Professional Documents

Culture Documents

Formulation and Evaluation of Multiunit Pellet System of Venlafaxine Hydrochloride

Uploaded by

vbadsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and Evaluation of Multiunit Pellet System of Venlafaxine Hydrochloride

Uploaded by

vbadsCopyright:

Available Formats

M Srujan Kumar et al.

/ JPBMS, 2012, 18 (05)

1 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Available online at www.jpbms.info

JPBMS

JOURNAL OF PHARMACEUTICAL AND BIOMEDICAL SCIENCES

Formulation and Evaluation of Multiunit Pellet System of Venlafaxine Hydrochloride

*M. Srujan Kumar

1

, Binayak Das

1

, S.V.S.Rama Raju

2

1

Department of Pharmaceutics, Samskruti college of Pharmacy,Kondapur,R.R District,Hyderabad,India.

2

Department of Pharmaceutics, C.L.Baid Metha College of pharmacy, Chennai, India.

Abstract:

Compaction of multiparticulate, commonly called MUPS, is one of the more recent and challenging technologies that

combine the advantages of both tablets and pellet-filled capsules in one dosage form. Venlafaxine is an anti depressant,

having an elimination half-life of 52 hrs and its maximum daily dose is 300mg. Since the drug belongs to BCS class I, it is

necessary to retard dissolution to ensure extended release of drug. The objective of the study is to prepare venlafaxine

extended release pellets by extrusion spheronization technology, coating them with mixture of rate controlling polymers

Ethyl cellulose and different grades of (Hydroxy propyl methyl cellulose (HPMC) using Wurster process to achieve the

desired dissolution pattern and compressing the pellets into tablets. The pellets were analyzed for the parameters such as

bulk density, tapped density, compressibility index, Hausners ratio and the results were found to be within the limits.

Drug release rate was more when compared with the innovator sample. The Venlafaxine hydrochloride extended release

pellets were compressed into the tablets. The dissolution profile of the prepared Venlafaxine hydrochloride extended

release tablets were compared with that of Innovator (VENLAR). Finally conclude like extended release pellets in tablets of

formulation (F9) have more drug release rate rather than innovator (VENLAR) and it have better Bioavailability.

Keywords: Extrusion and Spheronization, HPMC, MUPS, multiparticulate, wurster process.

Introduction:

The oral route of administration of drugs is the most

important method for achieving systemic effects. In the

process of absorption of drug from oral route dissolution is

the rate limiting step. Since the drug belongs to BCS class I,

it is necessary to retard dissolution to ensure extended

release of drug. Venlafaxine is an anti depressant, having

an elimination half-life of 52 hrs and its maximum daily

dose is 300mg. Hence it is an ideal candidate for extended

release formulation. The objective of the study is to

prepare venlafaxine extended release pellets by extrusion

spheronization technology and further coating them with

mixture of rate controlling polymers Ethyl cellulose and

hydroxy propyl methyl cellulose using Wurster process to

meet the desired dissolution pattern and compressing the

pellets into tablets.

Modified release can be categorized into delayed release

and extended, or prolonged, release. The primary aims of

using delayed release are to protect the drug from an un

favorable environment in the gastrointestinal tract, to

protect the gastrointestinal tract from high, local

concentrations of an irritating drug compound, or to target

a specific region of absorption or action. Delayed release

products are typically enteric-coated or targeted to the

colon. Extended release products aim at releasing the drug

continuously at a predetermined rate to ncrease the

patient compliance

1, 2

. The method pelletization technique

developed in the early 1960s and since then researched

and discussed extensively. Interest in the technology is still

strong, as witnessed by the extent of coverage of the topic

in scientific meetings and symposium proceedings, as well

as in scientific literature. The technology is unique in that it

is not only suitable for manufacture of pellets high drug

loading but it also can be used to produce extended release

pellets in certain situations in a single step and thus can

obviate the need for subsequent film coating. Pellets are

agglomerates of fine powders or granules of bulk drugs

and excipients. They consist of small, free-flowing,

spherical or semi-spherical solid units, typically from about

0.5 mm to 1.5 mm, and are intended usually for oral

administration

1, 2.

Pellets are agglomerates of fine powders or granules of

bulk drugs and excipients. They consist of small, free-

flowing, spherical or semi-spherical solid units, typically

from about 0.5 mm to 1.5 mm, and are intended usually for

oral administration. Implants of small, sterile cylinders

formed by compression from medicated masses are also

defined as pellets in pharmacy. Pellets can be prepared by

many methods, the compaction and drug layering

techniques being the most widely used today. Regardless

of which manufacturing process used, pellets have to meet

the following requirements.

1. They should be near spherical and have a smooth

surface; both considered optimum characteristics for

subsequent film coating.

2. The particle size range should be as narrow as possible.

The optimum size of pellets for pharmaceutical use are

considered between 600 and 1000 m.

3. The pellets should contain as much as possible of the

active ingredient to keep the size of the final dosage form

within reasonable limits. In the last two decades, pellets

have established their place for many reasons.

Pellets offer a great flexibility in pharmaceutical solid

dosage form design and development. They flow freely and

ISSN NO- 2230 7885

CODEN JPBSCT

Research article

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

2 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

pack easily without significant difficulties, resulting in

uniform and reproducible fill weight of capsules and

tablets. Successful film coating is applied on pellets due to

their ideal spherical shape and a low surface area to

volume ratio. Pellets composed of different drugs are

blended and formulated in a single dosage form. This

approach facilitates the delivery of two or more drugs,

chemically compatible or incompatible, at the same sites or

different sites in the gastrointestinal tract even pellets with

different release rates of the same drug is supplied in a

single dosage form. The most important reason for the

wide acceptance of multiple-unit products is the rapid

increase in popularity of oral controlled-release dosage

forms. Controlled-release oral solid dosage forms are

usually intended either for delivery of the drug at a specific

site within the gastrointestinal tract or to sustain the action

of drugs over an extended period With pellets, the

abovementioned goals are obtained through the

application of coating materials (mainly different

polymers), providing the desired function or through the

formulation of matrix pellets to give the desired effect. The

advantage of multiple-unit products as a controlled-release

dosage form believed to be their behaviour in vivo because

of their advantageous dispersion pattern in the

gastrointestinal tract and their special size characteristics.

The transit time of a gastrointestinal drug delivery system

along the gastrointestinal tract is the most limiting

physiological factor in the develop of a controlled-release

gastrointestinal drug delivery system targeted to once-a-

day medication. Gastro-intestinal transit time, greatly

affects the bioavailability of a drug from an orally

administered controlled release preparation. Gastric

transit of both single and multiple-unit solid dosage forms

prolonged in a fed stomach compared to a fasting one

1, 2, 3

.

Extrusion and spheronization:

The concept of multiparticulate dosage forms introduced

in the 1950s with the increasing use of multiparticulate

controlled release (CR) oral dosage forms, in recent times

there has been a rise in interest in the methods of

preparing these dosage forme. A method that has gained

increased usage over the past few years is that of extrusion

and spheronization.it has extensively as a potential

technique and also as a future method of choice for

preparation of multiparticulate CR dosage forms.

This is a multi step process involving dry mixing, wet

granulation, extrusion, spheronization, drying and

screening. The first step is dry mixing of the drug and

excepients in a suitable mixer followed by wet

granulation, in which the powder is converted into a plastic

mass that is easily extruded. The extruded strands

transferred into a spheronizer, where they are

instantaneously broken into short spherical rods on

contact with the rotating friction plate and pushed

outward and up the stationary wall of the processing

chamber by centrifugal force. Finally, owing to gravity, the

particles fall back to friction plate, and the cycles repeated

until the desired sphericity achieved.

Extrusion-spheronization is a multistep process involving a

number of unit operations and equipment. However, the

most critical part of processing equipment dictates the

outconme of overall quality of pellets.

Figure 1: Overview of the Formulation of ER Pellets

Extrusion:

Shaping of the wet mass into long rods are called as

extrusion. A variety of extruders, which differ in design

features and working principles, are currently on market

and can be classified as screw-fed extruder, gravity-fed

extruder and ram extruder. Screw-fed extruder have

screws that rotate along the horizontal axis and hence

transport the materials horizontally, they may axial or

radial screw extruders. The product temperature

controlled during extrusion by jacketed barrels. In radial

extruders, the transport zone is short, and the material

extruded radially through screens mounted around the

horizontal axis of the screws. Gravity-fed extruders include

the rotating cylinder and rotating gear extruders, which

differ primarily in the design of two counter-rotating

cylinders. In the rotating cylinder extruder, one of the two

counter rotating cylinders is hallow and perforated, where

as the other cylinder is solid and acts as a pressure roller.

In ram extruders, piston displaces and forces the materials

through a die at the end. Ram extruders preferred during

formulation development they designed to allow for

measurement of the rheological properties of formulation.

In an extrusion-spheronization process, formulation

components such as filler, lubricants and ph modifiers play

a critical role in producing pellets with desired attributes.

The granulated mass must plastic and sufficiently cohesive

and self lubricating during extrusion. During the

spheronization step, it is essential that the extrudates

break at appropriate length and have sufficient surface

moisture to enhance the formulaion of uniform spherical

pellets. Excepients play an important role during extrusion

spheronization than during with other pelletization

process. they facilitate extrusion and determine the

spherecity of the wet pellets, imparts strength and

integrity of the pellets.

Microcrystalline cellulose (MCC) is the most commonly

used excipient in extrusion spheronization it leads to the

formation of round spheres with desirable characteristics.

During spheronization, moisture entrapped in the MCC

microfibrils adds plasticity to the extrudates into spherical

pellets.

The pellet properties can be affected by many operational

variables during the extrusion stage, the spheronization

stage, or the drying stage. Both drying technique and

drying temperature have a considerable affect on the pellet

structure and properties. The variables that affect the final

pellet qualities are screen pressure, screen hole diameter,

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

3 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

extruder type and speed, the type of friction plate, and

spheronization time, speed and load. There is considerable

interaction between spheronization time and

spheronization load. With small and large spheronization

loads, the yield of large pellets increases with longer

spheronization time, an effect that is exacerbated by faster

spheronization speed. Unsuitable processing parameters

lead to pellet with poor qualities.

Spheronization:

During the third phase of extrusion spheronization process

the extrudates dumped on to the spinning plate of the

spheroniser, call the friction plate, where the extrudate

broken up into smaller cylinders with a length equal to

there diameter, those plastic cylinders rounded due to

frictional forces. In the spheronization process different

stages are distinguished depending on the shape of the

particles, I.e; starting from a cylinder over a cylinder with

rounded edges, dumbbells and elliptical particles to

eventually perfect spheres. Baert and remon (1993)

suggested that another pellet forming mechanism might

exist. In this mechanism twisting of a cylinder occurs after

the formation of cylinders with rounded edges, finally

resulting in the breaking of the cylinder into two distinct

parts. Both parts have round and flat side. Due to rotational

and frictional forces involved in the spheronization process

the edges of the flat side fold together like a flower

forming the cavity observed in certain pellets. The

spheronization of a product usually takes 2-10 minutes. A

rotational speed of friction plate in the range between 200

and 400 RPM would be satisfactory to get highly spherical

pellet. This statement is in a sharp contrast with most

reports indicating the use of spheronization speeds

exceeding 400 RPM. This contradiction are explained by

the fact that not the absolute speed is important but the

speed in combination with the diameter of the friction

plate. From those two parameters the plate peripheral

velocity is calculated and this data should be compared

instead of absolute rotational speed of the friction plate.

The friction plate has a grooved surface to increase the

frictional forces. Two types of geometry of the grooves

exist, cross hatch geometry where the grooves from right

angles and radial geometry where a radial pattern used.

Figure 2: Mechanism of pellet formation

A special kind of spheronizer designed by NICA-systems

with a lip around the rim of the friction plate which claims

to reduce the milling affect of the friction plate resulting in

small amount of fines. Depending upon composition of

formulation, substance soluble in the granulation liquid

might migrate to the outside of the pellets during

spheronization, leading to an in homogeneous distribution

of the substance throughout the pellet. Snapshot of

spheronization process:

Figure 3: Snap shot of spheronization process

Courtesy :- http:/ / spheronizer.com/ html/ spheronization.html

Wurster process

The wurster process can appropriately be described as an

upward moving, highly expanded pneumatically

transported bed of pellets coupled with a downward-

moving, more condensed, fluidized bed of pellets on the

periphery of a vertical column. The two beds separated by

tubular central partition. As the pellets pass through the

atomizer they wetted by the coating fluid and then

subjected to drying conditions created by the heated

conveying air moving upwardly in the column. The

partially coated solid pellets move downwardly in a

weightless condition along the periphery of the column,

where further drying occurs. When the solid pellets reach

the lower end of the column those directed back into the

upwardly moving bed and the entire process repeated.

The air pump, heater, provides the heated support air for

the process, and the distribution plate directs the proper

volume of air to the central and peripheral regions of the

column. The proper adjustment of the air flow, the

temperature, and fluid application rate is critical to the

successful operation of the process. Obviously, the drying

kinetics is influenced by air flow rate and the temperature

of the air. This kinetics in turn dictates the fluid application

rate. Since drying is a cooling process. The temperature of

the pellet surface is lower than either the inlet or exhaust

air temperature.

This permits the coating of heat-sensitive materials, since

process conditions are adjusted so that the exhaust

temperature will not exceed the temperature in which the

product can tolerate. Thus, it is readily apparent that the

drying kinetics are enhanced by increasing either the air

flow rate or air temperature while maintaining the fluid

application rate constant

1, 2

.

From the literature survey:

Steven H. Neau et al., (2010) evaluated the potential of

coarse ethyl cellulose (CPEC) and high molecular weight

polyethylene oxide (PEO) as excipients in the production of

beads by extrusion-spheronization. CPEC was investigated

as a diluents and PEO as an extrusion aid and a binder.

Beads manufactured with caffeine as a model drug. release

studies were conducted, and the bead size, shape, yield,

and friability determined. The results confirmed that

immediate release, spherical beads with low friability and

narrow size distribution to be produced with minimum

amounts of MCC

3

.

Fridrun podczeck et al., (2009) has studied influence of

adding two concentrations (5 and 25% ) of non-ionic

surfactants, one hydrophilic and the other hydrophobic,

plus mixtures of equal parts of the two, on the rheological

properties of a mixture of equal parts of microcrystalline

cellulose and ibuprofen with water by capillary rheometry .

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

4 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

The mixtures are also used to form pellets by extrusion-

spheronization and their in vitro dissolution in simulated

intestinal fluid measured. The 25% level of each of the

surfactant formulations provided a rapid release of drug

(100% within 30 minutes) but the 5% level and the mixed

surfactant formulations provided lower drug release

profiles

4

.

Lieven Baert et al., (2009) produced pellet formulation

containing a high drug loaded (80%) of the poorly soluble

HIV-protease inhibitor darunavir, using wet extrusion-

spheronization with K-carrageenan or microcrystalline

cellulose (MCC) as pelletization aid. When compared with

MCC pellets the bioavailability of darunavir was

substantially improved by sixty fold in K-carrageenan

pellets, likely due to their better disintegration behavior

5

.

Podczeck F. et al., (2008) investigated the ability to

incorporate non-ionic surfactants into pellets produced

from MCC by the process of extrusion-spheronization and

the properties of the pellets. A hydrophilic surfactant,

polysorbate 60 (PS 60), and two hydrophobic surfactants,

sorbitan monostearate (S 60) and sorbitan monooleate (S

80), Were included in the water used to form pellets in the

concentration ranging from 5 to 95%. The highest

concentration of the surfactant in water that is used to

form pellets ranged from 50% for S 60, to 80% for S 80 and

95% for PS 60. The maximum amount of surfactant, which

would be incorporated into final pellet, however, was

found approximately 22.5% for both hydrophobic

surfactants and 32.5% for hydrophilic surfactant

6

.

Sriamornsak et al., (2007) has investigated the

possibility in producing alginate-based pellets by

extrusion-spheronization and also to improve the

formation of spherical alginate-based pellets by

investigating the effect of additive in granulation liquid on

characteristics and drug release from resulting pellets.

Higher amount of 3% calcium chloride as granulating

liquid, formulations showed higher mean dissolution time

resulting from cross linking properties of calcium ions to

the negative charges of alginate molecules

7

.

Ramo n Marti nez-Pacheco et al., (2005) studied the

utility including superdisintegrants (croscaramellose

sodium or sodium starch glycolate) in microcrystalline

cellulose extrusion-spheronization pellets as means of

increasing the dissolution rate of hydrochlorothiazide.

Drug dissolution rate was slightly higher in pellets

prepared with sodium starch glycolate, propably because

this disintegrants higher swelling capacity

8

.

Steckel.H et al., (2003) successfully prepared chitosan

pellets replacing MCC. pellets with a maximum of 50%

(m/ m) of chitosan could be produced using demineralized

water and the mass fraction of chitosan within the pellets

could be increased to 100% by using diluted acetic acid for

the granulation step

9

.

Ingunn tho et al., (2003) studied low-soluble pectin

derivative, PA (degree of methoxylation, 10%) as an

extrusion aiding excipient in pellet preparation by

spheronisation / extrusion.

The substance has a high drug loading capacity and

produces disintegrating pellets that are well suited for fast

delivery of drugs with a low water-solubility. The pellets

are also mechanically stable, compared to MCC

10

.

Newton. J.M et al.,(2002) has experimented on five drug

models , 4-para hydroxyl benzoic acid(4HBA), methyl,

propyl and butyl benzoic acid and propyl gallate(PG) . All

of similar chemical natures were mixed in different

proportions (50-73.7%) with MCC (26.3-50%) plus

various levels of water (26.9-50%). The wet powder mass

extruded and spheronized under standard conditions. The

pellets produced, evaluated in terms of their median

diameter, their modal size range, the % within a given size

range (0.7-1.7 mm) and their shape factor. For the

majority of formulations, all drug models, except 4HBA,

produced pellets

11

.

Gayot .A et al.,(2002) successfully produced 400m

spheroids that is sprinkled on food to improve patient

compliance particularly in case of children and old people.

Gelucire 50/ 02 wetted with a sodium lauryl sulphate

solution at 0.5% was used which showed plastic flow

through the 400 m diameter orifice

12.

Materials and methods:

Table 1: List of Materials used

S.No

Active and inactive

pharmaceutical

ingredients

Suppliers

1 Venlafaxine Matrix laboratories ltd, Hyd.

2

Microcrystalline cellulose

(avicel PH 101)

FMC Biopolymer, USA

3

Hydroxypropyl

cellulose(Klucel)

Aqualon , USA

4 Opadry Clear Colorcon , Goa

5 Ethylcellulose (Ethocel) DOW , USA

6

Hydroxyl propyl methyl

cellulose

DOW , USA

Table 2: List of Equipments used:

S.No Equipments Manufacturers

1 Electronic balance Mettler Toledo, USA.

2 Rapid mixer granulator Kevin, Ahmedabad.

3 Extruder Fuji paudal co.Ltd, Japan.

4 Spheronizer/ Marumerizer

TM

Fuji paudal co.Ltd, Japan.

5 Rapid dryer Retsch, Germany.

6 Mechanical stirrer Heidolph, Germany.

7 Fluid bed coater Glatt, GmbH, Germany.

8 Mechanical sieve shaker Retsch, Germany.

9 Dissolution apparatus Electrolab, Mumbai.

10

UV-Visible

spectrophotometer

Shimadzu, Japan.

11

Tapped density apparatus

USP

Electrolab, Mumbai.

12 Tablet Punching machine Cadmach , Germany

Preparation of standard calibration graph of

Venlafaxine hydrochloride:

Preparation of standard solution of Venlafaxine

hydrochloride:

Stock solution: 100mg of venlafaxine HCl weighed

accurately and transferred into a 100 ml volumetric flask.

Then the volume made upto 100ml using water.

Standard solution: 10ml of solution was withdrawn from

the above stock solution and then made up to 100ml in

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

5 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Another 100ml volumetric flask and this solution

considered as standard solution (100g/ml).

From the above standard solution 0.5, 1, 1.5, 2,

2.5ml was withdrawn and diluted to 10ml to get 5,

10, 15, 20, 25g/ml concentration.

The solutions analysed spectrophotometrically at 226nm

using UV visible spectrophotometer.

Table 3: Standard Calibration Curve

S.No Concentration g/ml UV Absorbance at 226 nm

1 0 g/ml 0.00

2 5g/ml 0.1830.02

3 10g/ml 0.3580.02

4 15g/ml 0.5360.02

5 20g/ml 0.7100.02

6 25g/ml 0.8910.02

Formulation development:

Preparation of pellets:

Granulation:

Venlafaxine HCl, microcrystalline cellulose (avicel PH 101),

hydroxy propyl cellulose (klucel) passed through 30#

mesh, and the sifted material transferred into rapid mixer

granulator (Kelvin). Then the material allowed for dry

mixing for 10 min by using impeller speed of 150 RPM and

water was added for 3 min till formation of granules.

Chopper run for 3 min at 1000 RPM to complete the

granulation process.

Preparation of pellets: The granules passed through Fuji

Paudal extruder using 0.8 mm screen at 40 RPM, the

obtained spaghetti like extrudates collected and placed on

Fuji paudal Marumerizer using 2mm plate. The

spheronizer run at 800 RPM for 30 sec, 1800 RPM for 90

sec and 1300 RPM for 60 sec to get pellets of satisfactory

sphericity. The pellets collected and dried in rapid dryer at

45

0

C for 2 hrs and then sized through 16/ 30 mesh.

Coating of pellets:

Sub coating:

Pellets loaded into fluid bed wurster and initial subcoating

made with opadry clear at 4%build up.

Polymer coating: polymer EC: HPMC coating was done in

the ratio of 65:35 by giving 20% buildup to pellets.

Preparation of Tablets:

Granular part:

Hydroxyl propyl cellulose, microcrystalline cellulose,

aerosol, sodium stearyl fumarate blended in a roller

compactor to form hard mass, then the resulting hard mass

milled through 1.5mm screen and the obtained granules

are passed through sieve no 20# mesh at top and 60#

mesh at the bottom the particles retained on the 60# mesh

considered as the granules and the particles passed

through the sieve no 60# considered as fines, and the fines

are again subjected to milling and the same cycle is

repeated for several times to produce 60% of granule and

40% fines.

Extra granular part:

Sodium stearyl fumarate and aerosil taken for the

lubrication purpose.

Compression of tablet:

Required amount of pellets were taken and mixed with

granular part and extragranular part by mechanical

agitation and compressed into tablets in a 16 mm oval

shaped punch with a compression force of 5K.

Table 4: Formulation of venlafaxine hydrochloride pellets

Ingredient F 1 F 2 F 3 F 4 F5 F6 F7 F8 F9 F10 F11

Core spheroids

Venlafaxine HCl (Eq to

venlafaxine)

169.7 169.7 169.7 169.7 169.7 169.7 169.7 169.7 169.7 169.7 169.7

MCC (PH 101) 165.3 134.3 134.3 134.3 134.3 134.3 165.3 165.3 134.3 165.3 165.3

Lactose(Granular 200) 100 55 55 55 75 100 100 75 55 50 75

HPC(Klucel EXF) 10 6 10 6 10 10 6 1 6 6 10

Water QS

Total core spheroids 445 365 369 365 389

414 441 391 365 391 420

Sub coat

HPMC 4 cps 14 10.5 10.5 10.5 10.5 10.5 14 10.5 10.5 14.5 15.5

Talc 6 4.5 4.5 4.5 4.5 4.5 4.5 6 4.5 6 6

Total sub coated

spheroids

465 380 384 380.0 404 429 459.5 407.5 380 411.5 441.5

EC coating

Ethyl cellulose 20 cps 56 45 45 66.6 56 66.6 75 75 56.2 75 75

HPMC 4 cps 10.5 11 12 16.2 12.5 12.5 17 17 13.7 12 15

PEG 400 3.5 6 7 8.88 9.5 9 11 11.5 7.5 13 15

Total EC Coated

spheroids

535 442 448 471.8 482 516.8 562.5 511 457.5 511.5 546.5

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

6 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Table 5: Preparation of MCC granules

Preparation of MCC granules %w/ w

MCC 101 93

Aerosil 2

HPC LH 11 5

Total 100

Table 6: Compression of Tablets

Compression of Tablets using EC coated spheroids

Trial 1 Trial 2

Ingredient

(CP3) eq to 75 mg

venlafaxine

(CP3) eq to 150 mg

venlafaxine

mg/ tab mg/ tab

EC coated Spheroids 228.75 457.5

MCC Granules 653.25 657.5

Aerosil 9 10

Sodium stearyl

fumarate

9 10

Total tablet weight 900 1135

Evaluation

Evaluation of Pellets [Lachmann et al., 1987]

The pellets evaluated for in process quality control test.

The following tests performed for ER pellets

1. Determination of Bulk Density and Tapped Density:

An accurately weighed quantity of the granules/ powder

(W) was carefully poured into the graduated cylinder and

volume (V0) measured. Then the graduated cylinder was

closed with lid and set into the tap density tester (USP).

The density apparatus set for 100 tabs and after that the

volume (Vf) measured and continued operation till the two

consecutive readings were equal (Lachman et al., 1987).

The bulk density and the tapped density calculated using

the following formulae.

Bulk density =W/ V0

Tapped density =W/ Vf

Where, W=Weight of the powder

V0 =Initial volume

Vf =final volume

2. Compressibility Index (Carrs Index):

Carrs index (CI) is an important measure that can be

obtained from the bulk and tapped densities. In theory, the

less compressible a material the more flowable it is

(Lachman et al., 1987).

CI =(TD-BD) x 100/ TD

Where, TD is the tapped density and BD is the bulk density.

Table 7: Carrs Index Values

S.No. Carrs Index Properties

1 5-12 Free flowing

2 13-16 Good

3 18-21 Fair

4 23-35 Poor

5 33-38 Very poor

6 >40 Extremely poor

3. Hausners Ratio:

It is the ratio of tapped density and bulk density. Hausner

found that this ratio related to interparticle friction and, as

such, could be used to predict powder flow properties.

Generally a value less than 1.25 indicates good flow

properties, which is equivalent to 20% of Carrs index.

4. Particle size distribution:

100gms of pellets shifted into a sieve shaker where a series

of sieves was placed (16#, 22#, 25# and 30#). The machine

was run for 5 minutes, all the meshes were taken out and

retained granules collected by respective mesh and the

percentage retention of pellets by that mesh calculated.

5. Friability Test:

From each batch, 6.5gms of pellets accurately weighed and

placed in the friability test apparatus (Roche friabilator).

Apparatus was operated at 25 rpm for 4 minutes and

pellets observed while rotating. The tablets were then

taken after 100 rotations, the pellets were taken out and

intact pellets again weighed collectively after removing

fines using sieve#44. % friability calculated as follows

% Friability =(W1 W2) x 100/ W1

Where W1 =Initial weight of the 20 tablets.

W2 =Final weight of the 20 tablets after testing.

Friability values below 0.8% are generally acceptable.

6. In-vitro drug release:

In vitro drug release of the samples carried out using USP-

type 1 dissolution apparatus (Basket type). The dissolution

medium, used was water 900ml (as specified by the office

of generic drugs USFDA), placed into the dissolution flask

maintaining the temperature of 370.5

o

C and 100 RPM.

Accurately weighed pellets were placed in each flask of

dissolution apparatus. The apparatus allowed to run for

24hours. Samples measuring 10ml withdrawn using

cannula attached to a syringe. The samples were filtered

through 45m filter, which was in line with syringe. The

fresh dissolution medium replaced every time with same

amount of sample. Filtered samples were suitably diluted

with water (1ml diluted to 10ml) and analyzed at 226nm.

The cumulative percentage drug release calculated.

Evaluation of tablets:

1. Thickness:

Twenty tablets from the representative sample were

randomly taken and individual tablet thickness measured

by using digital vernier caliper. Average thickness and

standard deviation values calculated.

2. Hardness:

Tablet hardness measured by using Monsanto hardness

tester. From each batch six tablets were measured for the

hardness and average of six values noted along with

standard deviations.

3. Friability Test:

From each batch, ten tablets were accurately weighed and

placed in the friability test apparatus (Roche friabilator).

Apparatus operated at 25 rpm for 4 minutes and tablets

were observed while rotating. The tablets were then taken

after 100 rotations, dedusted and reweighed. The friability

calculated as the percentage weight loss.

Note: No tablet should stick to the walls of the apparatus. If

so, brush the walls with talcum powder. There should no

capping also.

% friability was calculated as follows:

% Friability =(W1 W2) x 100/ W1

Where W1 =Initial weight of the 20 tablets.

W2 =Final weight of the 20 tablets after testing.

Friability values below 0.8% are generally acceptable.

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

7 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

4. Weight Variation Test:

To study weight variation individual weights (WI) of 20

tablets from eachformulations werenoted using

electronic balance. Their average weight (WA) calculated.

Percent weight variation was calculated as follows.

Average weights of the tablets along with standard

deviation values calculated.

% weight variation =(WAWI) x 100/ WA

As the total tablet weight was 120 mg, according to IP

1996, out of twenty tablets 7.5 % variation can be allowed

for not more than two tablets.

According to USP 2004, 10% weight variation can be

allowed for not more than two tablets out of twenty

tablets.

5. In -Vitro Drug Release Characteristics:

In vitro drug release: in vitro drug release of the samples

carried out using USP-type II dissolution apparatus (Paddle

type). The dissolution medium, used was water 900ml (as

specified by the office of generic drugs USFDA), placed into

the dissolution flask maintaining the temperature of

370.5

o

C and 100 RPM. Tablets placed in each flask of

dissolution apparatus. The apparatus was allowed to run

for 24hours. Samples measuring 10ml were withdrawn

using cannula attached to a syringe. The samples filtered

through 45m filter, which was in line with syringe. The

fresh dissolution medium was replaced every time with

same amount of sample. Filtered samples were suitably

diluted with water (1ml diluted to 10ml) and analyzed at

226nm. The cumulative percentage drug release calculated

and compared with the innovator product (Effexor).

Results and discussion:

Pre-Formulation studies:

Table 8: Preformulation Studies of API (Venlafaxine Hydrochloride)

Table 9: Calibration Graph

S.No Concentration

g/ml

UV Absorbance 226 nm

1 0 0.00

2 5 0.1830.02

3 10 0.3580.02

4 15 0.5360.02

5 20 0.7100.02

6 25 0.8910.02

Figure 4: Standard Calibration Curve of Venlafaxine hydrochloride

Pre-Formulation studies

Table 10 : Bulk Density, Tap Density, Carrs Index, Hausners Ratio Of

Venlafaxine Hydrochloride Pellets

Formul

ation

code

Bulk density

(g/ cc)

Tap density

(g/ cc)

Carrs

Index

(%)

Hausners

ratio

F1 0.234 0.220 3.54 0.56

F2 0.324 0.320 3.24 0.43

F3 0.236 0.356 2.93 0.45

F4 0.421 0.254 3.87 0.36

F5 0.286 0.296 4.12 0.78

F6 0.412 0.342 4.23 0.99

F7 0.221 0.456 3.56 0.56

F8 0.332 0.451 4.56 0.68

F9

*

0.61 0.592 5.71 1.06

F10 0.286 0.523 3.67 0.83

F11 0.312 0.561 3.12 0.41

*The pellets were analyzed for the parameters such as bulk density,

tapped density, compressibility index, Hausners ratio and the

results were found to be within the limits.

Bulk density and tapped density values range between 0.446 0.480

gm/ cc and 0.539 0.637g/ cc tabulated and the values were found to

be within limits

Compressibility index has proposed as an indirect measure

of bulk density, size, shape, surface area and cohesiveness

of materials. Compressibility index values ranges between

5-12% for F1 to F11 formulations and the values tabulated.

Hausners ratio it is the ratio of tapped density and bulk

density. Hausner found that this ratio related to

interparticle friction and, as such, could be used to predict

powder flow properties. Generally a value less than 1.25

indicates good flow properties, which is equivalent to 20%

of Carrs index.

Table 11: Particle Size Distribution of Venlafaxine hydrochloride

Sieve number % Cumulative retains

#16 0

#18 2.9

#20 31.0

#25 95.0

#30 100

Formulation development

Based on the literature search and reference product

review, prototype development initiated with preparation

of core spheroids by extrusion spheronization technique

and coating the spheroids with an extended release rate

controlling polymer by wurster process. The composition

is given in table 5.

Pre Formulation Studies

S.No Characteristics Results

1 Nature White

2 Solubility water

3 Bulk Density (gm/ ml)

0.61

4 Tapped Density(gm/ ml) 0.592

5 Carrs Index (%) 5.71

6 Hausners Ratio 1.06

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

8 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Table 12: Optimization of Microcrystalline Cellulose

Batch details

Trial with45% w/ w MCC in

core spheroids

Trial with50% w/ w MCC in

core spheroids

Trial with55% w/ w MCC in

core spheroids

Trial with60% w/ w MCC in

core spheroids

Observation

Fines generation during

spheronization

Satisfactory spheroids Satisfactory spheroids. Tablet over weight

*From the table 13 it is observed that the spheroids with MCC concentration of 50% and 55% were found satisfactory hence 55% has been finalized.

Table 13: Optimization of Hydroxy Propyl Cellulose

Batch details Trial without HPC

Trial with0.5% w/ w HPC

in core spheroids

Trial with1% w/ w HPC in

core spheroids

Trial with1.5% w/ w HPC in

core spheroids

Observation

More Fines generation during

spheronization

Satisfactory spheroids,

acceptable fines generation

Satisfactory spheroids. Dumble shaped spheroids

Table 14: Selection of Extruder Screen

Batch Details 0.6mm screen 0.8mm screen 1mm screen

Observation

Spheroids found smaller with lesser

yield of #16/ 30 mesh fraction

Spheroids found with optimum

yield of #16/ 30 mesh fraction

Spheroids found bigger with lesser

yield of #16/ 30 mesh fraction

Table15: Optimization of Binder Concentration

Medium: Water (900ml)

Apparatus: Basket (100 RPM)

Time

(Hours)

% cumulative drug

Release

Innovator F5(0.5% HPMC) F9(1%HPMC) F4(0.7%HPMC)

2 19 21 21 21

4 38 42 41 41

8 67 67 63 63

12 87 88 86 86

20 103 107 102 102

*No much significant change is observed with change in binder concentration 0.5% is considered as optimum concentration.

Table 16: Optimization of extruder speed

Batch

Details

30 RPM 40 RPM 50 RPM

Observation Satisfactory Spheroids Satisfactory Spheroids Satisfactory Spheroids

Table 17: Selection of Spheronization Plate

Batch Details 2 mm chequered plate 3 mm chequered plate

Observation

Satisfactory spheroids 85% yield of #

16/ 30 mesh fraction

Satisfactory spheroids 85% yield of #

16/ 30 mesh fraction

Table 18 :Optimization of Spheronization Speed and Time

Batch details

Spheronization

Speed(2mm plate)

Time process Physical observation

Extrudates of 0.8mm screen

at 40 RPM

800RPM 30 to 60 sec

Cutting into small pieces

and uniform distribution

of extrudates

Satisfactory spheroids 1700-1800RPM 2 to 3 minutes spheronization

1300RPM 30 sec

Smoothening of

spheroid surface

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

9 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Table 19: Optimization of spheronization speed and time

Batch details Time

Spheronization

Speed(2mm plate)

Physical observation

Extrudates of 0.8mm

screen at 40 RPM

30 sec

800 RPM

Beadlets

1minutes Beadlets

2minutes Beadlets

3minutes Beadlets

4minutes Dumble shape

Extrudates of 0.8mm

screen at 40 RPM

1minutes

1300 RPM

beadlets

2minutes Beadlets

3 minutes Dumble shape

4 minutes Dumble shape

Extrudates of 0.8mm

screen at 40 RPM

1minutes

1600 RPM

beadlets

2 minutes Dumble shape

3 minutes Dumble shape

4 minutes Spheroids with irregular shape

Extrudates Of 0.8mm

screen at 40 RPM

1minutes

1700 RPM

Beadlets

2 minutes Dumble shape

3 minutes Spheroids with irregular shape

4 minutes Spheroids (fines generated)

Extrudates Of 0.8mm

screen at 40 RPM

1minutes

1800 RPM

Dumble shape

2 minutes Spheroids with irregular shape

3 minutes Spheroids but still irregular shape

4 minutes Spheroids (fines generated)

Optimization of sub coating

Medium: Water

Volume: 900ml (Venlafaxine hydrochloride 75mg), Apparatus: Basket (100 RPM)

Table 20:Optimization of sub coating

Time (Hours)

% Drug Release

Innovator

F8

(Without

subcoating)

F7 (3% sub coated) F9 (5% sub coated) F3 (7% sub coated)

2 19 34 31 21 15

4 38 57 55 41 32

8 67 80 78 68 55

12 87 91 90 88 76

20 103 111 110 105 96

Figure 5 : Dissolution Profile of Optimization of subcoating

*From the table 20 and fig.9 it was observed that formulations (F7, F9,

and F3) were sub coated with different concentrations of HPMC and the

dissolution profiles were compared with the Innovator (VENLAR),

formulation F9 showed the similar release profile to that of Innovator

(VENLAR), so formulation F9 was selected as the desired formulation

with subcoating concentration of 5%.

Optimization of Controlled Release Coating Build Up

Medium: Water (900 ml)

Apparatus: Basket (100 RPM)

Table 21: Optimization of Controlled Release Coating Build Up

Time

(Hours)

% Drug Release

Innovator

F2

16% build up of

EC/ HPMC

F9

16% build up

of EC/ HPMC

F1

24% build up

of EC/ HPMC

2 19 24 21 10

4 38 46 41 32

8 67 69 68 55

12 87 90 88 77

20 103 107 105 94

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

10 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

Figure 6: Dissolution Profile of Optimization of controlled release coating

*From the table 22 and fig.10 it was observed that formulations (F2, F9,

and F1) were optimized for controlled release coating build up with

different concentrations of 16% build up of EC/ HPMC, and 24% build up

of EC/ HPMC the dissolution profiles were compared with the Innovator

(VENLAR), formulation F9 showed the similar release profile to that of

Innovator (VENLAR), so formulation F9 was selected as the desired

formulation with controlled release coating of 16% build up of EC/ HPMC.

Optimization of Coating and Channeling Agent

Ratio:

Medium: Water (900ml)

Apparatus: Basket (100 RPM)

Table 22: Optimization of Coating and Channeling Agent Ratio

Time

(Hours)

% Drug Release

Innovator

F10

EC:HPMC

=60:40

F9

EC:HPMC

=60:40

F11

EC:HPMC

=60:40

2 19 25 21 11

4 38 48 41 33

8 67 71 68 60

12 87 93 88 81

20 103 110 105 99

Figure 7: Dissolution Profile of Optimization 0f coating & chanelling

agent ratio

*From the table 22 and fig.11 it was observed that formulations (F10, F9,

and F11) were optimized for coating and channeling agent ratio with

different ratios of EC: HPMC (60:40), the dissolution profiles were

compared with the Innovator (VENLAR), formulation F9 showed the

similar release profile to that of Innovator (r), so formulation F9 was

selected as the desired formulation with coating and channeling agent

ratio of EC/ HPMC (60:40).

Evaluation tests for the Prepared Venlafaxine

hydrochloride Tablets

Required amount of pellets were taken and mixed with

granular part and extra granular part by mechanical

agitation and compressed into tablets in a 16 mm oval

shaped punch with a compression force of 5KN, the

composition for the tablets was given in table 7.

The compressed tablets were evaluated for various post

compression parameters like weight variation, hardness,

friability etc. The results are shown in table 24.

Table 23: Evaluation tests for the Prepared Venlafaxine hydrochloride

Tablets

Formulations

Weight

variation

(mg)

Friability

(%)

Hardness

(kg/ cm

2

)

Thickness

F1* Passes 0.97 9 6.38

F2 Passes 0.98 8 6.45

*Visually examined tablets from each formulation batch showed (oval)

shaped compressed tablets.

Hardness, friability, thickness, weight variation of each

formulation was analyzed for formulations F1 to F2 and all

formulations were found to have good hardness, friability,

thickness, weight variation, so they were taken for further

studies.

In - Vitro Dissolution Study of Venlafaxine

hydrochloride pellets.

Dissolution Profile:

The dissolution test were carried out in water were taken

at predetermined time intervals and after suitable

dilutions absorbance was measured with the help of UV

spectrophotometer at 226 nm and the percentage drug

released at various time intervals calculated.

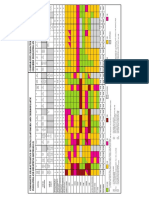

Table 24: Dissolution Profile

Time

(hours)

% Drug release

Innovator F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11

2 19 10 24 15 21 21 30 31 34 21 25 11

4 38 32 46 32 41 42 53 55 57 41 48 33

8 67 55 69 55 63 67 74 78 80 68 71 60

12 87 77 90 76 86 88 86 90 91 88 93 81

20 103 94 107 96 102 107 105 110 111 105 110 99

Figure 8: Dissolution Profile comparison of all the formulations of pellets

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

11 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

*Dissolution profile for the formulations (F1, F3 and F11) had poor dissolution profile, formulation (F9) showed good drug result when

compared to that of Innovator (VENLAR 75mg), and so it had been selected as desired formulation for compressing into the tablet

In - Vitro Dissolution Study of Venlafaxine

hydrochloride Tablets.

Table 25 : Dissolution Profile:

Time

(hours)

% Drug release

Innovator F1 F2

2 19 21 19

4 38 41 47

8 67 68 65

12 87 88 86

20 103 105 101

Figure 9: Dissolution Profile comparison of all the formulations of

tablets

*Pellets of formulation (F9) have been selected for compressing into the

tablets, MCC granules are added in equal quantities to the 75mg and

150mg tablets of formulation (F9). The tablet having 75mg (F1) showed

good drug result with the Innovator (VENLAR), when compared with the

formulation (F2).

Summary and conclusion:

Based on the literature search and reference product

review, prototype development initiated with preparation

of core spheroids by extrusion spheronization technique

and coating the spheroids with an extended release rate

controlling polymer by wurster process.

Spheroids with MCC concentration of 50% and 55% found

satisfactory hence 55% has finalized.

Spheroids with HPC concentration of 1% in core spheroids

found satisfactory, hence it has finalized.

Optimization of binder concentration done with HPMC

concentration of 0.5%, 1%, 0.7%. No much significant

change is observed with change in binder concentration

0.5% is considered as optimum concentration.

Optimization of binder concentration done with

concentration of 3%, 5%, 7%.the formulation with 5%

found satisfactory, hence it has finalized.

Optimization of controlled release coating builds up16%

build up of EC/ HPMC of formulation (F9). The result found

similar to that of Innovator (VENLAR 75mg).

The pellets were analyzed for the parameters such as bulk

density, tapped density, compressibility index, Hausners

ratio and the results were found within the limits.

Extended release pellets have minimum volume in size,

greater surface area and more surface activity. The area

of the drug loaded pellets release rate was also more. And

also there was no need of disintegration time for pellets in

capsules. Small volumes of pellets enter into the systemic

circulation very fast. Moreover there was no accumulation

of drug in the body. Drug release rate was more when

compared with the innovator sample.

The Venlafaxine hydrochloride extended release pellets

compressed into the tablets. It showed good results in

formulation of stable dosage. The dissolution profile of the

prepared Venlafaxine hydrochloride extended release

tablets compared with that of Venlafaxine hydrochloride

extended release capsules (Venlar) of the product. The

release found more in the case of pellets loaded in tablets.

The desired formulation was found to be formulation (F9),

due to its release profile was more when compared to the

Innovator (VENLAR) and dissolution profile of Venlafaxine

hydrochloride extended release tablets was compared with

that of innovator (VENLAR). The release was found similar

to that of innovator. So the prepared product said to be

equivalent with innovator.

Finally conclude like extended release pellets in tablets of

formulation (F9) have more drug release rate rather than

innovator (VENLAR) and it have better Bioavailability.

Nowadays Venlafaxine hydrochloride marketed

formulations (VENLAR.VENLEF) loaded in pellets. The

present formulation was compressed into a tablet; it is

more advantageous when compared to the pellets that

loaded in pellets by low cost, less chance of degradation.

References:

1. Aulton M.C., 2002. Pharmaceutics, The science of

dosage form design

.,2

nd

edition:414-18.

2. Sellassie G.,1989.

pharmaceutical pellatization

technology, Marcel Dekker., 37:1-13.

3. Steven H. Neau ., Michelle Y. Chow., Gregory A. Hileman.,

Manzer J. Durrani., Ferdous Gheyas., Barry A. Evans.

Formulation and process conciderations for beads

containing carbopol 974P,NF resin made by extrusion-

spheronization., European Journal of Pharmaceutics and

biopharmaceutics.,2000; 199:129-40.

4. Fridrun podczeck ., Ana Maghetti., Michael Newton J.,

2009. The influence of non-ionic surfactants on the

rheological properties of drug/ microcrystalline

cellulose/ water mixtures and their use in the preparation

and drug release performance of pellets prepared by

extrusion/ spheronization. , European Journal of

Pharmaceutical Sciences.,37:334-40.

5. Lieven Baert ., Markus Thommes., Gerben van t

Klooster., Marian Geldof., Laurent Schueller., Jan Rosier.,

Peter Kleinebudde., Improved bioavailability of darunavir

by use of -carrageenan versus microcrystalline cellulose

as pelletisation aid., European Journal of Pharmaceutics

and Biopharmaceutics., 2009; Volume 72: 614-20.

6. Podczeck F., Alessi P., Newton J.M.,

The preparation of

pellts containing non-ionic surfactants by extrusion and

spheronization

.,

International Journal of Pharmaceutics.

2008;36:36-40.

7. Ramo n Marti nez-Pacheco., Consuelo Souto., Alberto

Rodrguez., Silvia Parajes.,

A comparative study of the

utility of two super disintegrants in microcrystalline

cellulose pellts prepared by extrusion spheronization.,

European Journal of Pharmaceutics and biopharmaceutics.,

2005; 61:94-99.

8. Sriamornsak ., Jurairat Nunthanid., Manee Luangtana-

anan., Satit Puttipipatkhachorn.,

Alginate-based pellets

prepared by extrusion-spheronizaton, a preliminary study

M Srujan Kumar et al. / JPBMS, 2012, 18 (05)

12 Journal of Pharmaceutical and Biomedical Sciences (JPBMS), Vol. 18, Issue 18

on the effect of additive in granulating liquid., European

Journal of Pharmaceutics and biopharmaceutics., 2007;

67:227-35.

9. Ramo n Marti nez-Pacheco., Consuelo Souto., Alberto

Rodrguez., Silvia Parajes.,

A comparative study of the

utility of two super disintegrants in microcrystalline

cellulose pellts prepared by extrusion spheronization.,

European Journal of Pharmaceutics and biopharmaceutics.,

2005; 61:94-99.

10.Steckel.H ., Mindermann-Nogly .F., Production of

chitosan pellets by extrusion and spheronization.,

European Journal of Pharmaceutics and

biopharmaceutics.,2003; 557:107

11.Ingunn tho ., Sverre Arne Sande., Peter Kleinebudde.,

2003. Disintegration pellets form a water insoluble pectin

derivative eproduced by

extrusion/ spheronisation.,European Journal of

Pharmaceutics and biopharmaceutics.,2003; 56:371-80

12. Newton J.M., Sousa., Sousa. A., Podczeck. F.,

Factors

influencing the physical characteristics of pellets obtained

by extrusion and spheronization., International Journal of

Pharmaceutics.,2002; Vol 232:91-106.

13. Gayot .A ., Dupont.,Flament M.P.,Leterme P.,Farah N.,

Developing a study method for producing 400m

spheroids., International Journal of Pharmaceutics.,2002;

247:159-65.

14. Rabis kova M ., Prez J. P.,

Influence of drying

technique on theophylline pellets prepard by extrusion-

spheronization., International Journal of

Pharmaceutics.,2002; 242:349-51.

Source of funding: - None

Conflict of Interest: - Not declared.

Corresponding Author:-

M.Srujan Kumar.(Asst.Professor)

Samskruti college of Pharmacy

Kondapur,R.R District,Hyderabad,India-501301.

Quick Response code (QR-Code)

for mobile user to access JPBMS

website electronically.

Website link:- www.jpbms.info

You might also like

- Communicate Your Value With a 30-60-90 Day PlanDocument29 pagesCommunicate Your Value With a 30-60-90 Day PlanvbadsNo ratings yet

- Ardra NakshatraDocument8 pagesArdra NakshatraANTHONY WRITER50% (2)

- Chapter 9Document66 pagesChapter 9Geline Anne BenozaNo ratings yet

- Unit IV. Solid Modified Release Dosage FormsDocument24 pagesUnit IV. Solid Modified Release Dosage FormsMary-Ann Valencia SapnuNo ratings yet

- Excipient Qualification GuideDocument66 pagesExcipient Qualification Guidevbads67% (3)

- Dentin Biomodification AgentsDocument56 pagesDentin Biomodification AgentsRevathy M Nair100% (1)

- Paht CheeDocument78 pagesPaht CheeMba Sandzio100% (11)

- Extended-Release Oral Solid Dosage FormsDocument3 pagesExtended-Release Oral Solid Dosage FormsDiah MarianoNo ratings yet

- Boiler Water TreatmentDocument50 pagesBoiler Water Treatmentak_thimiriNo ratings yet

- Extended Release Formulation Review ArticleDocument60 pagesExtended Release Formulation Review ArticleSomasundaram JeevanandhamNo ratings yet

- PTQ Q3Document120 pagesPTQ Q3Atharva DatarNo ratings yet

- Supply Chain Manager ResponsibilitiesDocument8 pagesSupply Chain Manager ResponsibilitiesvbadsNo ratings yet

- Tablet KompresiDocument9 pagesTablet KompresiRatuNo ratings yet

- Dry Granulation by Slugging Method For Sustained Release of Model DrugDocument50 pagesDry Granulation by Slugging Method For Sustained Release of Model DrugBagus SetiawanNo ratings yet

- Formulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingDocument9 pagesFormulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingQoriNo ratings yet

- Matrix Tablets ThesisDocument4 pagesMatrix Tablets Thesisafbtbegxe100% (2)

- Oral Dispersible System A New Approach in Drug Del PDFDocument6 pagesOral Dispersible System A New Approach in Drug Del PDFHaider SalahNo ratings yet

- DDR SDRAM Controller IP Designed For ReuseDocument50 pagesDDR SDRAM Controller IP Designed For ReusejagruthimsNo ratings yet

- Controlled Release Pellets: An Effective Tool in Chronic TherapyDocument26 pagesControlled Release Pellets: An Effective Tool in Chronic TherapyfakhriNo ratings yet

- Controlled-Release Pelletized Dosage Forms Using TDocument11 pagesControlled-Release Pelletized Dosage Forms Using THà Thanh TúNo ratings yet

- 12.floating NanoparticlesDocument5 pages12.floating NanoparticlesBaru Chandrasekhar RaoNo ratings yet

- Different Aspects of Pellets Formulation and Their Evaluation PDFDocument6 pagesDifferent Aspects of Pellets Formulation and Their Evaluation PDFHely PatelNo ratings yet

- Advances in Oral Drug DeliveryDocument5 pagesAdvances in Oral Drug DeliveryvyshnosudhaNo ratings yet

- Ajptr 102021 111Document16 pagesAjptr 102021 11188-pranjal VasavNo ratings yet

- Formulation and Evaluation of Orally Disintegrating Tablets of SertralineDocument7 pagesFormulation and Evaluation of Orally Disintegrating Tablets of SertralineDinesh BabuNo ratings yet

- PIFADocument4 pagesPIFAMurali YennatiNo ratings yet

- Concepts of Buccal Drug Delivery System: Bioadhesion and MucoadhesionDocument6 pagesConcepts of Buccal Drug Delivery System: Bioadhesion and Mucoadhesionpathuri rangaNo ratings yet

- Phardose Lec Chapter 9Document11 pagesPhardose Lec Chapter 9megmayorNo ratings yet

- Mucoadhesive Microencapsulation: A New Tool in Drug Delivery SystemsDocument61 pagesMucoadhesive Microencapsulation: A New Tool in Drug Delivery SystemsLailatul QadarNo ratings yet

- Microspheres - An Overview: Prasanth V.V, Akash Chakraborthy Moy, Sam T Mathew, Rinku MathapanDocument7 pagesMicrospheres - An Overview: Prasanth V.V, Akash Chakraborthy Moy, Sam T Mathew, Rinku MathapanMadhu Mohan Paudel ChettriNo ratings yet

- Multi Particulate Drug Delivery SystemDocument23 pagesMulti Particulate Drug Delivery Systemasifghasi100% (1)

- Orally Dissolving Strips: A New Approach To Oral Drug Delivery SystemDocument19 pagesOrally Dissolving Strips: A New Approach To Oral Drug Delivery SystemDuong NguyenNo ratings yet

- Formulation and Evaluation of Floating Microspheres of Metformin HydrochlorideDocument10 pagesFormulation and Evaluation of Floating Microspheres of Metformin HydrochlorideBaru Chandrasekhar RaoNo ratings yet

- Article WJPR 1400475907Document13 pagesArticle WJPR 1400475907miserable1995No ratings yet

- Microsphere: A Review: IJRPC 2011, 1Document15 pagesMicrosphere: A Review: IJRPC 2011, 1Mahendra ReddyNo ratings yet

- Formulation Development and Evaluation of Mebeverine Extended Release PelletsDocument10 pagesFormulation Development and Evaluation of Mebeverine Extended Release PelletsMarchinez 2.5No ratings yet

- Modified-Release Drug Delivery Systems ExplainedDocument52 pagesModified-Release Drug Delivery Systems ExplainedFria Mariz SuperalesNo ratings yet

- Multi-Layer TabletsDocument14 pagesMulti-Layer Tabletsprasad_ram8850% (2)

- A Prolonged Release Parenteral Drug Delivery SystemDocument11 pagesA Prolonged Release Parenteral Drug Delivery SystemronnymcmNo ratings yet

- Design and Evaluation of Gastro Retentive Drug Deliverry System of Anti Ulcer DrugDocument6 pagesDesign and Evaluation of Gastro Retentive Drug Deliverry System of Anti Ulcer DrugmindaNo ratings yet

- Senthilnathan 2019Document8 pagesSenthilnathan 2019Alyna AlynaNo ratings yet

- A Study of Dissolution Enhancement and Invitro Evaluation of RoxithromycinDocument6 pagesA Study of Dissolution Enhancement and Invitro Evaluation of Roxithromycinanto_pharma7784No ratings yet

- Practice School Report on Sustained Release Tablet Formulation and EvaluationDocument45 pagesPractice School Report on Sustained Release Tablet Formulation and EvaluationSohail SheikhNo ratings yet

- Role of Polymers in Sustained Released Microbeads Formulation: A ReviewDocument9 pagesRole of Polymers in Sustained Released Microbeads Formulation: A ReviewVinayNo ratings yet

- Article WJPR 1464659783Document12 pagesArticle WJPR 1464659783Yogesh GholapNo ratings yet

- Microspheresdocx 2021 03 25 16 55Document6 pagesMicrospheresdocx 2021 03 25 16 55Ravirajsinh GohilNo ratings yet

- Extended Release Drug Delivery ReviewDocument9 pagesExtended Release Drug Delivery ReviewTuyến Đặng ThịNo ratings yet

- Lec 1 Industrial Pharmacy II 2023Document36 pagesLec 1 Industrial Pharmacy II 2023saifmohanad.usNo ratings yet

- Polymers in Pharmaceuticals: Advantages of Novel Drug DeliveryDocument15 pagesPolymers in Pharmaceuticals: Advantages of Novel Drug Deliveryosama saeedNo ratings yet

- Review ArticleDocument9 pagesReview ArticlemickydivyaNo ratings yet

- Pharmaceutical Characterization and Assessment of Drug Release Behaviour of Diclofenac Sodium Extended Release Matrix DevicesDocument8 pagesPharmaceutical Characterization and Assessment of Drug Release Behaviour of Diclofenac Sodium Extended Release Matrix DevicesnikhilsachanNo ratings yet

- 1 RJPT 10 12 2017Document9 pages1 RJPT 10 12 2017yahyaNo ratings yet

- Final Synopsis PHDDocument13 pagesFinal Synopsis PHDKishor KanaseNo ratings yet

- Abstract:: Extended Release Tablet With Active CoatingDocument10 pagesAbstract:: Extended Release Tablet With Active Coatingiloveit52252No ratings yet

- Formulation Design, Optimization and Evaluation of Domperidone Maleate Gastro Retentive Floating TabletsDocument10 pagesFormulation Design, Optimization and Evaluation of Domperidone Maleate Gastro Retentive Floating TabletsDr. Raghavendra Kumar GundaNo ratings yet

- Coatings 10 00490 PDFDocument22 pagesCoatings 10 00490 PDFValentina AnutaNo ratings yet

- Buccal Film Thesis PDFDocument7 pagesBuccal Film Thesis PDFafiwiafoc100% (2)

- Formulation Development and Evaluation of Sustained Release Tablet Chlorpromazine HCLDocument7 pagesFormulation Development and Evaluation of Sustained Release Tablet Chlorpromazine HCLWJPSR JournalNo ratings yet

- Microencapsulation As A Novel Drug Delivery System: Vol. 1 - Issue 1 - ©2011 IPSDocument7 pagesMicroencapsulation As A Novel Drug Delivery System: Vol. 1 - Issue 1 - ©2011 IPSsameersyed77No ratings yet

- Vol 7 | Issue 1 | 2017 | Colon Targeting Tramadol MicrobeadsDocument5 pagesVol 7 | Issue 1 | 2017 | Colon Targeting Tramadol MicrobeadsDHIVYANo ratings yet

- Pelletization Technology: Methods and Applications-A ReviewDocument9 pagesPelletization Technology: Methods and Applications-A ReviewAvhishek Rajan GuptaNo ratings yet

- Design and Evaluation of Gastro Retentive Drug Delivery System of Anti Ulcer DrugDocument6 pagesDesign and Evaluation of Gastro Retentive Drug Delivery System of Anti Ulcer DrugSiti RositahNo ratings yet

- Floating Microspheres ThesisDocument6 pagesFloating Microspheres Thesisstephaniebarkerpeoria100% (2)

- Formulation and in Vitro Evaluation of Fesoterodine Fumarate Sustained Release TabletsDocument13 pagesFormulation and in Vitro Evaluation of Fesoterodine Fumarate Sustained Release TabletsBaru Chandrasekhar RaoNo ratings yet

- Microsphere A Brief Review PDFDocument7 pagesMicrosphere A Brief Review PDFAnonymous kjYn00EqNo ratings yet

- PhytosomesDocument25 pagesPhytosomeskondamuri pushpalathaNo ratings yet

- BBC Ranks Top 100 Movies Since 2000 ListDocument3 pagesBBC Ranks Top 100 Movies Since 2000 ListvbadsNo ratings yet

- Conduct Stability Studies with SAP R/3Document47 pagesConduct Stability Studies with SAP R/3vbadsNo ratings yet

- How to Inspect a Used Car Checklist: The EssentialsDocument4 pagesHow to Inspect a Used Car Checklist: The EssentialsGzimGImeriNo ratings yet

- Mass Effect 3 PDFDocument863 pagesMass Effect 3 PDFvbadsNo ratings yet

- Project Profile On Kurkure Type Snacks SmallDocument2 pagesProject Profile On Kurkure Type Snacks SmallsethiaindiaNo ratings yet

- Merino Laminates Product Portfolio/TITLEDocument59 pagesMerino Laminates Product Portfolio/TITLEsukavasi1973No ratings yet

- Bangalore - 28 May Vivanta by Taj - M G Road 12:30pm - 6:00pmDocument1 pageBangalore - 28 May Vivanta by Taj - M G Road 12:30pm - 6:00pmvbadsNo ratings yet

- 1365mySAP - Pharma RD v8 Final PDFDocument4 pages1365mySAP - Pharma RD v8 Final PDFvbadsNo ratings yet

- BWP Pharmaceuticals Industry OverviewDocument8 pagesBWP Pharmaceuticals Industry OverviewvbadsNo ratings yet

- Dr. Fixit Dampguard 145 1 PDFDocument3 pagesDr. Fixit Dampguard 145 1 PDFvbadsNo ratings yet

- Abirami AnthathiDocument24 pagesAbirami Anthathijekay2ab92% (12)

- A Do-It-Yourself Guide To: This Document Has Been Prepared by Sunder Kidambi With The Blessings ofDocument34 pagesA Do-It-Yourself Guide To: This Document Has Been Prepared by Sunder Kidambi With The Blessings ofvbadsNo ratings yet

- L Glutamine COADocument1 pageL Glutamine COAvbadsNo ratings yet

- Cod Modern Warfare 3Document60 pagesCod Modern Warfare 3vbadsNo ratings yet

- APV Evaporator Handbook Guide to Evaporation Technology and SystemsDocument68 pagesAPV Evaporator Handbook Guide to Evaporation Technology and SystemsvbadsNo ratings yet

- MSMS Course Descriptions 2014-15Document4 pagesMSMS Course Descriptions 2014-15vbadsNo ratings yet

- Nutrition Innovation Worldwide: A Restless Imagination Starts Early..Document4 pagesNutrition Innovation Worldwide: A Restless Imagination Starts Early..vbadsNo ratings yet

- Solar watch manualDocument38 pagesSolar watch manualvbadsNo ratings yet

- Honda AmazeDocument16 pagesHonda AmazevbadsNo ratings yet

- JP Littlebook 2Q13 - CDN PDFDocument70 pagesJP Littlebook 2Q13 - CDN PDFvbadsNo ratings yet

- Solar watch manualDocument38 pagesSolar watch manualvbadsNo ratings yet

- 2011 Student Poster Competition GuidelinesDocument2 pages2011 Student Poster Competition GuidelinesvbadsNo ratings yet

- JP Littlebook 2Q13 - CDN PDFDocument70 pagesJP Littlebook 2Q13 - CDN PDFvbadsNo ratings yet

- Are You On A Business Process - Procedure JourneyDocument7 pagesAre You On A Business Process - Procedure JourneyvbadsNo ratings yet

- SCH 206-Carboxylic Acids PDFDocument48 pagesSCH 206-Carboxylic Acids PDFCon Amor Para TlaxcalaNo ratings yet

- Understanding Internal Defects in Mo Fabricated by Wire Arc Additive Manufacturing Through 3D Computed TomographyDocument10 pagesUnderstanding Internal Defects in Mo Fabricated by Wire Arc Additive Manufacturing Through 3D Computed TomographySaketh BachuNo ratings yet

- Whiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006Document5 pagesWhiskers The Root Cause of Spontaneous Short Circuits - PCIC - 2006wy6279No ratings yet

- Pre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsDocument18 pagesPre-Medical: Chemistry Allen: Carbonyl Compounds, Acids and It'S Derivatives Carbonyl CompoundsJK JHANo ratings yet

- Chemolube H - Product DescriptionDocument6 pagesChemolube H - Product DescriptionJulio VargasNo ratings yet

- 2020 SAJC H2 Prelim Paper 3 (QP)Document37 pages2020 SAJC H2 Prelim Paper 3 (QP)clarissa yeoNo ratings yet

- Label Ing2cDocument9 pagesLabel Ing2cSMPN 2No ratings yet

- Coa - Argan Oil Organic PDFDocument1 pageCoa - Argan Oil Organic PDFDhaval SoniNo ratings yet

- The Future of Composites in Gas Turbine EnginesDocument4 pagesThe Future of Composites in Gas Turbine EnginessenthilNo ratings yet

- Form 1 Science - Unit 3.3: The Concept of DensityDocument1 pageForm 1 Science - Unit 3.3: The Concept of DensitySuhaila SaniNo ratings yet

- ChemistryDocument22 pagesChemistrymacaronloverNo ratings yet

- NSEJS Previous Year Question PaperDocument16 pagesNSEJS Previous Year Question PaperUS CREATIONSNo ratings yet

- Comparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialsDocument1 pageComparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialskapilNo ratings yet

- Mp4f01 Ceramics 1 Khor 2011Document40 pagesMp4f01 Ceramics 1 Khor 2011Vincent KohNo ratings yet

- NCSE 2013 Integrated ScienceDocument22 pagesNCSE 2013 Integrated ScienceMicahNo ratings yet

- 06chapters13 15Document19 pages06chapters13 15Achmad Arifudin HidayatullohNo ratings yet

- 1Document3 pages1Febriani RintaNo ratings yet

- Effect of Different Disinfecting Procedures On The Hardness and Color Stability of Two Maxillofacial Elastomers Over TimeDocument6 pagesEffect of Different Disinfecting Procedures On The Hardness and Color Stability of Two Maxillofacial Elastomers Over TimepalliNo ratings yet

- CHEM Model QuestionDocument4 pagesCHEM Model QuestionAavash ChhetriNo ratings yet

- Ch-6 Q AnsDocument4 pagesCh-6 Q AnshhhNo ratings yet

- E-Comm Rates 15-6-2021Document3 pagesE-Comm Rates 15-6-2021ManojNo ratings yet

- Is 2932 2003 PDFDocument22 pagesIs 2932 2003 PDFSuyambu100% (1)

- Hydrolysis Worksheet Chemistry Unit 4.13Document3 pagesHydrolysis Worksheet Chemistry Unit 4.13Gideon CavidaNo ratings yet

- Pasar PDFDocument70 pagesPasar PDFRalph Carlo EvidenteNo ratings yet

- A Level Chemistry A H432/01 Periodic Table, Elements and Physical Chemistry Practice Paper - Set 2Document28 pagesA Level Chemistry A H432/01 Periodic Table, Elements and Physical Chemistry Practice Paper - Set 2apalanantha17No ratings yet

- Withdrawn latestHMlistDocument588 pagesWithdrawn latestHMlistjibran khanNo ratings yet

- Greener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityDocument5 pagesGreener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityIJAERS JOURNALNo ratings yet