Professional Documents

Culture Documents

Safety Data Sheet: 1. Product and Company Identification

Uploaded by

Thonny BarreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Data Sheet: 1. Product and Company Identification

Uploaded by

Thonny BarreraCopyright:

Available Formats

Page: 1(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

SAFETY DATA SHEET

This Safety Data Sheet complies with Regulation (EC) No. 1907/2006, ISO 11014-1 and ANSI Z400.1

1.

PRODUCT AND COMPANY IDENTIFICATION

Product Name:

Application:

Classification:

Supplier:

Telephone No.:

Web site:

2.

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX CORED STAINLESS STEEL ELECTRODES

Arc Welding

AWS A5.22

ESAB GROUP CANADA, INC., 6010 Tomken Road, Mississauga, ON L5T 1X9

(905) 670-0220, 1-877-935-3226

www.esab.ca

HAZARDS IDENTIFICATION

Emergency Overview: Metal wires in varying colors. These products are normally not considered hazardous as shipped. Gloves should be

worn when handling to prevent cuts and abrasions.

These products contain nickel, which is classified as toxic by prolonged inhalation, a skin sensitizer and a suspect carcinogen. Nickel

powder is harmful for the environment. Some of these products contain cryolite. Cryolite is classified as toxic and dangerous for the

environment. Some of these products contain potassium fluorosilicate which is classified as toxic by inhalation, skin contact, and

ingestion. In the form that these substances are present in these products, they do not contribute to a hazard classification of the

products. These products contain titanium dioxide which is possibly carcinogenic. These products contain quartz, but normally not in an

inhalable fraction. Quartz can cause silicosis and may cause cancer.

Avoid eye contact or inhalation of dust from these products. Skin contact is normally no hazard but should be avoided to prevent possible

allergic reactions.

Persons with a pacemaker should not go near welding or cutting operations until they have consulted their doctor and obtained

information from the manufacturer of the device.

When these products are used in a welding process, the most important hazards are heat, radiation, electric shock and welding fumes.

Heat:

Spatter and melting metal can cause burn injuries and start fires.

Radiation:

Arc rays can severely damage eyes or skin.

Electricity:

Electric shock can kill.

Fumes:

Overexposure to welding fumes may result in symptoms like metal fume fever, dizziness, nausea, dryness or irritation of

the nose, throat or eyes. Chronic overexposure to welding fumes may affect pulmonary function. Prolonged inhalation of

nickel and chromium compounds above safe exposure limits can cause cancer. Overexposure to manganese and

manganese compounds above safe exposure limits can cause irreversible damage to the central nervous system,

including the brain, symptoms of which may include slurred speech, lethargy, tremor, muscular weakness, psychological

disturbances and spastic gait.

3.

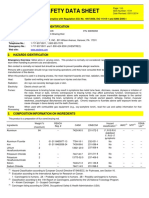

COMPOSITION/INFORMATION ON INGREDIENTS

These products are preparations of flux cored wire.

Ingredients

Aluminum Oxide

Chromium

Copper

Fluoride Compounds

Cryolite

Lithium Fluoride

Potassium Silico Fluoride

Sodium Fluoride

Iron

Iron Oxide

OSHA

List(4)

REACH

Reg. #

CAS#

EINECS#

Hazard

classification(1)

----

1344-28-1

7440-47-3

7440-50-8

215-691-6

231-157-5

231-159-6

No

No

No

----

----

----

01-2119511565-43

15096-52-3

239-148-8

--

--

--

----

7789-24-4

16871-90-2

7681-49-4

232-152-0

T; R48/23/25

Xn; R20/22

N; R51-53

No

--

--

--

240-896-2

231-667-8

---

---

---

01-2119462838-24

--

7439-89-6

1309-37-1

231-096-4

215-168-2

T; R23/24/25

T; R25

Xi; R36/38, R32

No

No

---

---

---

IARC(2) NTP(3)

Product Identity:

Ingredients

Manganese

Mineral Silicates

Bentonite Clays

Chlorite

Feldspar

Hectorite

Pyrropholite

Wollanstanite

Zircon

Molybdenum

Nickel

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

REACH

Reg. #

CAS#

EINECS#

Page: 2(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

Hazard

classification(1)

-7439-96-5

231-105-1

No

All substances with CAS # of 14808-60-7 are considered to be quartz.

-1302-78-9

215-108-5

No

-14808-60-7

238-878-4

T; R45

-14808-60-7

238-878-4

T; R45

-14808-60-7

238-878-4

T; R45

-14808-60-7

238-878-4

T; R45

-14808-60-7

238-878-4

T; R45

-14808-60-7

238-878-4

T; R45

-7439-98-7

231-107-2

No

-7440-02-0

231-111-4

Carc. Cat. 3; R40

T; R48/23

R43

IARC(2) NTP(3)

OSHA

List(4)

--

--

--

-1

1

1

1

1

1

-2B

-K

K

K

K

K

K

-S

----------

Nickel Powder

--

7440-02-0

231-111-4

Carc. Cat. 3; R40

T; R48/23

R43

R52/53

2B

--

Niobium

Potassium Fused Flux

Titanium Oxide

Manganese Oxide

Potassium Oxide

Silicon Dioxide (amorphous)

--

7440-03-1

231-113-5

No

--

--

--

------

13463-67-7

1344-43-0

12136-45-7

60676-86-0

7440-21-3

236-675-5

215-695-8

235-227-6

262-373-8

231-130-8

No

No

No

No

No

2B

-----

------

------

--

14808-60-7

238-878-4

T; R45

--

------

13463-67-7

1344-43-0

12401-86-4

60676-86-0

1313-59-3

236-675-5

215-695-8

215-208-9

262-373-8

215-208-9

No

No

No

No

No

2B

-----

------

------

Titanium Oxide

--

13463-67-7

236-675-5

No

2B

--

--

Zirconium

--

7440-67-7

231-176-9

F; R15-17

--

--

--

Zirconium Dioxide

--

1314-23-4

215-227-2

No

--

--

--

Silicon

Silicon Dioxide

Sodium Fused Flux

Titanium Oxide

Manganese Oxide

Sodium Oxide

Silicon Dioxide (amorphous)

Sodium Oxide

(1)

(2)

(3)

(4)

Hazard Classification according to European Council Directive 67/548/EEC, for R-phrases, see Section 16.

Evaluation according to the International Agency for Research on Cancer.

1 Carcinogenic to humans. 2A Probably carcinogenic to humans. 2B Possibly carcinogenic to humans.

Classification according to the 11th Report on Carcinogens, published by the US National Toxicology Program.

K Known Carcinogen S Suspect Carcinogen

Carcinogen listing according to OSHA, Occupational Safety & Health Administration (USA).

Product Identity:

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

Page: 3(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

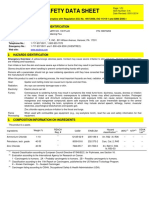

APPROXIMATE COMPOSITION (Wt. %)

Product Trade Name

Shield-Bright

308H

Shield-Bright

308L

Shield-Bright

309H

Shield-Bright

309L

Shield-Bright

309LMo

Shield-Bright

312

Shield-Bright

316H

Aluminum Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Chromium

17-20

17-20

21-24

21-24

21-24

25-28

17-20

Copper

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Fluoride Compounds

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Iron Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Manganese

1-3

1-3

1-3

1-3

1-3

1-3

1-3

--

--

--

--

--

--

--

Manganese Oxide

Mineral Silicates

<1

<1

<1

<1

<1

<1

<1

Molybdenum

<0.5

<0.5

<0.5

<0.5

1-3

<0.5

1-3

Nickel

8-10

8-10

10-12

10-12

10-12

8-10

9-11

Niobium

--

--

--

--

--

--

--

Potassium Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Silicon

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

<1

<1

<1

<1

<1

<1

<1

Silicon Dioxide

Sodium Oxide

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Titanium Oxide

8-12

8-12

8-12

8-12

8-12

8-12

8-12

Zirconium

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Zirconium Dioxide

<2

<2

<2

<2

<2

<2

<2

Iron

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

AWS A5.22

Classification

E308HT1-1

E308HT1-4

E308LT1-1

E308LT1-4

E309T1-1/T1-4

E309HT1-1/T1-4

E309LT1-1

E309LT1-4

E309LMoT1-1

E309LMoT1-4

E312T1-1

E312T1-4

E316T1-1/T1-4

E316HT1-1/T1-4

Product Trade Name

Shield-Bright Shield-Bright Shield-Bright

316L

317L

347

Shield-Bright

347H

Shield-Bright Shield-Bright

2209

2594

Shield-Bright

410NiMo

Cryo-Shield

308L

Aluminum Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Chromium

17-20

17-20

17-20

17-20

21-23

23-25

10-13

17-20

Copper

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Fluoride Compounds

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Iron Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Manganese

1-3

1-3

1-3

1-3

1-3

1-3

1-3

1-3

Manganese Oxide

--

--

--

--

--

<0.5

--

--

Mineral Silicates

<1

<1

<1

<1

<1

<1

<1

<1

Molybdenum

1-3

2-4

<0.5

<0.5

2-4

2-4

<0.5

<0.5

Nickel

9-11

10-12

8-10

8-10

7-9

8-10

3-5

8-10

--

--

<1

<1

--

--

--

--

Potassium Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Silicon

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

Niobium

Silicon Dioxide

<1

<1

<1

<1

<1

<1

<1

<1

Sodium Oxide

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Titanium Oxide

8-12

8-12

8-12

8-12

8-12

8-12

5-8

8-12

Zirconium

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<2

<2

<2

<2

<2

<2

<2

<2

Iron

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>70)

Bal. (>45)

AWS A5.22

Classification

E316LT1-1

E316LT1-4

E317LT1-1

E317LT1-4

E347T1-1

E347T1-4

E347T1-1/T1-4

E347HT1-1/T1-4

E2209T1-1

E2209T1-4

E2594T1-4

E410NiMoT1-1

E410NiMoT1-4

E308LT1-1J

E308LT1-4J

Zirconium Dioxide

Product Identity:

Product Trade Name

Shield-Bright

X-tra 308L

Shield-Bright

X-tra 309L

Shield-Bright

X-tra 309LMo

Shield-Bright

X-tra 316L

Page: 4(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

Shield-Bright

X-tra 317L

Shield-Bright

X-tra 347

Aluminum Oxide

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

<0.2

Chromium

17-20

17-20

21-24

21-24

17-20

17-20

18-20

Copper

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Fluoride Compounds

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Iron Oxide

<1.5

<1.5

<1.5

<1.5

<1.5

<1.5

<0.5

Manganese

1-3

1-3

1-3

1-3

1-3

1-3

1-3

0.2-1

Manganese Oxide

--

--

--

1-2

--

1-2

Mineral Silicates

<1

<1

<1

<1

<1

<1

<1

Molybdenum

<0.5

<0.5

<0.5

2-4

2-4

2-4

<0.5

Nickel

8-10

8-10

10-13

10-13

10-13

10-13

8-10

0.5-1

Niobium

--

--

--

--

--

--

Potassium Oxide

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Silicon

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-2

0.2-1

Silicon Dioxide

1-4

1-4

1-4

1-4

1-4

1-4

0.5-2

Sodium Oxide

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Titanium Dioxide

2-5

2-5

2-5

2-5

2-5

2-5

2-5

Zirconium

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

<0.5

Zirconium Dioxide

4.

Shield-Bright

X-tra 308

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

<2

<2

<2

<2

<2

<2

<2

Iron

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

Bal. (>45)

AWS A5.22

Classification

E308LT0-1

E308LT0-4

E308LT0-1

E308LT0-4

E309LT0-1

E309LT0-4

E309LMoT0-1

E309LMoT0-4

E316LT0-1

E316LT0-4

E317LT0-1

E317LT0-4

E347T0-1

E347T0-4

FIRST AID MEASURES

Inhalation:

If breathing has stopped, perform artificial respiration and obtain medical assistance immediately! If breathing is difficult,

provide fresh air and call physician.

Eye contact:

For radiation burns due to arc flash, see physician. To remove dusts or fumes flush with water for at least fifteen

minutes. If irritation persists, obtain medical assistance.

Skin contact:

For skin burns from arc radiation, promptly flush with cold water. Get medical attention for burns or irritations that persist.

To remove dust or particles wash with mild soap and water.

Electric shock:

Disconnect and turn off the power. Use a nonconductive material to pull victim away from contact with live parts or wires.

If not breathing, begin artificial respiration, preferably mouth-to-mouth. If no detectable pulse, begin Cardio Pulmonary

Resuscitation (CPR). Immediately call a physician.

General:

Move to fresh air and call for medical aid.

5.

FIRE FIGHTING MEASURES

No specific recommendations for welding consumables. Welding arcs and sparks can ignite combustible and flammable materials. Use

the extinguishing media recommended for the burning materials and fire situation. Wear self-contained breathing apparatus as fumes or

vapors may be harmful.

6.

ACCIDENTAL RELEASE MEASURES

Solid objects may be picked up and placed into a container. Liquids or pastes should be scooped up and placed into a container. Wear

proper protective equipment while handling these materials. Do not discard as refuse.

Personal precautions:

refer to Section 8.

Environmental precautions:

refer to Section 13.

7.

HANDLING AND STORAGE

Handling:

Handle with care to avoid stings and cuts. Wear gloves when handling welding consumables. Avoid exposure to dust. Do not ingest.

Some individuals can develop an allergic reaction to certain materials. Retain all warning and identity labels.

Storage:

Keep separate from chemical substances like acids and strong bases, which could cause chemical reactions.

Product Identity:

8.

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

Page: 5(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

EXPOSURE CONTROL/PERSONAL PROTECTION

Avoid exposure to welding fumes, radiation, spatter, electric shock, heated materials and dust.

Engineering measures:

Ensure sufficient ventilation, local exhaust, or both, to keep welding fumes and gases from breathing zone and general area. Keep

working place and protective clothing clean and dry. Train welders to avoid contact with live electrical parts and insulate conductive parts.

Check condition of protective clothing and equipment on a regular basis.

Personal protective equipment:

Use respirator or air supplied respirator when welding or brazing in a confined space, or where local exhaust or ventilation is not sufficient

to keep exposure values within safe limits. Use special care when welding painted or coated steels since hazardous substances from the

coating may be emitted. Wear hand, head, eyes, ear and body protection like welders gloves, helmet or face shield with filter lens, safety

boots, apron, arm and shoulder protection. Keep protective clothing clean and dry.

Use industrial hygiene monitoring equipment to ensure that exposure does not exceed applicable national exposure limits. The following

limits can be used as guidance. For information about welding fume analysis refer to Section 10.

Substance

CAS#

Aluminum Oxide

1344-28-1

Chromium Compounds

7440-47-3

Metal

1** (as Al)

OSHA PEL (2) mg/m3

15*, 5**

0.5

Cr (VI), inorganic, insoluble

0.01 (as Cr)

0.005 (as Cr VI)

Cr (VI), inorganic, water-soluble

0.05 (as Cr)

0.005 (as Cr VI)

0.2

1

0.1

1

Copper

(as Cr)

ACGIH TLV (1) mg/m3

(fume, as Cu)

(dust and mists, as Cu)

7440-50-8

Cryolite

(as F)

15096-52-3

2.5

2.5

Lithium Fluoride

(as F)

7789-24-4

2.5

2.5

Potassium Silico Fluoride

(as F)

16871-90-2

2.5

2.5

Sodium Fluoride

(as F)

7681-49-4

2.5

(as iron oxide)

7439-89-6

5**

10 (fume)

1309-37-1

5**

10 (fume)

(as Mn)

7439-96-5

0.02**, 0.1***

5 Ceiling

7439-96-5

0.02**, 0.1***

5 Ceiling

Fluoride Compounds

Iron

Iron Oxide

Manganese and

inorganic compounds

Manganese, fume, as Mn

2.5

Mineral Silicates (no exposure anticipated)

All substances with CAS # of 14808-60-7 are considered to be quartz.

Bentonite Clays

1302-78-9

None

Chlorite Silica-Crystalline-Quartz

14808-60-7

0.025**

Feldspar Silica-Crystalline-Quartz

14808-60-7

0.025**

Hectorite Silica-Crystalline-Quartz

14808-60-7

0.025**

Pyrropholite Silica-CrystallineQuartz

14808-60-7

0.025**

Wollanstanite Silica-CrystallineQuartz

14808-60-7

0.025**

10 mg/m3 ###

%SiO2+2

Zircon Silica-Crystalline-Quartz

14808-60-7

0.025**

10 mg/m3 ###

%SiO2+2

7439-98-7

3 **, 10 ***

15*

Molybdenum

(metal and insoluble

compounds, as Mo)

(soluble compounds,

as Mo)

0.5 **

5

1

Nickel, elemental

7440-02-0

1.5***

Niobium

7440-03-1

None

Potassium Fused Flux

Titanium Oxide

Manganese Oxide

Potassium Oxide

Silicon Dioxide (amorphous)

(as Mn)

13463-67-7

1344-43-0

12136-45-7

60676-86-0

None

10 mg/m3 ###

%SiO2+2

10 mg/m3 ###

%SiO2+2

10 mg/m3 ###

%SiO2+2

10 mg/m3 ###

%SiO2+2

10

0.02**, 0.1***

None

Withdrawn

None

15*

5 Ceiling

None

10 mg/m3 ###

%SiO2+2

Product Identity:

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

Page: 6(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

CAS#

ACGIH TLV (1) mg/m3

OSHA PEL (2) mg/m3

Silicon

7440-21-3

Withdrawn

Silicon Dioxide (quartz)

14808-60-7

0.025**

15*, 5**

10 mg/m3 ###

%SiO2+2

Substance

Sodium Fused Flux

Titanium Oxide

Manganese Oxide

Sodium Oxide

Silicon Dioxide (amorphous, fused)

(as Mn)

Sodium Oxide

13463-67-7

1344-43-0

12401-86-4

60676-86-0

1313-59-3

Titanium Oxide

10

0.02**, 0.1***

None

Withdrawn

None

15*

5 Ceiling

None

10 mg/m3 ###

%SiO2+2

None

13463-67-7

10

Zirconium & Zirconium Compounds

(as Zr)

7440-67-7

5, 10 (STEL)

15*

5

Zirconium Dioxide

(as Zr)

1314-23-4

5, 10 (STEL)

(1)

Threshold Limit Values according to American Conference of Governmental Industrial Hygienists, 2014

Permissible Exposure Limits according to the Occupational Safety & Health Administration (USA)

Unless noted, all values are for 8 hour time weighted averages (TWA).

(2)

* Total dust, ** Respirable fraction, *** Inhalable fraction.

^ Value from OSHA expressed in PPM and value shown is conversion to mg/m3

### Respirable dust

NOTE: Some of these products may not contain all of the materials listed. For details of composition, refer to the COMPOSITION

TABLES in Section 3.

9.

PHYSICAL AND CHEMICAL PROPERTIES

Appearance:

Solid, non-volatile with varying color.

Melting Point:

>1000C/>1800F

10. STABILITY AND REACTIVITY

General:

These products are only intended for normal welding purposes.

Stability:

These products are stable under normal conditions.

Reactivity:

Contact with chemical substances like acids or strong bases could cause generation of gas.

When these products are used in a welding process, hazardous decomposition products would include those from the volatilization,

reaction or oxidation of the materials listed in Section 3 and those from the base metal and coating.

The amount of fumes generated from these products varies with welding parameters and dimensions but is generally no more than 5 to

15 g/kg consumable. Fumes from these products may contain compounds of the following chemical elements: Fe, O, Mn, Zr, Cr, Ni, F,

Na, Si, K, Al, Mo, Cu, Nb, Li, and Ti. The rest is not analyzed, according to available standards.

Refer to applicable national exposure limits for fume compounds, including those exposure limits for fume compounds found in Section 8.

A significant amount of the chromium in the fumes can be hexavalent chromium, which has a very low exposure limit in some countries.

Manganese and nickel also have low exposure limits, in some countries, that may be easily exceeded.

Reasonably expected gaseous products would include carbon oxides, nitrogen oxides and ozone. Air contaminants around the welding

area can be affected by the welding process and influence the composition and quantity of fumes and gases produced.

11. TOXICOLOGICAL INFORMATION

Inhalation of welding fumes and gases can be dangerous to your health. Classification of welding fumes is difficult because of varying

base materials, coatings, air contamination and processes. The International Agency for Research on Cancer has classified welding

fumes as possibly carcinogenic to humans (Group 2B).

Acute toxicity:

Overexposure to welding fumes may result in symptoms like metal fume fever, dizziness, nausea, dryness or irritation

of the nose, throat or eyes.

Chronic toxicity:

Overexposure to welding fumes may affect pulmonary function. Prolonged inhalation of nickel and chromium

compounds above safe exposure limits can cause cancer. Overexposure to manganese and manganese compounds

above safe exposure limits can cause irreversible damage to the central nervous system, including the brain,

symptoms of which may include slurred speech, lethargy, tremor, muscular weakness, psychological disturbances and

spastic gait. Prolonged inhalation of titanium dioxide above safe exposure limits can cause cancer. Inhalable quartz is

a respiratory carcinogen; however, the process of welding converts crystalline quartz to the amorphous form which is

not considered to be a carcinogen.

Product Identity:

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

Page: 7(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

12. ECOLOGICAL INFORMATION

Welding consumables and materials could degrade/weather into components originating from the consumables or from the materials

used in the welding process. Avoid exposure to conditions that could lead to accumulation in soils or groundwater.

Nickel powder is harmful for the environment. Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

Some of these products contain cryolite, which is classified by European Council Directive 67/548/EEC, as toxic to aquatic organisms and

may cause long-term adverse effects in the aquatic environment.

13. DISPOSAL CONSIDERATIONS

Discard any product, residue, disposable container or liner in an environmentally acceptable manner, in full compliance with federal and

local regulations. Use recycling procedures if available.

USA RCRA: Unused products or product residue containing chromium is considered hazardous waste if discarded, RCRA ID

characteristic Toxic Hazardous Waste D007.

Residues from welding consumables and processes could degrade and accumulate in soils and groundwater. Welding slag from these

products typically contain mainly the following components originating from the powder filling of the flux cored wire: Fe, O, Mn, Zr, Cr, Ni,

F, Na, Si, K, Al, Mo, Cu, Nb, Li, and Ti.

14. TRANSPORT INFORMATION

No international regulations or restrictions are applicable.

15. REGULATORY INFORMATION

Read and understand the manufacturer's instructions, your employer's safety practices and the health and safety instructions on the label.

Observe any federal and local regulations. Take precautions when welding and protect yourself and others.

WARNING: Welding fumes and gases are hazardous to your health and may damage lungs and other organs. Use adequate ventilation.

ELECTRIC SHOCK can kill.

ARC RAYS and SPARKS can injure eyes and burn skin.

Wear correct hand, head, eye and body protection.

Canada: WHMIS classification: Class D; Division 2, Subdivision A

Canadian Environmental Protection Act (CEPA): All constituents of these products are on the Domestic Substance List (DSL).

USA:

Under the OSHA Hazard Communication Standard, these products are considered hazardous.

These products contain or produce a chemical known to the state of California to cause cancer and birth defects (or other

reproductive harm). (California Health & Safety Code 25249.5 et seq.)

United States EPA Toxic Substance Control Act: All constituents of these products are on the TSCA inventory list or are

excluded from listing.

CERCLA/SARA Title III

Reportable Quantities (RQs) and/or Threshold Planning Quantities (TPQs):

Ingredient name

RQ (lb)

Product is a solid solution in the form of a solid article.

--

TPQ (lb)

--

Spills or releases resulting in the loss of any ingredient at or above its RQ require immediate notification to the National

Response Center and to your Local Emergency Planning Committee.

Section 311 Hazard Class

As shipped:

Immediate

In use:

Immediate delayed

EPCRA/SARA Title III 313 Toxic Chemicals

The following metallic components are listed as SARA 313 Toxic Chemicals and potential subject to annual SARA 313

reporting. See Section 3 for weight percent.

Ingredient name

Disclosure threshold

Chromium

1.0% de minimis concentration

Copper

1.0% de minimis concentration

Manganese

1.0% de minimis concentration

Nickel

0.1% de minimis concentration

Product Identity:

SHIELD-BRIGHT AND SHIELD-BRIGHT X-TRA FLUX

CORED STAINLESS STEEL ELECTRODES

Page: 8(8)

SDS Number: CAN328-D

Date Revised: 05/01/2014

16. OTHER INFORMATION

This Safety Data Sheet has been revised due to modifications to Section 8. This SDS supersedes CAN328-C.

Refer to ESAB Welding and Cutting - Risks and Measures, F52-529 Precautions and Safe Practices for Electric Welding and Cutting

and F2035 Precautions and Safe Practices for Gas Welding, Cutting and Heating available from ESAB, and to:

USA:

Contact ESAB at www.esabna.com or 1-800-ESAB-123 if you have questions about this SDS.

American National Standard Z49.1 Safety in Welding and Cutting, ANSI/AWS F1.5 Methods for Sampling and Analyzing

Gases from Welding and Allied Processes, ANSI/AWS F1.1 Method for Sampling Airborne Particles Generated by Welding

and Allied Processes, AWSF3.2M/F3.2 Ventilation Guide for Weld Fume, American Welding Society, 550 North Le Jeune

Road, Miami, Florida, 33135. Safety and Health Fact Sheets available from AWS at www.aws.org.

OSHA Publication 2206 (29 C.F.R. 1910), U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954,

Pittsburgh, PA 15250-7954.

American Conference of Governmental Hygienists (ACGIH), Threshold Limit Values and Biological Exposure Indices, 6500

Glenway Ave., Cincinnati, Ohio 45211, USA.

NFPA 51B Standard for Fire Prevention During Welding, Cutting and Other Hot Work published by the National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02169.

UK:

WMA Publication 236 and 237, Hazards from Welding Fume, The arc welder at work, some general aspects of health and

safety.

Germany: Unfallverhtungsvorschrift BGV D1, Schweien, Schneiden und verwandte Verfahren.

Canada:

CSA Standard CAN/CSA-W117.2-01 Safety in Welding, Cutting and Allied Processes.

These products have been classified according to the hazard criteria of the CPR and the SDS contains all the information

required by the CPR.

Explanation of risk phrases mentioned in this SDS:

R-phrases:

R15 Contact with water liberates extremely flammable gases.

R17 Spontaneously flammable in air.

R20/22 Harmful by inhalation and if swallowed.

R23/24/25 Toxic by inhalation, in contact with skin and if swallowed.

R25 Toxic if swallowed.

R32 Contact with acids liberates very toxic gas.

R36/38 Irritating to eyes and skin.

R40 Limited evidence of a carcinogenic effect.

R43 May cause sensitization by skin contact.

R45 May cause cancer.

R48/23 Toxic: danger of serious damage to health by prolonged exposure through inhalation.

R48/23/25 Toxic: danger of serious damage to health by prolonged exposure through inhalation and if swallowed.

R51 Toxic to aquatic organisms.

R52/53 Harmful to aquatic organisms, may cause long-term adverse effects in the aquatic environment.

R53 May cause long-term adverse effects in the aquatic environment.

ESAB requests the users of these products to study this Safety Data Sheet (SDS) and become aware of product hazards and safety

information. To promote safe use of these products a user should:

- notify its employees, agents and contractors of the information on this SDS and any product hazards/safety information.

- furnish this same information to each of its customers for these products.

- request such customers to notify employees and customers for the same product hazards and safety information.

The information herein is given in good faith and based on technical data that ESAB believes to be reliable. Since the conditions of use

are outside our control, we assume no liability in connection with any use of this information and no warranty, expressed or implied is

given. Contact ESAB for more information.

You might also like

- Coreshield 8003 - ESABDocument6 pagesCoreshield 8003 - ESABBiju_PottayilNo ratings yet

- Esab Sds Can332-C Ercuni 70-30Document5 pagesEsab Sds Can332-C Ercuni 70-30jromero_rpgNo ratings yet

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Document5 pagesSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Msds Stainless SteelDocument11 pagesMsds Stainless Steelrakesh marwahNo ratings yet

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- 4 TUFTRAK#US En#99008#1,0Document9 pages4 TUFTRAK#US En#99008#1,0mohamed AdelNo ratings yet

- Flux cored stainless steel electrodes SDSDocument8 pagesFlux cored stainless steel electrodes SDSmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- 4 EUTECTRODE#US En#99006#1,0Document11 pages4 EUTECTRODE#US En#99006#1,0mohamed AdelNo ratings yet

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803No ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- Electrodes MSDSDocument5 pagesElectrodes MSDSJeganeswaranNo ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgeNo ratings yet

- MsdsDocument5 pagesMsdsLisa NurhasanahNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company IdentificationMohamed AdelNo ratings yet

- MSDS Tungsten Electrode Safety DataDocument2 pagesMSDS Tungsten Electrode Safety DataSerkan ApayNo ratings yet

- 308L-16 EutectrodeDocument10 pages308L-16 EutectrodeJuan LondonoNo ratings yet

- Safety Data Sheet for Core-Bright Flux Cored Stainless Steel ElectrodesDocument7 pagesSafety Data Sheet for Core-Bright Flux Cored Stainless Steel Electrodesmohamed AdelNo ratings yet

- Safety Data Sheet for DW-308 Welding WireDocument7 pagesSafety Data Sheet for DW-308 Welding WireKang Kawe Waone SetiaoneNo ratings yet

- Safety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERDocument4 pagesSafety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument6 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeNo ratings yet

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoNo ratings yet

- Safety Data Sheet for All-State AquaSafe No. 100 FluxDocument5 pagesSafety Data Sheet for All-State AquaSafe No. 100 Fluxmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument8 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument5 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- 54L EutectrodeDocument9 pages54L EutectrodeJuan LondonoNo ratings yet

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshNo ratings yet

- Steel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Document15 pagesSteel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Agustine SetiawanNo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationAdel AbduoNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument6 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Atom Arc MsdsDocument7 pagesAtom Arc MsdssalcabesNo ratings yet

- Superinox 2C MSDS Ador WeldingDocument9 pagesSuperinox 2C MSDS Ador WeldingyogipatilNo ratings yet

- Welding Wire SG2Document4 pagesWelding Wire SG2Ferry PrasetiaNo ratings yet

- MSDS NO: 415889 REVISED: JULY 16, 2007 TW 3113 MATERIAL SAFETY DATA SHEETDocument2 pagesMSDS NO: 415889 REVISED: JULY 16, 2007 TW 3113 MATERIAL SAFETY DATA SHEETabobeedoNo ratings yet

- Welding Wire and TIG Rods Type TD-S2Document4 pagesWelding Wire and TIG Rods Type TD-S2Ferry PrasetiaNo ratings yet

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetAUGUSTO LEUDO ANGELNo ratings yet

- In-W610 (Merit LMC 6 - Er70s-6) - 1Document2 pagesIn-W610 (Merit LMC 6 - Er70s-6) - 1Pratik LadNo ratings yet

- 2 TUFTRAK#US En#99004#1,0Document9 pages2 TUFTRAK#US En#99004#1,0Mohamed AdelNo ratings yet

- SDS HTW 50 2020Document3 pagesSDS HTW 50 2020Ari RosyadiNo ratings yet

- Covered Arc Welding Electrode For Mild SteelDocument3 pagesCovered Arc Welding Electrode For Mild Steelmuhamad bukhari abu hassanNo ratings yet

- Avesta Inox EDocument2 pagesAvesta Inox EMiguel Angel Sanchez FernandezNo ratings yet

- Nickel Base Welding Wire MSDS Provides Health and Safety InformationDocument7 pagesNickel Base Welding Wire MSDS Provides Health and Safety InformationLawrence Lancy LoboNo ratings yet

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelNo ratings yet

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelNo ratings yet

- Interactive CatalogDocument76 pagesInteractive CatalogahmedelhajNo ratings yet

- Lincoln 5P+ MsdsDocument2 pagesLincoln 5P+ MsdssalcabesNo ratings yet

- Safety Data Sheet: Thermic Lance RodsDocument6 pagesSafety Data Sheet: Thermic Lance RodsSaud NishatNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Careta Fotosensible TwecoDocument1 pageCareta Fotosensible TwecoThonny BarreraNo ratings yet

- Weld Filler WireDocument37 pagesWeld Filler WireSiva Raman MurugesanNo ratings yet

- Ay24 0Document4 pagesAy24 0Thonny BarreraNo ratings yet

- Ay24 0Document4 pagesAy24 0Thonny BarreraNo ratings yet

- Ay24 0Document4 pagesAy24 0Thonny BarreraNo ratings yet

- Magnetic Drilling Machines CatalogDocument96 pagesMagnetic Drilling Machines CatalogThonny BarreraNo ratings yet

- Blackboard Collaborate ?? 20133N-17-S05-S021 27/02/2014 08:50:09 PMDocument12 pagesBlackboard Collaborate ?? 20133N-17-S05-S021 27/02/2014 08:50:09 PMThonny BarreraNo ratings yet

- Analisis Risisko Kesehatan Pajanan Benzena Di Industri Percetakan X Kota SemarangDocument8 pagesAnalisis Risisko Kesehatan Pajanan Benzena Di Industri Percetakan X Kota SemarangAyunda SaputriNo ratings yet

- Magnasoft JSSDocument5 pagesMagnasoft JSSLe LocNo ratings yet

- This Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.Document8 pagesThis Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.Denise Maria CandidoNo ratings yet

- Us6007005 AbsDocument6 pagesUs6007005 AbsQadri Al HadidNo ratings yet

- CRBR Primary Brine For Caustic Soda - CRBR, An iNNOVATION FOR pRIMARY BRINE rEFINING IN cHLOR-ALKALI pLANTDocument7 pagesCRBR Primary Brine For Caustic Soda - CRBR, An iNNOVATION FOR pRIMARY BRINE rEFINING IN cHLOR-ALKALI pLANTbazediNo ratings yet

- GFB-2 Equalizing Check Valve technical specificationsDocument10 pagesGFB-2 Equalizing Check Valve technical specificationsCARLOS MORENONo ratings yet

- Ionic CompoundsDocument2 pagesIonic CompoundsShenneth De CastroNo ratings yet

- Ionic Liquids Enhanced Performance of PVC Gels ActuatorDocument7 pagesIonic Liquids Enhanced Performance of PVC Gels ActuatorFaisal ur RehmanNo ratings yet

- Chemistry Chapter 1 QPDocument10 pagesChemistry Chapter 1 QPAsif AyazNo ratings yet

- LGLT 2: SKF Product Data SheetDocument1 pageLGLT 2: SKF Product Data SheetRahul SharmaNo ratings yet

- Potential of Atsuete and Alugbati Extracts as Hair DyeDocument9 pagesPotential of Atsuete and Alugbati Extracts as Hair DyeLarry BesanesNo ratings yet

- F3055 14aDocument8 pagesF3055 14asenthilNo ratings yet

- Nevirapine Drug .Document11 pagesNevirapine Drug .AminaNo ratings yet

- CR39W Alloy Properties and ApplicationsDocument2 pagesCR39W Alloy Properties and ApplicationsJean-Noël LerouxNo ratings yet

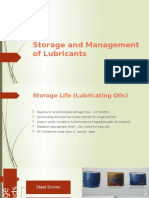

- For Storage & Management of LubricantsDocument7 pagesFor Storage & Management of LubricantsPrajyot MahajanNo ratings yet

- Fluidized Bed Jet MillDocument5 pagesFluidized Bed Jet Milln73686861No ratings yet

- C882Document4 pagesC882Jorge Luis Arevalo LopezNo ratings yet

- Bourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CaseDocument3 pagesBourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CasecarlosNo ratings yet

- Chemistry BasicsDocument10 pagesChemistry Basicsammuluhai333No ratings yet

- Utilisation of calcined mussel shells as partial cement replacementDocument8 pagesUtilisation of calcined mussel shells as partial cement replacementEugene Clark EridaoNo ratings yet

- PMC MDCAT Syllabus 2021 - FinalDocument46 pagesPMC MDCAT Syllabus 2021 - FinalbilalNo ratings yet

- Nonionic Surfactant Material Safety Data SheetDocument4 pagesNonionic Surfactant Material Safety Data SheetMayank DhawanNo ratings yet

- Kollidon VA 64Document10 pagesKollidon VA 64Rahma WatiNo ratings yet

- Distillation CurveDocument9 pagesDistillation CurveAmmar .kNo ratings yet

- Boiler Related QuestionDocument7 pagesBoiler Related QuestionBrijraj PandeyNo ratings yet

- Zep 14624Document4 pagesZep 14624Jorge AguirreNo ratings yet

- BS en 00046-2-2016Document28 pagesBS en 00046-2-2016amerNo ratings yet

- Cellular Transport Mechanisms ExplainedDocument9 pagesCellular Transport Mechanisms Explainedelyza gwenNo ratings yet

- To Cleaning & Degreasing Within The Industrial ManufacturingDocument8 pagesTo Cleaning & Degreasing Within The Industrial ManufacturingukalNo ratings yet

- Manufacturing Techniques ExplainedDocument5 pagesManufacturing Techniques ExplainedOsmar AlíNo ratings yet