Professional Documents

Culture Documents

Thermal PP Assign

Uploaded by

Abdul Ahad0 ratings0% found this document useful (0 votes)

32 views5 pagesjjk

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentjjk

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views5 pagesThermal PP Assign

Uploaded by

Abdul Ahadjjk

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

Thermal Power Plants

Combustion equipment:

Furnace

Grate Fired Furnace

Chamber Fired Furnace

Methods of Firing for Fuels

For obtaining maximum fuel combustion efficiency it is

required to proper and complete combustion of fuel inside the

boiler furnace. For that, proper and sufficient supply of air and

proper mixing of air with fuel are primary requirements.

Adequate supply of fuel particles for proper burning of

particles also to be maintained.

The combustion should produce designated temperature of the

steam boiler and maintains it consistently.

In addition to these, the method of firing steam boiler is such

that, the system may be easily handled and also, operation and

maintenance should be minimum. There are mainly two

methods of firing steam boiler with coal as fuel. One is solid

fuel firing other is pulverized fuel firing.

Let us discuss one by one.

There are mainly two types of solid fuel firing system

1 | Page

Thermal Power Plants

1) Hand firing 2) Mechanical stroke firing

Smaller size boiler can be operated by hand firing system.

This system was commonly used to drive coal engine

locomotive in past. Here, coal chips are put into the furnace

frequently by shovels.

Mechanical Stoker Firing

When fuel i.e. coal is put into the steam boiler furnace by

means of mechanical stoker, the firing of boiler method is

referred as mechanical stoker firing. There are mainly two

types of mechanical stoker firing systems.

Under Feed Mechanical Stoker Firing

Here, combustion takes place on the grate. The primary air is

fed below the grate. The primary air is fed below the grate.

The secondary air is allowed at the top. When the coal is

burnt, it is pushed down by fresh coal. The fresh coal is

pushed on the grate by means of rams as shown.

2 | Page

Thermal Power Plants

The ignition occurs downwards against the primary air flow.

The volatile matter filters through the bed and is completely

burnt. The combustion rate is high. The light ash contents and

combustion gases fly away to the atmosphere along with

primary air. Heavier ash content comes down over the grate

and ultimately falls into ash pit.

Travel Grate Stoker Solid Coal Firing

Here, the coal is burnt on a chain grate which continuously

travel forwards slowly combustion takes place during the

journey of coal from first end to last end of the furnace. At the

end of the combustion heavier ash content falls into ash pit by

gravitational force as the grate chain moves like conveyor

belt. The lighter ash particles and combustion gases fly away

with primary air.

3 | Page

Thermal Power Plants

Pulvarized Fuel Firing

For getting most calorific value of coal, the coal is pulvarized

in fine powder and then mixed with sufficient air. The mixture

of coal powder and air is fired in the steam boiler furnace to

achieve most efficient combustion process. This is most

modern and efficient method of boiler firing.

Due to pulverization, the surface area of coal becomes much

larger, and in this method air required for combustion is much

less. As the quantity of required air and fuel both are less, loss

of heat in this method of boiler firing is much less, hence

temperature can easily be reached to the designated level. As

the combustion is most efficient pulverized coal firing

increases the overall efficiency of steam boiler. As handling of

lighter coal dust is much easier than handling of heavier coal

chips, it is quite easy to control the output of the boiler by

controlling supply of fuel to the furnace. Hence fluctuation of

system load can smoothly be met.

In addition these advantages, pulverized coal firing system

has many disadvantages. Such as

1) The initial cost of installing this plant is very high.

2) Not only initial cost, running cost of this plant is quite high

as separate pulverization plant to installed and run

additionally.

3) High temperature causes high thermal loss through flue

gas.

4) This type of method of boiler firing has always a risk of

explosion.

4 | Page

Thermal Power Plants

5) This is also difficult and expensive to filter fine ash

particles from fine gas. Moreover, the quantity of ash particles

in the flue gas is more in pulverized system.

Pulvarization Process

Process of pulvarization is discussed here in brief.

1) First the coal is crushed by preliminary crasher. The coal is

crushed to 2.5 cm. or less.

2) Then this crushed coal is passed through magnetic

separator to separate any iron content in the coal. Iron must be

removed, otherwise during pulverizing iron particles will

cause spark which results unwanted fire hazard.

3) After that, crushed coal is dried properly before

pulverization. The moisture content must be less than 2% after

drying operation.

4) Then the coal is crushed again in fine particles in ball mill.

This process is referred as pulverization.

5) This pulverized coal is then puffed with air and put into

furnace as fluid.

5 | Page

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

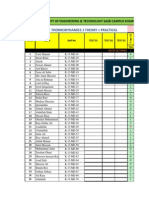

- Award List of Practical: ABS ABSDocument21 pagesAward List of Practical: ABS ABSAbdul AhadNo ratings yet

- ET 794 Gas Turbine Power TurbineDocument5 pagesET 794 Gas Turbine Power TurbineAbdul AhadNo ratings yet

- Mehran University of Engineering & Technology Szab Campus Khairpur Mir'S Corrective/Preventive Action RequestDocument9 pagesMehran University of Engineering & Technology Szab Campus Khairpur Mir'S Corrective/Preventive Action RequestAbdul AhadNo ratings yet

- Solar Energy Potential EstimationDocument14 pagesSolar Energy Potential EstimationAbdul AhadNo ratings yet

- Fluidized Bed CombustionDocument32 pagesFluidized Bed CombustionAbdul AhadNo ratings yet

- Gas Turbine With Power Turbine: Page 1/2 02/2013Document2 pagesGas Turbine With Power Turbine: Page 1/2 02/2013Abdul AhadNo ratings yet

- 7 Samples of Email To Professor For Admission Under ScholarshipsDocument8 pages7 Samples of Email To Professor For Admission Under ScholarshipsAbdul AhadNo ratings yet

- Advanced Metering InfrastructureDocument2 pagesAdvanced Metering InfrastructureAbdul AhadNo ratings yet

- Peng 311Document2 pagesPeng 311Abdul AhadNo ratings yet

- To Estimate The Global Solar Radiation: The Equation Postulated by (Angström, 1924) and Modified by (Prescott, 1940)Document5 pagesTo Estimate The Global Solar Radiation: The Equation Postulated by (Angström, 1924) and Modified by (Prescott, 1940)Abdul AhadNo ratings yet

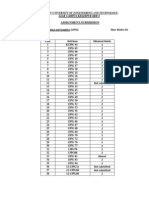

- Basic Electromechanical Engineering: ID - No./Seat NoDocument2 pagesBasic Electromechanical Engineering: ID - No./Seat NoAbdul AhadNo ratings yet

- Award List of PracticaDocument2 pagesAward List of PracticaAbdul AhadNo ratings yet

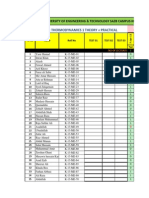

- Thermo Attaindance Record FileDocument14 pagesThermo Attaindance Record FileAbdul AhadNo ratings yet

- Thermo Attaindance Record FileDocument16 pagesThermo Attaindance Record FileAbdul AhadNo ratings yet

- Mehran University of Engineering and Technology, Jamshoro. Tentative Teaching PlanDocument1 pageMehran University of Engineering and Technology, Jamshoro. Tentative Teaching PlanAbdul AhadNo ratings yet

- Tentative Teaching Plan Department/Institute/Directorate: Mechanical EngineeringDocument2 pagesTentative Teaching Plan Department/Institute/Directorate: Mechanical EngineeringAbdul AhadNo ratings yet

- Assignment - Submission: Mehran University of Engineering and Technology, Szab Campus Khairpur Mir'SDocument1 pageAssignment - Submission: Mehran University of Engineering and Technology, Szab Campus Khairpur Mir'SAbdul AhadNo ratings yet

- Sessional Marks (Theory)Document1 pageSessional Marks (Theory)Abdul Ahad0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Turbin 1Document27 pagesTurbin 1Durjoy Chakraborty100% (1)

- Q3 NSP - SLP - RLPDocument41 pagesQ3 NSP - SLP - RLPRushi RavalNo ratings yet

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pages01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikNo ratings yet

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNo ratings yet

- State ManagementDocument16 pagesState Managementnegikamal703No ratings yet

- SR No Co Name Salutation Person Designation Contact NoDocument4 pagesSR No Co Name Salutation Person Designation Contact NoAnindya SharmaNo ratings yet

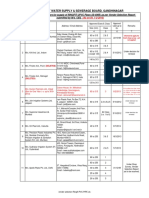

- GWSSB Vendor List 19.11.2013Document18 pagesGWSSB Vendor List 19.11.2013sivesh_rathiNo ratings yet

- Softening Point of AsphaltDocument2 pagesSoftening Point of AsphaltMuhammad Rizal RamliNo ratings yet

- Asme Wec Chapter Annual ReportDocument12 pagesAsme Wec Chapter Annual ReportManazar HussainNo ratings yet

- Network Analysis Chap. 4 First Order Differential EquationDocument5 pagesNetwork Analysis Chap. 4 First Order Differential EquationSreeram Vijapurapu0% (1)

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (2)

- C12200Document3 pagesC12200xgiorg100% (1)

- 1Document100 pages1Niomi GolraiNo ratings yet

- Sluice Gates ExportDocument20 pagesSluice Gates ExportsaishankarlNo ratings yet

- DSP45 12aDocument5 pagesDSP45 12aDaniel BarbuNo ratings yet

- Elevator Traffic Analysis - Passanger Elevators Option-1Document5 pagesElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNo ratings yet

- Advance Logic Activity On CountersDocument31 pagesAdvance Logic Activity On CountersKrinx BuliganNo ratings yet

- Using Dapper Asynchronously inDocument1 pageUsing Dapper Asynchronously inGiovani BrondaniNo ratings yet

- Lecture10 Combined FootingsDocument31 pagesLecture10 Combined FootingsGopalram Sudhirkumar100% (3)

- Bubbling Kun NiDocument7 pagesBubbling Kun NiBelen CRNo ratings yet

- Unit-II Some PPT NetDocument2 pagesUnit-II Some PPT NetbandisaidaiahNo ratings yet

- ED ProcessDocument9 pagesED ProcesskhanasifalamNo ratings yet

- 85GDocument4 pages85GBeny StephenNo ratings yet

- Klübersynth UH1 14-151: Product InformationDocument2 pagesKlübersynth UH1 14-151: Product InformationNathanael SuryantoroNo ratings yet

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDocument132 pagesBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNo ratings yet

- Kubernetes CommandsDocument36 pagesKubernetes CommandsOvigz Hero100% (2)

- Diesel Generator Set QSL9 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- Feasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)Document7 pagesFeasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)ollata kalanoNo ratings yet