Professional Documents

Culture Documents

Lean Six Sigma Black Belt Body of Knowledge PDF

Uploaded by

black bettyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean Six Sigma Black Belt Body of Knowledge PDF

Uploaded by

black bettyCopyright:

Available Formats

Lean Six Sigma Black Belt Body of Knowledge

1) History of Continuous Improvement

Western vs. Eastern Models

The 14 Deming Principles, The Deming Wheel, Seven Deadly Diseases

Joseph M. Juran, Pareto Principle, The Management Theory, The Quality Triolog

y

Phil Crosby, Quality Improvement Program, Stages of Improvement

Water Shewart, Statistical Process Control

Value Engineering

IDEAL Model

Seven QC Tools

New Seven QC Tools

Quality Circles

KAIZEN

Poka Yoke (Mistake Proofing)

5S

Total Productive Maintenance

Just-in-Time

2) Overview of Lean Six Sigma

Industry Snippets

What is Lean Six Sigma

Why is it so successful

Lean vs. Six Sigma

When to use Lean or Six Sigma and When not to use?

When do Individuals and Organizations Fail using Lean and Six Sigma

3) Perspectives of Lean Six Sigma

Historical Perspective

Evolution of Six Sigma

Mean vs. Variation

Quantitative Perspective

Statistical Perspective

Customer Perspective

Operational Perspective

Toyota Production System

Lean Thinking and Waste Elimination

Lean Benefits

Lean Toolkit

Lean Tool Overview

Integration of Lean and Six Sigma

4) Case Studies on Lean Six Sigma

10 short case studies of Lean Six Sigma

5) Leadership

Leadership Selection

Driving Benefits and Results

Questioning, Analysis and Decision Making Skills

Responsibilities of Leaders

Two Dimensions of Employee Satisfaction (Hygiene Factors and Motivators)

6) Leadership Change Management

Change Management

Change Acceleration Process

ARMI and RACI Matrix

GRPI Model

Stakeholder Analysis

7) Team Management

Organization Structures, pros and cons

Functional Structures, Divisional Structures, Customer & Matrix Structures, Netw

ork Structures, Virtual Structures

Formal Team Structures

Informal Team Structures

Cross Functional Teams

Foundations of Teamwork

Team Roles (Roles, Tasks, Formal Roles, Informal Roles, Team Leader, Team

Member, Team Facilitator, Additional Roles)

Team Member Selection

Building High-performance Teams

Launching Teams (Forming, Storming, Norming, Performing, Adjourning)

Factors effecting team performance

Schmidts view of conflicts

Delegation and SMART Goals

Team Motivation through Mentoring, Incentives and Feedback

Team Mentoring: Mentor Mentee Relationship

Team Mentoring: Lev VygotskyCognitive apprenticeship

Team Incentives: Incentive schemes

Team Feedback Management

Maslows Hierarchy of Needs

Sustenance of Change and Building Team and Organization Cultures

Four Quadrant Culture Management Model

Communication (Planning, Information Distribution, Performance Reporting, Man

aging Stakeholders)

Conflict Management

Running Meetings Effectively

Team Dynamics

Team Dynamics: Common Team Problems

Team Dynamics: Group Cohesion

Team Dynamics: Groupthink

Time Management

Team Decision Making

Team Decision Making: Brainstorming

Team Decision Making: Nominal Group Technique

Team Decision Making: Multi-voting

Management and Planning: Affinity Processes

Management and Planning: Tree Diagrams

Management and Planning: Process Decision Program Chart (PDPC)

Management and Planning: Matrix Diagrams

Management and Planning: Interrelationship Diagram Steps

Management and Planning: Prioritization Matrices

Management and Planning: Activity Network Diagram

Team Performance Evaluation and Rewards

Team Performance Evaluation and Rewards: 360 Evaluation

Team Performance Evaluation and Rewards: Reinforcement Theory

Team Performance Evaluation and Rewards: Intrinsic and Extrinsic Rewards

Team Performance Evaluation and Rewards: Administering Rewards

Team Performance Evaluation and Rewards: Innovative Reward Systems

8) Lean Six Sigma Organization

Lean Six Sigma Success Factors

A Lean Six Sigma Organization

Lean Six Sigma Roles and Responsibilities

Lean Six Sigma Champion

Lean Six Sigma Master Black Belts

Lean Six Sigma Black Belts

Lean Six Sigma Green Belts

Lean Six Sigma Yellow Belts

Lean Six Sigma White Belts

9) Recognize Phase

Strategic Priorities

Core / Non-core Process Identification

SWOT of Core Process

Customer Complaint Analysis

VRIO Analysis of Strengths, Weaknesses and Opportunities

Business Perceptions and Feedback

Matrix b/w Strategic Competitive Edge and Impact to Strategic Priorities

KINDUZ Business Excellence Framework

Baldrige Criteria for Performance Excellence Framework

European Foundation for Quality Management

Balanced Score Card

Cost of Quality

Understanding Financial Statements

Financial Metrics

10) Define Phase

Customer Identification

Market Segmentation

Market Sizing

Obtaining Voice of Customers (VOC) (Surveys, Focus Groups, Interviews, Custo

mer complaints, etc.)

Quality vs. Perceived Quality

Survey development steps

Customer Insight Research

KANO Model

Quality Function Deployment

Critical to Satisfaction Characteristics: CTQ, CTD, CTP, CTX

Converting VOC to CTS / CTQ

9-3-1-0 Analysis of CTQs

Defining CTQ Targets (USL & LSL)

Defining CTQ Tolerance Limits

CTQ Drill Down Chart

Team Charter

Defining Business Case

Defining Problem Statement

Defining Goal Statement and Estimated Benefits

Defining Financial Impact

Defining Project In-Scope

Defining Project Out-of-Scope

Defining Constraints i.e. Conflicting CTQs

Mapping to Strategic Priorities of Company

Defining Project Sponsor

Defining Process Owner

Defining Lean Six Sigma Mentor or Coach

Defining Lean Six Sigma Black Belt / Green Belt

Defining Team Members (RACI Matrix)

Work Breakdown Structures

Schedule Definition for DMAIC completion

Earned Value Management

COPIS

IDEF0

Swimlanes

Spaghetti Diagram

Circle Diagrams

Value Stream Mapping

11) Measure Phase

Types of Data (Discrete, Continuous)

Measurement Scales (Nominal, Ordinal, Interval and Ratio)

Sampling vs. Population

Statistics vs. Parameter

Descriptive Statistics vs. Inferential Statistics

Sampling (Random, Stratified, Systematic, etc.)

Sample Size Determination

Process Metrics (WIP, WIQ, TAKT Time, Wait Time, Throughput, etc.)

Defining Segmentation Factors of CTQ

Measurement System Analysis of CTQ

Operational Definition of CTQ and Segmentation Factors

Defining Data Collection Plan for CTQ and Segmentation Factors

Histogram of CTQ and Study of Histograms

Normality Test of CTQ

Mean, Median, Mode

Standard Deviation, Range, Variation Measures for Non-normal data

Defining measure of Central Tendency and Variation

Central Limit Theorem

Z value calculation and practical applications

Calculating Process Capability (Zmin, Cpk)

Calculating Process Capability (Pp, Ppk, and Cpm)

Z-Shift

Calculating Process Capability of Nonnormal data (including transformations like Box-Cox)

Process Capability

Process performance vs. specification (Diff. between natural process limits and s

pecification limits, and calculate process performance metrics

such

as percent defective, parts per million (PPM), defects per million opportunities (D

PMO),

defects per unit (DPU), process sigma, rolled throughput yield (RTY), etc.)

Defining Improvement Goals

Updating Goal Statement and Financial Impact

Time Value Map

Metrology

Causes of Measurement Error

Descriptive Statistics and Graphical Representation (Pie Chart, Bar Chart, Box Pl

ots, Histograms, Pareto Charts, Scatter Plots, Run charts)

Calibration System

Probability concepts (P)

Probability Commonly Used Distributions (normal, Poisson, binomial, chi

square, Student s t, and F distributions)

Probability Other Distributions (bivariate, exponential, lognormal, and Weibull.)

12) Analyze Phase

Control Charts & Identification of Special Causes and Warning Signals in Commo

n Causes

Correlation and Regression Analysis (correlation coefficient)

Confidence Interval for the Mean: Known)

Confidence Interval for the Mean: not known)

Confidence Interval for Standard Deviation

Confidence Interval for Capability Indices and Sigma Level

Confidence Interval for Proportion

Multiple Regression

Multiple Variable Studies

Data Mining with Descriptive Statistics by Variable

Multi-vari Studies

Main Effects Plots

Interactions Plots

Multivariate Statistical Analysis

Sample Size for Proportions Hypothesis Testing

Sample Size for Means Hypothesis Testing

ANNOVA

Hypothesis Testing (Terminology, Statistical Vs. Practical Significance, Sample S

ize,

Point and Interval Estimates, Tests for means, Variances and Proportions, Analy

sis of Variance(ANOVA),

Goodness of Fit(Chi-Square), Contingency Tables, Non Parametric Tests)

Check sheets

Cause Effect Diagrams / Fish Bone Diagrams; 4 types:

Dispersion Analysis

Cause enumeration

Production process classification

Cause Effect Matrix

Pareto Chart

Run chart

Cross Functional Flowchart

Requirements Review

Threads of Similarity

Opportunities of Error

FMEA (RPN, PFMEA, DFMEA)

Gap Analysis (gap analysis, scenario planning, etc.)

Seven Deadly Wastes (MUDA)

Kaizen & Kaizen Blitz

Kaikaku

Continuous Flow

Quick Changeovers / Single Minute Exchange of Die

Pull Production: Just in Time

Pull Production: Kanban

Visual Management

Heijunka: Leveling

Heijunka: Sequencing

Heijunka: Standardization

Jidoka / Autonomation

5S: Sort

5S: Set in Oder

5S: Shine

5S: Standardize

5S: Sustain / Systemize

Poka Yoke: Elimination

Poka Yoke: Replacement

Poka Yoke: Facilitation

Poka Yoke: Detection

Poka Yoke: Mitigation

Benchmarking

Benchmarking: Metrics Benchmarking

Benchmarking: Process Benchmarking

13) Improve Phase

Theory of Constraints

PEST Analysis

Decision Matrix

Effort Impact Matrix

Force Field Analysis

Pilot Plan

Design of Experiments (DOE)

14) Control Phase

Process Control Plan

Statistical Process Control (Objectives, Selection Of Variables, Rational Sub grou

ping, Control chart selection, Control chart analysis)

Other Control Tools (Total productive maintenance (TPM), Visual factory)

Maintain Controls (Measurement System Re-Analysis)

PTAP (Project Transition Action Plan)

Sustain Improvements (Lessons learned, Training plan Deployment, Documentat

ion, Ongoing Evaluation)

Project Closure

Project Sign-off

15) Design for Lean Six Sigma

Common DFSS Methodologies (DMADV, DMADOV)

Design for X (DFX)

Robust Design and Process

Special Design Tools (Strategic, Tactical)

Strategic

Porters five forces analysis, portfolio architecting, and other tools can be used in

strategic design and planning

Tactical theory of inventive problemsolving (TRIZ), systematic design, critical parameter management, and Pugh analysis in

designing products or processes

You might also like

- The Six Sigma Leader: How Top Executives Will Prevail in the 21st CenturyFrom EverandThe Six Sigma Leader: How Top Executives Will Prevail in the 21st CenturyNo ratings yet

- Design for Six SIGMA Complete Self-Assessment GuideFrom EverandDesign for Six SIGMA Complete Self-Assessment GuideRating: 1 out of 5 stars1/5 (1)

- The Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsFrom EverandThe Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsRating: 3.5 out of 5 stars3.5/5 (5)

- Simulation-based Lean Six-Sigma and Design for Six-SigmaFrom EverandSimulation-based Lean Six-Sigma and Design for Six-SigmaRating: 3 out of 5 stars3/5 (2)

- Statistics for Six Sigma Made Easy! Revised and Expanded Second EditionFrom EverandStatistics for Six Sigma Made Easy! Revised and Expanded Second EditionRating: 3 out of 5 stars3/5 (7)

- Six Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneFrom EverandSix Sigma Green Belt, Round 2: Making Your Next Project Better than the Last OneNo ratings yet

- The Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICFrom EverandThe Six Sigma Project Planner: A Step-by-Step Guide to Leading a Six Sigma Project Through DMAICRating: 4.5 out of 5 stars4.5/5 (7)

- Lean Action Workout: Lean Six Sigma Project Execution Essentials, #5From EverandLean Action Workout: Lean Six Sigma Project Execution Essentials, #5No ratings yet

- Lean Six Sigma: The Ultimate Practical Guide. Discover The Six Sigma Methodology, Improve Quality and Speed and Learn How to Improve Your BusinessFrom EverandLean Six Sigma: The Ultimate Practical Guide. Discover The Six Sigma Methodology, Improve Quality and Speed and Learn How to Improve Your BusinessNo ratings yet

- Lean Six Sigma: Combining Six Sigma Quality with Lean Production SpeedFrom EverandLean Six Sigma: Combining Six Sigma Quality with Lean Production SpeedRating: 4 out of 5 stars4/5 (12)

- Lean Six Sigma That Works: A Powerful Action Plan for Dramatically Improving Quality, Increasing Speed, and Reducing WasteFrom EverandLean Six Sigma That Works: A Powerful Action Plan for Dramatically Improving Quality, Increasing Speed, and Reducing WasteRating: 4 out of 5 stars4/5 (1)

- Best Practices in Lean Six Sigma Process Improvement: A Deeper LookFrom EverandBest Practices in Lean Six Sigma Process Improvement: A Deeper LookNo ratings yet

- Maximizing Lean Six Sigma Sustainability: Secrets to Making Lean Six Sigma LastFrom EverandMaximizing Lean Six Sigma Sustainability: Secrets to Making Lean Six Sigma LastNo ratings yet

- Lean Six Sigma - An Introduction and Toolkit (EBOOK BUNDLE)From EverandLean Six Sigma - An Introduction and Toolkit (EBOOK BUNDLE)No ratings yet

- Modular Kaizen Vs Kaizen Blitz: How to Choose Between These Two Kaizen Business Process Improvement Methodologies for Accelerated Productivity, Profitability and Organizational Excellence: Business Process Management and Continuous Improvement Executive Guide series, #7From EverandModular Kaizen Vs Kaizen Blitz: How to Choose Between These Two Kaizen Business Process Improvement Methodologies for Accelerated Productivity, Profitability and Organizational Excellence: Business Process Management and Continuous Improvement Executive Guide series, #7No ratings yet

- The Lean Six Sigma Guide to Doing More With Less: Cut Costs, Reduce Waste, and Lower Your OverheadFrom EverandThe Lean Six Sigma Guide to Doing More With Less: Cut Costs, Reduce Waste, and Lower Your OverheadRating: 4.5 out of 5 stars4.5/5 (10)

- The Big Book of Six Sigma Training Games: Proven Ways to Teach Basic DMAIC Principles and Quality Improvement ToolsFrom EverandThe Big Book of Six Sigma Training Games: Proven Ways to Teach Basic DMAIC Principles and Quality Improvement ToolsRating: 4 out of 5 stars4/5 (7)

- Certified Six Sigma Black Belt A Complete Guide - 2020 EditionFrom EverandCertified Six Sigma Black Belt A Complete Guide - 2020 EditionNo ratings yet

- Lean Six Sigma Project Charter Creation ProcessDocument8 pagesLean Six Sigma Project Charter Creation ProcessSteven Bonacorsi100% (3)

- Lean Six Sigma Black Belt Mock ExamDocument26 pagesLean Six Sigma Black Belt Mock ExamHamid Hamid75% (4)

- Six Sigma ExamDocument5 pagesSix Sigma Exammajid4uonly100% (5)

- Lean Six Sigma ProjectDocument7 pagesLean Six Sigma ProjectOlumide Ambali100% (3)

- Lean Six Sigma Exam Practice QuestionsDocument5 pagesLean Six Sigma Exam Practice Questionswoodsy0802100% (4)

- Lean Six Sigma Green Belt OrientationDocument18 pagesLean Six Sigma Green Belt OrientationJyoti Thonte-BukkapatilNo ratings yet

- Lean Six Sigma OverviewDocument5 pagesLean Six Sigma Overviewexamplecg83% (6)

- Sample ExamDocument38 pagesSample ExamjayarajanNo ratings yet

- CEH Exam Blueprint v2.0Document3 pagesCEH Exam Blueprint v2.0aqil_shamsiNo ratings yet

- CEHv9 Instructor GuideDocument112 pagesCEHv9 Instructor Guideblack bettyNo ratings yet

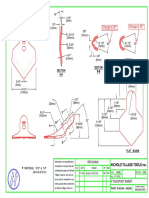

- W 2045002 SaleDocument1 pageW 2045002 Saleblack bettyNo ratings yet

- MindCert CEH Ethical Hacking MindMapDocument1 pageMindCert CEH Ethical Hacking MindMapyki01No ratings yet

- W2045002 SalDocument1 pageW2045002 Salblack bettyNo ratings yet

- W225002 SaleDocument1 pageW225002 Saleblack bettyNo ratings yet

- Certified Ethical Hacking Module 5 MapDocument1 pageCertified Ethical Hacking Module 5 MapRismal Ray VaughanNo ratings yet

- W2045002 - SAL - Rev 06-08Document1 pageW2045002 - SAL - Rev 06-08black bettyNo ratings yet

- Hacking - CEH Cheat Sheet ExercisesDocument49 pagesHacking - CEH Cheat Sheet ExercisesTetuan AzlanNo ratings yet

- W225001 SaleDocument1 pageW225001 Saleblack bettyNo ratings yet

- G9a G9BDocument1 pageG9a G9Bblack bettyNo ratings yet

- W2045002 SalDocument1 pageW2045002 Salblack bettyNo ratings yet

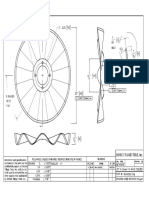

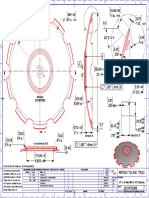

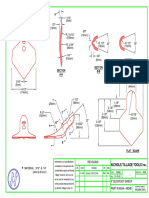

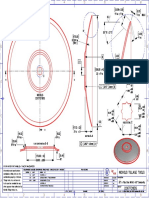

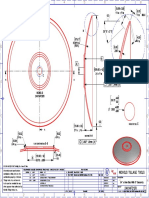

- Seed Disc Assembly SchemeDocument1 pageSeed Disc Assembly Schemeblack bettyNo ratings yet

- W 174001 WfeDocument1 pageW 174001 Wfeblack bettyNo ratings yet

- W184001WFDMEDocument1 pageW184001WFDMEblack bettyNo ratings yet

- W164131 WfeDocument1 pageW164131 Wfeblack bettyNo ratings yet

- MG2B - Rev 01 - 2012-11-16Document1 pageMG2B - Rev 01 - 2012-11-16black bettyNo ratings yet

- MG4A-MG4B - Rev 01 - 2012-11-16Document1 pageMG4A-MG4B - Rev 01 - 2012-11-16black bettyNo ratings yet

- UWQC7 Blank LayoutDocument1 pageUWQC7 Blank Layoutblack bettyNo ratings yet

- 22X14FCN12RDocument1 page22X14FCN12Rblack bettyNo ratings yet

- 22X14FCN18SDocument1 page22X14FCN18Sblack bettyNo ratings yet

- Mg4a MG4BDocument1 pageMg4a MG4Bblack bettyNo ratings yet

- 8" Disk Assembly (Nichols PN 08035DYCAB) 540500: Revisions Zone Rev. Description Date ApprovedDocument1 page8" Disk Assembly (Nichols PN 08035DYCAB) 540500: Revisions Zone Rev. Description Date Approvedblack bettyNo ratings yet

- 24X14FC12SDocument1 page24X14FC12Sblack bettyNo ratings yet

- 22X7FCN18SDocument1 page22X7FCN18Sblack bettyNo ratings yet

- 22X7FC18SDocument1 page22X7FC18Sblack bettyNo ratings yet

- 22X7FC18DSDocument1 page22X7FC18DSblack bettyNo ratings yet

- 24X14FC12RDocument1 page24X14FC12Rblack bettyNo ratings yet

- 22X14FC18SDocument1 page22X14FC18Sblack bettyNo ratings yet

- Applying Lean to Improve Welding OperationsDocument10 pagesApplying Lean to Improve Welding Operationskarthiks12008658No ratings yet

- Chapter 12. B2B E Commerce Supply Chain Management and Collaborative CommerceDocument58 pagesChapter 12. B2B E Commerce Supply Chain Management and Collaborative CommerceThiên HươngNo ratings yet

- Customer Service Center Manager in Chicago IL Resume Mark HardyDocument2 pagesCustomer Service Center Manager in Chicago IL Resume Mark HardyMarkHardy2No ratings yet

- The Lean Concept in The Food IndustryDocument11 pagesThe Lean Concept in The Food Industryfelipe_aaNo ratings yet

- Test Bank For M Management 3rd Edition Bateman Full DownloadDocument67 pagesTest Bank For M Management 3rd Edition Bateman Full Downloadmelissapollardoxieprwsdb100% (44)

- Introduction To Computer-Aided Engineering (Lecture #2)Document59 pagesIntroduction To Computer-Aided Engineering (Lecture #2)Rodion CiupercaNo ratings yet

- Supply Chain Management of Nike Company ProjectDocument26 pagesSupply Chain Management of Nike Company ProjectflemingNo ratings yet

- FDC - Kaizen One Pager NLSDocument1 pageFDC - Kaizen One Pager NLSEduardo MaganaNo ratings yet

- Infor LXDocument4 pagesInfor LXcarrot123456No ratings yet

- Achieving Sustainability Through Lean ProductionDocument9 pagesAchieving Sustainability Through Lean ProductionWya Kara Da SilvaNo ratings yet

- Ford Motor Company Case StudyDocument4 pagesFord Motor Company Case StudycorNo ratings yet

- 5S Implementation Plan UploadDocument21 pages5S Implementation Plan UploadRahul KumarNo ratings yet

- Measurement and Validity of Jennifer Aaker's Brand Personality Scale For Colgate BrandDocument3 pagesMeasurement and Validity of Jennifer Aaker's Brand Personality Scale For Colgate BrandNikhil KasatNo ratings yet

- Chapter 14: Lean Supply Chains: Mcgraw-Hill/IrwinDocument30 pagesChapter 14: Lean Supply Chains: Mcgraw-Hill/IrwinKhathutshelo KharivheNo ratings yet

- IKEA Model Provides Solution for Lean Construction ImplementationDocument41 pagesIKEA Model Provides Solution for Lean Construction Implementationarlindo HartonoNo ratings yet

- JIT and Lean Operations Techniques for Eliminating WasteDocument8 pagesJIT and Lean Operations Techniques for Eliminating WasteGerline MaeNo ratings yet

- Six Sigma Awareness TrainingDocument171 pagesSix Sigma Awareness TrainingAshok100% (1)

- الاختبار الشامل PDFDocument28 pagesالاختبار الشامل PDFHussein MahmoudNo ratings yet

- Supply Chain Management For Dummies - A Quick RefresherDocument2 pagesSupply Chain Management For Dummies - A Quick Refresherrenzoc.helixNo ratings yet

- Ohno's Method - The Origins of The Toyota Production SystemDocument10 pagesOhno's Method - The Origins of The Toyota Production SystemDinoora Canavaro TisanogaNo ratings yet

- Management Theory and PracticeDocument6 pagesManagement Theory and PracticeMax MarvelNo ratings yet

- Lean MFG - GoldDocument4 pagesLean MFG - Goldpragthedog100% (1)

- E14 - M&M CaseDocument2 pagesE14 - M&M Casemohan k rongalaNo ratings yet

- Summer Training Report Yamaha Motors Pvt. Ltd.Document86 pagesSummer Training Report Yamaha Motors Pvt. Ltd.Cheshta Naval100% (1)

- Carrier Network Outsourcing – A Realistic AlternativeDocument19 pagesCarrier Network Outsourcing – A Realistic AlternativeVladimir PodshivalovNo ratings yet

- Barbieri - Corto (Coniti) PDFDocument5 pagesBarbieri - Corto (Coniti) PDFRolando DávilaNo ratings yet

- Prelim ExaminationDocument46 pagesPrelim ExaminationJenny Rose M. YocteNo ratings yet

- Siemens PLM Tecnomatix Plant Simulation Value Stream Mapping Fs Tcm1023 206379 PDFDocument5 pagesSiemens PLM Tecnomatix Plant Simulation Value Stream Mapping Fs Tcm1023 206379 PDFmouad hamdaniNo ratings yet

- Supply Chain ManagementDocument25 pagesSupply Chain ManagementshikinNo ratings yet

- Staufen Polska One Piece Flow 2009Document4 pagesStaufen Polska One Piece Flow 2009tiwintli14No ratings yet