Professional Documents

Culture Documents

PCD SF 193

Uploaded by

mOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCD SF 193

Uploaded by

mCopyright:

Available Formats

Quality Management System

Document

Doc. No.: PCD-SF193

Page: 1 of

Rev.: 1

5

Procedure for Design of

Water Spray System

1

0

Rev

.

11 Jun

14

15 Mar

07

Date

Change of Format

Issued for implementation

Description

H.Hosseini

I.Zamani

A. Fallahi

Prepared by

Reviewed

by

A.Zamani

E.

Behbahani

Approved

by

Sections changed in the last revision are identified by

This document is the property of Tehran Raymand Consulting Engineers and should not be disclosed or reproduced without a

prior written permission.

Procedure for Design of

Water Spray System

Doc. No.: PCD-SF193

Page: 2 of

Rev.: 1

5

1. Preface

The present document is intended to outline the procedure of designing a

Fixed water spray system.

2. Applicable Documents

The following documents have to be obtained by the Project Lead

Engineer and referred to by the Engineer, prior to prepare it:

Design Basis

Project references

Project references.

3. Definitions

Project lead engineer is the lead engineer directly responsible for the

performance of activities of the project, set forth by the project manager

and/or head of the department.

Engineer is the engineer responsible to calculate under the direct

supervision of the project lead engineer.

4. Overview

For designing of the water spray system for a specific hazard, identifying

the hazard source and arrangement of hazard is needed.

Therefore all of equipment, like tanks, compressor, pumps, steel

structures, transformers vessels, air coolers and also their contents

shall be available..

5. General Requirements

For which are listed in item No. 2 shall be available.

The project lead engineer is responsible to obtain and ensure that the

engineer uses the latest revision/edition of the mentioned documents.

Procedure for Design of

Water Spray System

Doc. No.: PCD-SF193

Page: 3 of

Rev.: 1

5

After receiving the exact dimension and content of above mentioned

equipments by considering the available utilities and economic factors a

suitable fixed water spray system will be selected.

6. Procedure

6.1. General

6.1.1. Design Objectives

In general, water spray system shall be considered effective for any one

of or a combination of the following objectives:

(1) Extinguishments of fire

(2) Control of burning

(3) Exposure protection

(4) Prevention of fire

6.1.2. Size of system and water demand

A single system shall not protect more than one fire area

The number of systems expected to operate simultaneously shall be

determined by evaluating the following factors:

(1) Possible flow of burning liquids between areas before or during

operation of the water spray system

(2) Possible flow of hot gases between fire areas that could actuate

adjoining system, thereby increasing demand

(3) Flammable gas detection set to automatically actuate systems

(4) Manual operation of multiple system

(5) Other factors that would result in operation of system outside of the

primary fire area.

6.1.2.1. Extinguishments

System shall be designed so that extinguishments shall be accomplished

and all protected surface shall be cooled to prevent flashback occurring

after the system is shutt off.

Extinguishments methods:

Procedure for Design of

Water Spray System

Doc. No.: PCD-SF193

Page: 4 of

Rev.: 1

5

(1) Surface cooling

(2) Smothering by produced steam

(3) Emulsification

(4) Dilution

(5) Other factors

6.1.2.2. Design density

A general range of water spray application rates that shall apply to most

ordinary combustible solids or liquids shall be from 6.1 Lpm/m2 of

protected surface.

(1) Cable trays and cable rooms

Where insulated wire and cable or nonmetallic tubing is to be protected

by an automatic water spray (one nozzle) system designed for

extinguishments of fire that originates within the cable or tube, the

system shall be hydrically designed to impinge water directly on each

tray or group of cable or tubes at a net rate of 6.1 Lpm/m2 on the

protected plane containing the cable or tubing tray or run.

(2) Belt conveyors

Discharge pattern of water spray nozzle shall envelop, at a net rate at

not less than 10.2 Lpm/m2, the top and bottom belt surface area,

conveyor surface where combustible materials are likely to accumulate,

the structural parts and the idlerrolls supporting the belt.

(3) Drive unit

The net rate of water application for the drive unit shall be not less than

102 LPM/m2 of roll and belt.

6.1.2.3. Control of burning

The water application rate shall be at a net rate of not less than 20.4

Lpm/m2 of protected area.

(1) Pumps, compressor, and related equipment

Procedure for Design of

Water Spray System

Doc. No.: PCD-SF193

Page: 5 of

Rev.: 1

5

Pumps or other devises that handle flammable liquids or gases shall have

the shafts, seals, and other critical parts enveloped by directed water

spray at a net rate of not less than 20.4 Lpm/m2.

(2) Flammable and combustible liquid pool fires

Water spray system designed to control pool fires resulting from a

flammable or combustible liquid spill fires shall be designed to apply a

net rate of not less than

12.2 Lpm/m2 of protected area.

6.1.2.4. Exposure protection

(1) Vessels

Water spray shall be applied to vessel surfaces (including top and bottom

surfaces) at a net rate of net less than 10.2 Lpm/m2 of exposed surfaces.

(2) Structures and miscellaneous equipment

Horizontal,

stressed

(primary)

structure

steel

members

shall

be

protected by nozzles and piping of such as size and arrangement to

discharge a net rate of not less than 4.1 Lpm/m2 over the welted area.

6.2. Geometrical arrangement of system

System piping shall be so arranged that the spray pattern can wet all parts

of the protected equipment and spray patterns shall have a suitable

overlapping length.

Arrangement of spray nozzle for a specific equipment, is completely related

to the shape of the equipment and the sensitive parts on the body (locations

where maximum thermal and mechanical stress may be occur). To

illuminate this part, each equipment is considered separately as below:

6.2.1. Atmospheric storage tanks

- Maximum distance between spray nozzle face and shell shall not exceed

600 mm and not be less than 450 mm. (d)

- If the tank is adjacent to other tanks with higher height, roof of tank shall

be protected by spray system.

- Cooling of shell and roof shall be done separately by different risers.

- Total Number of spray nozzle, is calculated by following formula:

Procedure for Design of

Water Spray System

Doc. No.: PCD-SF193

Page: 6 of

Rev.: 1

5

2.2. Spherical storage tank

- Total number of spray nozzle shall be calculated by following formula:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Organic Chemistry ACS Sample QuestionsDocument20 pagesOrganic Chemistry ACS Sample QuestionsNajmusawwa Aulia RahmahNo ratings yet

- Syme Mebasc Enme Speq 0210 b03 PDFDocument12 pagesSyme Mebasc Enme Speq 0210 b03 PDFmNo ratings yet

- Non Concurrent ForcesDocument6 pagesNon Concurrent ForcesLeah Rivera0% (1)

- Data and SignalsDocument3 pagesData and Signalsnr syhdhNo ratings yet

- HSR 1.63 (For HYSYS V10.0)Document4 pagesHSR 1.63 (For HYSYS V10.0)Ba Jun Thối0% (1)

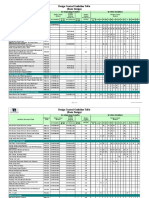

- Data Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectDocument3 pagesData Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectmNo ratings yet

- Procedure For Application of Foam Protection System: Quality Management System DocumentDocument9 pagesProcedure For Application of Foam Protection System: Quality Management System DocumentmNo ratings yet

- Procedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetDocument5 pagesProcedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetmNo ratings yet

- Procedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentDocument6 pagesProcedure For Preparation of Water Hose Reel Data Sheet: Quality Management System DocumentmNo ratings yet

- Procedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentDocument7 pagesProcedure For Preparation of Water/Foam Monitor Data Sheet: Quality Management System DocumentmNo ratings yet

- Syme Hvbasc Enhv Bsde 0001 B02Document16 pagesSyme Hvbasc Enhv Bsde 0001 B02mNo ratings yet

- Procedure For Fire Water Max. Demand Calculation: Quality Management System DocumentDocument4 pagesProcedure For Fire Water Max. Demand Calculation: Quality Management System DocumentmNo ratings yet

- PCD-SF-187-Attachment#1 Water Hose Reel Data SheetDocument4 pagesPCD-SF-187-Attachment#1 Water Hose Reel Data SheetmNo ratings yet

- PCD SF 191Document7 pagesPCD SF 191mNo ratings yet

- PCD ED 451 Attachment 02Document13 pagesPCD ED 451 Attachment 02mNo ratings yet

- Design Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientDocument3 pagesDesign Input Control Checklist: 1) Complete 2) Incomplete But Sufficient To Start 3) InsufficientmNo ratings yet

- Syme Elbasc Enel Rqma 0001 b02Document16 pagesSyme Elbasc Enel Rqma 0001 b02m100% (1)

- Syme Elbasc Enel Lilc 0002 b02Document6 pagesSyme Elbasc Enel Lilc 0002 b02m100% (1)

- Refrence DWG.: Yaran Oil Field Development ProjectDocument4 pagesRefrence DWG.: Yaran Oil Field Development Projectm100% (1)

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- .:f:.t:::l:. L::. (I.::,.i. .Document12 pages.:f:.t:::l:. L::. (I.::,.i. .mNo ratings yet

- PCD ED 451 Attachment 11Document2 pagesPCD ED 451 Attachment 11mNo ratings yet

- North Yaran Oil Field Development ClusterDocument4 pagesNorth Yaran Oil Field Development ClustermNo ratings yet

- Vendor Progress Report-01Document2 pagesVendor Progress Report-01mNo ratings yet

- Sem - Course - Curriculum-ECE - DTU - 3rd SemDocument8 pagesSem - Course - Curriculum-ECE - DTU - 3rd SemRohit Kumar SinghNo ratings yet

- Advanced Structural Design - Lecture Note 03Document29 pagesAdvanced Structural Design - Lecture Note 03cdmcgc100% (1)

- Euler-Maclaurin Expansion and Woolhouse's Formula: A S. M Volume 2, Pp. 631-633 inDocument3 pagesEuler-Maclaurin Expansion and Woolhouse's Formula: A S. M Volume 2, Pp. 631-633 inAyu Nurul AtiqohNo ratings yet

- EDR DesignGuidelines VAVDocument331 pagesEDR DesignGuidelines VAVRegina Ng100% (1)

- EC - Communication-System - by WWW - LearnEngineering.inDocument68 pagesEC - Communication-System - by WWW - LearnEngineering.inAnkitaNo ratings yet

- 7805Document2 pages7805pandiNo ratings yet

- 6.user Guide To CAN-bus Tester SoftwareDocument12 pages6.user Guide To CAN-bus Tester SoftwareFranco FaziNo ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFperro sNo ratings yet

- Virtual Memory and Demand PagingDocument50 pagesVirtual Memory and Demand PagingPrakash SinghNo ratings yet

- Note CHP 2-Material Science 281 Uitm Em110Document74 pagesNote CHP 2-Material Science 281 Uitm Em110bino_rye100% (1)

- Line Matching Unit For PLC: Features and ApplicationsDocument2 pagesLine Matching Unit For PLC: Features and ApplicationsLaurentiuNo ratings yet

- Business Combinations : Ifrs 3Document45 pagesBusiness Combinations : Ifrs 3alemayehu100% (1)

- Explosive Welding 1 WeldingDocument4 pagesExplosive Welding 1 WeldingRabindra DashNo ratings yet

- ME415 CondensersDocument4 pagesME415 Condensersagafina0No ratings yet

- Super Had CCD IIDocument2 pagesSuper Had CCD IIMohd Safian ZakariaNo ratings yet

- The Key of It AllDocument91 pagesThe Key of It AllSimonida Mona VulićNo ratings yet

- 3D Design SyllabusDocument6 pages3D Design SyllabusIoana PetcuNo ratings yet

- Step-by-Step Guide: How To Book An For: Appointment Tracker ExchangeDocument4 pagesStep-by-Step Guide: How To Book An For: Appointment Tracker ExchangeJames NgNo ratings yet

- Sampling, Sampling Techniques and Sampling DistributionsDocument70 pagesSampling, Sampling Techniques and Sampling Distributionssinte beyuNo ratings yet

- Chapter 5 Final A5 EditDocument8 pagesChapter 5 Final A5 EditkINGNo ratings yet

- Conduction Convection RadiationDocument23 pagesConduction Convection Radiationsuhaila bakarNo ratings yet

- Dart Language SpecificationDocument111 pagesDart Language SpecificationLiaboNo ratings yet

- Structural and Process Dimensions of OrgDocument12 pagesStructural and Process Dimensions of OrgrafaelwidiNo ratings yet

- ASTM e 186Document4 pagesASTM e 186Ashish GuptaNo ratings yet

- Manual de AVERIAS Codigos SC RICOH MP C4500Document84 pagesManual de AVERIAS Codigos SC RICOH MP C4500Erika Velásquez100% (1)

- Cisco CCNA 640-607 CompleteDocument30 pagesCisco CCNA 640-607 CompleteAnkit OswalNo ratings yet