Professional Documents

Culture Documents

Larrard1998 PDF

Uploaded by

MohamedRaahimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Larrard1998 PDF

Uploaded by

MohamedRaahimCopyright:

Available Formats

Materials and Structures/Mat6riaux et Constructions,Vol.

31, August-September 1998, pp 494-498

Fresh concrete: A HerscheI-Bulkley material

F. de Larrard 1, C.F. Ferraris2, T. Sedran3

(1) Laboratoire Central des Ponts et Chauss&s (LCPC), Paris, France. Guest researcherat National Institute of Standards and Technology

(NIST), Gaithersburg, Maryland, USA

(2) NIST, Gaithersburg

(3) LCPC, Paris

Paper received:April 4, 1997; Paper accepted:July 15, 1997

A B S T R A C T

R I~ S O M I~

Some preliminary results of an experimental program

on the rheological behavior of flesh concrete are presented.

In the rheological tests, performed with a plane-to-plane

rheometer, it appears that the relationship between torque

and rotation speed is not exactly linear. The flesh concrete

behavior is better described by the Herschel-Bulkley

model: ~ = z' 0 + a ~b; ~ and ~ are the shear stress and the

strain gradient applied to the specimen, respectively, z'0, a

and b are three material parameters describing the concrete

behavior. Among other advantages, this new description

avoids the problem of negative yield stress encountered

with the Bingham model.

Quelques r&ultats pr(liminaires d'un programme exp(rimental de grande envergure, traitant de la rhdologie du

bdton frais, sont pre'sent&. Les caract&istiques rh&logiques

des m(langes sont mesur&s avec le rhdom~tre B T R H E O M .

I1 apparaft que la relation entre couple et vitesse de rotation

n'est pas strictement lin&ire; une description plus fine est

fournie par le module de Herschel-Bulkley, de la forme

= z' o + a ~b; ~est la contrainte de cisaillement, et ~ legradient de vitesse m

t pose" "a l'&hantillon. Les parametres" z 'o, a

and b d&rivent le comportement du b(ton. Entre autres avantages, cette nouvelle approche permet d'&iter le probl~me des

seuils n(gatifs, rencontr( avec le module de Bingham.

1. INTRODUCTION

where z is the shear stress, ~, the strain gradient (or shear

rate), z 0 the yield stress, and t.t the plastic viscosity. The

two last parameters are assumed to be material constants.

However, this relationship was only suggested by an

analogy between fundamental parameters (stress, strain

gradient) and macroscopic measurements (torque, speed

of rotation). More recently, de Larrard et al. developed a

parallel-plate rheometer called B T R H E O M 1 [4], where

the strain field is imposed by the geometry (see Fig. 1).

From the relation between the torque and the rotation

speed, one can deduce the material law of behavior.

Therefore, for the first time, characteristics in funda-

The rheology of flesh concrete is a relatively young science. There have been many attempts to characterize the consistency of flesh concrete by a variety of technological tests

[1, 2], but few researchers have applied continuous media

mechanics to the rheological behavior of flesh concrete.

Tatersall was probably the first to carry out systematic

investigations in this field, which have been summarized in

a book [3]. Pointing out that testing fresh concrete in a

classical coaxial viscometer would require a gigantic apparatus, he suggested the use of a more modest device (the

'Two-point test') where the concrete is mixed in a sort of

instrumented mixer. Finding a linear relationship between

the increase of the torque and the rotation speed of the

impeller, Tatersall stated that fresh concrete had a Bingham

behavior, which can be expressed by the relationship:

~=~0+g ,)

1359-5997/98 9 RILEM

(1)

494

I) The names of manufacturers are identified in this report to adequately

describethe experimentalprocedure. Such an identificationdoesnot imply recommendation or endorsement by the National Institute of Standards and

Technology, nor doesit imply that the materialidentifiedis necessarilythe best

availablefor thispurpose.

De Larrard,Ferraris,Sedran

Fig. 1 - Velocity field in BTR/-IEOM [3, 4].

mental units can be measured on fresh concrete. This

rheometer was developed taking into account a comprehensive series of specifications, encompassing both engineering and scientific requirements. The measurements

were validated by finite-element calculations, and comparisons with most existing types of concrete rheometers

[5, 6]. The use of this rheometer for characterizing a

series of concretes, mostly high-performance concretes,

led to the conclusion that the Bingham behavior was an

acceptable description of the flow behavior of most fresh

concretes [5, 7]. However, some of our recent measurements suggest that this is not always a good approximation and that a more general description of the flow

curves seems necessary. A possible model is similar to

the one used by Coussot and Piau, who studied the rheology of coarse aggregate-mud suspensions with a large

coaxial rheometer [8].

2. EXPERIMENTAL PLAN

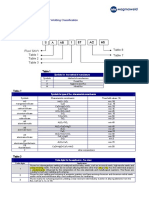

additions of silica fume. A total of 78

mixes was studied. The concretes

were produced with a gravel having a

maximum size of 12 mm, a coarse

sand, a single-size fine sand from

Ottawa (Illinois), and an ordinary

Portland cement (ASTM Type I/II).

The HRWRA used is of the naphthalene type (having a solid content

of 40%). Some of the mixtures are

detailed in Table 1.

Within the three series considered herein, the mutual proportions

of dry materials remain constant.

Only the water concentration was

changed from one mixture to

another. The mixtures had watercement ratios in the range 0.55-0.60 by mass ('NormalStrength Concretes'), 0.36-0.38 ('High-Performance

Concretes'), and 0.26-0.27 ('Self-Compacting Concretes'),

respectively.

A slump test (ASTM C143 [9]) and a BTRHEOM

rheometer test were performed on every mix. All slump

values were higher than 80-100 mm, which ensured that

the concretes were sufficiently fluid for testing in the

rheometer. For the rheometer tests, a 15 s previbration was

applied to the specimens (with a frequency of 40 Hz)2,

then the shear tests were carried out without vibration.

Five measurements were taken for rotation speeds ranging

between 0.2 and 0.8 rev/s. This corresponds to a strain gradient between 0.25 and 6 s-1. Lower rotation speeds

would be desirable, but lead to difficulties in regulating the

rotation speed of the rheometer. At each rotation speed

level, torque measurements are taken after twenty seconds,

in order to decrease the contribution of thixotropy.

However, it has been shown that, for a constant rotation

speed, no real stabilization of the torque appears within a

In an on-going experiTable 1 - Mixture-proportions of some concretes. *: free water/cement ratio

mental plan carried out at

Coarse

Fine

Ottawa Cement HRWRA Water

w/c*

the National Institute of

Mixtures aggregate Aggregate Sand

Series

Standards and Technology

(kg/m 3) (kg/m 3) (kg/m 3) (kg/m 3) (kg/m 3) (kg/m 3)

(NIST), an attempt is made

B01C

953

614

191

360

0

209

0.55

to assess the rheological

801B'

952

614

190

360

0

214

0.57

Normalbehavior of all feasible concretes within a fixed set of

B01A

940

606

188

355

0

217

0.58

Strength

components. In a first series

943

608

189

356

0

222

0.60

Concretes B01A'

of tests, 33 concretes or

BHPIA'

992

617

176

419

10.5

159

0.36

Highmortars without admixtures

were generated by system990

616

176

418

10.4

161

0.37

Performance BHPIB

atic variations of cement

984

612

175

415

10.4

166

0.38

Concretes BHPIC

content, coarse/fine aggreBHP8C

882

549

157

619

15.5

162

0.26

Selfgate ratio and water conCompacting BHP8B

878

546

156

616

15.4

167

0.27

tent. In a similarly designed

series, the mixtures were

868

540

154

609

15.2

171

0.27

Concretes BHP8A

highly "superplasticized",

with a high-range water

reducer agent (HRWRA).

Finally, two more series completed the program, one with

2) The previbration ensures that the placement of the concrete sample is not

influenced by the operator [5].

intermediate amounts of HRWRA, and one with various

495

Materials and Structures/MatOriaux et Constructions, Vol. 31, August-September 1998

Normal-Strength Concretes

10

9

8

7

High-Performance Concretes

12

X-

BO1C

10

Fitting

BO1B'

--'Cig I-"*

....

=0 4

O'

'r

0.25

0.5

.......

/4

:~

BHP1B

....

I.../"

Fitting

9

_ _

Fitting

BHP1C

Fitting

0.25

0.75

BHP1A'

BO1A'

0.5

0.75

rotation s pe ed (rev/s)

(o)

rotation speed (revls)

Self-Compacting

9- I

Fitting

X:

Fitting

BO1A

_ _

.90 3

g8

Fitting

"

.A

(b)

Concretes

18

14

12

BHPSC

Fitting

=o

x~

6

fl

BHP8B

Fig. 2 - Relationship between torque and rotation speed in

- - -Fitting

BTRHEOM

r h e o m e t e r , for s ome c o n c r e t e m i x t u r e s .

BHP8A

Fitting

0.25

0.5

0.75

rotation speed (rev/s)

(c)

Table 2 - Properties of the concretes at the fresh state.

*mean diameter of the spread after the slump test

Bingham m o d e l

Mi~ums

HemcheI-Bulkley

model

Slump Slump ~eld Pla~ic Yield

a

flow* ~mss viscosi~ ~mss

(ea.s)

(Pa) (Pa.s b)

(mm) (mm) (Pa)

Equivalent

pla~icviscosi~

(Pa.s)

B01C

80

1717

174

1804

111

1.23

156

BOIB'

100

1489

163

1599

86

1.33

140

BOIA

130

1219

160

1341

74

1.40

134

BOIA'

165

881

133

983

62

1.40

111

BHPIA'

180

593

517

774

385

1.15

479

BHPIB

205

473

530

608

430

1.10

501

BHPIC

235

141

439

471

205

1.40

370

BHP8C

265

560

-452

1960

675

792

1.88

2956

BHP8B

285

700

-373

879

457

269

1.73

795

BHP8A

290

750

-147

488

385

132

1.70

376

reasonable time [5]. There is first a decrease of the torque

due to a structural breakdown phenomenon. Then, an

increase appears, caused by the early cement hydration.

Therefore, the obtained measurements slightly depend on

the test duration, which is unavoidable in the case of

cementitious materials. For two very thick mixtures

(BHP8C and BHP8B), the maximum rotation speed had

to be reduced, because the power of the

motor was not high enough to reach the

intended maximum speed. The results of

the tests are given in Table 2 and Fig. 2.

As a preliminary result, it appears that

experimental relationships between torque

and rotation speeds generally deviate from a

straight line (see Fig. 2), even if the linear

correlation is rather high (between 0.970

and 0.999). Moreover, if a linear regression

is applied to the experimental points (following the usual procedure to deduce the

Bingham parameters), a negative yield stress

is sometimes found (in the case of the SelfCompacting mixtures).

3. FIYrlNG THE EXPERIMENTAL

CURVES WITH THE HERSCHELBULKLEY MODEL

It seems that a better model for representing the

experimental points is the following

F = F0 + A N b

(2)

where F is the measured torque (bulk value minus the

contribution of the empty rheometer [10]), N the speed

of rotation (in rev/s), F 0, A and b numerical parameters

496

De Larrard,Ferraris,Sedran

determined by the least square difference method. This

type of model has been referred to as the HerschelBulkley (HB) model. HB behavior is the same as the

Bingham behavior when the exponent is equal to 1 [11]:

=

+ a

(3)

Following this model, the description of the rheological behavior requires three parameters: z'0 (the HB yield

stress), a and b.

Integrating the contribution of each surface element

to the torque, the following equations are obtained:

A=((2~);;lhb(Rb+3-Rbl+3)a

(4)

where R 1 and R 2 are the inner and outer radii, and h the

height of the sheared concrete specimen. In BTRHEOM,

R 1 = 20 m m , R 2 = 120 mm and h = 100 mm.

These equations can be inverted to deduce the material parameters from the fitting of the bulk curve. A 10%

correction is applied to the a parameter to account for

the skirt friction effect, as is normally done in determining the plastic viscosity [6]. Therefore, we have for the

HB parameters:

3

(5)

a__0.9 (b+3)

The fitting of the experimental points appears in Fig. 2,

and the parameters found are given in Table 2. The experimental relative errors are about 0.7% and 1% for the

torque and for the rotation speed, respectively [51. Here,

the coefficients of variation provided by the regressions

have been found close to 1%. Thus, it appears that the HB

model provides an excellent approximation to the measurements. The HB yield stress is always positive, and,

within each series, it decreases when the water content

increases. Also, the exponent b differs significantly from 1,

which shows the limits of the Bingham model.

In favor of the Bingham model, it could be argued that

the Bingham yield stress values provide a better ranking of

the mixtures than the HB yield stress, with respect to the

slump values (see Table 2). However, it is thought that the

ability of the Self-Compacting Concretes to produce high

spread in the slump test is due not only to the low yield

stress, but also to the high amount of cement paste (here,

about 40%), which lubricates the aggregates up to the end

of the test. The paste volume of the high-performance

concretes is less (32%), then a part of the paste is squeezed

from the skeleton during the slumping of the sample, until

friction between aggregates stops the flow.

4. C O N C L U D I N G

REMARKS

The Herschel-Bulkley model appears to offer some

benefit in describing the flow behavior of concretes.

However, its ability needs further confirmation.

Nevertheless, after a systematic fitting of 62 tests dealing

with HPCs made in the past at the Laboratoire Central des

Ponts et Chauss&s (LCPC), the b parameter was only

rarely equal to 1. Further, a hnk seems to exist between a

and b (Fig. 3). However, this hnk could depend on some

mixture-design parameters, e.g. the presence of HRWRA.

From a practical viewpoint, a 3-parameter model

may be difficult to handle (especially if the aim is to

specify the rheological characteristics, and to control

them by optimizing the mixture-design). If a systematic

link exists between a and b in equation (3), then the

model only contains two independent parameters. If the

relationship between a and b is not general, another solu-

2.5

BHPIC

3000

,,N.

2500

~Herschel*

Bulkley

Bingham

1.5

"~ 2000

.....

15oo

~x,,

Mod

Bingham

./

1000

0.5

B = -0.[899 ogA

2.7985

500

0

0.0

0.5

1.0

1.5

2.0

2.5

3,0

log A

strain gradient (s-l)

Fig. 3 - Relationship between a and b parameters, in a set of

High-Performance Concretes tested at L C P C .

Fig. 4 - Approximation of the l i b rheogram by a modified

Bingham straight line.

497

Materials and Structures/Materiaux et Constructions,Vol. 31, August-September 1998

tion would be to keep the Bingham model, with parameters deduced from the HB model. Then the yield

stress would be %, and the equivalent plastic viscosity p'

would be calculated enabling the Bingham straight line

to give the best possible approximation of the HB curve,

in a certain strain gradient range [0, 9max] (Fig. 4). By

using the least square method, it is found that:

bt'

3a

= ~)'

-b-1

max

(6)

In this case, g' would become a good parameter for

characterizing the secondary aspects of concrete workability. For the mixtures tested, ~'max= 6 S-1 (see Table 2).

ACKNOWLEDGMENTS

The authors would like to thank John Winpigler and

Frank Davis for their valuable help in performing the

tests and setting up the needed instruments. Also their

appreciation goes to W.R. Grace Co. for providing the

concrete mixer and the HR.WRA used in this study.

REFERENCES

[1] Bartos, P., 'Fresh Concrete: Properties and Tests' (Elsevier,

1992).

[2] Ferraris, C.F.,'Measurement of Rkeological Properties of HighPerformance Concrete: State-of-the-Art Report', National

Institute of Standards and Technology, NISTIR 5869, July 1996,

33 p.

[3] Tatersall, G.H., 'Workability and Quality-Control of Concrete'

(E & FN SPON, London, 1991).

[4] De Larrard, F., Szitkar, J.C., Hu, C. and Joly, M., 'Design of a

rheometer for fluid concretes', Proceedings of the International

RILEM Workshop Special Concretes: Workability and Mixing,

P.J.M. Bartos ed. (E & FN SPON, 1994)201-208.

[5] Hu, C., 'Rh~ologie des b&ons fluides", Etudes et recherches des

Laboratoires des Ponts et Chauss&s, OA 16, 1995, 203 p., available at LCPC, 58 Bd. Lefebvre, 75732 PARIS CEDEX 15,

France (in French).

[6] Hu, C., De Larrard, F., Sedran, T., Boulay, C., Bosc, F. and

Deflorenne, F., 'Validation of BTRHEOM, the new rheometer

for soft-to-fluid concrete', .Mater. Struct. 29 (194) (December

1996).

[7] Hu, C. and De Larrard, F., 'The rheology of fresh high-performance concrete', Cement and ConcreteResearch26 (2) (1996) 283294.

[8] Coussot, P. and Piau, J.-M., 'A large-scale field coaxial cylinder

rheometer for the study of the rheology of natural coarse suspensions',doumal of Rheology 39 (1995) 104-123.

[9] 'Standard Test Method for Slump of Hydraulic Cement

Concrete', ASTM C143-90, vol. 04.02, 1995.

[10] De Larrard, F., Sedran, T., Hu, C., Sitzkar, J.C., Joly, M. and

Derkx, F., 'Evolution of the workability of superplasticized concretes: assessment with BTRJqEOM rheometer', Proceedings of

the International RILEM Conference on Production Methods

and Workability of Concrete, Paisley, edited by P.J.M. Bartos,

D.L. Marrs and D.J. CMand, June 1996, 377-388.

[11] Bird, R.B., Dai, G.C. and Yarusso, B.J., 'The rheology and flow

ofviscoplastic materials', Rev. Chem.Eng. 1 1-70.

498

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ICTAD Procurement of Work ICTAD SBD 01-2007Document80 pagesICTAD Procurement of Work ICTAD SBD 01-2007Wickramathilaka198196% (146)

- ICTAD Procurement of Work ICTAD SBD 01-2007Document80 pagesICTAD Procurement of Work ICTAD SBD 01-2007Wickramathilaka198196% (146)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Disadvantages of Ductile Iron Pipe: Comparision Di HdpeDocument5 pagesDisadvantages of Ductile Iron Pipe: Comparision Di Hdpeengineer63No ratings yet

- Overhead Pedestrian Crossings Reduce Travel CostsDocument18 pagesOverhead Pedestrian Crossings Reduce Travel CostsMohamedRaahimNo ratings yet

- Sri Emr PDFDocument101 pagesSri Emr PDFMohamedRaahimNo ratings yet

- Thesis Final Document Tall BuildingsDocument194 pagesThesis Final Document Tall BuildingsPab Fer Man100% (3)

- Design For RC Flat Slabs 1 PDFDocument70 pagesDesign For RC Flat Slabs 1 PDFMohamedRaahimNo ratings yet

- Green Buildings For Sustainable Built Environment in Sri Lanka-Lecture 6 PDFDocument7 pagesGreen Buildings For Sustainable Built Environment in Sri Lanka-Lecture 6 PDFMohamedRaahimNo ratings yet

- EIAKukulaText Eng PDFDocument100 pagesEIAKukulaText Eng PDFMohamedRaahimNo ratings yet

- 3199 9209 1 PB PDFDocument9 pages3199 9209 1 PB PDFMohamedRaahimNo ratings yet

- Design For RC Flat Slabs 1 PDFDocument70 pagesDesign For RC Flat Slabs 1 PDFMohamedRaahimNo ratings yet

- CE4921 Module Guide-2016 PDFDocument10 pagesCE4921 Module Guide-2016 PDFMohamedRaahimNo ratings yet

- BSR Civil 2011Document116 pagesBSR Civil 2011Karma Jamtsho100% (1)

- National Environmental ActDocument15 pagesNational Environmental ActSanjaya RupasingheNo ratings yet

- CE 4921 - Recap Questions-Set 1 PDFDocument7 pagesCE 4921 - Recap Questions-Set 1 PDFMohamedRaahimNo ratings yet

- Colombo Port City ProjectDocument6 pagesColombo Port City ProjectMohamedRaahimNo ratings yet

- Notes 4 PDFDocument18 pagesNotes 4 PDFMohamedRaahimNo ratings yet

- Notes 6geology NotesDocument13 pagesNotes 6geology Notesmecajun1No ratings yet

- Boserup1965 PDFDocument108 pagesBoserup1965 PDFJuan DavidNo ratings yet

- Geo NotesDocument7 pagesGeo Noteskeshav1980No ratings yet

- Notes 5 Geology NotesDocument7 pagesNotes 5 Geology Notesmecajun1No ratings yet

- Notes 3 PDFDocument20 pagesNotes 3 PDFMohamedRaahimNo ratings yet

- (Raissa P. Douglas) Properties of Self-Consolidati PDFDocument84 pages(Raissa P. Douglas) Properties of Self-Consolidati PDFMohamedRaahimNo ratings yet

- Notes 8 Geology Notes Geology NotesDocument7 pagesNotes 8 Geology Notes Geology Notesmecajun1No ratings yet

- Teori Self Compacting ConcreteDocument11 pagesTeori Self Compacting ConcretediartoNo ratings yet

- Monteiro1997 PDFDocument7 pagesMonteiro1997 PDFMohamedRaahimNo ratings yet

- Notes 7 Geology Notes Geology NotesDocument13 pagesNotes 7 Geology Notes Geology Notesmecajun1No ratings yet

- Notes 2geology NotesDocument9 pagesNotes 2geology Notesmecajun1No ratings yet

- (Raissa P. Douglas) Properties of Self-Consolidati PDFDocument84 pages(Raissa P. Douglas) Properties of Self-Consolidati PDFMohamedRaahimNo ratings yet

- Nehdi2004 PDFDocument15 pagesNehdi2004 PDFMohamedRaahimNo ratings yet

- Larrard1998 PDFDocument5 pagesLarrard1998 PDFMohamedRaahimNo ratings yet

- Hkaa Gm&Ws - July 2019Document2 pagesHkaa Gm&Ws - July 2019Alvin To AAHK0% (1)

- InvestmentDocument5 pagesInvestmentMohamed Ali100% (1)

- SV60 Safety Valves: For Use With Steam, Gas and LiquidsDocument8 pagesSV60 Safety Valves: For Use With Steam, Gas and LiquidscmpuckNo ratings yet

- A Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Document31 pagesA Review On Hydrogen Embrittlement Risk Based Inspection 1688970506Pranav PramodNo ratings yet

- K2 PDFDocument48 pagesK2 PDFstctoolNo ratings yet

- Surge CalculationsDocument21 pagesSurge CalculationsHieuNo ratings yet

- Corbec Guide-Pliage Eng CourrielDocument36 pagesCorbec Guide-Pliage Eng CourrielOlgalycosNo ratings yet

- Buttress Wall - R1Document110 pagesButtress Wall - R1عصام السامرائيNo ratings yet

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaNo ratings yet

- EN 760 (Flux-SAW)Document2 pagesEN 760 (Flux-SAW)HoangNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- Coatings For Extreme Applications: Perma-Z Hi-Pro-ZDocument4 pagesCoatings For Extreme Applications: Perma-Z Hi-Pro-Zrijothomasv777No ratings yet

- Seminar S.G IronDocument32 pagesSeminar S.G Ironravikataria02No ratings yet

- SECTION 211313 Wet Pipe Sprinkler SystemsDocument7 pagesSECTION 211313 Wet Pipe Sprinkler SystemsDanZel DanNo ratings yet

- Proje Celik DoğanDocument15 pagesProje Celik Doğanmert180No ratings yet

- Imperfections in The Atomic and Ionic ArrangementsDocument66 pagesImperfections in The Atomic and Ionic Arrangementssusanweb100% (1)

- ARNOLD - Thread Forming ScrewDocument4 pagesARNOLD - Thread Forming ScrewgirishawantiNo ratings yet

- Multiple Choice Question Material ScienceDocument2 pagesMultiple Choice Question Material Sciencemanish_agr8567% (3)

- Cumene Storage Tank DesignDocument8 pagesCumene Storage Tank DesignMaria Eloisa Angelie ArellanoNo ratings yet

- Edutor Tank MixerDocument2 pagesEdutor Tank MixerLeandro BuosiNo ratings yet

- Ratings of Cables in Tunnels - The Heart of the MatterDocument3 pagesRatings of Cables in Tunnels - The Heart of the Mattersaghaee.rezaNo ratings yet

- ACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Document5 pagesACI 350 06 ACI224R 01 Rec Sec Flexural Crack Width Control Rev00 07 Sep 2013Aie Bantugan100% (5)

- PSV LPG TankDocument8 pagesPSV LPG TankyosafatedenNo ratings yet

- 3 - Engineering Critical Analyses To BS 7910 - in UK Guide On Methods For Assessing The Acceptability of Flaws in Metallic StructurDocument11 pages3 - Engineering Critical Analyses To BS 7910 - in UK Guide On Methods For Assessing The Acceptability of Flaws in Metallic StructurRenato Vargas100% (1)

- Stirling Engine Project ReportDocument39 pagesStirling Engine Project Reportapi-328800450100% (2)

- Optimization of Cooling TowersDocument49 pagesOptimization of Cooling TowersKhalil LasferNo ratings yet

- Fretting Wear in An Interference FiDocument13 pagesFretting Wear in An Interference Fism_carvalhoNo ratings yet