Professional Documents

Culture Documents

Sae Ams 5796D 2000 (En) PDF

Sae Ams 5796D 2000 (En) PDF

Uploaded by

William LooCopyright:

Available Formats

You might also like

- 12 and 16v92 Ta Spec SheetDocument4 pages12 and 16v92 Ta Spec SheetBrandon Atz67% (3)

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181No ratings yet

- Aerospace StandardDocument35 pagesAerospace Standardbondo2011No ratings yet

- AMS 2417 G Plating, Zinc-Nickel AlloyDocument9 pagesAMS 2417 G Plating, Zinc-Nickel AlloyMauroNo ratings yet

- Ams 4928Document8 pagesAms 4928REKHA100% (3)

- Acsr ConductorsDocument10 pagesAcsr ConductorsPhani KumarNo ratings yet

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- Astm C933-11Document2 pagesAstm C933-11Luis Galarreta LedesmaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Sae Ams 5796D 2000 (En) PDFDocument6 pagesSae Ams 5796D 2000 (En) PDFLidija StojanovaNo ratings yet

- Astm A1007-2002Document9 pagesAstm A1007-2002Jorge ToribioNo ratings yet

- Ams 5622 DDocument11 pagesAms 5622 DPma CorpNo ratings yet

- Index PHP PDFDocument9 pagesIndex PHP PDFEloise CamposNo ratings yet

- A 928 - A 928M - 04 Qtkyoc9boti4tqDocument6 pagesA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdNo ratings yet

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument7 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalSameh AminNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationyazNo ratings yet

- 32 Samss 031Document7 pages32 Samss 031naruto256No ratings yet

- Ams 2400Document11 pagesAms 2400SURYAS63No ratings yet

- Tech. Spec. For ConductorDocument26 pagesTech. Spec. For ConductorbinodeNo ratings yet

- Astm A193 A193m 23Document7 pagesAstm A193 A193m 23huicholeNo ratings yet

- Chromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification Forquiensabe0077No ratings yet

- Astm A234 A234m - 20252Document9 pagesAstm A234 A234m - 20252OscarBoneNo ratings yet

- A 401 - A401m - 98 Qtqwms05oa - PDFDocument4 pagesA 401 - A401m - 98 Qtqwms05oa - PDFTiến Lượng NguyễnNo ratings yet

- 10 TMSS 02 R0Document0 pages10 TMSS 02 R0renjithas2005No ratings yet

- Irsm 46 2012Document28 pagesIrsm 46 2012Rakesh Srivastava100% (3)

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument5 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalJosé Ramón GutierrezNo ratings yet

- 12 TMSS 10 R0Document0 pages12 TMSS 10 R0renjithas2005No ratings yet

- HFY3-3125-ELE-SPC-0008 - 0 Code-ADocument8 pagesHFY3-3125-ELE-SPC-0008 - 0 Code-AAshraf AbdulredhaNo ratings yet

- A193Document13 pagesA193JEn LisNo ratings yet

- Astm - A905Document3 pagesAstm - A905masoud132No ratings yet

- Astm A194 A194m - 13Document12 pagesAstm A194 A194m - 13Danilo YamaguchiNo ratings yet

- 9Document25 pages9pcelisNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- Consumable Spec Rev 12Document24 pagesConsumable Spec Rev 12megastar0604No ratings yet

- E20-Conductor, Earth Wire, Insulator, HW, CCDocument69 pagesE20-Conductor, Earth Wire, Insulator, HW, CCYASHASHWYNo ratings yet

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNo ratings yet

- Technical Specification For Acsr Conductor: 1. ScopeDocument7 pagesTechnical Specification For Acsr Conductor: 1. ScopegaladrialNo ratings yet

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Asme Section II A Sa-395Document12 pagesAsme Section II A Sa-395Anonymous GhPzn1xNo ratings yet

- SA905Document6 pagesSA905Chenjie ZhuNo ratings yet

- A 564 - A 564M - 02 Qtu2nc0wmg - PDFDocument7 pagesA 564 - A 564M - 02 Qtu2nc0wmg - PDFHassan FekiNo ratings yet

- 02 Samss 008Document11 pages02 Samss 008inatt101No ratings yet

- Aluminiumconductorforoverhead Transmissionpurposes-SpecificationDocument12 pagesAluminiumconductorforoverhead Transmissionpurposes-SpecificationSINU0607IITEEENo ratings yet

- ASTM A 194 Carbon and Alloy Steel Nuts PDFDocument13 pagesASTM A 194 Carbon and Alloy Steel Nuts PDFAhmad ZaidNo ratings yet

- 111 - Spec. No. 45 of AL-59 PantherDocument17 pages111 - Spec. No. 45 of AL-59 Pantherdeepthik27No ratings yet

- Technical Specification For Acsr Conductors: WbsedclDocument9 pagesTechnical Specification For Acsr Conductors: Wbsedclraja kumarNo ratings yet

- A242 A242M (2001) Standard Specification For High-Strength Low-Alloy Structural SteelDocument3 pagesA242 A242M (2001) Standard Specification For High-Strength Low-Alloy Structural SteelGagan Singh100% (1)

- Aluminium Conductor For Overhead Transmission Purposes - SpecificationDocument11 pagesAluminium Conductor For Overhead Transmission Purposes - Specificationmanir_b4u2002No ratings yet

- A 231 - A231m - 96 Qtizms05ng - PDFDocument4 pagesA 231 - A231m - 96 Qtizms05ng - PDFTiến Lượng NguyễnNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- A 381 - 96 QTM4MS05NGDocument5 pagesA 381 - 96 QTM4MS05NGnica tamNo ratings yet

- AAAC Conductor SpecificationsDocument9 pagesAAAC Conductor SpecificationsShrikant KajaleNo ratings yet

- A 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFDocument2 pagesA 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFMung Duong XuanNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Thân KhaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Shippers Letter of InstructionDocument2 pagesShippers Letter of InstructionWilliam LooNo ratings yet

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- Sae Ams 5662M 2004 (En) PDFDocument11 pagesSae Ams 5662M 2004 (En) PDFWilliam LooNo ratings yet

- Financial Management - MGT201: 7 Week of LecturesDocument10 pagesFinancial Management - MGT201: 7 Week of LecturesSyed Abdul Mussaver ShahNo ratings yet

- Monde Nissin Paper PDFDocument16 pagesMonde Nissin Paper PDFJenny BagonNo ratings yet

- Mcs 022 PDFDocument2 pagesMcs 022 PDFAnonymous lbeDK1tPGLNo ratings yet

- Ferreteria de Linea PDFDocument71 pagesFerreteria de Linea PDFcristian rosales romaoNo ratings yet

- STIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinDocument276 pagesSTIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinsanitermNo ratings yet

- SCP Technical GuideDocument108 pagesSCP Technical GuideJosé Luis Morán HernándezNo ratings yet

- LTE Physical Layer OverviewDocument16 pagesLTE Physical Layer OverviewHasanShahabNo ratings yet

- Master The Boards USMLE Step 2 CKDocument2 pagesMaster The Boards USMLE Step 2 CKMuhammad ShakeelNo ratings yet

- Industrial FlangeDocument7 pagesIndustrial FlangeJohn SmithNo ratings yet

- Assessment Task 1.2 Tabular PresentationDocument10 pagesAssessment Task 1.2 Tabular PresentationheyheyNo ratings yet

- Alinox: Insulated Conductor Rail For Electrical Feeding of CranesDocument20 pagesAlinox: Insulated Conductor Rail For Electrical Feeding of CranesabnicolescuNo ratings yet

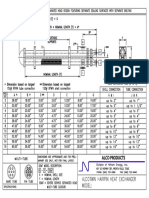

- HX DimensionsDocument1 pageHX DimensionsMarquinho LsNo ratings yet

- Vermiculture & VermicompostingDocument4 pagesVermiculture & VermicompostingclothespinNo ratings yet

- KROSS CATALOG 2016 en PDFDocument208 pagesKROSS CATALOG 2016 en PDFmiroNo ratings yet

- Ti 275900190 SK Tu3 PNT en 1617 ScreenDocument8 pagesTi 275900190 SK Tu3 PNT en 1617 ScreenyotruvustoNo ratings yet

- Annexure-197 LL.M. (2 Year - 3 Year)Document259 pagesAnnexure-197 LL.M. (2 Year - 3 Year)ABHISHEK SUCHARINo ratings yet

- For UploadDocument6 pagesFor UploadDino AbieraNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument3 pagesJZ-500 / OZ-500: Technical Datademetrio lopezNo ratings yet

- Handy Purge 100 Weld Purge Monitor PDFDocument1 pageHandy Purge 100 Weld Purge Monitor PDFnishant361No ratings yet

- Ergese of EthiopiaDocument62 pagesErgese of Ethiopiasamuel petrosNo ratings yet

- 31261Document7 pages31261Athirah Amer HamzahNo ratings yet

- Rule 4: Jurisdiction of Arbitral Tribunal Article 4.16. Competence of Arbitral Tribunal To Rule On Its JurisdictionDocument1 pageRule 4: Jurisdiction of Arbitral Tribunal Article 4.16. Competence of Arbitral Tribunal To Rule On Its JurisdictionTaroy CeeNo ratings yet

- Geothermal TecuanburroDocument5 pagesGeothermal TecuanburroErwin QuiroaNo ratings yet

- YORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeDocument68 pagesYORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeQuốc Nguyễn MinhNo ratings yet

- Apple Iphone Investigation ProjectDocument9 pagesApple Iphone Investigation ProjectNowMyLoveNo ratings yet

- Study Guide Cyber SecurityDocument17 pagesStudy Guide Cyber SecurityAhmed ZouaghiNo ratings yet

- Ironpump PDFDocument14 pagesIronpump PDFrpicho0% (1)

- Mathematical Modeling Simulation and Control of Ball and Beam SystemDocument5 pagesMathematical Modeling Simulation and Control of Ball and Beam SystemCamilo Andrés BeltránNo ratings yet

- Partnership Accounting PDFDocument4 pagesPartnership Accounting PDFPamela BugarsoNo ratings yet

Sae Ams 5796D 2000 (En) PDF

Sae Ams 5796D 2000 (En) PDF

Uploaded by

William LooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sae Ams 5796D 2000 (En) PDF

Sae Ams 5796D 2000 (En) PDF

Uploaded by

William LooCopyright:

Available Formats

400 Commonwealth Drive, Warrendale, PA 15096-0001

AEROSPACE

MATERIAL

SPECIFICATION

AMS 5796D

Issued

Revised

FEB 1952

MAR 2000

Superseding AMS 5796C

Cobalt Alloy, Corrosion and Heat Resistant, Welding Wire

52Co - 20Cr - 10Ni - 15W

UNS R30605

1. SCOPE:

1.1

Form:

This specification covers a corrosion and heat resistant cobalt alloy in the form of welding wire.

1.2

Application:

This wire has been used typically as filler metal for gas-tungsten-arc or gas-metal-arc welding of

parts fabricated from alloys of similar or dissimilar composition, and as stapling pins requiring high

strength up to 1500 F (816 C) and oxidation resistance up to 2000 F (1093 C), but usage is not

limited to such applications.

2. APPLICABLE DOCUMENTS:

The issue of the following documents in effect on the date of the purchase order form a part of this

specification to the extent specified herein. The supplier may work to a subsequent revision of a

document unless a specific document issue is specified. When the referenced document has been

canceled and no superseding document has been specified, the last published issue of that document

shall apply.

2.1

SAE Publications:

Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

AMS 2269

AMS 2371

AMS

AMS

AMS

AMS

2813

2814

2816

2819

ARP1876

ARP4926

Chemical Check Analysis Limits, Nickel, Nickel Alloys, and Cobalt Alloys

Quality Assurance Sampling and Testing, Corrosion and Heat Resistant Steels and

Alloys, Wrought Products and Forging Stock

Packaging, and Marking of Packaging of Welding Wire, Standard Method

Packaging, and Marking of Packaging of Welding Wire, Premium Quality

Identification, Welding Wire, Tab Marking Method

Identification, Welding Wire, Direct Color Code System

Weldability Test for Weld Filler Metal Wire

Alloy Verification and Chemical Composition Inspection of Welding Wire

SAE Technical Standards Board Rules provide that: This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

Copyright 2000 Society of Automotive Engineers, Inc.

All rights reserved.

QUESTIONS REGARDING THIS DOCUMENT:

TO PLACE A DOCUMENT ORDER:

SAE WEB ADDRESS:

Printed in U.S.A.

(724) 772-7161

(724) 776-4970

http://www.sae.org

FAX: (724) 776-0243

FAX: (724) 776-0790

AMS 5796D

2.2

SAE

AMS 5796D

ASTM Publications:

Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.

ASTM E 354 Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron,

Nickel, and Cobalt Alloys

3. TECHNICAL REQUIREMENTS:

3.1

Composition:

Wire shall conform to the percentages by weight shown in Table 1, determined by wet chemical

methods in accordance with ASTM E 354, by spectrochemical methods, or by other analytical

methods acceptable to purchaser.

TABLE 1 - Composition

Element

min

max

0.05

0.15

Carbon

1.00

2.00

Manganese

-1.00

Silicon

-0.04

Phosphorus

-0.03

Sulfur

Chromium

19.00

21.00

9.00

11.00

Nickel

14.00

16.00

Tungsten

Iron

-3.00

Cobalt

remainder

3.1.1

Check Analysis: Composition variations shall meet the applicable requirements of AMS 2269.

3.1.2

Chemical analysis of initial ingot, bar, or rod stock before drawing, is acceptable provided the

processes used for drawing or rolling, annealing, and cleaning, are controlled to insure continued

conformance to chemical composition requirements.

3.2

Condition:

Cold finished, bright annealed, in a temper and with a surface finish which will provide proper feeding

of the wire in machine welding equipment.

3.3

3.3.1

Fabrication:

Wire shall be formed from rod or bar descaled by a process which does not affect the composition

of the wire. Surface irregularities inherent with a forming process that does not tear the wire

surfaces are acceptable provided the wire conforms to the tolerances of 3.6.

-2-

AMS 5796D

SAE

AMS 5796D

3.3.2

Butt welding is permissible provided both ends to be joined are alloy verified using a method

capable of distinguishing the alloy from all other alloys processed in the facility, or the repair is

made at the wire processing station. The butt weld shall not interfere with uniform, uninterrupted

feeding of the wire in machine welding.

3.3.3

In-process annealing, if required, between cold rolling or drawing operations, shall be performed in

vacuum or protective atmospheres to ensure freedom from surface oxidation and absorption of

other extraneous elements.

3.3.4

Residual elements, drawing compounds, oxides, dirt, oil, dissolved gasses and other foreign

materials picked up during wire processing that can adversely affect the welding characteristics,

the operation of the equipment, or the properties of the weld metal, shall be removed by cleaning

processes that will neither result in pitting nor cause gas absorption by the wire or deposition of

substances harmful to welding operations.

3.4

Properties:

Wire shall conform to the following requirements:

3.4.1

Weldability: Melted wire shall flow smoothly and evenly during welding and shall produce

acceptable welds. ARP1876 may be used to resolve disputes.

3.4.2

Spooled Wire: Shall conform to 3.4.2.1 and 3.4.2.2.

3.4.2.1

Cast: Wire, wound on standard 12-inch (305-mm) diameter spools, shall have imparted to it a

curvature such that a specimen sufficient in length to form one loop with a one inch (25 mm)

overlap, when cut from the spool and laid on a flat surface, shall form a circle 15 to 50 inches

(381 to 1270 mm) in diameter.

3.4.2.2

Helix: The specimen on which cast was determined, when laid on a flat surface and measured

between adjacent turns, shall show a vertical separation not greater than one inch (25 mm).

3.5

Quality:

Wire, as received by purchaser, shall be uniform in quality and condition, sound, and free from

foreign materials and from imperfections detrimental to welding operations, operation of welding

equipment, or properties of the deposited weld metal.

3.6

Sizes and Tolerances:

Wire shall be supplied in the sizes and to the tolerances shown in 3.6.1 and 3.6.2.

3.6.1

Diameter: Shall be as shown in Table 2.

-3-

AMS 5796D

SAE

AMS 5796D

TABLE 2A - Sizes and Tolerances, Inch/Pound Units

Tolerance Tolerance

Inch

Inch

Plus

Minus

Form

Nominal Diameter

Inch

Cut Lengths

Cut Lengths

Spools

Spools

Spools

0.030, 0.045, 0.062, 0.078

0.094, 0.125, 0.156, 0.188

0.007, 0.010, 0.015

0.020, 0.030, 0.035, 0.045, 0.062

0.078, 0.094

0.002

0.002

0.0005

0.001

0.002

0.002

0.002

0.0005

0.002

0.002

TABLE 2B - Sizes and Tolerances, SI Units

3.6.2

Form

Nominal Diameter

Millimeters

Cut Lengths

Cut Lengths

Spools

Spools

Spools

0.76, 1.14, 1.57, 1.98

2.39, 3.18, 3.98, 4.78

0.18, 0.25, 0.38

0.51, 0.76, 0.89, 1.14, 1.57

1.98, 2.39

Tolerance Tolerance

Millimeter Millimeter

Plus

Minus

0.05

0.05

0.013

0.025

0.05

0.05

0.05

0.013

0.05

0.05

Lengths: Cut lengths shall be furnished in 18, 27, or 36 inches (457, 686, or 914 mm) lengths, as

ordered, and shall not vary more than +0, -0.5 inch (-13 mm) from the length ordered.

4. QUALITY ASSURANCE PROVISIONS:

4.1

Responsibility for Inspection:

The vendor of wire shall supply all samples for vendors tests and shall be responsible for the

performance of all required tests. Purchaser reserves the right to sample and to perform any

confirmatory testing deemed necessary to ensure that the wire conforms to specified requirements.

4.2

Classification of Tests:

4.2.1

Acceptance Tests: Composition (3.1), sizes and tolerances (3.6), and alloy verification (5.2.1) are

acceptance tests and shall be performed on each heat or lot as applicable.

4.2.2

Periodic Tests: Weldability (3.4.1), cast (3.4.2.1), and helix (3.4.2.2) are periodic tests and shall be

performed at a frequency selected by the vendor unless frequency of testing is specified by

purchaser.

-4-

AMS 5796D

4.3

SAE

AMS 5796D

Sampling and Testing:

Shall be in accordance with AMS 2371 and as specified herein.

4.4

Reports:

The vendor of wire shall furnish with each shipment a report showing the results of tests for chemical

composition of each heat and stating that the wire conforms to the other technical requirements.

This report shall include the purchase order number, heat and lot numbers, AMS 5796D, nominal

size, and quantity.

4.5

Resampling and Retesting:

Shall be in accordance with AMS 2371.

5. PREPARATION FOR DELIVERY:

5.1

Wire shall be supplied either on spools in one continuous length for machine welding or in cut

lengths for manual welding, as ordered. Wire on each spool or in each package of cut lengths shall

be from the same heat of steel.

5.2

Alloy Verification:

5.2.1

Wire from each spool or package of cut lengths shall be alloy verified by a method acceptable to

purchaser and vendor. The alloy verification methods of ARP4926 are recommended.

5.2.2

An 8 inch (203 mm) length of wire shall be made accessible at both ends of each spool for alloy

verification.

5.3

Identification:

Shall be in accordance with AMS 2816 unless AMS 2819 or another method is specified by

purchaser.

5.4

Packaging and Marking:

Shall be in accordance with AMS 2813 unless AMS 2814 or another method is specified by

purchaser.

6. ACKNOWLEDGMENT:

A vendor shall mention this specification number and its revision letter in all quotations and when

acknowledging purchase orders.

-5-

AMS 5796D

SAE

AMS 5796D

7. REJECTIONS:

Wire not conforming to this specification, or to modifications authorized by purchaser, will be subject to

rejection.

8. NOTES:

8.1

A change bar ( l ) located in the left margin is for the convenience of the user in locating areas where

technical revisions, not editorial changes, have been made to the previous issue of this specification.

An (R) symbol to the left of the document title indicates a complete revision of the specification,

including technical revisions. Change bars and (R) are not used in original publications, nor in

specifications that contain editorial changes only.

8.2

Terms used in AMS are clarified in ARP1917.

8.3

Dimensions in inch/pound units are primary; dimensions in SI units are shown as the approximate

equivalents of the primary units and are presented only for information.

8.4

Purchase documents should specify not less than the following:

AMS 5796D

Size and form (spools or cut lengths) of wire desired

Length of cut lengths or weight of spools desired

Quantity of wire desired

PREPARED UNDER THE JURISDICTION OF AMS COMMITTEE "F"

-6-

You might also like

- 12 and 16v92 Ta Spec SheetDocument4 pages12 and 16v92 Ta Spec SheetBrandon Atz67% (3)

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181No ratings yet

- Aerospace StandardDocument35 pagesAerospace Standardbondo2011No ratings yet

- AMS 2417 G Plating, Zinc-Nickel AlloyDocument9 pagesAMS 2417 G Plating, Zinc-Nickel AlloyMauroNo ratings yet

- Ams 4928Document8 pagesAms 4928REKHA100% (3)

- Acsr ConductorsDocument10 pagesAcsr ConductorsPhani KumarNo ratings yet

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- Astm C933-11Document2 pagesAstm C933-11Luis Galarreta LedesmaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Sae Ams 5796D 2000 (En) PDFDocument6 pagesSae Ams 5796D 2000 (En) PDFLidija StojanovaNo ratings yet

- Astm A1007-2002Document9 pagesAstm A1007-2002Jorge ToribioNo ratings yet

- Ams 5622 DDocument11 pagesAms 5622 DPma CorpNo ratings yet

- Index PHP PDFDocument9 pagesIndex PHP PDFEloise CamposNo ratings yet

- A 928 - A 928M - 04 Qtkyoc9boti4tqDocument6 pagesA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdNo ratings yet

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument7 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalSameh AminNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationyazNo ratings yet

- 32 Samss 031Document7 pages32 Samss 031naruto256No ratings yet

- Ams 2400Document11 pagesAms 2400SURYAS63No ratings yet

- Tech. Spec. For ConductorDocument26 pagesTech. Spec. For ConductorbinodeNo ratings yet

- Astm A193 A193m 23Document7 pagesAstm A193 A193m 23huicholeNo ratings yet

- Chromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification Forquiensabe0077No ratings yet

- Astm A234 A234m - 20252Document9 pagesAstm A234 A234m - 20252OscarBoneNo ratings yet

- A 401 - A401m - 98 Qtqwms05oa - PDFDocument4 pagesA 401 - A401m - 98 Qtqwms05oa - PDFTiến Lượng NguyễnNo ratings yet

- 10 TMSS 02 R0Document0 pages10 TMSS 02 R0renjithas2005No ratings yet

- Irsm 46 2012Document28 pagesIrsm 46 2012Rakesh Srivastava100% (3)

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument5 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalJosé Ramón GutierrezNo ratings yet

- 12 TMSS 10 R0Document0 pages12 TMSS 10 R0renjithas2005No ratings yet

- HFY3-3125-ELE-SPC-0008 - 0 Code-ADocument8 pagesHFY3-3125-ELE-SPC-0008 - 0 Code-AAshraf AbdulredhaNo ratings yet

- A193Document13 pagesA193JEn LisNo ratings yet

- Astm - A905Document3 pagesAstm - A905masoud132No ratings yet

- Astm A194 A194m - 13Document12 pagesAstm A194 A194m - 13Danilo YamaguchiNo ratings yet

- 9Document25 pages9pcelisNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- Consumable Spec Rev 12Document24 pagesConsumable Spec Rev 12megastar0604No ratings yet

- E20-Conductor, Earth Wire, Insulator, HW, CCDocument69 pagesE20-Conductor, Earth Wire, Insulator, HW, CCYASHASHWYNo ratings yet

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNo ratings yet

- Technical Specification For Acsr Conductor: 1. ScopeDocument7 pagesTechnical Specification For Acsr Conductor: 1. ScopegaladrialNo ratings yet

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Asme Section II A Sa-395Document12 pagesAsme Section II A Sa-395Anonymous GhPzn1xNo ratings yet

- SA905Document6 pagesSA905Chenjie ZhuNo ratings yet

- A 564 - A 564M - 02 Qtu2nc0wmg - PDFDocument7 pagesA 564 - A 564M - 02 Qtu2nc0wmg - PDFHassan FekiNo ratings yet

- 02 Samss 008Document11 pages02 Samss 008inatt101No ratings yet

- Aluminiumconductorforoverhead Transmissionpurposes-SpecificationDocument12 pagesAluminiumconductorforoverhead Transmissionpurposes-SpecificationSINU0607IITEEENo ratings yet

- ASTM A 194 Carbon and Alloy Steel Nuts PDFDocument13 pagesASTM A 194 Carbon and Alloy Steel Nuts PDFAhmad ZaidNo ratings yet

- 111 - Spec. No. 45 of AL-59 PantherDocument17 pages111 - Spec. No. 45 of AL-59 Pantherdeepthik27No ratings yet

- Technical Specification For Acsr Conductors: WbsedclDocument9 pagesTechnical Specification For Acsr Conductors: Wbsedclraja kumarNo ratings yet

- A242 A242M (2001) Standard Specification For High-Strength Low-Alloy Structural SteelDocument3 pagesA242 A242M (2001) Standard Specification For High-Strength Low-Alloy Structural SteelGagan Singh100% (1)

- Aluminium Conductor For Overhead Transmission Purposes - SpecificationDocument11 pagesAluminium Conductor For Overhead Transmission Purposes - Specificationmanir_b4u2002No ratings yet

- A 231 - A231m - 96 Qtizms05ng - PDFDocument4 pagesA 231 - A231m - 96 Qtizms05ng - PDFTiến Lượng NguyễnNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- A 381 - 96 QTM4MS05NGDocument5 pagesA 381 - 96 QTM4MS05NGnica tamNo ratings yet

- AAAC Conductor SpecificationsDocument9 pagesAAAC Conductor SpecificationsShrikant KajaleNo ratings yet

- A 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFDocument2 pagesA 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFMung Duong XuanNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Thân KhaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Shippers Letter of InstructionDocument2 pagesShippers Letter of InstructionWilliam LooNo ratings yet

- Sae Arp 5483-8 2002 (En) PDFDocument9 pagesSae Arp 5483-8 2002 (En) PDFWilliam LooNo ratings yet

- Sae Ams 5662M 2004 (En) PDFDocument11 pagesSae Ams 5662M 2004 (En) PDFWilliam LooNo ratings yet

- Financial Management - MGT201: 7 Week of LecturesDocument10 pagesFinancial Management - MGT201: 7 Week of LecturesSyed Abdul Mussaver ShahNo ratings yet

- Monde Nissin Paper PDFDocument16 pagesMonde Nissin Paper PDFJenny BagonNo ratings yet

- Mcs 022 PDFDocument2 pagesMcs 022 PDFAnonymous lbeDK1tPGLNo ratings yet

- Ferreteria de Linea PDFDocument71 pagesFerreteria de Linea PDFcristian rosales romaoNo ratings yet

- STIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinDocument276 pagesSTIEBEL ELTRON Produktkatalog 2018 VMW Komplett KleinsanitermNo ratings yet

- SCP Technical GuideDocument108 pagesSCP Technical GuideJosé Luis Morán HernándezNo ratings yet

- LTE Physical Layer OverviewDocument16 pagesLTE Physical Layer OverviewHasanShahabNo ratings yet

- Master The Boards USMLE Step 2 CKDocument2 pagesMaster The Boards USMLE Step 2 CKMuhammad ShakeelNo ratings yet

- Industrial FlangeDocument7 pagesIndustrial FlangeJohn SmithNo ratings yet

- Assessment Task 1.2 Tabular PresentationDocument10 pagesAssessment Task 1.2 Tabular PresentationheyheyNo ratings yet

- Alinox: Insulated Conductor Rail For Electrical Feeding of CranesDocument20 pagesAlinox: Insulated Conductor Rail For Electrical Feeding of CranesabnicolescuNo ratings yet

- HX DimensionsDocument1 pageHX DimensionsMarquinho LsNo ratings yet

- Vermiculture & VermicompostingDocument4 pagesVermiculture & VermicompostingclothespinNo ratings yet

- KROSS CATALOG 2016 en PDFDocument208 pagesKROSS CATALOG 2016 en PDFmiroNo ratings yet

- Ti 275900190 SK Tu3 PNT en 1617 ScreenDocument8 pagesTi 275900190 SK Tu3 PNT en 1617 ScreenyotruvustoNo ratings yet

- Annexure-197 LL.M. (2 Year - 3 Year)Document259 pagesAnnexure-197 LL.M. (2 Year - 3 Year)ABHISHEK SUCHARINo ratings yet

- For UploadDocument6 pagesFor UploadDino AbieraNo ratings yet

- JZ-500 / OZ-500: Technical DataDocument3 pagesJZ-500 / OZ-500: Technical Datademetrio lopezNo ratings yet

- Handy Purge 100 Weld Purge Monitor PDFDocument1 pageHandy Purge 100 Weld Purge Monitor PDFnishant361No ratings yet

- Ergese of EthiopiaDocument62 pagesErgese of Ethiopiasamuel petrosNo ratings yet

- 31261Document7 pages31261Athirah Amer HamzahNo ratings yet

- Rule 4: Jurisdiction of Arbitral Tribunal Article 4.16. Competence of Arbitral Tribunal To Rule On Its JurisdictionDocument1 pageRule 4: Jurisdiction of Arbitral Tribunal Article 4.16. Competence of Arbitral Tribunal To Rule On Its JurisdictionTaroy CeeNo ratings yet

- Geothermal TecuanburroDocument5 pagesGeothermal TecuanburroErwin QuiroaNo ratings yet

- YORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeDocument68 pagesYORK - Double Effect Steam Fired ABS Chiller - YHAU-CW CatalogeQuốc Nguyễn MinhNo ratings yet

- Apple Iphone Investigation ProjectDocument9 pagesApple Iphone Investigation ProjectNowMyLoveNo ratings yet

- Study Guide Cyber SecurityDocument17 pagesStudy Guide Cyber SecurityAhmed ZouaghiNo ratings yet

- Ironpump PDFDocument14 pagesIronpump PDFrpicho0% (1)

- Mathematical Modeling Simulation and Control of Ball and Beam SystemDocument5 pagesMathematical Modeling Simulation and Control of Ball and Beam SystemCamilo Andrés BeltránNo ratings yet

- Partnership Accounting PDFDocument4 pagesPartnership Accounting PDFPamela BugarsoNo ratings yet