Professional Documents

Culture Documents

Spur 1

Uploaded by

Wayan E P KsamawatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spur 1

Uploaded by

Wayan E P KsamawatiCopyright:

Available Formats

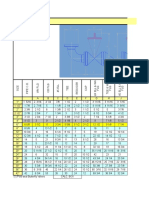

Module 0.

5 3

SSS

Spur Pinion Shafts

Spur Pinion Shafts

G

G

E

Spur

Gears

Standard full depth

S45C

Material

Heat treatment Thermal refined

Pitch dia.

Outside dia. Face width Shaft dia. (R) Shaft length (R) Total length

Allowable torque (Nm)

Allowable torque (kgfm)

Backlash

Weight

Catalog No.

A'

F'

SA

SA

SA

SA

5

5.5

6

6.5

6

6.5

7

7.5

7

7

7

7

6

6.5

7

7.5

38

38

38

38

45

45

45

45

0.20

0.26

0.32

0.38

0.0077

0.0094

0.011

0.013

0.021

0.026

0.032

0.039

0.0008

0.0010

0.0011

0.0014

0

0

0

0

~0.10

~0.10

~0.10

~0.10

0.0095

0.011

0.013

0.015

SSS0.5-10

SSS0.5-11

SSS0.5-12

SSS0.5-13

(mm)

Bending strength Surface durability Bending strength Surface durability

(kg)

SSS0.5-10

SSS0.5-11

SSS0.5-12

SSS0.5-13

m0.5

10

11

12

13

SSS0.8-10

SSS0.8-11

SSS0.8-12

SSS0.8-13

m0.8

10

11

12

13

0

0

0

0

SA

SA

SA

SA

8

8.8

9.6

10.4

9.6

10.4

11.2

12

10

10

10

10

9.6

10.4

11.2

12

60

60

60

60

70

70

70

70

0.83

1.05

1.29

1.56

0.032

0.039

0.047

0.055

0.084

0.11

0.13

0.16

0.0032

0.0040

0.0048

0.0056

0

0

0

0

~0.10

~0.10

~0.10

~0.10

0.038

0.045

0.052

0.060

SSS0.8-10

SSS0.8-11

SSS0.8-12

SSS0.8-13

SSS1-10

SSS1-11

SSS1-12

SSS1-13

m1

10

11

12

13

0

0

0

0

SA

SA

SA

SA

10

11

12

13

12

13

14

15

12

12

12

12

12

13

14

15

78

78

78

78

90

90

90

90

1.62

2.04

2.52

3.05

0.063

0.077

0.092

0.11

0.16

0.21

0.26

0.31

0.0064

0.0078

0.0094

0.011

0.09~0.20

0.09~0.20

0.09~0.20

0.09~0.20

0.077

0.090

0.10

0.12

SSS1-10

SSS1-11

SSS1-12

SSS1-13

SSS1.5-10

SSS1.5-11

SSS1.5-12

SSS1.5-13

m1.5

10

11

12

13

+0.5

+0.5

0

0

SB

SB

SB

SB

12.2

13.7

13.7

15.2

25

25

25

25

15

16.5

18

19.5

19.35

20.85

21

22.5

15

15

15

15

12.2

13.7

13.7

15.2

100

100

100

100

140

140

140

140

12.7

14.5

9.97

12.1

0.71

0.88

0.89

1.05

1.30

1.48

1.02

1.23

0.073

0.089

0.091

0.11

0.10~0.23

0.11~0.24

0.11~0.24

0.11~0.24

0.14

0.17

0.17

0.21

SSS1.5-10

SSS1.5-11

SSS1.5-12

SSS1.5-13

SSS2-10

SSS2-11

SSS2-12

SSS2-13

m2

10

11

12

13

+0.5

+0.5

0

0

SB

SB

SB

SB

16.2

18.2

18.2

20.2

30

30

30

30

20

22

24

26

25.8

27.8

28

30

20

20

20

20

16.2

18.2

18.2

20.2

120

120

120

120

170

170

170

170

30.2

34.3

23.6

28.6

1.75

2.14

2.18

2.57

3.08

3.50

2.41

2.92

0.18

0.22

0.22

0.26

0.12~0.26

0.13~0.28

0.13~0.28

0.13~0.28

0.30

0.38

0.38

0.46

SSS2-10

SSS2-11

SSS2-12

SSS2-13

SSS2.5-10

SSS2.5-11

SSS2.5-12

SSS2.5-13

m2.5

10

11

12

13

+0.5

+0.5

0

0

SB

SB

SB

SB

20.2

22.7

22.7

25.2

35

35

35

35

25

27.5

30

32.5

32.25

34.75

35

37.5

25

25

25

25

20.2

22.7

22.7

25.2

135

135

135

135

195

195

195

195

58.9

67.1

46.2

55.9

3.50

4.29

4.37

5.13

6.01

6.84

4.71

5.70

0.36

0.44

0.45

0.52

0.14~0.29

0.15~0.31

0.15~0.31

0.15~0.31

0.54

0.68

0.68

0.83

SSS2.5-10

SSS2.5-11

SSS2.5-12

SSS2.5-13

SSS3-10

SSS3-11

SSS3-12

SSS3-13

m3

10

11

12

13

+0.5

+0.5

0

0

SB

SB

SB

SB

24.2

27.2

27.2

30.2

40

40

40

40

30

33

36

39

38.7

41.7

42

45

30

30

30

30

24.2

27.2

27.2

30.2

150

150

150

150

220

220

220

220

102

116

79.8

96.5

6.15

7.54

7.68

9.02

10.4

11.8

8.14

9.84

0.63

0.77

0.78

0.92

0.15~0.32

0.16~0.35

0.16~0.35

0.16~0.35

0.89

1.11

1.11

1.35

SSS3-10

SSS3-11

SSS3-12

SSS3-13

[Caution on Product Characteristics]

The allowable torques shown in the table are calculated values according to the assumed usage conditions. Please see Page 31 for more details.

10- and 11-tooth gears with a pitch of module 1.5 or greater are profile shifted gears (x = +0.5). Please refer to the tables below for calculating the center distance when assembled.

The backlash values shown in the table are the theoretical values for the normal direction for a pair of identical SS Spur Gears with 30 teeth in mesh.

Center distance of Stock Spur Gears

Meshing with Profile Shifted Spur Gears

The table on the right shows the center distance

of the spur gears (x=0) which can be meshed with

prole shifted spur gears (x=+0.5) with module 1.

Multiply by the actual module to determine your

center distance.

Center distance when gear has 12 to 30 teeth (unit : mm)

No. of teeth(x=+0.5)

10

11

12

11.4410

11.9428

13

11.9428

12.4446

14

12.4446

12.9462

15

12.9462

16

13.4477

17

13.9492

18

19

20

Center distance when gear has 32 to 62 teeth (unit : mm)

No. of teeth(x=+0.5)

[Caution on Secondary Operations]

Please read Caution on Performing Secondary Operations (Page 32) when performing modifications and/or

secondary operations for safety concerns. KHK Quick-Mod Gears, the KHK's system for quick modification of

KHK stock gears is also available.

Avoid performing secondary operations that narrow the tooth width as it affects precision and strength.

Center distance when gear has 64 to 200 teeth (unit : mm)

No. of teeth(x=+0.5)

10

11

32

21.4640

21.9647

64

37.4777

37.9780

34

22.4653

22.9660

65

37.9780

38.4782

35

22.9660

23.4666

66

38.4782

38.9785

13.4477

36

23.4666

23.9671

68

39.4787

39.9790

13.9492

38

24.4677

24.9683

70

40.4792

40.9794

14.4505

40

25.4688

25.9693

72

41.4796

41.9799

14.4505

14.9518

42

26.4698

26.9703

75

42.9803

43.4805

14.9518

15.4530

44

27.4707

27.9712

76

43.4805

43.9807

15.4530

15.9542

45

27.9712

28.4716

80

45.4813

45.9814

21

15.9542

16.4553

46

28.4716

28.9721

84

47.4820

47.9822

22

16.4553

16.9564

48

29.4725

29.9729

85

47.9822

48.4823

23

16.9564

17.4574

50

30.4733

30.9736

88

49.4826

49.9828

24

17.4574

17.9583

52

31.4740

31.9744

90

50.4830

25

17.9583

18.4592

54

32.4747

32.9750

95

52.9837

53.4838

26

18.4592

18.9601

55

32.9750

33.4754

100

55.4844

55.9845

27

18.9601

19.4610

56

33.4754

33.9757

120

28

19.4610

19.9618

58

34.4760

34.9763

150

80.4890

80.9890

29

19.9618

20.4625

60

35.4766

35.9769

200

105.4915

105.9915

30

20.4625

20.9633

62

36.4772

36.9774

No. of teeth(x=0)

No. of teeth(x=0)

No. of teeth(x=0)

Internal

Gears

0

0

0

0

Shaft dia. (L) Shaft length (L)

Racks

Shape

CP Racks

& Pinions

Profile shift

coefficient

Miter

Gears

No. of teeth

SB

Bevel

Gears

Module

SA

Screw

Gears

The precision grade of products with a module less than 0.8 is equivalent to the value shown in the table.

Items with the shape SA are not thermally refined and have a hardness of less than (194HB).

Helical

Gears

Tooth hardness 200 270HB

Helical

Gears

Internal

Gears

Racks

CP Racks

& Pinions

Miter

Gears

Bevel

Gears

Screw

Gears

Other

Bevel

Worm

Products Gearboxes Gear Pair

JIS grade N8 (JIS B1702-1: 1998)

JIS grade 4 (JIS B1702: 1976)

Gear teeth

Pressure angle 20

Catalog No.

62

Precision grade

10

65.4866

Assembly distance of profile shifted gear and the meshing rack

11

a=

zm

+H+xm

2

Where

aAssembly Distance

HHeight of pitch line of rack

mModule

zNo. of Teeth

xProle Shift Coecient

Other

Bevel

Worm

Products Gearboxes Gear Pair

Spur

Gears

Specifications

50.9831

65.9867

63

You might also like

- Especificacion API 5lDocument44 pagesEspecificacion API 5ljpcc1986100% (1)

- Standard SAE DimensionDocument1 pageStandard SAE DimensionWidi PrasetyoNo ratings yet

- Rotork ActuatorsDocument10 pagesRotork Actuatorsthavaselvan80% (5)

- Power ScrewsDocument53 pagesPower ScrewsEko bellick0% (1)

- Acople Grilla Love JoyDocument1 pageAcople Grilla Love JoyClaudia C. DiazNo ratings yet

- Caracteristicas Motores PDFDocument60 pagesCaracteristicas Motores PDF0ZKRCITHONo ratings yet

- Group 2 - Clutch - Gearbox - OverdriveDocument50 pagesGroup 2 - Clutch - Gearbox - Overdrivealex_christiebNo ratings yet

- Ms660 Parts ListDocument46 pagesMs660 Parts ListVladut MariusNo ratings yet

- SW/SP/SH Series: Soul of Special AutomationDocument20 pagesSW/SP/SH Series: Soul of Special AutomationelecompinnNo ratings yet

- File VSL Data Sheets MultistrandDocument13 pagesFile VSL Data Sheets MultistrandStephanie K ChanNo ratings yet

- Nachi Ballscrew BearingsDocument8 pagesNachi Ballscrew BearingsHakan AdaNo ratings yet

- AMK DT ServomotorsDocument30 pagesAMK DT ServomotorsPaolo GiorgianniNo ratings yet

- Internal Gears: KHK Products Are Available From Maryland MetricsDocument6 pagesInternal Gears: KHK Products Are Available From Maryland MetricsbtfreekNo ratings yet

- Stihl 084 IPLDocument30 pagesStihl 084 IPLReinaldo GuttNo ratings yet

- Harmonic Drive Ultra Flat Component SpecsheetDocument4 pagesHarmonic Drive Ultra Flat Component SpecsheetElectromateNo ratings yet

- Voith Hirth couplings standard and custom-made ringsDocument10 pagesVoith Hirth couplings standard and custom-made ringssgupta_615796No ratings yet

- 8645 enDocument2 pages8645 enhoangmy0106No ratings yet

- Components For Chain Conveyors: Heko Ketten GMBHDocument36 pagesComponents For Chain Conveyors: Heko Ketten GMBHCesar AraujoNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- Medidas para Mecanizar Alojamiento Anillo Sello EspejoDocument11 pagesMedidas para Mecanizar Alojamiento Anillo Sello EspejoJhonatan Valencia MillanNo ratings yet

- Imperial To Find:-: Telephone+44 (0) 1246268080 Fax +44 (0) 1246260003Document13 pagesImperial To Find:-: Telephone+44 (0) 1246268080 Fax +44 (0) 1246260003roger1231175100% (1)

- Advul EnusDocument17 pagesAdvul EnusErlangga PrabowoNo ratings yet

- Torque Systems MDM-5000 Product GuideDocument4 pagesTorque Systems MDM-5000 Product GuideElectromateNo ratings yet

- 994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsDocument58 pages994F Wheel Loader 44200001-UP (MACHINE) POWERED by 3516 Engine (SEBP3851 - 50) - Systems & ComponentsEvan AT YoelNo ratings yet

- Grid Coupling PDFDocument6 pagesGrid Coupling PDFsgupta_615796100% (1)

- Plummer Block Housings: FeaturesDocument3 pagesPlummer Block Housings: FeaturesrefeiNo ratings yet

- Flare CalculationDocument22 pagesFlare CalculationHomer SilvaNo ratings yet

- Stihl 034 Parts ManualDocument58 pagesStihl 034 Parts ManualSonnie Ledbetter100% (2)

- KissoftDocument7 pagesKissoftGopi Krishnan VNo ratings yet

- ZF Maschinenantriebe GMBH: Planetary GearboxesDocument20 pagesZF Maschinenantriebe GMBH: Planetary Gearboxesrandevu17No ratings yet

- Fits & TolerancesDocument6 pagesFits & Tolerancessuperman92makNo ratings yet

- Calculation of Torsional Vibration Tvd-1121-Pt110Document19 pagesCalculation of Torsional Vibration Tvd-1121-Pt110asdNo ratings yet

- Cas Quil HosDocument4 pagesCas Quil HosLuisSilvaNo ratings yet

- FLURO Motor Sport Cataloque EnglishDocument16 pagesFLURO Motor Sport Cataloque EnglishRMCsportNo ratings yet

- PC Board PrototypingDocument9 pagesPC Board PrototypingJana JrabNo ratings yet

- Rotary IndexingDocument10 pagesRotary IndexingdeadmatrixNo ratings yet

- Char-Lynn: Parts InformationDocument4 pagesChar-Lynn: Parts InformationFernando SabinoNo ratings yet

- MzeDocument9 pagesMzeTungstenCarbideNo ratings yet

- Calculation of Service Life: Load DataDocument4 pagesCalculation of Service Life: Load Datarafael rodarteNo ratings yet

- Manual Rotex CouplingDocument21 pagesManual Rotex CouplingAndrei MorariuNo ratings yet

- Sealed & Shielded Type Double Row Angular Contact Ball BearingsDocument3 pagesSealed & Shielded Type Double Row Angular Contact Ball BearingsAnonymous 5RUnMVLMPNo ratings yet

- Toughcarrier TCH10: Super High Load Capacity Single-Axis ActuatorDocument2 pagesToughcarrier TCH10: Super High Load Capacity Single-Axis ActuatornvkjayanthNo ratings yet

- ZF2 Belt Drive Slide: Product Finder Home PageDocument6 pagesZF2 Belt Drive Slide: Product Finder Home PageawemetalNo ratings yet

- Mission S and W Dims and Curve Chart PDFDocument28 pagesMission S and W Dims and Curve Chart PDFcaballero_tigreNo ratings yet

- Spare Parts ListDocument188 pagesSpare Parts ListhanhccidNo ratings yet

- Altra Industrial Motion 700 Series Worm Gear Speed Reducers Now with Hollow Output ShaftsDocument4 pagesAltra Industrial Motion 700 Series Worm Gear Speed Reducers Now with Hollow Output ShaftsJulio C. SalinasNo ratings yet

- Chapter 7Document39 pagesChapter 7SayeedIshtiaqueNo ratings yet

- Atlas Copco DKR-36 Rotary Hammer Parts ListDocument13 pagesAtlas Copco DKR-36 Rotary Hammer Parts ListSumit BhasinNo ratings yet

- Paval Marius Catalin IMEN 1531: An Example of Peculiar Press Structure: Shop PressDocument14 pagesPaval Marius Catalin IMEN 1531: An Example of Peculiar Press Structure: Shop PressMihailNo ratings yet

- 460 IplDocument46 pages460 IplClifford HubbardNo ratings yet

- Hydraulic Cylinders CHDocument8 pagesHydraulic Cylinders CHStoianovici CristianNo ratings yet

- Stripper Plate ProgramDocument3 pagesStripper Plate ProgramAme KhunNo ratings yet

- Service BrakesDocument3 pagesService BrakeselyeszebdaNo ratings yet

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 pagesBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371No ratings yet

- 1FK6 AC Servomotors: For SIMODRIVE 611Document3 pages1FK6 AC Servomotors: For SIMODRIVE 611FelipepolixbarbosaNo ratings yet

- Ponto de Injeção (D342)Document3 pagesPonto de Injeção (D342)Lucas ApostoloNo ratings yet

- Spherical BearingsDocument3 pagesSpherical BearingsGMT Rubber-Metal-TechnicNo ratings yet

- Tetra Pak Valves LklatDocument4 pagesTetra Pak Valves LklatNguyễnNgọcMinhNo ratings yet

- 03 ShaperDocument5 pages03 ShaperHridoyNo ratings yet

- Hydraulic Control SystemDocument16 pagesHydraulic Control SystemHeerok Kumar100% (1)

- Air Brake ManualDocument64 pagesAir Brake ManualMohamed Yahia ElgeziryNo ratings yet

- Pressure relief and anti-cavitation valves for mobile applicationsDocument12 pagesPressure relief and anti-cavitation valves for mobile applicationsOleg080No ratings yet

- Sampling Conditioning SystemDocument24 pagesSampling Conditioning System王祚No ratings yet

- Cat 740 Parts ManualDocument1,198 pagesCat 740 Parts Manualgerhard100% (27)

- Solenoid Valve Common SymbolsDocument9 pagesSolenoid Valve Common SymbolsLovan SoNo ratings yet

- Curves MF - GouldsDocument3 pagesCurves MF - GouldssanvidwansNo ratings yet

- Case CS78 CS86 CS94 Workshop ManualDocument933 pagesCase CS78 CS86 CS94 Workshop ManualJo Marbe100% (2)

- Hydraulic QJ330Document40 pagesHydraulic QJ330PRISCILA FAGUNDESNo ratings yet

- 14 RH 120-E Pressure Checking and SettingDocument30 pages14 RH 120-E Pressure Checking and SettingMiguel AtencioNo ratings yet

- Delta & Brizo Kitchen Faucets GuideDocument24 pagesDelta & Brizo Kitchen Faucets GuideShikha BombJainNo ratings yet

- Product Data SheetsDocument72 pagesProduct Data SheetstreetreeNo ratings yet

- Gate Valve Inspection ChecklistDocument2 pagesGate Valve Inspection ChecklisternmrajaNo ratings yet

- Transaxle - TECUMSEH PEERLESS TRANSAXLE MST 205-535EDocument3 pagesTransaxle - TECUMSEH PEERLESS TRANSAXLE MST 205-535EJindřich Nenza100% (1)

- Design of Worm GearsDocument9 pagesDesign of Worm GearsMugisha OlivierNo ratings yet

- Working Hydraulic - XpsDocument33 pagesWorking Hydraulic - XpsThein Htoon lwinNo ratings yet

- GMK 5100 Gear Control SystemDocument14 pagesGMK 5100 Gear Control Systemالمهندسوليدالطويل83% (6)

- Threaded Mould Tool DesignDocument65 pagesThreaded Mould Tool DesignShubham ChoudhariNo ratings yet

- d6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraDocument3 pagesd6t Track-Type Tractor STD, XL Differential Steering Gct00001-Up (Machine) Powered by c9 Engine (Sebp4963 - 45) - Armação Dos Roletes Da EsteiraDouglas FernandesNo ratings yet

- Epicyclic Gear Train Design PDFDocument30 pagesEpicyclic Gear Train Design PDFThomas VallenderNo ratings yet

- Razvodni VentilDocument17 pagesRazvodni VentilalexkeserNo ratings yet

- Kuliah Ke-4Document59 pagesKuliah Ke-4Rafael PriambadhaNo ratings yet

- Solenoid Valve (Proportional Reducing) - Power Shift SystemDocument4 pagesSolenoid Valve (Proportional Reducing) - Power Shift SystemMoncefNo ratings yet

- Pipe FittingsDocument273 pagesPipe FittingsRyan Goh Chuang HongNo ratings yet

- Aisin Aw Tr-60snDocument1 pageAisin Aw Tr-60snJesus Alejandro Miranda PalaciosNo ratings yet

- Landing Gear and Brakes: Citation Mustang Operating ManualDocument21 pagesLanding Gear and Brakes: Citation Mustang Operating ManualkeeferNo ratings yet

- HYDRAULIC HAND PUMP SERIES PARTS LISTDocument4 pagesHYDRAULIC HAND PUMP SERIES PARTS LISTjavierlocooNo ratings yet

- Technical Manuals: ILL# Part# QTY Ref#Document2 pagesTechnical Manuals: ILL# Part# QTY Ref#escoleinNo ratings yet