Professional Documents

Culture Documents

9 Ciprofloxacin

Uploaded by

Baru Chandrasekhar RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 Ciprofloxacin

Uploaded by

Baru Chandrasekhar RaoCopyright:

Available Formats

IAJPS 2016, 3 (8), 826-830

M. P. Subash Chandran and K.Janakiraman

ISSN 2349-7750

CODEN (USA): IAJPBB

ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

Available online at: http://www.iajps.com

Research Article

EFFECT OF GRANULATION METHODS ON CIPROFLOXACIN

FILM COATED TABLETS

M. P. Subash Chandran*1 and K.Janakiraman1

* Department of Pharmacy, Annamalai University, Annamalai nagar, Chidambaram,

Tamilnadu - 608002, India.

1

Abstract:

Tablet dosage forms remain popular because of the advantages to the patient like accuracy of dosage, compactness,

portability, blandness of taste, and ease of administration. Film-coated tablets are compressed tablets that are

covered with a thin layer or film of a water-soluble material. Ciprofloxacin, an antibacterial agent, a

flouroquinolones derivative was used for this study. In this study, work was done to evaluate the ciprofloxacin film

coated tablets prepared by different granulation techniques, wet granulation and dry granulation. Dry granulation

was conducted on a press using a chilsonator, which offers a wide range of pressure and roll types to attain proper

densification. In wet granulation method, solutions of the binding agent were added to the mixed powders before

compression. Tablets prepared by both granulation methods were film coated and evaluated for tablet thickness,

tablet weight, friability testing, hardness testing, disintegration and dissolution. Though both the formulations

passed all tests for evaluation, tablets prepared by wet granulation method showed better results in hardness test,

friability test, disintegration test and dissolution test than the tablets prepared by dry granulation method.

Accelarated stability studies, conducted for a period of three months, proved that the tablets prepared by wet

granulation method showed better stability than the tablets prepared by dry granulation method.

Keywords: Tablet dosage form, film coated tablets, antibiotics, ciprofloxacin, granulation method.

Corresponding Author:

M. P. Subash Chandran,

Department of Pharmacy,

Annamalai University, Annamalai nagar,

Chidambaram,

Tamilnadu - 608002, India

Email: subashjr@rediffmail.com

Contact: +91-9843524878

QR code

Please cite this article in press as M. P. Subash Chandran and K.Janakiraman, Effect of Granulation Methods on

Ciprofloxacin Film Coated Tablets , Indo Am. J. P. Sci, 2016; 3(8).

www.iajps.com

Page 826

IAJPS 2016, 3 (8), 826-830

M. P. Subash Chandran and K.Janakiraman

INTRODUCTION:

Tablets are solid pharmaceutical dosage forms

containing drug substances with or without suitable

diluents and have been traditionally prepared by

either compression or molding methods [1]. They

differ greatly in size and weight depending on the

amount of drug substance present and the intended

method of administration. Compressed tablets usually

are prepared by large scale production methods while

molded tablets are generally produced in small scale

[2]. Tablets remain popular as a dosage form because

of its advantages like simplicity and economy of

preparation, stability, convenience in packaging,

shipping, and dispensing, accuracy of dosage,

compactness, portability, blandness of taste, ease of

administration.

The various tablet types are compressed tablets, sugar

coated tablets, film-coated tablets, enteric coated

tablets, multiple compressed tablets, controlled

release tablets, compressed tablets for solution,

effervescent tablets and compressed tablets. Three

general methods typically used for commercial tablet

preparation are wet-granulation method, dry

granulation method, and direct compression method.

The method of preparation and the added ingredients

give the tablet formulation, the desirable physical

characteristics allowing the rapid compression of

tablets [3]. After compression, the tablets must have a

number of additional attributes such as appearance,

hardness,

disintegration

ability,

appropriate

dissolution characteristics, and uniformity, which

also are influenced both by the method of preparation

and by the added materials present in the formulation.

In addition to the active or therapeutic ingredient,

tablets contain a number of inert materials called

excipients. The ingredients diluents, binders, glidants,

and lubricants help to impart satisfactory processing

and compression characteristics to the formulation

whereas disintegrants, surfactants, colors, flavours

and sweetening agents help to give additional

desirable physical characteristics to the finished

tablets.

Antibiotics are drugs used to treat infections caused

by bacteria and other microorganisms [4]. Originally,

an antibiotic was a substance produced by one

microorganism that selectively inhibits the growth of

another. The quinolone antibacterial drugs, the

flouroquinolones are strong inhibitors of DNA gyrase

and topoisomerage. The flouroquinolones possess

activity against gram positive, gram negative and the

atypical organism. The older fluoroquinolones,

namely, ciprofloxacin, norfloxacin and ofloxacin are

highly active against gram negative pathogens.

www.iajps.com

ISSN 2349-7750

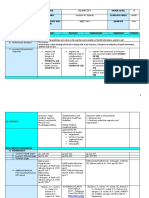

Fig 1: Structure of ciprofloxacin

Ciprofloxacin is an antibiotic used to treat a number

of bacterial infections [5]. Ciprofloxacin remains the

fluoroquinolone with the most potent in vitro activity

against

P.aeruginosa.

Resistance

to

one

fluoroquinolone usually confers resistance to all other

quinolones, but not to other classes of antimicrobial

drugs. Fluoroquinolones are all effective orally but

also may be administered parenterally. They have

large volumes of distribution and reach therapeutic

concentrations in most tissues. They have long half

lives and may be administered only once or twice a

day. Ciprofloxacin tablets can be prepared by two

methods, dry granulation and wet granulation. Wet

granulation was done by using binding agents

whereas dry granulation without binders.

MATERIALS AND METHODS:

Ciprofloxacin was obtained as gift sample from

Dr.Miltons Laboratories, Puducherry. Sodium starch

glycollate and povidone were purchased from

HiMedia Laboratories Pvt Ltd. All the other

ingredients used are of high standard analytical

grade.

Pre-Formulation Studies

Drug-excipients compatibility studies:

Compatibility of the drug with other excipients was

studied by using FT-IR technique in the wavelength

of 4000-400cm-1.

Method of preparation

In dry granulation method, formulation F1 sufficient

quantity of ciprofloxacin, colloidal silicon dioxide

and micro crystalline cellulose powder were sifted

through mesh [6]. The mixed granules were passed

through sifter. Granules were prepared using purified

tale, colloidal silicon dioxide, sodium starch

glycollate and dried starch. The sifted ingredients

were mixed with magnesium stearate in a mass

mixer. The lubricated granules were transferred to the

punching machine for compression. The compliance

of the parameters like average weight, hardness,

thickness, disintegration time and friability for the

compressed tablets were ensured. The tablets were

loaded and coated in a coating pan. The tablets were

checked for uniformity of film formation edge

coverage and color. Wet granulation method

Page 827

IAJPS 2016, 3 (8), 826-830

M. P. Subash Chandran and K.Janakiraman

formulation F2 was performed by the same procedure

with the addition of binding agent, starch paste.

Evaluation of coated ciprofloxacin tablets

Weight variation:

The weight of the tablets was evaluated with the help

of electronic balance [7]. 50 tablets were taken

randomly from both F1 and F2 Formulation during

compression process and weighed individually. The

average weight of the tablets and their standard

deviation from the mean value were obtained.

Table 1: Weight variation of ciprofloxacin tablets

Formulation

Theoretical average weight (mg)

Average weight of tablets (mg)

S.D of weight of tablets (mg)

F1

714.00

714.46

+ 1.7

F2

714.00

714.82

+ 5.96

Tablet thickness:

The thicknesses of the tablets were evaluated with the

help of the Vernier Caliper after calibrating to zero.

and each individual tablets were checked for their

thickness. 20 tablets from each of both F1

Formulation and F2 Formulation were taken for

evaluation. The standard deviation from their average

thickness was calculated [8].

Table 2: Thickness of ciprofloxacin tablets

Formulation

Theoretical thickness of tablet

(mm)

Average thickness of tablets

(mm)

S.D of thickness of tablets (mm)

F1

5.700

F2

5.700

5.672

5.784

+ 0.03

+

0.038

Friability:

The friability of the ciprofloxacin tablets were

evaluated by using a friabilator. 20 tablets were taken

from both F1 Formulation and F2 Formulation and

their total weight were noted. The tablets were placed

in the rotating chamber of the friabilator and the

friabilator was allowed to rotate for 100 times. The

tablets remained after rotations were taken and

weighed again. The difference between the weights

before and after rotation was found out and the

percentage of weight loss was calculated and

tabulated.

ISSN 2349-7750

Hardness:

A hardness tester was used for testing the hardness of

the tablet. 20 tablets were taken for testing and the

hardness of each tablet was checked and their

deviation from required hardness was calculated and

tabulated [9].

Table 4: Hardness of Ciprofloxacin Tablets

Formulation

Theoretical hardness of tablet

(kg/cm2)

Average hardness of tablets

(kg/cm2)

S.D of hardness of tablets

(kg/cm2)

F1

6.0

F2

6.32

6.0

6.12

+ 0.29

+ 0.36

Disintegration:

Six ciprofloxacin tablets from each formulation were

taken for testing the disintegration. DM water was

taken as medium and maintained at a constant

temperature of 37+0.5oC. Six tablets were placed in

the basket as one in each and the time taken for the

tablets to disintegrate was noted and tabulated [10].

Table 5: Disintegration Test of Ciprofloxacin

Tablets

Formulation

F1

F2

B1 (sec)

746

535

B2 (sec)

740

526

Dissolution of Ciprofloxacin tablets:

Dissolution of ciprofloxacin was studied by using

USP II apparatus (paddle type) with 900ml DM water

as dissolution medium. Paddle was rotated at 50rpm

at 37+0.5oC for 30 min. 5ml of aliquots was

withdrawn at predetermined time interval and an

equal amount of the medium was replaced to

maintain sink conditions. Three samples (sample 1,

sample 2 and sample 3) were taken in the initial

middle and final stage respectively, for analysis. The

amount of drug released was determined

spectrophotometrically. The absorbance of standard

and sample was measured at the wave length 276nm,

by using dissolution medium as a blank on UVspectrophotometer [11].

Table 6: Dissolution Profile of Ciprofloxacin

Tablets

Test

F1 (%)

F2 (%)

Limits (%)

Table 3: Friability Test of Ciprofloxacin Tablets

Sample 1

99.15

97.37

NLT 80

Formulation

F1

F2

Sample 2

98.82

96.72

NLT 80

Sample 3

97.89

96.12

NLT 80

B1 (%)

6.0

6.0

www.iajps.com

B2 (%)

6.32

6.12

Limits (%)

NMT 1.0

NMT 1.0

Page 828

IAJPS 2016, 3 (8), 826-830

M. P. Subash Chandran and K.Janakiraman

Stability studies:

Since the drug substances are naturally reactive,

some additives may react with drug molecules on

long storage. So accelerated stability studies are

performed. Tablets are stored at a temperature of

37+2oC at relative humidity 70+5oC after blister

packing for three months. They were periodically (1

month, 2 months and 3 months) evaluated by assay.

B.No

F1

F2

Period

Initial

After 1 month

After 2 months

After 3 months

Initial

After 1 month

After 2 months

After 3 months

www.iajps.com

Table 7: Assay of Ciprofloxacin Tablets

Test

F1 (%)

F2 (%)

Limits (%)

Sample 1

99.19

99.89

95-105

Sample 2

99.52

100.01

95-105

Sample 3

99.09

99.79

95-105

Table 8: Accelerated Stability Data

Description

A pale yellow colored round shaped

slightly biconvex film coated tablets,

plain on both sides

A pale yellow colored round shaped

slightly biconvex film coated tablets,

plain on both sides

RESULTS AND DISCUSSION:

Preformulation studies results did not show any drugexcipients interaction. From the results of analysis,

the physical stability studies showed the formulation

of F1 was better compared with F2. Mostly all the

physical parameters were good in F1 formulation

when compared with F2.

The weight variation studies showed that there is less

deviation in the weight of the tablets in formulation

F2 which was within the acceptable limit, which does

not cause any problem during packing, whereas in

formulation F2, there was a great deviation in the

weight of the tablets (Table 1). The reason is because,

in formulation F1 there is uniformity in the size of the

granules, which helped in flow property of the

granules during compression. But in formulation F 2,

the size of the granules is not uniform which directly

affected the flow property and indirectly caused

weight variation of the tablets.

When performed the tablet thickness test the tablets

in formulation F1 was closer to the required thickness

(Table 2). Due to the presence of uniform granules,

the compression was perfect, so desired thickness is

obtained. In formulation F2 the ununiformity of the

granules failed to flow uniformly and the

compression was affected and the thickness was

increased beyond the desired thickness.

In the hardness test the tablets of formulation F1 were

hard enough to withstand the effects caused during

shipping (Table 3). Though formulation F2 produced

required hardness there was a greater variation in the

hardness between the tablets. Due to the less hardness

ISSN 2349-7750

Assay(in mg)

499.52

497.06

496.52

494.38

498.26

496.06

495.86

493.40

%

99.90

99.41

99.30

98.81

99.65

99.21

99.17

98.60

of formulation F2, its friability loss was more than

formulation F1.

The tablet containing Ciprofloxacin was determined

UV-Spectrophotometrically in stability studies. The

Ciprofloxacin content showed slight difference

between F1 formulation and F2 formulation which

was within acceptable limit.

CONCLUSION:

Ciprofloxacin coated tablets were formulated in two

different methods like wet granulation and dry

granulation. These two formulations were named as

F1 and F2 respectively. The evaluation and stability of

the Ciprofloxacin coated tablets in the two

formulations were determined analytically. From the

results of this study it was conclude that the

formulation F1 prepared by wet granulation was

found to be better than the formulation F2 prepared by

dry granulation method.

REFERENCES:

1.Beverly Nickerson, William B. Arikpo. Leveraging

elevated temperature and particle size reduction to

various

tablet

formulations,

Journal

of

Pharmaceutical and Biomedical Analysis. 2008;

47(2): 268-278.

2.Windheuser J, Copper JJ. The pharmaceutics of

coating of tablets by compression, Journal of

American Pharmaceutical association. 1956; 45: 542545

3.Baojain WU, Ningyun S, Xiuli W, Wei W.

Characterization of 5-fluorouracil release from

Page 829

IAJPS 2016, 3 (8), 826-830

M. P. Subash Chandran and K.Janakiraman

HPMC compression coated tablets, Pharm Dev

Technology. 2007; 12: 203-210.

4.Rubinstein, E. History of Quinolones and their side

effects, Chemotheraphy. 2001; 47: 3-8.

5.Drusano GL, Standiford HC. Absolute Oral

Bioavailability of Ciprofloxacin, Antimicrob Agents

Chemother. 1986; 30: 444-446.

6.Srujan Reddy, Palash Das, Harika Das, Arpita

Ghosh. MUPS (Multiple Unit Pellet System) Tablets

A Brief Review, Journal of pharmaceutical and

biomedical sciences. 2012; 12(2): 1-5.

7.Nandini D Banerjee, Sushma R Singh. Formulation

and evaluation of compression coated tablets of

cefpodoxime proxetil, International journal of

pharma science and research. 2013; 4(7): 104-112.

www.iajps.com

ISSN 2349-7750

8.N. C. Ngwuluka1, K. Lawal1, P. O. Olorunfemi1

and N. A. Ochekpe2*. Post-market in vitro

bioequivalence study of six brands of ciprofloxacin

tablets/caplets in Jos, Nigeria. 2009; 4(4): 298-305.

9.Polk, R. E. Drug-drug interactions with

ciprofloxacin and other fluoroquinolones, American

Journal of Medicine. 1989; 87(5): 76-81.

10.Rani S. Bioequivalence; Issues and perspectives,

Indian journal of pharmacology. 2007; 39(5): 218225.

11.Tadashi Fukunaka, Yoshiko Yaegashi. Dissolution

characteristics of cylindrical particles and tablets,

International Journal of Pharmaceutics. 2006; 310(12) 146-153.

Page 830

You might also like

- Renr Study GuideDocument57 pagesRenr Study GuideJerilee SoCute Watts92% (12)

- PleuritisDocument32 pagesPleuritisBinot's TogamaNo ratings yet

- Peplau's Groundbreaking Theory of Interpersonal Nursing RelationshipsDocument5 pagesPeplau's Groundbreaking Theory of Interpersonal Nursing Relationshipsgandhialpit100% (1)

- Jurnal CarbamazepinDocument9 pagesJurnal CarbamazepinRosamaria Yuni UtamiNo ratings yet

- 9.colon TargetDocument6 pages9.colon TargetBaru Chandrasekhar RaoNo ratings yet

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 pagesFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuNo ratings yet

- Fast-dissolving tablets of Flunarizine DihydrochlorideDocument10 pagesFast-dissolving tablets of Flunarizine DihydrochlorideAccung BuccuNo ratings yet

- Formulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochlorideDocument12 pagesFormulation and Evaluation of Multiunit Pellet System of Venlafaxine HydrochloridevbadsNo ratings yet

- International Journal of Pharma and Bio Sciences V1 (2) 2010Document10 pagesInternational Journal of Pharma and Bio Sciences V1 (2) 2010Desy Ratna Sari NainggolanNo ratings yet

- Product Quality Management During Production of Tablet'S: April 2016Document8 pagesProduct Quality Management During Production of Tablet'S: April 2016Hasanali IldirimovNo ratings yet

- (216 235) V10N5CTDocument20 pages(216 235) V10N5CTgritty gallantNo ratings yet

- Formulation and Evaluation of Quinapril Sustained Release Matrix TabletsDocument14 pagesFormulation and Evaluation of Quinapril Sustained Release Matrix TabletsSyed Qasim MehmoodNo ratings yet

- Admin, Journal Manager, 823Document7 pagesAdmin, Journal Manager, 823vijay mNo ratings yet

- Na DastinibDocument20 pagesNa DastinibPradheep SNo ratings yet

- Admin,+journal+manager,+70 AJPCR 21211 RA QueryDocument4 pagesAdmin,+journal+manager,+70 AJPCR 21211 RA QueryTareq Al MahmudNo ratings yet

- Buccal Film Thesis PDFDocument7 pagesBuccal Film Thesis PDFafiwiafoc100% (2)

- 6 Vol 1 Issue 8 Paper 3Document7 pages6 Vol 1 Issue 8 Paper 3WaqasskhanNo ratings yet

- DDS (Design & Development of Controlled Release)Document8 pagesDDS (Design & Development of Controlled Release)Zaw Min SoeNo ratings yet

- Article WJPR 1400475907Document13 pagesArticle WJPR 1400475907miserable1995No ratings yet

- Article Wjpps 1420087262Document16 pagesArticle Wjpps 1420087262ainNo ratings yet

- Dry Granulation by Slugging Method For Sustained Release of Model DrugDocument50 pagesDry Granulation by Slugging Method For Sustained Release of Model DrugBagus SetiawanNo ratings yet

- 3Document5 pages3Isma UddinNo ratings yet

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDocument5 pagesFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784No ratings yet

- Colon-Specific Flurbiprofen TabletsDocument11 pagesColon-Specific Flurbiprofen TabletsFahriz HibatullahNo ratings yet

- Biofar TerapanDocument4 pagesBiofar TerapanWelly IrwandaNo ratings yet

- Comparative Evaluation of in Vitro Physicochemical Parameters of Some Commercially Available Metformin HCL 500mg Tablets in BangladeshDocument5 pagesComparative Evaluation of in Vitro Physicochemical Parameters of Some Commercially Available Metformin HCL 500mg Tablets in BangladeshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Timolol maleate buccal patches using natural polymersDocument6 pagesTimolol maleate buccal patches using natural polymersIsma UddinNo ratings yet

- Q.C in YemenDocument6 pagesQ.C in YemenWafa BadullaNo ratings yet

- Formulation and evaluation of pulsatile release tablets of celecoxibDocument19 pagesFormulation and evaluation of pulsatile release tablets of celecoxibSiva PrasadNo ratings yet

- Jurnal First Pass MetabolismDocument11 pagesJurnal First Pass MetabolismLelyta Ayu DewankgaNo ratings yet

- DiltiazemDocument10 pagesDiltiazemSari Puspita DewiNo ratings yet

- A C A D e M I C S C I e N C e SDocument6 pagesA C A D e M I C S C I e N C e SKris Natalia ManihurukNo ratings yet

- Ijarnd Deepthi PDFDocument5 pagesIjarnd Deepthi PDFdeepthi_mpharmacy613No ratings yet

- Formulation and Evaluation of Cefuroxime Axetil Orodispensible TabletsDocument10 pagesFormulation and Evaluation of Cefuroxime Axetil Orodispensible TabletsBaru Chandrasekhar RaoNo ratings yet

- John 2013Document5 pagesJohn 2013Fhyrdha Slaluw ZetiaaNo ratings yet

- IJDFR206Document11 pagesIJDFR206Agustinus VincentNo ratings yet

- Formulation Development and Evaluation of Sustained Release Tablet Chlorpromazine HCLDocument7 pagesFormulation Development and Evaluation of Sustained Release Tablet Chlorpromazine HCLWJPSR JournalNo ratings yet

- Mucoadhesive Microencapsulation: A New Tool in Drug Delivery SystemsDocument61 pagesMucoadhesive Microencapsulation: A New Tool in Drug Delivery SystemsLailatul QadarNo ratings yet

- 223 PDFDocument9 pages223 PDF26nazilarenoatNo ratings yet

- Floating Microspheres ThesisDocument6 pagesFloating Microspheres Thesisstephaniebarkerpeoria100% (2)

- Design and Development of Controlled Porosity Osmotic Pump Tablets of Zidovudine Using Sodium Chloride As Osmogen For The Treatment of Aids JPR 19Document8 pagesDesign and Development of Controlled Porosity Osmotic Pump Tablets of Zidovudine Using Sodium Chloride As Osmogen For The Treatment of Aids JPR 19gritty gallantNo ratings yet

- Local drug delivery of chitosan strips containing sparfloxacinDocument11 pagesLocal drug delivery of chitosan strips containing sparfloxacinNadya PurwantyNo ratings yet

- JPSR 03110106Document9 pagesJPSR 03110106sunilpdNo ratings yet

- 61Document4 pages61Ta RaNo ratings yet

- Amytriptilin FormulationDocument7 pagesAmytriptilin FormulationWahyu RedfieldNo ratings yet

- Captopril FloatingDocument6 pagesCaptopril FloatingMira TjakkuduNo ratings yet

- Formulation and Evaluation of Floating Microspheres of Metformin HydrochlorideDocument10 pagesFormulation and Evaluation of Floating Microspheres of Metformin HydrochlorideBaru Chandrasekhar RaoNo ratings yet

- Formulationandin vitroEvaluationofBuccalTabletsofPiroxicam PDFDocument11 pagesFormulationandin vitroEvaluationofBuccalTabletsofPiroxicam PDFFransisca Cornelia PutriNo ratings yet

- Monte LukastDocument6 pagesMonte LukastPham XuanNo ratings yet

- 8 CF 3Document10 pages8 CF 3nelisaNo ratings yet

- Formulation and Evaluation of ValsartanDocument15 pagesFormulation and Evaluation of Valsartanningsih rezekiNo ratings yet

- Ibu, PenetrationDocument8 pagesIbu, PenetrationDucNo ratings yet

- CumulativeReleaseofadrug PDFDocument4 pagesCumulativeReleaseofadrug PDFkumar purushotamNo ratings yet

- Formulation and Evaluation of Zolmitriptan Fast Dissolving Buccal FilmsDocument8 pagesFormulation and Evaluation of Zolmitriptan Fast Dissolving Buccal FilmsKumar GalipellyNo ratings yet

- Vol 7 | Issue 1 | 2017 | Colon Targeting Tramadol MicrobeadsDocument5 pagesVol 7 | Issue 1 | 2017 | Colon Targeting Tramadol MicrobeadsDHIVYANo ratings yet

- 1 RJPT 10 12 2017Document9 pages1 RJPT 10 12 2017yahyaNo ratings yet

- Design of Novel Oral Films As Drug Delivery SystemDocument7 pagesDesign of Novel Oral Films As Drug Delivery SystemReza-ul JalilNo ratings yet

- My Research PaperDocument10 pagesMy Research PaperMamta AroraNo ratings yet

- Development and evaluation of transdermal patches with Cissus Quadrangularis plant extractDocument6 pagesDevelopment and evaluation of transdermal patches with Cissus Quadrangularis plant extractMeirianaNo ratings yet

- Develop pediatric ODT paracetamol tabletsDocument8 pagesDevelop pediatric ODT paracetamol tabletsAmanuel TamiruNo ratings yet

- Ijpbs 5757220f69381Document12 pagesIjpbs 5757220f69381ashwaniNo ratings yet

- Parenteral Products: The Preparation and Quality Control of Products for InjectionFrom EverandParenteral Products: The Preparation and Quality Control of Products for InjectionNo ratings yet

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDocument9 pagesFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoNo ratings yet

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNo ratings yet

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDocument13 pagesNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoNo ratings yet

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDocument6 pagesSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoNo ratings yet

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDocument12 pagesNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoNo ratings yet

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNo ratings yet

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDocument6 pagesDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoNo ratings yet

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Document5 pagesGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoNo ratings yet

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoNo ratings yet

- Preparation of Silver Nanoparticles From Herbal PlantDocument9 pagesPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoNo ratings yet

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoNo ratings yet

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDocument8 pagesThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoNo ratings yet

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNo ratings yet

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDocument6 pagesAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoNo ratings yet

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNo ratings yet

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDocument4 pagesRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoNo ratings yet

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNo ratings yet

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Document8 pagesIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoNo ratings yet

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDocument4 pagesAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoNo ratings yet

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDocument4 pagesAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoNo ratings yet

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDocument5 pagesC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoNo ratings yet

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Document6 pagesStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoNo ratings yet

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDocument10 pagesOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocument6 pagesAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoNo ratings yet

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDocument6 pagesAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoNo ratings yet

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNo ratings yet

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDocument8 pagesA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- Fact Sheet Squamous Cell Carcinoma Oct 2013Document10 pagesFact Sheet Squamous Cell Carcinoma Oct 2013Triven Nair HutabaratNo ratings yet

- Measures of Association in EpidemiologyDocument56 pagesMeasures of Association in EpidemiologyAmsaluNo ratings yet

- Repertory: Information On Health Concerns in A Health DirectoryDocument17 pagesRepertory: Information On Health Concerns in A Health DirectoryShalinta Dubey SharmaNo ratings yet

- Hospital Waste Water TreatmentDocument5 pagesHospital Waste Water TreatmentNP100% (1)

- Nursing ProcessDocument118 pagesNursing Processɹǝʍdןnos100% (30)

- Potential Long-Term Side Effects of Exposure To ChemoDocument21 pagesPotential Long-Term Side Effects of Exposure To ChemoMichael BubleNo ratings yet

- Imir Studyguide2014Document499 pagesImir Studyguide2014Sam GhaziNo ratings yet

- Humalog - Uses, Dosage & Side Effects - DrugsDocument4 pagesHumalog - Uses, Dosage & Side Effects - Drugsremyde07100% (1)

- Q1 Grade 10 HEALTH DLL Week 2Document14 pagesQ1 Grade 10 HEALTH DLL Week 2Leonor MayoyaNo ratings yet

- Nerve PainDocument1 pageNerve PainRahafNo ratings yet

- The Egyptian Heart Journal: Haitham Galal Mohammed, Adel Mohamed ShabanaDocument6 pagesThe Egyptian Heart Journal: Haitham Galal Mohammed, Adel Mohamed ShabanaDaniel Zagoto100% (1)

- Jack Poylangada - Copy of Stamper Self-Care JournalDocument8 pagesJack Poylangada - Copy of Stamper Self-Care Journalapi-503633296100% (3)

- Research ArticleDocument4 pagesResearch ArticleBharathi RagavanNo ratings yet

- Cataract: Presented By: HomipalDocument12 pagesCataract: Presented By: Homipalankita singhNo ratings yet

- DAILY LESSON Plan 4 - 1.8Document4 pagesDAILY LESSON Plan 4 - 1.8Wilbeth PanganibanNo ratings yet

- Practicing The A, B, C'S: Albert Ellis and REBTDocument24 pagesPracticing The A, B, C'S: Albert Ellis and REBTShareenjitKaurNo ratings yet

- Healthy Performer - WorkbookDocument17 pagesHealthy Performer - WorkbookChantelle Penhorwood-richardsNo ratings yet

- WREBDocument94 pagesWREBJessica Bahga100% (1)

- On The Medicinal Chemistry of Gold Complexes As Anticancer DrugsDocument12 pagesOn The Medicinal Chemistry of Gold Complexes As Anticancer DrugsJeffersonNo ratings yet

- Motion SicknessDocument5 pagesMotion SicknessIbrahim AbdullahNo ratings yet

- Class II Division 2 Malocclusion What The Clinician Should KnowDocument10 pagesClass II Division 2 Malocclusion What The Clinician Should KnowNawaf RuwailiNo ratings yet

- EGA Factsheet 01Document1 pageEGA Factsheet 01Rajeeb Chandra ShahaNo ratings yet

- Guidelines Antibiotic Step-Down TherapyDocument1 pageGuidelines Antibiotic Step-Down TherapyGayle GreyNo ratings yet

- Psychotherapeutic Traditions HandoutDocument5 pagesPsychotherapeutic Traditions HandoutTina Malabanan CobarrubiasNo ratings yet

- Formulation and Evaluation of Antiseptic Polyherbal OintmentDocument11 pagesFormulation and Evaluation of Antiseptic Polyherbal OintmentandrapradeshsseNo ratings yet

- Applications of Humic and Fulvic Acids in AquacultureDocument2 pagesApplications of Humic and Fulvic Acids in AquacultureAlexandra Nathaly Beltran Contreras100% (1)

- Bio Medical Waste Management and Handling Environment LawDocument15 pagesBio Medical Waste Management and Handling Environment LawAnkit Tyagi100% (1)