus RS Cylinder Head RemovalRobertSorokanich75% (4)

- MazdaDocument30 pagesMazdagerber damianNo ratings yet

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- Engine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Document19 pagesEngine - Repair - 1999-2000 Engine - Repair - AAA, AFP VR6Dany Pistiner100% (3)

- Subaru Ea81 GL 1983Document14 pagesSubaru Ea81 GL 1983David Emmanuel Turcios CarrilloNo ratings yet

- Engine IdentificationDocument47 pagesEngine Identificationgerber damianNo ratings yet

- Nissan Z24Document29 pagesNissan Z24Gustavo Gamez100% (2)

- Aba Aeg 2 0Document25 pagesAba Aeg 2 0Diego NunesNo ratings yet

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6Juan RiveraNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Toyota Tercel 3e 1991Document30 pagesToyota Tercel 3e 1991David Emmanuel Turcios Carrillo100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Manual de Motor Toyota Corolla 4a-Ec 1990Document30 pagesManual de Motor Toyota Corolla 4a-Ec 1990David Emmanuel Turcios CarrilloNo ratings yet

- Sampling, Testing and Tagging of Rebar Ir-17 PDFDocument3 pagesSampling, Testing and Tagging of Rebar Ir-17 PDFKidd Torno100% (1)

- PEB Specs Zamil SteelDocument12 pagesPEB Specs Zamil Steelkashyap_structuralNo ratings yet

- Standard ECDIS Requirements PDFDocument16 pagesStandard ECDIS Requirements PDFBright Okunkpolor100% (2)

- 2.0L ENGINE Chevy Tracker 1999Document52 pages2.0L ENGINE Chevy Tracker 1999andres german romeroNo ratings yet

- (PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 InglesDocument34 pages(PONTIAC) Manual de Taller Armado y Desarmado Motor Pontiac Aztek 2001 Inglesjorge Angel LopeNo ratings yet

- ISO 5660-1 Reaction To Fire TestDocument11 pagesISO 5660-1 Reaction To Fire TestBrian Luke100% (1)

- Siemens Simatic S 7 300 - 400 - System and Standard Functions For S7-300 and S7-400Document486 pagesSiemens Simatic S 7 300 - 400 - System and Standard Functions For S7-300 and S7-400duniaengineering8666100% (7)

- Engine IdentificationDocument30 pagesEngine Identificationgerber damianNo ratings yet

- Engine 1.6L (Steem G16) PDFDocument18 pagesEngine 1.6L (Steem G16) PDFAry Duran0% (1)

- Expo 2.4Document27 pagesExpo 2.4Percy RojasNo ratings yet

- Manual - de - Servicio - Isuzu - 2.2l (LUV) PDFDocument24 pagesManual - de - Servicio - Isuzu - 2.2l (LUV) PDFLuis ValenzNo ratings yet

- Toyota Nico PDFDocument33 pagesToyota Nico PDFDaniel GarciaNo ratings yet

- 1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesDocument24 pages1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesRubenNo ratings yet

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6pegoNo ratings yet

- Samuray 1994 1.3LDocument34 pagesSamuray 1994 1.3LjoseNo ratings yet

- Expo 1.8Document25 pagesExpo 1.8Percy RojasNo ratings yet

- Engine Identification: Cavalier & SunfireDocument33 pagesEngine Identification: Cavalier & SunfireMiguelNo ratings yet

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictor100% (1)

- VW 2.0L 4-cylinder engine guideDocument25 pagesVW 2.0L 4-cylinder engine guideVictorNo ratings yet

- Kia Sepia 1999-2000Document40 pagesKia Sepia 1999-2000El asesino MoustronNo ratings yet

- Motor Toyota Tercel 1983Document27 pagesMotor Toyota Tercel 1983denny_marvinNo ratings yet

- Engine IdentificationDocument54 pagesEngine IdentificationDEIDRE ANTONIETA BERNAL MORALESNo ratings yet

- Engine Identification: WarningDocument34 pagesEngine Identification: WarningLuis RodriguezNo ratings yet

- 1.6l 4 CylDocument29 pages1.6l 4 Cyl25912530100% (1)

- Contour 2.5Document63 pagesContour 2.5fausto gutierrezNo ratings yet

- Engine Overhaul 2.2LDocument29 pagesEngine Overhaul 2.2LalbertoNo ratings yet

- 2.0l 4 Cyl Nissan b13Document52 pages2.0l 4 Cyl Nissan b1325912530No ratings yet

- 2.4L 5-CYL VIN (55) : 1995 Volvo 850Document25 pages2.4L 5-CYL VIN (55) : 1995 Volvo 850apek1No ratings yet

- 10 Data-Tech 1995 Chevrolet S10 2.2L Vin 4 - Mecanica de MotorDocument25 pages10 Data-Tech 1995 Chevrolet S10 2.2L Vin 4 - Mecanica de MotorRubenNo ratings yet

- MX5 Mk1 Miata Eunos Cylinder Head RemovalDocument3 pagesMX5 Mk1 Miata Eunos Cylinder Head RemovalburgerbiterNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Printing From OnDemand5Document1 pagePrinting From OnDemand5lopezdestructionNo ratings yet

- Printing From OnDemand5Document1 pagePrinting From OnDemand5lopezdestructionNo ratings yet

- Engine Electrical Wiring Explorer 91Document1 pageEngine Electrical Wiring Explorer 91Adán Castro GallegosNo ratings yet

- Printing From OnDemand5Document1 pagePrinting From OnDemand5lopezdestructionNo ratings yet

- Printing From OnDemand52Document1 pagePrinting From OnDemand52lopezdestructionNo ratings yet

- 1992 Nissan Sentra E Wiring Diagram Cruise ControlDocument1 page1992 Nissan Sentra E Wiring Diagram Cruise ControllopezdestructionNo ratings yet

- ECCS Relay, Power SteerDocument1 pageECCS Relay, Power SteerlopezdestructionNo ratings yet

- 1992 Nissan Sentra E: Friday, May 20, 2016 03:47PM © 2011 Mitchell Repair Information Company, LLCDocument1 page1992 Nissan Sentra E: Friday, May 20, 2016 03:47PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- 2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutyDocument1 page2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutylopezdestructionNo ratings yet

- FusesDocument2 pagesFuseslopezdestructionNo ratings yet

- 2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutyDocument1 page2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super Dutylopezdestruction100% (1)

- 1992 Nissan Sentra E 1992 Nissan Sentra E: System Wiring Diagrams System Wiring DiagramsDocument1 page1992 Nissan Sentra E 1992 Nissan Sentra E: System Wiring Diagrams System Wiring DiagramslopezdestructionNo ratings yet

- 1992 Nissan Sentra E: Friday, May 20, 2016 03:52PM © 2011 Mitchell Repair Information Company, LLCDocument1 page1992 Nissan Sentra E: Friday, May 20, 2016 03:52PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- 1992 Nissan Sentra E: Friday, May 20, 2016 03:48PM © 2011 Mitchell Repair Information Company, LLCDocument1 page1992 Nissan Sentra E: Friday, May 20, 2016 03:48PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- 2Document85 pages2lopezdestruction100% (2)

- 2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutyDocument1 page2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutylopezdestructionNo ratings yet

- 1992 Nissan Sentra E: Friday, May 20, 2016 03:38PM © 2011 Mitchell Repair Information Company, LLCDocument1 page1992 Nissan Sentra E: Friday, May 20, 2016 03:38PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- 2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutyDocument1 page2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutylopezdestructionNo ratings yet

- 2001 Ford Escort: Wednesday, December 09, 2015 04:04PM © 2011 Mitchell Repair Information Company, LLCDocument1 page2001 Ford Escort: Wednesday, December 09, 2015 04:04PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- 2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutyDocument1 page2001 Ford Pickup F350 Super Duty 2001 Ford Pickup F350 Super DutylopezdestructionNo ratings yet

- CajaDocument33 pagesCajalopezdestructionNo ratings yet

- Visual Engine/Chassis Inspection: 2005 Ford Econoline E250 2005 Ford Econoline E250Document1 pageVisual Engine/Chassis Inspection: 2005 Ford Econoline E250 2005 Ford Econoline E250lopezdestructionNo ratings yet

- Tiempo Puesta A PuntoDocument2 pagesTiempo Puesta A PuntolopezdestructionNo ratings yet

- Engine Coding: 1988 Mazda 626 1988 Mazda 626Document26 pagesEngine Coding: 1988 Mazda 626 1988 Mazda 626lopezdestructionNo ratings yet

- 2001 Ford Escort: Wednesday, December 09, 2015 04:04PM © 2011 Mitchell Repair Information Company, LLCDocument1 page2001 Ford Escort: Wednesday, December 09, 2015 04:04PM © 2011 Mitchell Repair Information Company, LLClopezdestructionNo ratings yet

- E Specific Ac I OnesDocument25 pagesE Specific Ac I OneslopezdestructionNo ratings yet

- LandixDocument2 pagesLandixlopezdestructionNo ratings yet

- Printing From Undefined ..Document200 pagesPrinting From Undefined ..lopezdestructionNo ratings yet

- API Optic System 5 Wire With Onboard MonitorDocument1 pageAPI Optic System 5 Wire With Onboard MonitorlopezdestructionNo ratings yet

- Iaa 2010Document84 pagesIaa 2010KarlitosmanNo ratings yet

- Based On Author ForouzanDocument51 pagesBased On Author ForouzanBRAHMA REDDY AAKUMAIIANo ratings yet

- General Environmental Law KUWAITDocument9 pagesGeneral Environmental Law KUWAITFahadAlNo ratings yet

- Tolerances: Drawing Third Angle Projection REV MillimetersDocument12 pagesTolerances: Drawing Third Angle Projection REV MillimetersAaron JuarezNo ratings yet

- Argelith Lieferprogramm GBDocument24 pagesArgelith Lieferprogramm GBmutyokaNo ratings yet

- BSC6900V900R011 GO Data Configuration ISSUE1.0-20091130-BDocument61 pagesBSC6900V900R011 GO Data Configuration ISSUE1.0-20091130-BUsersNo ratings yet

- Installation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneDocument12 pagesInstallation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneFernando Gonzales HNo ratings yet

- As 1055.2-1997 Acoustics - Description and Measurement of Environmental Noise Application To Specific SituatiDocument7 pagesAs 1055.2-1997 Acoustics - Description and Measurement of Environmental Noise Application To Specific SituatiSAI Global - APACNo ratings yet

- Reliance: LED Taxiway Centerline, Lead-on/Exit, Apron Lead-In, L-852C (L), L-852D (L), L-852K (L)Document7 pagesReliance: LED Taxiway Centerline, Lead-on/Exit, Apron Lead-In, L-852C (L), L-852D (L), L-852K (L)giant360No ratings yet

- SAMM Policy 5, Measurement Uncertainty, Issue 2, 28 Feb 2007 (Amd. 2, 13 Feb 2019)Document9 pagesSAMM Policy 5, Measurement Uncertainty, Issue 2, 28 Feb 2007 (Amd. 2, 13 Feb 2019)Terrick TayNo ratings yet

- Release - Notes - Baseline - 2xxx - Plus Switch - v1.1.0.15 PDFDocument3 pagesRelease - Notes - Baseline - 2xxx - Plus Switch - v1.1.0.15 PDFSamir MussoiNo ratings yet

- Advanced Programming Chapter 5 Distributed Programming Using RMI and CORBADocument46 pagesAdvanced Programming Chapter 5 Distributed Programming Using RMI and CORBAkassahunNo ratings yet

- resume-Business-Presentation-Specialist-(Trainee)-BengaluruDocument1 pageresume-Business-Presentation-Specialist-(Trainee)-BengaluruDakshesh SoodNo ratings yet

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFDocument470 pagesPCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFKAREEM OLAWALE100% (1)

- Tangix TesterPRO Error 2017-11-09 131942Document100 pagesTangix TesterPRO Error 2017-11-09 131942VishNo ratings yet

- Java GuiDocument3 pagesJava GuiLouigene Tinao DonatoNo ratings yet

- (VESPA) Manual de Taller Vespa SDocument144 pages(VESPA) Manual de Taller Vespa SBairon PeñaNo ratings yet

- User Manual of Turbo HD DVRDocument328 pagesUser Manual of Turbo HD DVRAlexandruClaudiuDaniel0% (1)

- Lxmldoc-2 3Document439 pagesLxmldoc-2 3Angelo SilvaNo ratings yet

- Metodo 2 MESES DE NETFLIX WORDDocument12 pagesMetodo 2 MESES DE NETFLIX WORDwilson david ramos mamaniNo ratings yet

- 2553 CTSDocument1 page2553 CTSThe Rude1No ratings yet

- CLL f399 Imp EngDocument73 pagesCLL f399 Imp EngJesus CastroNo ratings yet

- Sugercane Grabber Loader OptDocument12 pagesSugercane Grabber Loader Optحمزة hamzaNo ratings yet

- Garlock Gasketing GYLON Catalog HS-1.0-GYL-35516 EN-EU LRDocument16 pagesGarlock Gasketing GYLON Catalog HS-1.0-GYL-35516 EN-EU LRMohammad FouladiNo ratings yet