Professional Documents

Culture Documents

Packinox For Catalytic Reforming

Packinox For Catalytic Reforming

Uploaded by

Asad RazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Packinox For Catalytic Reforming

Packinox For Catalytic Reforming

Uploaded by

Asad RazaCopyright:

Available Formats

Alfa Laval Packinox for catalytic reforming

Standard combined feed/effluent heat exchanger

make-up

Alfa Laval

Packinox

Recycled

Naphtha

Reformate

Alfa Laval Packinox supplied the first Standard Combined

Feed/Effluent Heat Exchanger to a Catalytic Reforming Unit in

1982. Over a decade later, a report from the client congratulated Alfa Laval Packinox on the heat exchangers constant

good performance and minimum maintenance requirements.

fitting basis for debottlenecking existing units as Alfa Laval

Packinox allows higher duty with lower pressure drop. No

other change to the units existing equipment (compressors,

heaters, etc.) is needed to obtain higher throughput and/or

higher H2 production.

In one piece of equipment, Alfa Laval Packinox large welded

plate heat exchangers offer the superior efficiency of plate

exchangers together with the resistance to high temperatures

and pressures generally associated with Shell & Tubes.

Moreover, the compact design of a single Alfa Laval Packinox

can replace several tubulars, thus enhancing the impact on

capex and opex by cutting installation costs and pressure

drop consumption.

As a result of general satisfaction with the performance of

Alfa Laval Packinox Standard Combined Feed/Effluent Heat

Exchangers in catalytic reforming, Alfa Laval Packinox is now

considered the industry standard for CRUs and is specified

by the main process licensors for both semi-regenerative and

CCR units.

Alfa Laval Packinox heat exchangers improve the overall economics of greenfield units, and also serve as a low cost retro-

Typical process conditions:

Flow:

5 000 to 70 000 bpd (with one exchanger)

Temperatures:

from 80C (cold end) to 530C (hot end)

Hot approach:

as low as 30C or less

Operating pressure: 7 to 45 bars depending on process

P in exchanger:

2 to 0.7 bar

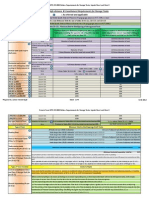

New unit case study

50 000 bpsd Continuous Catalytic Reforming Process Unit

Hot End Approach

Number of shells

Duty

Heat recovery

Estimated dry weight

S&T

HEA = 44C

4

123

419.7

3,000,000

2,100,000

5,100,000

$US

3,300,000

1,320,000

4,620,000

480,000

500,000

980,000

$US

$US

3,150,000

560,000

MW

MM Btu/h

MW

MM Btu/h

kg

CAPEX

Estimated equipment cost

Estimated installation cost

Estimated installed cost

CAPEX Savings on installed heat exchanger

CAPEX Savings on other installed equipment (Heater, Cooler)

TOTAL CAPEX SAVINGS

OPEX

ENERGY SAVINGS PER YEAR:

CHARGE HEATER,COMPRESSOR,

EMISSIONS SAVINGS PER YEAR: Nox, Sox, GHG

ALFA LAVAL PACKINOX

HEA = 28C

1

130

443.6

7

23.9

150,000.00

$US

$US

$US

$US

275,000.00

assuming: 10.5 $US/ MM BTU, 1 Euro = 1,2 $US, GHG = 20 $US/Ton, Nox = 0,5 $US/Lb, Sox = 0,5 $US/Lb

Revamp case study from an actual catalytic reforming revamp

Prior to revamp Packinox solution

Naptha flow rate

15,000 b/d

20,000 b/d

Arrangement

12 (2 x 6)

1 vertical

horizontal S&Ts

Total weight

236 tons

114 tons

Total H.E. duty

82 MW

Feed outlet temp.

440 C

475 C

Hot approach

60 C

25 C

Total pressure drop

4 bar

1.3 bar

(no new compressor needed)

In this case as in others, one Alfa Laval Packinox heat

exchanger replaced 12 horizontal tubulars with no changes to

the units compressor or furnaces (only new connections

were required).

Capacity rose by 33% at this unit where a Alfa Laval

Packinox exchanger has been in service for over 12 years

without major maintenance or repair operations.

A report from the client furthermore says Alfa Laval Packinox

improved the units energy efficiency, resulting in a reduction

of SO2 emissions and a significant drop in total fuel consumption.

PPI00202EN 0705

How to contact Alfa Laval

Up-to-date Alfa Laval contact details for

all countries are always available on our

website at www.alfalaval.com

Alfa Laval reserves the right to change specifications without prior notification.

You might also like

- Chemistry The Molecular Nature of Matter 7th Edition Jespersen Test Bank PDFDocument31 pagesChemistry The Molecular Nature of Matter 7th Edition Jespersen Test Bank PDFa464583056100% (3)

- Freak The Mighty Chapter 9Document3 pagesFreak The Mighty Chapter 9KCNo ratings yet

- The Natural Phenomena of Anti Gravitation and Invisibility in Insects and The Grebennikov Cavernous Structures EffectDocument15 pagesThe Natural Phenomena of Anti Gravitation and Invisibility in Insects and The Grebennikov Cavernous Structures EffectNirolf34100% (1)

- 50 Olefin ReductionDocument2 pages50 Olefin ReductiondimkuhNo ratings yet

- Intro To HAZID of PipelinesDocument30 pagesIntro To HAZID of Pipelineszohaib_farooq100% (3)

- Separation of Liquid Nitrogen and Oxygen by Cryogenic DistillationDocument9 pagesSeparation of Liquid Nitrogen and Oxygen by Cryogenic Distillationzohaib_farooqNo ratings yet

- ASTM Laboratory Information Management Systems Rte1nzgDocument27 pagesASTM Laboratory Information Management Systems Rte1nzgAamirx64No ratings yet

- Long-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryDocument2 pagesLong-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryOsmar DiasNo ratings yet

- Packinox Hydrotreating PDFDocument4 pagesPackinox Hydrotreating PDFzubair195No ratings yet

- Valero Emerson BlendingDocument3 pagesValero Emerson BlendingGerrard ArchuletaNo ratings yet

- CRU PresentationDocument18 pagesCRU PresentationManish KalraNo ratings yet

- PTQ Enhancing Heat TransferDocument5 pagesPTQ Enhancing Heat TransferkulaspiroNo ratings yet

- Vis BreakingDocument21 pagesVis BreakingAhmed Hassan RashedNo ratings yet

- 16 Options For Gasoline Pool Benzene ManagementDocument14 pages16 Options For Gasoline Pool Benzene Managementxinghust100% (1)

- Buell: Division ofDocument10 pagesBuell: Division ofguptadheerNo ratings yet

- Catalytic Reforming PDFDocument3 pagesCatalytic Reforming PDFAbey SamuelNo ratings yet

- Management Corner: MILESTONE Heater Fouling ControlDocument6 pagesManagement Corner: MILESTONE Heater Fouling ControlUmer PirachaNo ratings yet

- Catalytic IsomerizationDocument7 pagesCatalytic Isomerizationanasaie20% (1)

- Refining CatalystsDocument91 pagesRefining CatalystsOstom Ray100% (1)

- Quiz Mohd Rafiq Mohd ZubirDocument11 pagesQuiz Mohd Rafiq Mohd ZubirMohd RafiqNo ratings yet

- Distillation Column BasicsDocument4 pagesDistillation Column BasicsTejas PatelNo ratings yet

- Paul Reagan, Sampling Associates International, US, Discusses The Issues To Be Considered When Sampling Petroleum CokeDocument4 pagesPaul Reagan, Sampling Associates International, US, Discusses The Issues To Be Considered When Sampling Petroleum CokeBudi Pranata RitongaNo ratings yet

- Unit 5 Catalytic ReformingDocument32 pagesUnit 5 Catalytic ReformingStudy purposeNo ratings yet

- Conversion of Isobutylene To Propylene PDFDocument9 pagesConversion of Isobutylene To Propylene PDFtannytranNo ratings yet

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503No ratings yet

- TSPenex ProcessDocument2 pagesTSPenex Processstavros7100% (1)

- 45 Naptha ReformingDocument23 pages45 Naptha ReformingJ Martínez100% (1)

- Transportation: EGEE 102 - Energy Conservation and Environmental ProtectionDocument45 pagesTransportation: EGEE 102 - Energy Conservation and Environmental ProtectionTanweer SalahNo ratings yet

- Abelmarle Referencia KF-868 PDFDocument24 pagesAbelmarle Referencia KF-868 PDFEdgar Hector GarciaNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- Advances in The OCC Process For Propylene ProductionDocument6 pagesAdvances in The OCC Process For Propylene ProductionAngel Richard MamaniNo ratings yet

- Performance Analysis of Reciprocating Refrigerant CompressorDocument6 pagesPerformance Analysis of Reciprocating Refrigerant CompressorIjsrnet EditorialNo ratings yet

- FCC Trouble Shooting TRG by SpalitDocument59 pagesFCC Trouble Shooting TRG by SpalitSaugata Palit100% (1)

- Gasoline PropertiesDocument6 pagesGasoline PropertiesbahadorNo ratings yet

- Reforming Process - Catalyst Advancement: A Presentation OnDocument23 pagesReforming Process - Catalyst Advancement: A Presentation OnSiddharth Sharma100% (1)

- Column InternalsDocument15 pagesColumn InternalsOlman VargasNo ratings yet

- Upgrade HDK Resid HP 2008-EnglishDocument6 pagesUpgrade HDK Resid HP 2008-Englishsaleh4060No ratings yet

- Debutaniser OptimisationDocument5 pagesDebutaniser OptimisationAntonNo ratings yet

- Hydrotreating Amine Treating & Sulphur Recovery: PetroDocument8 pagesHydrotreating Amine Treating & Sulphur Recovery: PetroIlham HakimNo ratings yet

- JamnagarDocument4 pagesJamnagarkatariamanojNo ratings yet

- H OilRC ProcessDocument2 pagesH OilRC Processdiego.lopez1870No ratings yet

- UOP Olefin Production Solutions BrochureDocument2 pagesUOP Olefin Production Solutions BrochureJonas FloresNo ratings yet

- Fundamentals of Reforming Catalyst and Advances: Dr. Y. K. KuchhalDocument52 pagesFundamentals of Reforming Catalyst and Advances: Dr. Y. K. KuchhalfarooqkhanerNo ratings yet

- 20 - Optimising FCC Operation - UOPDocument24 pages20 - Optimising FCC Operation - UOPVirgo LeezdevilNo ratings yet

- A Financial Analysis For The Production of HQ Propylene-MustangDocument19 pagesA Financial Analysis For The Production of HQ Propylene-Mustangandrei12320003181No ratings yet

- Motor Gasoline Analysis and SpecificationsDocument4 pagesMotor Gasoline Analysis and SpecificationsFrançois LeroyNo ratings yet

- Achieve Success in Gasoline HydrotreatingDocument6 pagesAchieve Success in Gasoline Hydrotreatingdonald55555No ratings yet

- Isomerization Process: Basudha Maurya Department of Chemical Engineering MNNIT, AllahabadDocument18 pagesIsomerization Process: Basudha Maurya Department of Chemical Engineering MNNIT, Allahabadduyhieu1122No ratings yet

- 10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFDocument26 pages10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFmujeebtalib100% (1)

- 09 Gasoline UpgradingDocument63 pages09 Gasoline UpgradingLượng NguyễnNo ratings yet

- AcquaconvertionDocument10 pagesAcquaconvertionGreysi N. Moreno CedeñoNo ratings yet

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsDocument6 pagesAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaNo ratings yet

- Benzene, Xylene, Toluene (BTX) 2018Document10 pagesBenzene, Xylene, Toluene (BTX) 2018Matthew SantawNo ratings yet

- Modeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical EngineerDocument30 pagesModeling of Naphtha Reforming Unit Applying Detailed 2014 Chemical Engineerdownload100% (1)

- Aromatics Complex Project in Mangalore SezDocument21 pagesAromatics Complex Project in Mangalore SezCNo ratings yet

- Informacion Sobre FCC, Boquillas y Parametros A OptimizarDocument14 pagesInformacion Sobre FCC, Boquillas y Parametros A OptimizarEQP1210No ratings yet

- ERC Refinery ProjectDocument16 pagesERC Refinery ProjectTarek Fawzy100% (1)

- UOP CCR Catalysts Target A Range of Objectives Tech Paper1Document5 pagesUOP CCR Catalysts Target A Range of Objectives Tech Paper1nikitaambeNo ratings yet

- Refining Margin Supplement OMRAUG 12SEP2012Document30 pagesRefining Margin Supplement OMRAUG 12SEP2012Won JangNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

- Alfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat ExchangerDocument3 pagesAlfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat Exchangerrizwan khan100% (1)

- Sample Job Description For Sr. Risk EngineerDocument3 pagesSample Job Description For Sr. Risk Engineerzohaib_farooqNo ratings yet

- NFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIDocument4 pagesNFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIzohaib_farooqNo ratings yet

- The Galaxy Industries Production Problem - A Prototype ExampleDocument25 pagesThe Galaxy Industries Production Problem - A Prototype Examplezohaib_farooqNo ratings yet

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- Mechanics of AirDocument4 pagesMechanics of Airzohaib_farooqNo ratings yet

- Pages From Selection and Sizing of Pressure Relief ValvesDocument1 pagePages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNo ratings yet

- CryogenicDocument19 pagesCryogeniczohaib_farooq100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Study Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent ReactDocument1 pageStudy Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent Reactzohaib_farooqNo ratings yet

- Number Name Description Halal StatusDocument16 pagesNumber Name Description Halal Statuszohaib_farooqNo ratings yet

- Spring 2009 Ballot Guide - HOPE Coalition Newsletter Humboldt Organized For People and The EnvironmentDocument1 pageSpring 2009 Ballot Guide - HOPE Coalition Newsletter Humboldt Organized For People and The EnvironmentKornarosParaskeviNo ratings yet

- Convenience Electronics Polo 9N 1,4 TDI PD 2002 55 KW AMFDocument12 pagesConvenience Electronics Polo 9N 1,4 TDI PD 2002 55 KW AMFflorea tulituNo ratings yet

- Heart Failure in The Last Year: Progress and Perspective: Journal ReadingDocument31 pagesHeart Failure in The Last Year: Progress and Perspective: Journal ReadingIkmah FauzanNo ratings yet

- Buku 1Document9 pagesBuku 1ayundaaqila5No ratings yet

- ASiT Yearbook 2011Document126 pagesASiT Yearbook 2011Association of Surgeons in TrainingNo ratings yet

- Nursing Philosophy PaperDocument5 pagesNursing Philosophy Paperapi-532587700No ratings yet

- Lab 11 MultisimDocument6 pagesLab 11 MultisimMichael MatteoNo ratings yet

- Surappakasam StaffDocument4 pagesSurappakasam StaffBhargavi BhumaNo ratings yet

- Bell's Palsy - Treatment and Prognosis in Adults - UpToDateDocument15 pagesBell's Palsy - Treatment and Prognosis in Adults - UpToDateImad RifayNo ratings yet

- (0117) KPN ABCi C 8.2 (A) PDFDocument15 pages(0117) KPN ABCi C 8.2 (A) PDFMechanical PowerNo ratings yet

- Agrofood Sistema Vrie 2012Document40 pagesAgrofood Sistema Vrie 2012PaulinaNo ratings yet

- CRV Air Valve Catalogue PDFDocument10 pagesCRV Air Valve Catalogue PDFsathishNo ratings yet

- SSCP Exam OutlineDocument11 pagesSSCP Exam OutlineironmanNo ratings yet

- SECTION 6: Spleen: and OverviewDocument38 pagesSECTION 6: Spleen: and Overviewtudoranluciana1No ratings yet

- Depression:-: Bipolar-I Disorder Bipolar-Ii Disorder Cyclothymic DisorderDocument1 pageDepression:-: Bipolar-I Disorder Bipolar-Ii Disorder Cyclothymic DisorderAli NawazNo ratings yet

- Alternative 1Document8 pagesAlternative 1JeanNo ratings yet

- A Male Client Who Has Severe Burns Is Receiving H2 Receptor Antagonist TherapyDocument3 pagesA Male Client Who Has Severe Burns Is Receiving H2 Receptor Antagonist TherapyMc Joewell HudencialNo ratings yet

- EVOLIS Twin Plus User Manual EN (English)Document88 pagesEVOLIS Twin Plus User Manual EN (English)Adnan MistryNo ratings yet

- Mixture and Allegation Prepared by Suparna Chakraborty Namrata Ipe, Sust Emba, Du PGDHRM BimDocument8 pagesMixture and Allegation Prepared by Suparna Chakraborty Namrata Ipe, Sust Emba, Du PGDHRM Bimবিপ্লব নীলাদ্রিNo ratings yet

- Mod 07 ESSAYS PT 7Document4 pagesMod 07 ESSAYS PT 7weikeat90No ratings yet

- O&M BW213dh, PDH, PDBH-3 10158027000 Up 00814011Document102 pagesO&M BW213dh, PDH, PDBH-3 10158027000 Up 00814011Flavio VerNo ratings yet

- JAPAN Insurance MarketDocument12 pagesJAPAN Insurance MarketGabriela DendeaNo ratings yet

- Astm B622 PDFDocument3 pagesAstm B622 PDFgaminNo ratings yet

- Technical Catalog JD c13965 PDFDocument473 pagesTechnical Catalog JD c13965 PDFOmar BecerraNo ratings yet

- Final Hydrogen Fuel Cell VehicleDocument8 pagesFinal Hydrogen Fuel Cell VehiclePrashon GNo ratings yet

- Body WeaknessDocument1 pageBody Weaknessnymphaaugustus100% (3)