Professional Documents

Culture Documents

IM784REV09

Uploaded by

Mackinder LijarzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IM784REV09

Uploaded by

Mackinder LijarzaCopyright:

Available Formats

OPERATION, SERVICE AND PARTS

INSTRUCTION MANUAL

755

HYDRAULIC HAND PUMP

Read and understand this material before

operating or servicing this equipment. Failure

to understand how to safely operate this tool

could result in an accident causing serious

injury or death. This device should only be

operated by qualified personnel.

999 5632.2

1997 Greenlee Textron Inc.

IM 784 REV 9 5/97

755 Hydraulic Hand Pump

Description

The 755 Hydraulic Hand Pump develops 10,000 psi (68,950 kPa) and is intended to be used with the following Greenlee conduit benders, tubing bender,

and punch driver.

Conduit Benders:

model 777

Punch Driver:

model 1732

model 880

Tubing Bender:

model 782

model 882

model 882CB

Fill with Greenlee hydraulic oil or Mobil DTE-13 only.

Purpose of this Manual

This instruction manual is intended to familiarize operators and maintenance

personnel with the 755 Hydraulic Hand Pump. This manual should be kept

available to the operating and maintenance personnel.

SAFETY

ALERT

SYMBOL

The symbol above is used to call your attention

to instructions concerning your personal safety.

Watch for this symbol. It points out important safety

precautions. It means ATTENTION! Become alert!

Your personal safety is involved! Read the

message that follows and be alert to the possibility

of personal injury or death.

Immediate hazards which WILL, if not avoided, result in

severe personal injury or death.

Hazards or unsafe practices which COULD, if not avoided,

result in severe personal injury or death.

Hazards or unsafe practices which COULD, if not avoided,

result in minor personal injury or property damage.

Safety is a critical factor in the design of Greenlee equipment. The best program starts with a safety-conscious

operator. The information highlighted in this bulletin describes operating practices for the benefit of the workers

who will use our equipment in their daily jobs. Comments from users are appreciated.

A person who has not read and does not understand all

operating instructions is not qualified to operate this tool.

Failure to read and understand safety instructions may

result in injury or death.

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

IMPORTANT SAFETY INSTRUCTIONS

Electric shock hazard:

Inspect pump, hoses and couplers. Replace any

worn, damaged or missing components with

Greenlee replacement parts.

This is not an insulated tool.

Contact with live circuits can result

in severe injury or death.

Wear eye protection when using

this pump.

Skin injection hazard:

Oil under pressure easily punctures

skin causing serious injury, gangrene

or death. If you are injured by

escaping oil, seek medical attention

immediately.

Follow the operating instructions and safety

information supplied with the hydraulic ram or

accessory.

Hand-tighten all couplers

completely before operating the

pump. Do not use tools to tighten

the couplers.

Failure to observe this warning could result in

severe injury or death.

Do not use fingers or hands to

check for leaks while operating

the pump.

Do not hold hose or couplers

while operating the pump.

Use this tool for the manufacturers intended

use only.

Release the hydraulic pressure

before disconnecting hoses or

couplers, and before servicing

the pump or accessory.

Work in areas that are well-lit, uncluttered

and dry.

SAVE THESE INSTRUCTIONS

Additional copies of this manual are available upon request at no charge.

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Operation

Filling the Pump with Oil

1. Remove the dust cap.

1. Clamp the pump into a vise with the end cap (1)

upward. Loosen the set screw (26) and remove the

end cap.

2. Connect the hose to the bender or punch unit.

Note:

Hand-tighten the couplers completely.

Do not use tools.

2. Remove the cap screw (31) with O-ring (18) from

the reservoir follower (3). Remove the follower from

the reservoir. Inspect both V-packings (28); replace

them if they are worn or damaged.

3. Twist the release knob (7) clockwise until it stops.

4. Pump the handle (9) until the bend or punch is

complete.

3. Pour Greenlee hydraulic oil* into the reservoir until it

is within 1-3/4" from the top.

5. Twist the release knob (7) counterclockwise to

release the hydraulic pressure.

4. Reinstall the reservoir follower.

6. Disconnect the hose from the bender or punch unit.

Replace all dust caps.

5. Turn the release knob (7) counterclockwise so the

valve is open. Pump the handle (9) two or three

times.

6. Turn the release knob (7) clockwise so the valve is

closed. Pump the handle (9) two or three times.

7. Slowly turn the release knob (7) to counterclockwise. This will allow any air trapped in the pump

block (10) or reservoir (8) to escape.

Note: Do this slowly to prevent the oil from suddenly

gushing up through the cap screw hole.

8. Repeat steps 5 through 7 one or two more times.

9. Inspect the O-ring (18) in the cap screw (31);

replace O-ring if it is worn or damaged.

10. Replace the cap screw (31) with O-ring (18) in the

follower (3). Hand-tighten the cap screw.

11. Wipe any excess oil from the outside of the reservoir and replace the end cap (1). Tighten the set

screw (26).

*

Greenlee Textron Inc. / Subsidiary of Textron Inc.

Order Greenlee hydraulic oil by the gallon

(part number 905 1059.3) or by the quart

(part number 905 0806.8).

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Troubleshooting

PROBLEM

Oil leak at coupler.

PROBABLE CAUSE

POSSIBLE REMEDY

Fitting loose or damaged.

Tighten or replace fitting and/or coupler.

O-ring is worn or damaged.

Replace O-ring.

Pump builds pressure, but ram

does not advance, or ram will

not return.

Coupler is not tightened sufficiently,

and check balls are not engaged.

Hand-tighten coupler completely so

check balls engage. Replace coupler

if necessary.

Oil leak at OPEN/CLOSE

release knob.

O-ring and/or backup ring is worn

or damaged.

Replace O-ring (18) and/or backup

ring (17).

Release shaft is bent.

Replace release shaft knob unit (7).

O-ring, backup ring and/or washer

are worn or damaged.

Replace O-ring (29), backup ring (15),

and washer (16).

Injector packing nut is worn.

Replace injector packing nut (6).

V-packing seal is worn or damaged.

Replace two V-packing seals (28).

Cylinder wall damaged.

Replace reservoir tube (8).

Cant hold load or excessive

pumping is required.

Ball in release knob leaking.

Discharge ball (20) or intake ball (22)

below discharge ball (20) is leaking.

Check seat for scratches or contamination. Reseat ball or return to

an authorized Greenlee service center

for repair.

Cant raise load with excessive

pumping but handle is rigid.

Intake ball (22) below discharge ball (20)

is leaking.

Check seat for scratches or contamination. Reseat ball or return to

an authorized Greenlee service center

for repair.

Load on system causes handle

to lift.

Discharge ball (20) is leaking.

Check seat for scratches or contamination. Reseat ball or return to

an authorized Greenlee service center

for repair.

Oil leak at plunger.

(Attached to handle.)

Oil leak at reservoir end.

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

25.60

20.22

7.18

5.62

10

11

19

SERIAL NUMBER LOCATION

(4) 5/16" HOLD DOWN BOLT HOLES

16.50

21

2.93

3.75

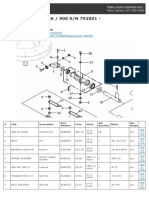

Exploded View

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Exploded View (contd)

4

12

18

33 13

31

6

15

29

16

20

22

22

25 32

3 28

26

27 14

SECTION A-A

24

18

17

30

7

34

23

SECTION B-B

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Pump Block Seat

.332 (Q) DRILL

1/4 REAM

9/32 BALL SEAT

(11/64) REAM

0.238 (B) DRILL

7/32 BALL SEAT

.256 (F) DRILL

(NOTE DRILL ANGLE)

7/32 BALL SEAT

9/64 DRILL

5/32 REAM

Greenlee Textron Inc. / Subsidiary of Textron Inc.

15

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

755 Hydraulic Hand Pump

Parts List

KEY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

37

UPC NO.

78-3310- PART NO.

DESCRIPTION

QTY.

501 5721.3

Cap, End ........................................................................ 1

501 5724.8

Lever, Injector ................................................................ 1

501 1716.5

Reservoir Follower (Replaces 501 5814.7) ................... 1

501 5725.6

Plunger ........................................................................... 1

501 5726.4

Link, Lever ...................................................................... 1

501 5727.2

Nut, Injector Packing ...................................................... 1

501 8182.3

Release Unit (Includes Key Nos. 17, 18 and 22) ........... 1

(Replaces 501 5728.0 and 501 6773.6 Units)

500 3467.7

Reservoir Tube (Replaces 501 5730.2) ......................... 1

501 5731.0

Handle ............................................................................ 1

501 5732.9

Block Weldment, Pump .................................................. 1

501 5735.3

Pin, Fulcrum ................................................................... 2

500 3177.5

Washer, Sealing ............................................................. 1

500 6111.9

Spring, Compression ...................................................... 1

500 3422.7

Filter, Felt ....................................................................... 1

905 1455.6

Ring, 9/16 x 3/4 Single Turn Scarf-Cut Back-Up ........... 1

(Replaces 905 1173.5)

501 5736.1

Washer, Sealing ............................................................. 1

905 3853.6

Ring, 1/4 x 3/8 Teflon Spiral Back-Up ............................ 1

905 0418.6

O-Ring, 1/4 x 3/8 x 1/16 ................................................. 2

905 0434.8

Ring, Retaining ............................................................... 4

905 0436.4

Ball, 9/32 dia. Grade #1 Chrome Steel .......................... 1

905 1174. 3 Grip, 1-1/16 ID x 1-3/8 OD x 5" Long Plastic ................. 1

905 0452.6

Ball, 7/32 Dia. Grade #1 Chrome Steel ......................... 2

905 0385.6

O-Ring, 2-1/8 x 2-3/8 x 1/8 (Replaces 905 4770.5*) ..... 1

905 0449.6

Pin, 5/16 x 1-1/4 ............................................................. 1

905 0619.7

Screw, 5/16-18 NC x 1/4 Flat Point Socket Set ............. 1

905 0617.0

Screw, 1/4-20 NC x 1/4 Flat Point Screw Socket Set .... 1

905 0744.4

Ring, Retaining ............................................................... 1

905 0745.2

V-Packing, 2-1/4 OD x 1-7/8 ID x 3/16 .......................... 2

905 0782.7

O-Ring, 9/16 x 3/4 x 3/32 (Replaces 905 4771.3*) ........ 1

905 0807.6

Quick-Coupler, 3/8 NPTF ............................................... 1

905 0558.1

Screw, 5/16-18 NC x 1/2 Fillister Head Cap .................. 1

905 0885.8

Pin, 1/4 x 3/8 Spiral ........................................................ 1

905 1450.5

Screw, 3/8-24 NF x 1/2 Skt. Hd. Cap ............................. 1

(Replaces 905 0904.8)

905 1137.9

Elbow, 3/8-18 NPTF x 90 Street ................................... 1

905 0441.0

Oil, Greenlee Hydraulic ............................................... 1 Qt.

502 0450.5

Decal, Product/Safety/Caution ....................................... 1

501 8272.2

Optional Parts

Kit, Packing Repair

*Fluorocarbon O-rings used at factory as part of production process.

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

Greenlee Textron Inc. / Subsidiary of Textron Inc.

4455 Boeing Drive, Rockford, IL 61109-2988 USA

General Offices: 815/397-7070

Customer Center and Field Service: 800/435-0786

Fax (24 Hour) Customer Center: 800/451-2632 815/397-1865

Canada Fax (24 Hour) Customer Center: 800/524-2853

Printed in the U.S.A.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Young Dong Railroad Tunnel (Korea) Ventilation and Risk ControlDocument1 pageYoung Dong Railroad Tunnel (Korea) Ventilation and Risk ControlMackinder LijarzaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ventilation of Railway Tunnels: Typical Metro StationDocument1 pageVentilation of Railway Tunnels: Typical Metro StationMackinder LijarzaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Annual Book of ASTM Standards: La Siguiente Información Hay Que Tener en Cuenta A La Hora de Diseñar Una EstructuraDocument1 pageAnnual Book of ASTM Standards: La Siguiente Información Hay Que Tener en Cuenta A La Hora de Diseñar Una EstructuraMackinder LijarzaNo ratings yet

- Part 7 Guide To ColorsDocument1 pagePart 7 Guide To ColorsMackinder LijarzaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 5990-8685en Appnote 4100mp-Aes FoodsDocument6 pages5990-8685en Appnote 4100mp-Aes FoodsMackinder LijarzaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- U90M Guide To ColorsDocument1 pageU90M Guide To ColorsMackinder LijarzaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- U90M Notice 1Document1 pageU90M Notice 1Mackinder LijarzaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ford Focus PCMDocument58 pagesFord Focus PCMEl OhmimetroNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Omm 1106eDocument84 pagesOmm 1106eDedy setiawanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 543Q-7 Parts List (2) Bomba Quintuplex (TWM)Document121 pages543Q-7 Parts List (2) Bomba Quintuplex (TWM)JOHNME8205No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Synchronous Non Excited Reluctance MotorDocument14 pagesSynchronous Non Excited Reluctance Motorcamming soonNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Active Suspension SeminarDocument12 pagesActive Suspension Seminarmujeeb0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 4X4 RangeDocument2 pages4X4 RangeAmit YadavNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Location of Chassis and Engine NumbersDocument9 pagesLocation of Chassis and Engine NumbersPrashantNo ratings yet

- Manitowoc 2250Document108 pagesManitowoc 2250Michael SerraNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2x16 BOGIE SPARE PARTSDocument7 pages2x16 BOGIE SPARE PARTSVignesh PrabhuNo ratings yet

- KR 96068 237899 569585Document4 pagesKR 96068 237899 569585Ronald BosNo ratings yet

- Speed Control of Hydraulic CylinderDocument3 pagesSpeed Control of Hydraulic CylinderSriram SastryNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Hybrid Stepper Motor: Technical DataDocument3 pagesHybrid Stepper Motor: Technical Datajohn deereNo ratings yet

- Assembly Procedure: 1 StageDocument4 pagesAssembly Procedure: 1 StageArjun ChopraNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Pneumatics Festo DidacticDocument218 pagesPneumatics Festo Didacticvab88100% (6)

- Hayward Gordon ULC: Start-Up Checklist Page 1 of 2Document2 pagesHayward Gordon ULC: Start-Up Checklist Page 1 of 2blackhand20xxNo ratings yet

- Chapter 10 Profile Cam Designv2Document85 pagesChapter 10 Profile Cam Designv2劉德信No ratings yet

- Cobra Proi: Spare Parts ListDocument52 pagesCobra Proi: Spare Parts ListTasha KuskNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 4 Chimi WangmoDocument3 pages4 Chimi WangmoChimi Wangmo0% (1)

- SIP TP550 - 206 Pressure WasherDocument14 pagesSIP TP550 - 206 Pressure WasheradpierceNo ratings yet

- 2022 Alexrims Catalog WEB 0318Document74 pages2022 Alexrims Catalog WEB 0318car0985l4No ratings yet

- Chain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1Document22 pagesChain Feed CF 145 H + RH 714 Maintenance Instruction: C 31360 - 4 en 0904 / JT 1cristianNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Lubricant Viscocities 140hDocument8 pagesLubricant Viscocities 140hPablo Gaspar D'Agostini AmengualNo ratings yet

- Circuit Breaker Grade 9 PresentationDocument13 pagesCircuit Breaker Grade 9 PresentationJeffrey SawatiNo ratings yet

- ATPL Inst 3.1 PDFDocument10 pagesATPL Inst 3.1 PDFKoustubh VadalkarNo ratings yet

- Generador Honda GX 690Document60 pagesGenerador Honda GX 690Julio Chinguel BeltránNo ratings yet

- CHAPTER 7: Control Panels: Section I: Overview ControlsDocument19 pagesCHAPTER 7: Control Panels: Section I: Overview ControlsabilrajprNo ratings yet

- Features:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFDocument7 pagesFeatures:: 1250kVA, Open Type, 4012-46TWG2A, PI734A, 3phase, AMFhelmy muktiNo ratings yet

- BN 20367Document2 pagesBN 20367HarmanNo ratings yet

- Carraro 26.22Document9 pagesCarraro 26.22Mindaugas MonkevičiusNo ratings yet

- Manufacturer: Ford Model: Transit ('00) 2,0D Di Engine Code: ABFA Output: 74 (100) 4000 Tuned For: Year: 2000-06 © Autodata Limited 2007 14.06.2009Document3 pagesManufacturer: Ford Model: Transit ('00) 2,0D Di Engine Code: ABFA Output: 74 (100) 4000 Tuned For: Year: 2000-06 © Autodata Limited 2007 14.06.2009elvishernandezNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)