Professional Documents

Culture Documents

Tundish Cover Ladle Nodularizing

Uploaded by

arnaldorcr8646Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tundish Cover Ladle Nodularizing

Uploaded by

arnaldorcr8646Copyright:

Available Formats

Technical Information 10

Tundish Cover Ladle Nodularizing

Magnesium treatment for nodularization of ductile iron can be made by several different

treatment processes. The tundish cover ladle process will under most conditions, be a

convenient, effective and reliable process with good economy. The process provides good

consistency and high recoveries of magnesium over a wide range of treatment sizes. A

well-operated system will give between 60 – 80 % recovery of magnesium while the opera-

ting and maintenance costs normally fall well below most other commercial processes.

Tundish ladle treatments also offer virtually no flare, about 90 % fume reduction, no metal

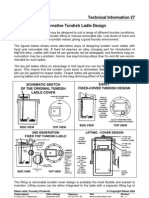

splashing and minimum carbon and temperature losses. The figure below shows an

example of a tundish cover ladle.

Figure 1: Schematic representation of a tundish

cover ladle with dual alloy pockets.

Calculation of Filling Hole Dimensions

The following formula can be used to calculate the diameter of the tundish lid filling hole:

W

d = 0.07

t ⋅h

where d is the filling hole diameter in centimetres (cm), W is the liquid iron batch weight in

grams (g), t is the pouring time in seconds (s), and h is the ferrostatic height of metal in the

tundish basin in centimetres (cm). Note: h is the height of metal, not the height of the basin

itself.

Base metal sulphur contents should preferably not exceed 0.02% before treatment to

ensure maximum efficiency of the tundish ladle. If sulphur levels are higher, a desulphuri-

zing step is recommended prior to nodularization.

Elkem ASA, Foundry Products © Copyright Elkem ASA

Postal address Office address Telephone Web Revision

P.O.Box 5211 Majorstuen Hoffsveien 65B +47 22 45 01 00 www.foundry.elkem.com No. 2.1

NO-0302 Oslo Oslo Telefax Org. no. 20.03.2004

Norway Norway +47 22 45 01 52 NO 911 382 008 MVA

Technical Information 10 2

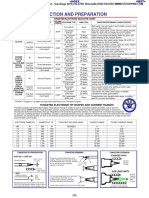

Magnesium Alloy Selection and Addition

The tundish cover process may be used with most magnesium ferrosilicon alloys contai-

ning between 3 to 12 % magnesium but generally alloys containing 4 – 6% Mg are used.

Typically an alloy with the composition given in the table would be Element Contents

used to treat base iron composed of a mixture of steel scrap, pig iron Si 45%

and returns. Alloy size grading of about 1 – 10 mm is most suitable Mg 6%

for small treatments while sizes up to 4 – 35 mm are preferable for

Ca 1%

larger treatments. See Elkem Technical Information Sheet No. 20 for

RE 1%

more details on selection of nodularizers in ductile iron.

Al max. 1%

The amount of alloy added usually lies between 1.2 and 1.8 weight % Fe Balance

depending on the base sulphur content, the metal temperature, the

magnesium content of the alloy and the consistency with which the

process is carried out.

Cover Material Selection

It is recommended to use a cover material over the magnesium alloy in the reaction

chamber in order to obtain maximum treatment economy. The cover should retain the alloy

in the chamber for as long as possible before the reaction starts. Covers commonly consist

of clean steel plate or clippings of a grade similar to that used in the melt charges. Cast

iron cover plates can be cast from the spare metal left at the end of a cast thus avoiding

the carbon dilution due to the steel cover. However, the best results are obtained using a

ferrosilicon alloy as a cover material.

Example of Recovery Improvements

Figure 2: Schematic representation of recovery improvements as a

function of sulphur content, treatment temperature, and ladle

design modifications. The initial case of 2.0 wt% addition rate

represents a situation with 0.03% S and 1520°C treatment

temperature.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Common Metallurgical Defects in Ductile Cast IronDocument10 pagesCommon Metallurgical Defects in Ductile Cast IronsateeshkoriNo ratings yet

- Elkem 19 Aluminum in Cast IronDocument2 pagesElkem 19 Aluminum in Cast Ironmarcotulio123No ratings yet

- Slag Defects in Grey IronDocument1 pageSlag Defects in Grey Ironarnaldorcr8646100% (1)

- Hydrogen PinholesDocument1 pageHydrogen Pinholesarnaldorcr8646No ratings yet

- Fading of Nodularity in Ductile IronDocument2 pagesFading of Nodularity in Ductile Ironarnaldorcr8646100% (4)

- ASTM B564 (2011) - Standard Specification For Nickel Alloy ForgingsDocument11 pagesASTM B564 (2011) - Standard Specification For Nickel Alloy Forgingsanoop100% (1)

- Determining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004Document8 pagesDetermining The Optimum Level of Inoculant Addition by Thermal Analysis - A Case Study, Ductile Iron News, Dec 2004arnaldorcr8646No ratings yet

- Heat Conservation in Liquid Iron, 2005-07-10Document5 pagesHeat Conservation in Liquid Iron, 2005-07-10arnaldorcr8646100% (1)

- Compacted Iron ElkemDocument20 pagesCompacted Iron ElkemAmol ThakurNo ratings yet

- Inoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesDocument12 pagesInoculation of Grey and Ductile Iron A Comparison of Nucleation Sites and Some Practical AdvisesZody YtuNo ratings yet

- Internal Shrinkage PorosityDocument1 pageInternal Shrinkage Porosityarnaldorcr8646100% (2)

- Nitrogen FissuresDocument1 pageNitrogen Fissuresarnaldorcr8646100% (1)

- Magnesium Slag Defects in Ductile IronDocument1 pageMagnesium Slag Defects in Ductile Ironarnaldorcr8646100% (1)

- Magnesium Versus Sulphur in Ductile IronDocument2 pagesMagnesium Versus Sulphur in Ductile Ironarnaldorcr8646100% (2)

- In The Mould Nodular Is IngDocument2 pagesIn The Mould Nodular Is Ingarnaldorcr8646No ratings yet

- Heat Conservation in Liquid IronDocument2 pagesHeat Conservation in Liquid Ironarnaldorcr8646No ratings yet

- Inoculation of Heavy Section CastingsDocument2 pagesInoculation of Heavy Section Castingsarnaldorcr8646100% (1)

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronDocument2 pagesPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646No ratings yet

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

- Poor Nodularity in Ductile IronDocument2 pagesPoor Nodularity in Ductile Ironarnaldorcr864675% (4)

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- Factors Influencing The Recovery and Addition of MagnesiumDocument4 pagesFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646No ratings yet

- Carbon Monoxide Blowholes in Grey IronDocument1 pageCarbon Monoxide Blowholes in Grey Ironarnaldorcr8646No ratings yet

- Late Metal Stream InoculationDocument2 pagesLate Metal Stream Inoculationarnaldorcr8646No ratings yet

- Selection of Inoculants For Grey Cast IronDocument2 pagesSelection of Inoculants For Grey Cast Ironarnaldorcr8646No ratings yet

- Alternative Tundish Ladle DesignDocument2 pagesAlternative Tundish Ladle Designarnaldorcr8646No ratings yet

- Recommended Target Analysis For Grey IronDocument2 pagesRecommended Target Analysis For Grey Ironarnaldorcr8646No ratings yet

- The "Sandwich Pocket Process"Document2 pagesThe "Sandwich Pocket Process"arnaldorcr8646No ratings yet

- Selection of Inoculants For Ductile Cast IronDocument1 pageSelection of Inoculants For Ductile Cast Ironarnaldorcr8646100% (1)

- Metal ExtractionDocument58 pagesMetal ExtractionVikasNo ratings yet

- File NameDocument25 pagesFile NameGagan VarshneyNo ratings yet

- Group 7 (Halogens) - Chlorine, Bromine, Iodine 2 QPDocument9 pagesGroup 7 (Halogens) - Chlorine, Bromine, Iodine 2 QPFahim Faisal ZishanNo ratings yet

- Hydrogen Greek: Z Sym ElementDocument10 pagesHydrogen Greek: Z Sym ElementJohnVictorCahatianNo ratings yet

- METREXDocument6 pagesMETREXalborz99No ratings yet

- Chemical Bonding Ans Key 01 To 14 1661942715773 1673836727008Document9 pagesChemical Bonding Ans Key 01 To 14 1661942715773 1673836727008STUDENT ARYANo ratings yet

- Electron Affinity: Atom MoleculeDocument3 pagesElectron Affinity: Atom MoleculeMj Sebastian GuadalupeNo ratings yet

- Study of Constituents of An AlloyDocument18 pagesStudy of Constituents of An AlloyMohammed Anis RahmanNo ratings yet

- June 2020 (9-1) (v1) QP - Paper 6 CIE Chemistry IGCSEDocument8 pagesJune 2020 (9-1) (v1) QP - Paper 6 CIE Chemistry IGCSENatalie RossetteNo ratings yet

- Lead NitrateDocument1 pageLead NitrateSophie100% (3)

- Mil HDBK 735Document508 pagesMil HDBK 735NicolasSuchNo ratings yet

- Tungsten Electrodes PDFDocument1 pageTungsten Electrodes PDFtyeuqmaiNo ratings yet

- Production Range of SJV Valve-2022Document1 pageProduction Range of SJV Valve-2022Vick YangNo ratings yet

- As 2503.1-2006 Refractories and Refractory Materials - Chemical Analysis Silica RefractoriesDocument7 pagesAs 2503.1-2006 Refractories and Refractory Materials - Chemical Analysis Silica RefractoriesSAI Global - APACNo ratings yet

- Minor09 QP DLP NEET2019 (Pmtcorner - In)Document33 pagesMinor09 QP DLP NEET2019 (Pmtcorner - In)jay danenjeyanNo ratings yet

- Pgms or Pges: Platinum Group Metals or Platinum Group ElementsDocument2 pagesPgms or Pges: Platinum Group Metals or Platinum Group Elementsrefpt007No ratings yet

- Chemistry Calculations Ws 2: Moles & MassDocument5 pagesChemistry Calculations Ws 2: Moles & Masspedrohmoreno2008No ratings yet

- Cytec Solutions 14 FinalDocument24 pagesCytec Solutions 14 FinalAnonymous KDM8wArgNo ratings yet

- Limiting Reactants RevisedDocument12 pagesLimiting Reactants Revisedmaryelle conejarNo ratings yet

- Group 2 Notes (Sem 2)Document7 pagesGroup 2 Notes (Sem 2)Geethanjali SivakumarNo ratings yet

- Chemistry Nat5 Specimen PaperDocument63 pagesChemistry Nat5 Specimen PaperHariNo ratings yet

- Unit 13 Metals and Reactivity: Summary QuestionsDocument2 pagesUnit 13 Metals and Reactivity: Summary QuestionsLei YinNo ratings yet

- Dogan HaleDocument1 pageDogan HaleMuzeul LampilorNo ratings yet

- Sai Study Centre: Amit TripathiDocument16 pagesSai Study Centre: Amit Tripathiphineasferb000% (1)

- Latihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofDocument5 pagesLatihan Menjawab Kertas 3 1 A Student Carried Out An Experiment To Determine The Empirical Formula ofMasitah Abu BakarNo ratings yet

- Potassium Nitrate Without Anticaking (BP, Ph. Eur.) Pure, Pharma GradeDocument1 pagePotassium Nitrate Without Anticaking (BP, Ph. Eur.) Pure, Pharma GradeMiguel CruzNo ratings yet

- Qualitative Analysis of A Single Solid Organic CompoundDocument9 pagesQualitative Analysis of A Single Solid Organic CompoundPranabes BhattacharyyaNo ratings yet

- Sulphuric AcidDocument12 pagesSulphuric AcidHarveyKhooNo ratings yet

- Chapter - 3: Metals and Non MetalsDocument23 pagesChapter - 3: Metals and Non Metalsuma mishraNo ratings yet