Professional Documents

Culture Documents

Simulation 133 Bollard

Uploaded by

Anonymous IpqcBBOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation 133 Bollard

Uploaded by

Anonymous IpqcBBCopyright:

Available Formats

13th International LS-DYNA Users Conference

Session: Simulation

Analysis and Design of a Unique Security Bollard

Installment Using LS-DYNA for a K12 Vehicle Impact

Joseph M. Dulka, Eric R. Dietrich, Kelley S. Elmore,

Kendra D. Jones, Clyde S. Harmes, Robert H. Moyer

Abstract

This paper presents the design process for a unique security bollard providing protection against

a K12 [1] (M50 [2]) vehicle crash load. LS-DYNA was used to aid in the design of the security

bollard to account for the highly dynamic and inelastic behavior during a vehicle impact. The

bollard was installed along the top of a wall for a below-grade courtyard in order to maintain a

building security perimeter, providing protection against a potential malevolent vehicle attack.

Contrary to typical bollard installations where the foundation is supported on all sides with well

compacted soil or other substrata, no significant support was provided on the protected side of

the bollard foundation. As a result, this posed significant difficulty in the design of an effective

security bollard required to resist a potential K12 (M50) vehicle impact load with zero vehicle

penetration. The initial conceptual bollard design originated from the standard Department of

State (DoS) DS-22 K-12 rated bollard system [3]. Hand calculations were used to develop a

preliminary bollard design with equivalent static design stopping forces based upon existing

physical K12 test results. LS-DYNA aided the engineering team in observing structural and

material responses characteristic of impact loading which may have otherwise not been

perceived by method of traditional hand calculations. Utilizing LS-DYNA as not only an

analysis tool, but a powerful design tool enabled the engineering team to optimize the design of

the security bollard.

Keywords: Protective Design, VBIED, Crash Barrier, Security Bollard, Vehicle Impact

1-1

Session: Simulation

13th International LS-DYNA Users Conference

1. Introduction

Protective design has steadily increased into a global concern in the post 9/11 world. Protection

against explosive threats and vehicular impact threats has developed into a requirement rather

than a decision during building and site design phases. Building security starts by defining an

exterior perimeter to provide a safe standoff distance for a Vehicle-Borne Improvised Explosive

Device (VBIED).

The simplest and most effective way to reduce the blast or impact effects of a VBIED is to

provide a further standoff distance. However, in urban settings where standoff is limited this is

accomplished by designing a hardened structure for blast loading and a Vehicle Barrier System

(VBS) capable of stopping a design malevolent vehicle load within the predetermined safe

standoff distance (i.e. building site protection perimeter).

There are many potential barrier options to consider when designing a VBS for protection

against a VBIED. Typical VBS designs consist of concrete mass barriers, cable barriers,

bollards, crash gates, natural terrain, etc. Selection of a suitable VBS is based upon the

requirements which are adherent to the needs of the building site, level of protection, budget, and

aesthetics. For the design presented herein, protection is required to resist a K12 (M50) vehicle

impact (15,000 lbm. at 50 mph) at the top of a subgrade courtyard. Figure 1 below illustrates the

coincidence between the courtyard wall and the required building VBIED security perimeter at

the street elevation.

Figure 1 Illustrative Description of Site Specific Courtyard Coinciding with the Protected Perimeter

Inadequate support on the protected side of the prospective barrier systems foundation imposed

limitations on the design of the VBS. Additionally, the project scope, as developed by the

building owner and architect, required sensitivity to a VBS design which aesthetically

complemented a streetscape setting.

1-2

13th International LS-DYNA Users Conference

Session: Simulation

Simply idealizing a static load to account for the dynamics of a vehicle impact tends to result in

highly conservative and overly robust designs. If this approach alone is applied as the design

methodology, the results typically yield overdesigned, uneconomical options for the client.

Therefore Finite Element Analysis (FEA) software was used by engineering to account for the

behavior inherent to vehicle impact loading (nonlinear, inelastic, dynamic, strain-rate dependent

material modeling, etc.).

LS-DYNA is widely used in crashworthiness and vehicle barrier design applications. While

physical testing is the ideal method for simulating a VBSs crash effectiveness, this likely will

not always be a cost-effective or schedule permitting option. In the case of the courtyard VBS

design for a malevolent vehicle, LS-DYNA Explicit Solver was employed to simulate the vehicle

impact.

This paper discusses an overview of the methods applied in designing the VBS from concept to

construction. Though multiple design iterations were performed, the final design is presented

herein for brevity with supporting discussion regarding intermediate design phases. This paper

demonstrates the use of LS-DYNA as a powerful design optimization tool.

2. Analysis and Development of the Preliminary Design Concept

The clients design criteria required the VBS to halt a K12 (M50) vehicle impact load with

essentially zero penetration. Since zero penetration was required, the level of protection needed

to surpass the DoS standard K12 L3 rating [1] and ASTM standard M50 P1 [2] crash rating.

Figure 2 below provides a comparison between the DoS and ASTM vehicle crash rating

standards.

Figure 2 Comparison between DoS and ASTM Crash Barrier Rating [1] [2]

Additional criteria required limiting bollard rotation to a maximum of 8. Existing data from

physical bollard crash tests provides basis for concluding that when bollard rotation exceeds 8

the vehicle has a tendency to ride up and over a bollard system resulting in vehicle penetration.

The obvious challenge facing engineering was providing a cost effective solution meeting the

stringent level of protection.

1-3

Session: Simulation

13th International LS-DYNA Users Conference

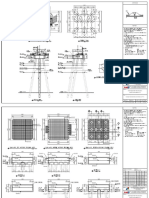

Inception of the preliminary VBS bollard concept stemmed from a previously qualified DoS

bollard design. Figure 3 illustrates the DoS DS-22 K12 rated bollard with revisions to highlight

specific limitations at the courtyard. Steel section sizes and reinforcement detailing of the DS-22

bollard provided the frame work for the initial conceptual design.

Inadequate protected

side support

Limited under

side support

Figure 3 DoS Standard DS-22 K12 Rated Bollard [3] with Site Specific Considerations

The primary concern with the bollard installation at the subgrade courtyard was the nonexistence of soil on the protected side and bottom side of the foundation as indicated in Figure 3.

This posed the most considerable challenge to develop a bollard system capable of meeting the

design criteria.

Early stages of the design started with simplified hand calculations assuming an idealized time

duration to stop the K12 vehicle from maximum to zero velocity. Physical crash data shows that

typical K12 L3 (M50 P1) crash events will last approximately 0.1 seconds to durations in excess

of 1 second, depending upon barrier and vehicle deformation. For the initial design, a

conservative stopping time of 0.1 seconds was assumed, yielding an equivalent static stopping

force of approximately 340 kips (1520 kN). Figure 4. illustrates the conceptual bollard design.

1-4

13th International LS-DYNA Users Conference

Session: Simulation

BOLLARD PIPE

w/ STIFFENER

DEADMAN

CLEVISES

SLEEVE

TIE RODS

ADDITIONAL

REBAR

COLLAR

PLATE

Figure 4 Section View of Conceptual Subgrade Courtyard Bollard Design

To address the absence of support on the protected side of the bollard foundation, a concept was

adopted in which a concrete mass (deadman) was integrated into the foundation via tie rods.

Upon vehicle impact, load is transferred through contact between the collar plate and bollard

assembly. Bolted clevises transfer load from the collar plate to the tie rods and into the

deadman, successively resisting the forward momentum of the vehicle. As a precautionary

measure, a sleeve was fitted around the bollard in the foundation which provided resistance for

plastic hinge development in the bollard below the top of the concrete foundation. As an

enhancement, the bollard stiffener was changed to a HSS steel shape. Furthermore, two

additional layers of rebar were added at the top most layers on the protected side of the

foundation to resist concrete punch-out failure.

1-5

Session: Simulation

13th International LS-DYNA Users Conference

3. LS-DYNA Bollard Model

Hand calculations provided the conceptual design based upon idealized static loads. LS-DYNA

was then used as an analysis and design tool to optimize the bollard system and visualize

dynamic response. LS-PrePost was utilized to generate the VBS geometry and *KEYWORD

input file. Figure 5 illustrates the bollard model from LS-PrePost. The bollard, stiffener, and

collar plate were assembled using shell elements. The concrete foundation and deadman were

constructed using solid elements, while concrete reinforcement and tie rods were represented

with beam elements. Shell elements were defined as fully integrated shells, ELFORM 16, with

hourglass control IHQ = 8. Solid elements were modeled with constant stress solids, ELFORM

1, and hourglass control IHQ = 3. Beam elements were assigned with Hughes-Liu with cross

section integration, ELFORM 1, with CST = 1 for tubular sections.

Figure 5 LS-DYNA Bollard Model

Steel material for the bollard, stiffener and collar plate was defined using *MAT_024

*MAT_PIECEWISE_LINEAR_PLASTICITY with Cowper and Symonds strain rate parameters

for mild steels to account for strain rate effects on material behavior. Concrete was modeled

using the *MAT_159 *MAT_CSCM_CONCRETE material model. Documentation on this

material model is readily available from the Federal Highway Administration [4].

Reinforcement and tie rod steel material were defined using material model *MAT_24

*MAT_PIECEWISE_LINEAR_PLASTICITY. *CONSTRAINED_LAGRANGE_IN_SOLID

key was used to couple the beam elements (i.e. reinforcement and tie rods) to the solid elements

(i.e. concrete) with default CTYPE = 2.

1-6

13th International LS-DYNA Users Conference

Session: Simulation

The collar plate-clevis-tie rod assembly was idealized as a plate (shell elements) with connection

to the tie rods (beam elements). Bolted connection and clevises were omitted due to complexity

and to avoid long run times.

*BOUNDARY_SPC_SET conditions were simulated to account for a continuously poured

concrete foundation on the sides of the foundation and deadman. A support boundary on the

underside and attack side of the concrete foundation and deadman was modeled with shell

elements representing well compacted fill. The model was generated this way to provide

resistance against contacting bodies toward the boundary surface only, as opposed to a

*BOUNDARY_SPC_SET which resists both positive and negative direction motion.

4. LS-DYNA Vehicle Model

The K12 (M50) vehicle model was obtained from the National Crash Analysis Center (NCAC)

website [5]. The available model was a typical Ford Single Unit Truck. The mass of the vehicle

was increased to accurately conform to the requirement of 15,000 lbm. (~6800 kg). This was

accomplished by increasing the payload material density (ballasting shown on truck bed) until

the desired mass for the vehicle was obtained. Figure 6 below presents the LS-DYNA vehicle

model. Additionally, keyword inputs were revised to eliminate solution errors and early

terminations due to spurious modes during the analysis without adversely affecting the bollard

system.

Figure 6 LS-DYNA K12 (M50) Vehicle Model

1-7

Session: Simulation

13th International LS-DYNA Users Conference

5. LS-DYNA Vehicle Impact Analysis and Results

The vehicle impact with the bollard design was simulated using contact type

*CONTACT_AUTOMATIC_SINGLE_SURFACE. Bollards are typically spaced with some

minimum clear distance so as to prevent a VBIED from exploiting the security perimeter.

However only one bollard was modeled. Qualifying a single bollard for the K12 (M50) load

ensured less likelihood of any vulnerability in the VBS design.

In order to reduce run times, the analysis started with the front bumper of the truck a few

millimeters away from the bollard (Figure 7). Initial vehicular motion was modeled by defining

a *INITIAL_VELOCITY_GENERATION which initiated a velocity of 50 mph (22.35 m/s).

Figure 7 LS-DYNA Vehicle Impact Analysis at Initial Time Step

Screen capture time steps of the impact simulation are presented in Figure 8. The simulation

shows the bollard system stopping the K12 (M50) vehicle load with no discernible penetration.

It was observed from the simulation results that during the onset of vehicle deformation and

bollard rotation, linear horizontal momentum of the vehicle was converted into vertical motion.

This is very common behavior in physical crash testing, especially characteristic of barrier

systems stopping the vehicle with minor penetrations, i.e. L3 (P1) ratings.

1-8

13th International LS-DYNA Users Conference

0.05 s

0.1 s

0.15 s

0.2 s

0.3 s

0.5 s

Session: Simulation

Figure 8 Vehicle Impact Time Steps

The dynamic simulation in LS-DYNA enabled the engineering team to visualize the performance

of the bollard system in real-time. Any unconventional failure mechanisms, design

deficiencies, or potential optimizations were easily observed. This accounted for any

components that exhibited signs of structural vulnerability or over strength. An extensive

number of iterations were conducted, altering components, working towards an optimized

design. Once the results from LS-DYNA were accepted with a high level of confidence,

additional code based hand calculations were performed to further validate that the bollard

system was adequate in resisting vehicle impact.

In contrast to the original DoS DS-22 bollard, the final design consisted of a 10 Sch. 140 pipe

bollard with an HSS stiffener. A 12 pipe sleeve was fitted to the bollard in the foundation to

drive plastic hinge development above the surface of the concrete. The maximum resultant

forces output from the beam elements simulating the tie rods provided the design basis for sizing

and detailing the collar plates, clevises and tie rods.

Figure 9 presents the velocity versus time plot from the final bollard system design. The analysis

shows that forward motion of the vehicle payload was brought to rest approximately 0.15

seconds after initial collision. It is interesting to note that when the front bumper initially

impacts the bollard, there is a short duration from 0 seconds to about 0.05 seconds where the

slope of the plot is close to zero, implying that there is a negligible deceleration rate of the

vehicle. This describes the soft behavior of less stiff components of the vehicle deforming

1-9

Session: Simulation

13th International LS-DYNA Users Conference

until the impact of the hard mass (i.e. engine block, transmission, etc.) on the bollard at 0.05

seconds. Linearly decreasing velocity (constant acceleration) is exhibited from 0.05 seconds to

0.15 seconds. This validated the conservative assumption using a stopping time of 0.1 seconds

for preliminary design purposes.

Figure 9 Forward Vehicle Payload Velocity vs. Time

Change in the bollard rotation versus time is plotted in Figure 10 below. The bollard rotation

approaches a maximum value of approximately 6 thus meeting the 8 maximum bollard rotation

criteria. As expected this criterion prevented the vehicle from riding over the bollard system.

Figure 10 Bollard Rotation Angle vs. Time

1-10

13th International LS-DYNA Users Conference

Session: Simulation

6. Conclusion

This paper presents a viable solution for a security bollard subjected to a VBIED impact to

maintain a building security perimeter. The protected building perimeter coincided with a

below-grade courtyard which required a unique design for a K12 (M50) rated VBS requiring

zero penetration. Hand calculations were used to develop a preliminary conceptual bollard

design. LS-DYNA enabled the engineering team to visualize failure mechanisms that may have

otherwise been overlooked with traditional static analysis methods. LS-DYNA was utilized as

an analysis and design tool in order to optimize the bollard system design by accounting for

inelastic, nonlinear, dynamic behavior inherent to crash simulations.

Figure 11 Final Construction of VBIED Perimeter Protection Installed at Top of Subgrade Courtyard

1-11

Session: Simulation

13th International LS-DYNA Users Conference

References

[1] DoS, SD-STD-02.01 Test Method for Vehicle Crash Testing of Perimeter Barrier and Gates,

Washington: U.S. Department of State, 2003.

[2] ASTM, F 2656-07 Standard Test Method for Vehicle Crash Testing of Perimeter Barriers,

West Conshohocken: American Society for Testing and Materials International, 2009.

[3] DoS, Anti-Ram Bollards (K-12) DS-22, U.S. Department of State, 2007.

[4] F. H. Administration, Users Manual for LS-DYNA Concrete Material Model 159, McLean:

U.S. Department of Transportation, 2007.

[5] National Crash Analysis Center, 3 November 2008. [Online]. Available:

http://www.ncac.gwu.edu/vml/models.html.

[6] LSTC, LS-DYNA Keyword User's Manual Volume I, Livermore Software Technology

Corporation.

[7] LSTC, LS-DYNA Keyword User's Manual Volume II Materials Models, Livermore Software

Technology Corporation.

[8] ANSYS, "ANSYS(R) Mechanical APDL Product Launcher Release 14.5 LS-DYNA Solver,"

2011.

1-12

You might also like

- 2019 SATs Year 6 Maths Merged Large Print PDFDocument89 pages2019 SATs Year 6 Maths Merged Large Print PDFAnonymous IpqcBBNo ratings yet

- Mooring & Breasting Jetty IIIDocument16 pagesMooring & Breasting Jetty IIIDwiki AdriyantoNo ratings yet

- Hydodynamic Loads During The Deployment of ROVs - P.sayerDocument6 pagesHydodynamic Loads During The Deployment of ROVs - P.sayerDavid ThomsonNo ratings yet

- Uniform Accelerated Motion (Horizontal)Document19 pagesUniform Accelerated Motion (Horizontal)Ronie MarquezNo ratings yet

- Calculus Honors WorkbookDocument157 pagesCalculus Honors Workbookgbengel100% (2)

- Catamaran Wetdeck Slamming Loads Using CFDDocument6 pagesCatamaran Wetdeck Slamming Loads Using CFDAhmadA.SwidanNo ratings yet

- Mooring & Breasting Jetty IIDocument12 pagesMooring & Breasting Jetty IIDwiki AdriyantoNo ratings yet

- Part 3 - 5.mooring FacilitiesDocument49 pagesPart 3 - 5.mooring FacilitiesIlham Hussein RasyidNo ratings yet

- Oslo Rules Tonnage PDFDocument5 pagesOslo Rules Tonnage PDFCari RiveraNo ratings yet

- Bolt Tightening Handbook Technical DataDocument12 pagesBolt Tightening Handbook Technical Datalwin_oo2435100% (3)

- Examining Flettner Rotors For Ship Propulsion Using CFDDocument59 pagesExamining Flettner Rotors For Ship Propulsion Using CFDnavidsmith0% (1)

- Sustainable Marine Structures - Volume 05 - Issue 01 - March 2023Document52 pagesSustainable Marine Structures - Volume 05 - Issue 01 - March 2023Bilingual PublishingNo ratings yet

- CODAC Final ReportDocument98 pagesCODAC Final ReportChristopher GarciaNo ratings yet

- HE Nozzle DevDocument21 pagesHE Nozzle DevJonathan MooreNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- Prediction of Warship Manoeuvring CoefficientsDocument76 pagesPrediction of Warship Manoeuvring Coefficientsa aNo ratings yet

- HCIS Security Devices-TurnstileDocument3 pagesHCIS Security Devices-TurnstileAnonymous IpqcBBNo ratings yet

- Engineering Mechanics - KL - Ramachandran SDocument744 pagesEngineering Mechanics - KL - Ramachandran SFe Fernandez100% (1)

- Fundamentals of Stability: From 0° To 7°/10° of Inclination To Resist Capsizing in A Given Condition of LoadingDocument10 pagesFundamentals of Stability: From 0° To 7°/10° of Inclination To Resist Capsizing in A Given Condition of LoadingHafiz MellianiNo ratings yet

- SPM - Rules Notes OCIMF 2023 For Mooring HosesDocument6 pagesSPM - Rules Notes OCIMF 2023 For Mooring Hosesbobuncle03No ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- Use of Commercial CFD Codes To Enhance Performance Prediction Capabilities For Planning BoatsDocument9 pagesUse of Commercial CFD Codes To Enhance Performance Prediction Capabilities For Planning Boatsgnd100No ratings yet

- Xiaobo Chen. Offshore Hydrodynamics and ApplicationsDocument19 pagesXiaobo Chen. Offshore Hydrodynamics and ApplicationsYuriy KrayniyNo ratings yet

- Key Stage 2: MathematicsDocument20 pagesKey Stage 2: MathematicsAnonymous IpqcBBNo ratings yet

- Shipboard Mooring Equipment: Course No. 12Document39 pagesShipboard Mooring Equipment: Course No. 12Dan CobeliNo ratings yet

- An Overview of The Prediction Methods For Roll Damping of ShipsDocument22 pagesAn Overview of The Prediction Methods For Roll Damping of ShipsВасил ЙордановNo ratings yet

- Motor Yacht Hull Form DesignDocument16 pagesMotor Yacht Hull Form Designale barbNo ratings yet

- 59m Ahts Addendum For Final Intact Stability Booklet - 91751918Document18 pages59m Ahts Addendum For Final Intact Stability Booklet - 91751918NHÓM 2 GTSNo ratings yet

- Response Amplitude Operator - Wikipedia, The Free EncyclopediaDocument3 pagesResponse Amplitude Operator - Wikipedia, The Free EncyclopediaFuadNo ratings yet

- Numerical Simulation of Ship Motion Due To Waves and ManoeuvringDocument48 pagesNumerical Simulation of Ship Motion Due To Waves and ManoeuvringHung NguyenNo ratings yet

- CEFILAIR English A4 Low ResDocument16 pagesCEFILAIR English A4 Low ResAnonymous IpqcBBNo ratings yet

- Stability of CatamaransDocument8 pagesStability of CatamaransVinayak29No ratings yet

- Matlab TutorialDocument55 pagesMatlab TutorialSahil JawaNo ratings yet

- 03 The Ship Design ProcessDocument10 pages03 The Ship Design Processw12n_sbyNo ratings yet

- 06 NAC Free Surface Effect (160213)Document10 pages06 NAC Free Surface Effect (160213)Gilles MathieuNo ratings yet

- Arc Length MethodDocument22 pagesArc Length MethodJoe Satch100% (1)

- Ac Controller and Display Panel - (03-2009) - Us-EnDocument74 pagesAc Controller and Display Panel - (03-2009) - Us-EnChristian Bedoya89% (9)

- SPM Physics Formula List Form4Document18 pagesSPM Physics Formula List Form4Zailinda Zakaria100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Chapter 5 - Seakeeping TheoryDocument31 pagesChapter 5 - Seakeeping TheoryWilson Toncel ZuletaNo ratings yet

- PCS120 F2014 Final Exam With Answers To PostDocument15 pagesPCS120 F2014 Final Exam With Answers To PostAbdulrahman Jijawi100% (1)

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceNo ratings yet

- Volume IIDocument246 pagesVolume IIathanasios niotisNo ratings yet

- The First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)Document5 pagesThe First Hybrid CRP-POD Driven Fast ROPAX Ferry (Paper)pal_malayNo ratings yet

- 04 NAC Initial Transverse Stability (160213)Document21 pages04 NAC Initial Transverse Stability (160213)Gilles MathieuNo ratings yet

- GZ CurvesDocument30 pagesGZ CurvesAhtashamuddin Nizamudin100% (1)

- Its All About Bollard PullDocument10 pagesIts All About Bollard PullHanafi AjahNo ratings yet

- (Mooring) : 1. GeneralDocument18 pages(Mooring) : 1. GeneralSushanta Kumar RoyNo ratings yet

- Intact StabilityDocument1 pageIntact StabilityislimaNo ratings yet

- Design Optimization of The Lines of The Bulbous BowDocument12 pagesDesign Optimization of The Lines of The Bulbous BowFernando Raúl LADINONo ratings yet

- Approved Grain Stability Book PDFDocument254 pagesApproved Grain Stability Book PDFDaryl JumuadNo ratings yet

- Stefan Harries CAESES DevelopmentsAndPerspectivesDocument44 pagesStefan Harries CAESES DevelopmentsAndPerspectivesghassenNo ratings yet

- Simulation of Flow Around KCS HullDocument11 pagesSimulation of Flow Around KCS HullMilovan PericNo ratings yet

- Ansys AQWA Automation - Boat Design NetDocument4 pagesAnsys AQWA Automation - Boat Design NetKester IyinborNo ratings yet

- CFD Assignment May 2017Document2 pagesCFD Assignment May 2017蒲俊雄No ratings yet

- Materi 7 - DST - Maxsurf MotionDocument14 pagesMateri 7 - DST - Maxsurf MotionIlmia HamzahNo ratings yet

- Hande - A Computer-Aided Design Approach For Hydrofoil ShipsDocument11 pagesHande - A Computer-Aided Design Approach For Hydrofoil Shipsjwpaprk1No ratings yet

- New IMO Requirements - 10th Edition - May 2004Document71 pagesNew IMO Requirements - 10th Edition - May 2004LucianNo ratings yet

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- Upfront CAE For Simulation-Driven Shape Optimization: SoftwareDocument4 pagesUpfront CAE For Simulation-Driven Shape Optimization: SoftwareJuniorJavier Olivo FarreraNo ratings yet

- Mosaad 86 PDFDocument294 pagesMosaad 86 PDFdoğancan uzunNo ratings yet

- Group Work - Case ChemxDocument11 pagesGroup Work - Case Chemxwerya aghamiriNo ratings yet

- Variation - Swing MethodDocument5 pagesVariation - Swing MethodDuy Ngô0% (1)

- 1 s2.0 S0029801817301646 Main PDFDocument15 pages1 s2.0 S0029801817301646 Main PDFOdumoduChigozieUzomaNo ratings yet

- Vibration of Deckhouse StructuresDocument10 pagesVibration of Deckhouse StructuresrthyhtNo ratings yet

- Transport Canada Small Fishing Vessel Safety Manual BookDocument102 pagesTransport Canada Small Fishing Vessel Safety Manual BookAlex HoperNo ratings yet

- FSM CalculationDocument20 pagesFSM CalculationRama Krishna100% (1)

- Small Angle StabilityDocument8 pagesSmall Angle StabilityAthulRKrishnanNo ratings yet

- Compass and Gyroscope: Integrating Science And Politics For The EnvironmentFrom EverandCompass and Gyroscope: Integrating Science And Politics For The EnvironmentNo ratings yet

- Contemporary Megaprojects: Organization, Vision, and Resistance in the 21st CenturyFrom EverandContemporary Megaprojects: Organization, Vision, and Resistance in the 21st CenturySeth SchindlerNo ratings yet

- Timber Folded Plate Structures - Topological and Structural ConsiderationsDocument11 pagesTimber Folded Plate Structures - Topological and Structural ConsiderationsAnonymous IpqcBBNo ratings yet

- (22558551 - Construction Science) The Use of Steel Cord Scrap in ConcreteDocument5 pages(22558551 - Construction Science) The Use of Steel Cord Scrap in ConcreteAnonymous IpqcBBNo ratings yet

- How To Identify A Modified PCBDocument3 pagesHow To Identify A Modified PCBAnonymous IpqcBBNo ratings yet

- Fixings Hilti PDFDocument257 pagesFixings Hilti PDFAnonymous IpqcBBNo ratings yet

- Nitronic60 MainDocument28 pagesNitronic60 MainAnonymous IpqcBBNo ratings yet

- 1116 - Safety TS 011-2016Document49 pages1116 - Safety TS 011-2016Anonymous IpqcBBNo ratings yet

- Better Barriers For The 21 Century: Archer 1200Document1 pageBetter Barriers For The 21 Century: Archer 1200Anonymous IpqcBBNo ratings yet

- XS618B1PBL2 DocumentDocument2 pagesXS618B1PBL2 DocumentAnonymous IpqcBBNo ratings yet

- NPT Torque ValuesDocument2 pagesNPT Torque ValuesAnonymous IpqcBBNo ratings yet

- Dowel Pin TolerancesDocument5 pagesDowel Pin TolerancesAnonymous IpqcBBNo ratings yet

- Pneuma Seal 2012Document24 pagesPneuma Seal 2012Anonymous IpqcBBNo ratings yet

- On The Fall of An Object With Both Linear and Quadratic Air ResistanceDocument4 pagesOn The Fall of An Object With Both Linear and Quadratic Air ResistanceALDO MAYME MARTINEZNo ratings yet

- MOTION in IN ONE DIMENSIONDocument45 pagesMOTION in IN ONE DIMENSIONAyushman MohantyNo ratings yet

- PHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Document2 pagesPHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Sabine MohamadNo ratings yet

- CAPE® Physics Past Papers Unit 1Document11 pagesCAPE® Physics Past Papers Unit 1AlexNo ratings yet

- 11th Physics Ch.3 Conceptual QuestionsDocument9 pages11th Physics Ch.3 Conceptual QuestionsMega TubeNo ratings yet

- Student Performance Q&A: 2001 AP Physics Free-Response QuestionsDocument8 pagesStudent Performance Q&A: 2001 AP Physics Free-Response QuestionsSTNo ratings yet

- Week 1 2 (Detailed Information) Chapter 1 - Rectilinear, Curvelinear, Projectile MotionDocument73 pagesWeek 1 2 (Detailed Information) Chapter 1 - Rectilinear, Curvelinear, Projectile MotionfauzaniNo ratings yet

- Dokumen - Tips - Indra Works Ds Tuning Procedure Ams Controls 2015 10 12 Continuing Place TheDocument19 pagesDokumen - Tips - Indra Works Ds Tuning Procedure Ams Controls 2015 10 12 Continuing Place TheSaanounNo ratings yet

- Physics Chapter 1Document16 pagesPhysics Chapter 1PASCUA, Louisse I.No ratings yet

- Sample Paper Class 11Document198 pagesSample Paper Class 11Kia Sharma100% (1)

- Understeer and OversteerDocument12 pagesUndersteer and OversteerMuhamad Nur Issam100% (1)

- Grade 9 Review Pack With AnswersDocument16 pagesGrade 9 Review Pack With AnswersShereen Abd EL HamidNo ratings yet

- Worksheet 2 IX - Physics - Force & Law of MotionDocument2 pagesWorksheet 2 IX - Physics - Force & Law of Motionkumar KvNo ratings yet

- 9TH GUESS Physics - For 2019-1Document4 pages9TH GUESS Physics - For 2019-1میاں مدثر وٹوNo ratings yet

- Vexta Vexta: SG8030J SG8030JDocument16 pagesVexta Vexta: SG8030J SG8030JramjoceNo ratings yet

- AS Level WorksheetDocument10 pagesAS Level WorksheetVivehaNo ratings yet

- Ch07 KinematicsDocument17 pagesCh07 KinematicsKhansa RazzaqNo ratings yet

- Boxing PunchDocument4 pagesBoxing PunchMahdicheraghiNo ratings yet

- MotionDocument35 pagesMotionAiza CabatinganNo ratings yet

- Projectiles I MD I RnsDocument4 pagesProjectiles I MD I RnsKhabi Nada50% (2)

- Accelerometer Load As A Measure of Activity Profile in Different Standards of Netball Match PlayDocument9 pagesAccelerometer Load As A Measure of Activity Profile in Different Standards of Netball Match PlayPabloAñonNo ratings yet

- Activity 7Document2 pagesActivity 7ProfED TVNo ratings yet

- Assignment 1 - Kinematics in 2 and 3 DimensionsDocument14 pagesAssignment 1 - Kinematics in 2 and 3 DimensionsMrshuaiNo ratings yet

- MR Ch09 Trajectory GenerationDocument28 pagesMR Ch09 Trajectory GenerationandersonNo ratings yet