Professional Documents

Culture Documents

Mil Cid A A 52082

Uploaded by

kpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mil Cid A A 52082

Uploaded by

kpCopyright:

Available Formats

INCH-POUND

A-A-52082D

17 AUGUST 2009

SUPERSEDING

A-A-52082C

4 SEPTEMBER 2007

COMMERCIAL ITEM DESCRIPTION

TAPE, LACING AND TYING, TFE-FLUOROCARBON

The General Services Administration has authorized the use of this commercial item

description as a replacement for Type III of MIL-T-43435B for all federal agencies.

1. SCOPE. This Commercial Item Description (CID) covers TFE-fluorocarbon (tetra fluorocarbon) tape,

flat braided, for lacing and tying.

2. CLASSIFICATION. Tape shall conform to the sizes and finishes as specified. (see 3.3 and 3.6)

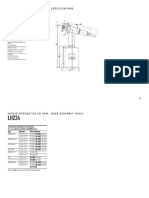

2.1 Size. The size shall be identified as 2, 4 and 5. (see Table 1)

2.2 Finish. The finish shall be identified as A or C. (see 3.6)

3. SALIENT CHARACTERISTICS.

3.1 Material. The yarn used in the fabrication of the tape shall be a high tenacity, continuous

filament, TFE-fluorocarbon yarn.

3.2 Construction. The tape shall be a flat braid construction.

3.3 Physical requirements. Tape shall conform to the requirements of Table 1.

TABLE 1: Tape, Lacing and Tying, TFE-Fluorocarbon

Size

2

4

5

Width

in inches

Min

Max

.108

.132

.059

.072

.023

.028

Thickness

in inches

Min

Max

.009 .014

.009 .014

.009 .014

Breaking

strength

(Lbs, min)

30

15

10

3.4 Elongation. Maximum elongation at breaking strength shall not be greater than 30% when

tested as specified in Fed-STD-191 Method 4108. This test to be performed simultaneously with

breaking strength.

3.5 Color. Unless otherwise specified (see 7.4), the color of the tape shall be natural.

3.6 Finish. A finish option shall be specified, in accordance with 3.6.1 or 3.6.2. Tape finishes

shall not contain any mercury or copper. All finishes shall be able to be used freely in direct contact with

insulated cable or wire.

Comments, suggestions, or questions on this document should be addressed to Defense Supply

Center Philadelphia (DSCP), ATTN: DSCP-NASA, 700 Robbins Avenue, Philadelphia, PA 191115096 or e-mail to dscpg&inspecomments@dla.mil . Since contact information can change, you may

want to verify the currency of this address information using ASSIST Online database at

http://assist.daps.dla.mil .

FSC 4020

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52082D

3.6.1 Finish A - Natural. No finish shall be added.

3.6.2 Finish C - Synthetic rubber. Tape shall be uniformly impregnated with a synthetic rubber or

elastomer finish. Treated tape shall contain 7-17% rubber by weight. (see 5.2.1)

3.7 Deleted.

3.8 Put-up. Unless otherwise specified, the tape shall be furnished on parallel wind spools

(reels) or universal wind tubes (holders). Size 2 tape shall be put-up in a minimum of 250 yard lengths,

and size 4 and 5 tapes shall be put-up in a minimum of 500 yard lengths. The tape shall be free from

twists, lumps, or projecting ends and shall be evenly wound so that each turn and layer is free from

entanglement and twisting. There shall be no more than four pieces per reel or holder, and no piece shall

be less than 50 yards in length.

3.9 Breaking strength Minimum breaking strength shall be as stated in Table 1 when tested as

specified in FED-STD-191 Method 4108

3.10 Fungus resistance. No tape shall show visible growth (to the naked eye) of fungus on the

surface of the test specimens when tested as specified in FED-STD-191 Method 5760.

3.11 Blocking. There shall be no visible damage or removal of the coatings on finish C tapes

when tested as specified in 5.2.3.

3.12 Accelerated aging. When specified (see 7.4), finish C tapes shall show no evidence of

stiffness, brittleness, softness, or tackiness when tested as specified in FED-STD-191 Method 5852,

except that the specimen shall be six inches in length by the full width of the tape.

3.13 Identification. Tape shall be tagged with a label or ticket containing at least the following

information: CID part number, National Stock Number, date of manufacture, and manufacturers name.

When put-up is non-standard, the tag shall indicate the actual length.

4. REGULATORY REQUIREMENTS

4.1 The offerer/contractor is encouraged to use recovered materials to the maximum extent

practicable, in accordance with paragraph 23.403 of the Federal Acquisition Regulation (FAR).

4.2 Type 3 tape shall be accompanied by a warning label or sheet calling attention to the

generation of hazardous vapors at temperatures above 400 degrees fahrenheit (204 degrees celsius).

5. PRODUCT CONFORMANCE PROVISIONS.

5.1 Product conformance. The products provided shall meet the salient characteristics of this

commercial item description, conform to the producers own drawings, specifications, standards, and

quality assurance practices and be the same product offered for sale in the commercial market. The

government reserves the right to require proof of such conformance.

2

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52082D

5.2 Inspection requirements

5.2.1 Determination of percentage of finish. The percentage of finish C impregnating materials

on the respective type tapes shall be determined during processing, by the manufacturer, by weighing an

identical sample of tape or yarn (see 3.6), before and after the impregnating process. The test specimen

shall be a minimum of 30 yards of tape or 120 yards of yarn as applicable. Weight (Length per pound)

shall be determined in accordance with Method 4010 of FED- STD-191. The percentage of finish shall be

calculated as follows:

Percent Finish

A-B x 100

A

Where: A = Length per pound of untreated tape or yarn, as applicable.

B = Length per pound of treated tape or yarn, as applicable.

5.2.2 Deleted.

5.2.3 Determination of blocking. Ten turns of the tape shall be wound on a one-quarter inch

diameter clean metal mandrel under a two pound tension and the end secured through holes in the

mandrel. Eight turns of tape shall then be wound on top of the first layer under the two pound tension

and the ends secured as before. The wound mandrel shall then be placed in a temperature controlled

oven at 70 1o C for two hours, and in such a manner that no part of the specimen comes in contact with

the surface of the oven. The specimen shall then be removed and cooled at room temperature. After

cooling, the outer layer shall be unwound and examined for evidence of damage to the coatings due to

adhesion between layers of turns. The first layer shall be examined while still in place for similar

evidence of adherence and damage.

6. PACKAGING.

6.1 Preservation, packing and marking shall be as specified in the contract or order.

7. NOTES.

7.1 Intended use. The tape is intended for lacing and tying electrical wire and cable bundles.

Tape with finish C provides the best knot holding characteristics. TFE-fluorocarbon may provide good

resistance to fluids and fuels. Useful temperature range of TFE-fluorocarbon tape is -100 F to 450 F.

7.2 Part Identification Number (PIN). The PIN shall consist of the basic CID number, followed by

the finish code letter from 3.6, followed by the size number from Table 1.

PIN Example:

AA52082 - A - 2

Size from Table 1

Finish from 3.5

Basic CID number

7.3 Source of documents.

7.3.1 Government documents. FED-STD-191 Textile Test Methods is available from the Navy

Publications and Printing Service Office, Standardization Document Order Desk, Bldg. 4D, 700 Robbins

Avenue, Philadelphia, PA 19111-5094 or at http://assist.daps.dla.mil.

7.4 Ordering data.

a.

b.

c.

d.

e.

Title, Number and Date of this Commercial Item Description.

Size and finish required (see 3.3 and 3.6).

Color, if other than specified (see 3.5).

Put-up if other than specified (see 3.8).

When accelerated aging is required (see 3.12).

3

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

A-A-52082D

7.5 National Stock Numbers (NSNs). The following is a list of NSNs assigned which correspond

to this CID. This list may not be indicative of all possible NSNs associated with the CID.

NSN

4020-00-809-9407

4020-01-446-4647

Type

3

3

Size

4

4

Finish

A

C

7.6 Changes from previous issue. The margins of this specification are marked with vertical lines

to indicate where changes from the previous issue were made. This was done as a convenience only

and the Government assumes no liability whatsoever for any inaccuracies in these notations. Bidders

and contractors are cautioned to evaluate the requirements of this document based on the entire content

irrespective of the marginal notations and relationship to the last previous issue.

MILITARY INTERESTS:

CUSTODIANS:

Army - GL

Navy - SH

Air Force - 99

CIVIL AGENCY COORDINATING ACTIVITIES:

GSA - FAS

PREPARING ACTIVITY:

DLA - IS

REVIEWERS:

Army - AR, CR, CR4, MD, MI

Navy - AS, MC, OS

Air Force 71

(Project 4020-2009-006)

NOTE: The activities listed above were interested in this document as of the date of this document. Since

organizations and responsibilities can change, you should verify the currency of the information above

using the ASSIST Online database at http://assist.daps.dla.mil

4

Source: https://assist.dla.mil -- Downloaded: 2015-03-06T06:48Z

Check the source to verify that this is the current version before use.

You might also like

- Aramid Tape CIDDocument4 pagesAramid Tape CIDkpNo ratings yet

- Mil Cid A A 52083Document4 pagesMil Cid A A 52083kpNo ratings yet

- Tape CIDDocument5 pagesTape CIDbabshuagNo ratings yet

- MGVCL Cables Technical SpecDocument10 pagesMGVCL Cables Technical SpecRAJ PATELNo ratings yet

- D 5168 - 03 - RduxnjgDocument6 pagesD 5168 - 03 - Rduxnjgjamaljamal20No ratings yet

- Aerospace Material SpecificationDocument10 pagesAerospace Material SpecificationanilkumarNo ratings yet

- CBLCT-3.4 Cable TilesDocument11 pagesCBLCT-3.4 Cable Tilesdhayalasundaram5689No ratings yet

- Shelter Half SpecDocument21 pagesShelter Half Speccjnjr1No ratings yet

- Mil PRF 26514Document30 pagesMil PRF 26514anon_513551868No ratings yet

- MIL Aa 58092Document6 pagesMIL Aa 58092sanjay_aranakeNo ratings yet

- Check The Source To Verify That This Is The Current Version Before UseDocument4 pagesCheck The Source To Verify That This Is The Current Version Before UseBryan MartinezNo ratings yet

- Mil DTL 5886HDocument21 pagesMil DTL 5886HjohnneracalNo ratings yet

- Reinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsDocument6 pagesReinforced and Filled Poly (Phenylene Sulfide) (PPS) Injection Molding and Extrusion Materials Using ASTM MethodsJosé Miguel Palomino GarciaNo ratings yet

- Astm F477-08Document4 pagesAstm F477-08ALARCONISTANo ratings yet

- LT XLPE Power Cable SpecificationDocument9 pagesLT XLPE Power Cable SpecificationRakesh ShinganeNo ratings yet

- Mil C 44048GDocument54 pagesMil C 44048GutentefintoNo ratings yet

- Chocks, Panama, Mooring CastDocument3 pagesChocks, Panama, Mooring CastLyudmyla BobinaNo ratings yet

- GL PD 08 81BDocument18 pagesGL PD 08 81BgearshoutNo ratings yet

- 150 5345 26DDocument21 pages150 5345 26DmarckalhiNo ratings yet

- Check The Source To Verify That This Is The Current Version Before UseDocument31 pagesCheck The Source To Verify That This Is The Current Version Before Useketab_doostNo ratings yet

- Technical Specifications 2c X 4 mm2 4C X 6mm2 XLPE 2025Document7 pagesTechnical Specifications 2c X 4 mm2 4C X 6mm2 XLPE 2025cricket storiesNo ratings yet

- 48 TMSS 01 R0Document0 pages48 TMSS 01 R0renjithas2005No ratings yet

- D 5047 - 95 - RduwndctotuDocument3 pagesD 5047 - 95 - RduwndctotuSérgio CallaiNo ratings yet

- Scotchcast Polyolefin Fibers: For Use in Wet-Mix ShotcreteDocument2 pagesScotchcast Polyolefin Fibers: For Use in Wet-Mix Shotcretejack21abNo ratings yet

- Aerospace Material Specification: Cloth, Glass, Finished, For Resin Laminates FSC 8305Document17 pagesAerospace Material Specification: Cloth, Glass, Finished, For Resin Laminates FSC 8305anilkumar100% (1)

- FS Ss-S-200eDocument23 pagesFS Ss-S-200eGiorgos LympertasNo ratings yet

- Mil PRF 81705d - Esd BagDocument28 pagesMil PRF 81705d - Esd BagRNo ratings yet

- Coal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingDocument3 pagesCoal-Tar-Saturated Organic Felt Used in Roofing and WaterproofingRufo CascoNo ratings yet

- 2014 12 05 - Wi PFX GRP 0001Document22 pages2014 12 05 - Wi PFX GRP 0001hariharanoilgasNo ratings yet

- C 1032 - 96 r02 QzewmzitukveDocument5 pagesC 1032 - 96 r02 QzewmzitukveHumberto GutierrezNo ratings yet

- 1v005 045Document24 pages1v005 045Romany AllamNo ratings yet

- Bitumen-Saturated Cotton Fabrics 2Document4 pagesBitumen-Saturated Cotton Fabrics 2A MahmoodNo ratings yet

- Mil PRF 121gDocument14 pagesMil PRF 121gacapocNo ratings yet

- 23 TMSS 02 R0Document0 pages23 TMSS 02 R0renjithas2005No ratings yet

- 6C9FDB6B0AD9436FB05722DB4EED4B61Document9 pages6C9FDB6B0AD9436FB05722DB4EED4B61Gabrielle JohnsonNo ratings yet

- Australian Standard: Extruded Rod and TubeDocument14 pagesAustralian Standard: Extruded Rod and TubeWidodo MuisNo ratings yet

- Astm C 171 2007Document2 pagesAstm C 171 2007sabruno100% (3)

- CW2Document38 pagesCW2Steve CowanNo ratings yet

- Is 15466 (2004)Document16 pagesIs 15466 (2004)slamienkaNo ratings yet

- ASTM D2467-1999 Accesorios PlasticosDocument8 pagesASTM D2467-1999 Accesorios PlasticosRicardoLauferNo ratings yet

- FS4005 Cable TraysDocument8 pagesFS4005 Cable TraysRamesh AnanthanarayananNo ratings yet

- A Standard For Asphaltic Plug JointsDocument20 pagesA Standard For Asphaltic Plug JointsbrelightsNo ratings yet

- Mil DTL 6000Document17 pagesMil DTL 6000John Néstor Ramirez CalderónNo ratings yet

- VT285Document19 pagesVT285Florin NiteNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument8 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- C 475 C 475m 01 Qzq3ns9dndc1ts1sruq PDF FreeDocument3 pagesC 475 C 475m 01 Qzq3ns9dndc1ts1sruq PDF FreeManuela AvendañoNo ratings yet

- Prihoda Recycled Fabric Duct SpecificationDocument5 pagesPrihoda Recycled Fabric Duct SpecificationaverentzNo ratings yet

- Mil DTL 19834c Amendment 1Document11 pagesMil DTL 19834c Amendment 1Logo SkyNo ratings yet

- F 438 - 99 Rjqzoc05oqDocument5 pagesF 438 - 99 Rjqzoc05oqHumberto GutierrezNo ratings yet

- Plug Terminated Links. It Is Offered As A General Guide. Suitability For Any Intended Use Is The Responsibility of The User. This DocumentDocument9 pagesPlug Terminated Links. It Is Offered As A General Guide. Suitability For Any Intended Use Is The Responsibility of The User. This DocumentGatomeroNo ratings yet

- Astm d1871Document5 pagesAstm d1871Edwin RamirezNo ratings yet

- Binding Sites Per Per Unit Length or Width of Pile Yarn Floor CoveringsDocument7 pagesBinding Sites Per Per Unit Length or Width of Pile Yarn Floor CoveringsJuanNo ratings yet

- Pressure Releaving StationDocument11 pagesPressure Releaving StationSreejesh Sundaresan100% (1)

- Parts List For Electrostatic Precipitator 1F400/H2P1/3x40-1x128150/1K/1K/L2D Access FacilitiesDocument12 pagesParts List For Electrostatic Precipitator 1F400/H2P1/3x40-1x128150/1K/1K/L2D Access Facilitieshiddenhidden16No ratings yet

- 09 66 13 Portland Cement Terrazzo FlooringDocument9 pages09 66 13 Portland Cement Terrazzo FlooringHans Hans SadzNo ratings yet

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Document9 pagesSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashNo ratings yet

- Evaluating High-Density Rigid Cellular Thermoplastics PlasticsDocument4 pagesEvaluating High-Density Rigid Cellular Thermoplastics PlasticsdanoninoNo ratings yet

- MS-JF-1000 - Rev B - Jan 2018 - Seating and DoorsDocument19 pagesMS-JF-1000 - Rev B - Jan 2018 - Seating and DoorsKnw CalidadNo ratings yet

- Ves 5145 R3Document10 pagesVes 5145 R3danikakaNo ratings yet

- Huck® Interactive CD Rom: Specifications: Hydraulic Installation ToolDocument2 pagesHuck® Interactive CD Rom: Specifications: Hydraulic Installation ToolkpNo ratings yet

- Huck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolDocument2 pagesHuck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolkpNo ratings yet

- 224Document2 pages224kpNo ratings yet

- Professional Manufacturer in High Tg Copper Clad LaminatesDocument3 pagesProfessional Manufacturer in High Tg Copper Clad LaminateskpNo ratings yet

- Huck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolDocument2 pagesHuck® Interactive CD Rom: Specifications: Pneudraulic Powered Installation ToolkpNo ratings yet

- Mil DTL 22529 - 1Document4 pagesMil DTL 22529 - 1kpNo ratings yet

- General Semiconductor 1N56xxDocument3 pagesGeneral Semiconductor 1N56xxkpNo ratings yet

- NMC G24 Flanged Hole Grommet ProtectionDocument2 pagesNMC G24 Flanged Hole Grommet ProtectionkpNo ratings yet

- 202VDocument2 pages202VkpNo ratings yet

- KEMET Part Number: PHE450MD6270JR06L2: (F450DT274J630Z)Document1 pageKEMET Part Number: PHE450MD6270JR06L2: (F450DT274J630Z)kpNo ratings yet

- NMC G51Document2 pagesNMC G51kpNo ratings yet

- NMC GR1554Document2 pagesNMC GR1554kpNo ratings yet

- Altera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingDocument2 pagesAltera MT2000 Modified, Medical Grade, Polyolefin, Heat - Shrinkable TubingkpNo ratings yet

- Ixys Dss 2x101-015aDocument3 pagesIxys Dss 2x101-015akpNo ratings yet

- Application Guide BlockingDocument1 pageApplication Guide BlockingkpNo ratings yet

- Kemet PHE840MDocument2 pagesKemet PHE840MkpNo ratings yet

- Ms 27488Document9 pagesMs 27488echobravo1No ratings yet

- Eng CD DWP-125 D1Document1 pageEng CD DWP-125 D1kpNo ratings yet

- Te 323062Document1 pageTe 323062kpNo ratings yet

- Eng CD HFT5000 5Document2 pagesEng CD HFT5000 5kpNo ratings yet

- Illinois Capacitor PPBDocument3 pagesIllinois Capacitor PPBkpNo ratings yet

- Eng CD HRSRXHRHFXHRNF d1Document2 pagesEng CD HRSRXHRHFXHRNF d1kpNo ratings yet

- Delron 1835Document2 pagesDelron 1835kpNo ratings yet

- Product Dimensions & Notes: RW-2063 SpecsDocument1 pageProduct Dimensions & Notes: RW-2063 SpecskpNo ratings yet

- Eng CD DR-25 B1Document1 pageEng CD DR-25 B1kpNo ratings yet

- Eng CD DR-25 B1Document1 pageEng CD DR-25 B1kpNo ratings yet

- Eng CD JS-XX-XX HDocument1 pageEng CD JS-XX-XX HkpNo ratings yet

- HF Highly Flexible Heat-Shrinkable TubingDocument2 pagesHF Highly Flexible Heat-Shrinkable TubingkpNo ratings yet

- HF Highly Flexible Heat-Shrinkable TubingDocument2 pagesHF Highly Flexible Heat-Shrinkable TubingkpNo ratings yet

- NKK S Series SwitchesDocument11 pagesNKK S Series SwitcheskpNo ratings yet

- Klueber Summit Varnasolv FG 050017 PI GB enDocument2 pagesKlueber Summit Varnasolv FG 050017 PI GB enRodrigo Augusto TeixeiraNo ratings yet

- CBADocument7 pagesCBAAida Kamila ArzulkhaNo ratings yet

- RS232 ProtocolDocument2 pagesRS232 ProtocolAneesh RaveendranNo ratings yet

- 70-410 SyllabusDocument4 pages70-410 SyllabusraadreamzNo ratings yet

- Piper Pa-28r-201 Arrow - Normal ProceduresDocument2 pagesPiper Pa-28r-201 Arrow - Normal ProceduresSinan ÖzNo ratings yet

- Electrical Safety 3 Steps To Test Your RCCB PosterDocument1 pageElectrical Safety 3 Steps To Test Your RCCB PosterGoogool YNo ratings yet

- Bonfiglioli Products Range GuideDocument40 pagesBonfiglioli Products Range GuideTauseef EjazNo ratings yet

- Roof Mounted Fan Performance DataDocument14 pagesRoof Mounted Fan Performance DataCapserVNo ratings yet

- Unified Maneuvering and Seakeeping TheoryDocument28 pagesUnified Maneuvering and Seakeeping TheoryGeoffjones4No ratings yet

- Grounding Products MACDocument26 pagesGrounding Products MACAshley Julietita AriasNo ratings yet

- Statcom Static Synchronous Compensator: Theory, Modeling, ApplicationsDocument7 pagesStatcom Static Synchronous Compensator: Theory, Modeling, ApplicationsCesario GillasNo ratings yet

- BS 5977 - 1 Lintels PDFDocument14 pagesBS 5977 - 1 Lintels PDFTom YeeNo ratings yet

- Wollam - Bryan API Q2 PDFDocument18 pagesWollam - Bryan API Q2 PDFsyedainahmadNo ratings yet

- Course Outline-Hydraulics and PneumaticsDocument2 pagesCourse Outline-Hydraulics and Pneumaticsmuru0105100% (1)

- Slide Gates Eng Guide BrochureDocument6 pagesSlide Gates Eng Guide Brochureraghunandanr1993No ratings yet

- RMFDocument245 pagesRMFsuryadiwaNo ratings yet

- Writing technical reports guideDocument15 pagesWriting technical reports guidemuhammad_ajmal_25No ratings yet

- De400 CatDocument2 pagesDe400 CatLena LorenkoNo ratings yet

- Basic Principles of PropulsionDocument45 pagesBasic Principles of PropulsionEverson VieiraNo ratings yet

- Andis BGR ManualDocument24 pagesAndis BGR ManualRebeca BookerNo ratings yet

- Autonomous Vehicle Implementation Predictions: Implications For Transport PlanningDocument19 pagesAutonomous Vehicle Implementation Predictions: Implications For Transport PlanningLethal11No ratings yet

- Paint ProductionDocument40 pagesPaint ProductionNemerem Ignatius80% (5)

- Document Numbering Procerdure Rev 1Document1 pageDocument Numbering Procerdure Rev 1Mohammed AshrafNo ratings yet

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- The Affinity Laws of Centrifugal PumpsDocument5 pagesThe Affinity Laws of Centrifugal PumpsJohannis ReyNo ratings yet

- Turboplast Metric PDFDocument2 pagesTurboplast Metric PDFdeli34No ratings yet

- Chinese Code Implementation 2Document19 pagesChinese Code Implementation 2Partha Pratim RoyNo ratings yet

- Unigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsDocument48 pagesUnigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsMohd Nawawi Ab AzizNo ratings yet

- Guidance Note On WeldingDocument102 pagesGuidance Note On WeldingVishal SharmaNo ratings yet

- Datasheet de Uma Memória Eeprom - 95640Document46 pagesDatasheet de Uma Memória Eeprom - 95640Anthony AndreyNo ratings yet