Professional Documents

Culture Documents

Shimano Anleitung ST5500 en-SI6BS0E-En

Uploaded by

GA16DETCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shimano Anleitung ST5500 en-SI6BS0E-En

Uploaded by

GA16DETCopyright:

Available Formats

SERVICE INSTRUCTIONS

ST-6500

ST-6501

ST-5500

ST-5500-C

SI-6BS0E

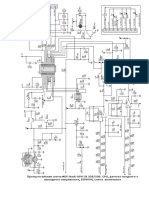

Operation

Rear

Front

Lever

Lever

Lever

Lever

Shimano Total

Integration

Lever F

b

Lever F

B

Before use, read these instructions carefully, and follow them for correct use.

Assembling the bracket

and lever

Installation

Lever F

a

Lever F

A

F

A : Shifts from smaller to larger rear sprocket.

F

B : Shifts from larger to smaller rear sprocket.

F

a : Shifts from smaller to larger chainring.

F

b : Shifts from larger to smaller chainring.

Installation to the handlebar

Secure the assembly with the installation nut on the outside

of the bracket. Pull the bracket cover

bracket cover

back and use a 5 mm Allen

key to tighten the bolt.

Obtain, read and carefully service instructions when installing

parts. A loose, worn, or damaged parts may cause injury to the

rider.

We strongly recommend that only genuine Shimano replacement

parts be used.

Lever F

A : Shifts from smaller to lager rear sprocket.

Lever F

A has a click stop at positions , ,and .

Lever F

B : Shifts from larger to smaller rear sprocket.

Press lever F

B once to shift from a larger to one smaller

sprocket.

Operation of the levers related to gear shifting should be

made only when the front chainwheel is turning.

Click

lever F

A

start position

Series

ST-6500/ST-6501/SL-7700/SL-BS77

Outer casing

SP40

Gears

18

27

Front derailleur

FD-6500

FD-6503

Front chainwheel

FC-6500

FC-6503

Bottom bracket

RD-6500

FH-6500

Cassette sprocket

CS-6500

Chain

Bottom bracket cable guide

Wire lead

Be sure to leave some excess cable, even if cutting it to

the full length of the handlebars.

Note:

The front lever cannot be tilted to

the inside until lever F

b is pushed

once or twice.

Insert the inner cable into the outer casing from the end

with the marking on it. Apply grease from the end with the

marking in order to maintain cable operating

efficiency.

Cutting the outer casing

6

: Quick-shifts three sprockets

E.x. : from 3rd to 6th

Be sure to read these service instructions in conjunction with

the service instructions for the RD-6500 / RD-6500GS /

RD-5500 / RD-5500GS before use.

Tilt

Operation of front derailleur levers

Operation of front derailleur levers

(FD-6500 / FD-5500)

(FD-6503 / FD-5503)

Lever F

a : Shifts from smaller to larger front chainring.

Lever F

a : Shifts from smaller to larger front chainring.

end of the return spring does not protrude from the

hole in the bearing member at this time.

Bracket

Lever

Maintenance

Bracket and lever disassembly

1. Use a 2 mm Allen key to

Make sure the spring is properly positioned.

remove the lever stud set

screw on the bottom of

the bracket.

Outer end cap

Lever F

b

Pull

3. Assemble the bracket and lever. Be careful that the

When cutting the outer casing, cut the opposite end to the

end with the marking. After cutting the outer casing, make

the end round so that the inside of the hole has a uniform

diameter.

Attach the same outer end cap to the cut end of the outer

casing.

Lever F

B will also move when lever F

A is operated, but

be careful not to apply pressure to lever F

B . Similarly

be careful not to press lever F

A when operating lever

F

B . Gears will not shift when both levers are pressed

simultaneously.

Confirm

Make sure the outer

casing is firmly seated

in the outer stopper.

Caution on operation

Rear lever

Lever stud set screw

2 mm Allen key

B at least 8 times

Push lever F

to make sure the mechanism

is in top gear

Lever F

B

before installing.

Cable hook

Inner cable

SM-SP17

Series

Inserting the inner cable

2. Pass the inner cable through.

CN-HG92 / CN-7700

Return spring installation tool

(TL-ST02)

f 1.6 mm

RD-6500GS

Freehub

Outer casing

pass the cable though the cable hook.

BB-6500

Rear derailleur

Outer stopper

1. Tilt the lever in (as when shifting) to make it easier to

ULTEGRA

Shifting lever

2. Set the special installation tool for the return spring.

Marking

: Quick-shifts two sprockets

E.x. : from 3rd to 5th

Return spring

Hole

E.x. : from 4th to 3rd

: Shifts one sprocket

E.x. : from 3rd to 4th

In order to realize the best performance, we recommend that

the following combination be used.

4 3

4 3

Bearing

member

4. Align the stud holes, and then press-fit

2. Insert a 2.5 mm Allen key or

Operate at

least 8 times

Depress the brake lever, and then

pass the inner cable through the

cable hole.

Cable hole

the lever stud.

similar tool into the lever stud

hole, and tap it gently with a

plastic mallet to push out the

lever stud. When the lever

stud comes out, the bracket

body and lever body can be

disassembled.

Lever stud

Lever stud set

screw

SHIMANO 105

Shifting lever

ST-5500

Outer casing

ST-5500-C

SIS SP40

Gears

3. Fix the outer guide to the inner cable, and set the angled

18

27

Front derailleur

FD-5500

FD-5503

Front chainwheel

FC-5500

FC-5503

Bottom bracket

BB-5500

Rear derailleur

RD-5500

Freehub

RD-5500GS

FH-5500

Cassette sprocket

Lever F

a

Lever F

a

lever F

a

start position

If operation of lever F

a dose not

complete the chainring shift stroke,

operate lever F

a again for the

distance (X') to complete that part of

the lever stroke (X) which was short.

lever F

a

start position

If operation of lever F

a dose not

complete the chainring shift stroke,

operate lever F

a again for the

distance (X') to complete that part of

the lever stroke (X) which was short.

CN-HG72

Bottom bracket cable guide

SM-SP17

Note

For smooth operation, always be sure to use the specified outer

casing and the bottom bracket cable guide.

Grease the inner cable and the inside of the outer casing before

use to ensure that they slide properly.

Because the high cable resistance of a frame with internal cable

routing would impair the SIS function, this type of frame should not

be used.

The end of the outer casing which has the aluminum

cap should be at the derailleur side.

4-mm cap

Derailleur side

Aluminum cap

Plastic cap or 4-mm cap

Use the ST-6501/ST-5500-C in combination with the SM-6500

cycle computer.

Be sure to read these service instructions in conjunction with the

service instructions for the SM-6500 before use.

77 Oimatsu-cho 3-cho Sakai Osaka 590-8577 Japan Phone 0722-23-3243

Please note: specifications are subject to change for improvement without notice. (English)

Jan. 1999 by Shimano Inc. XBC SZK Printed in Japan.

Lever and bearing assembly

disassembly

If the cable hook does not align with the shifting cable

hole, press lever F

B again until it does, and then install

the cable.

1. Remove the cable hook.

Cable hook

5. Remove the return

Inner cable

spring installation tool

with pliers.

Cable hook

Full gear shift stroke

Actual stroke

x'

Lever F

b : Shifts from largest chainring to intermediate

chainring.

Actual stroke

Outer guide

Make sure that the inner end is firmly seated in the

cable hook.

x'

2. Disassemble using the special tool and

Inner end

a 5 mm Allen key.

Lever F

b : Shifts from largest chainring to intermediate

chainring.

Return spring

installation tool

Cable hook

Torque tightening during assembly:

8 - 10 Nm {70 - 85 in. lbs.}

4. Set the outer casing on the inner cable, and in the

lever F

b

start position

When lever F

b is operated, there is one click where trimming (the

noise prevention mechanism) engages,

and a second stronger click when the

gear shift stroke is completed. After

trimming, the next push will complete

the gear shift stroke to the

smaller front chainring.

Gear shift

Front lever

Outer casing

Lever F

b

lever F

b

start position

Lever F

b : Shifts from intermediate chainring to smallest

chainring.

Outer holder

Trim operation

Click

Trimming (noise prevention operation)

If the chain is on the large front chainwheel and the

larger rear sprocket, the chain will rub in the front

derailleur plate, producing a characteristic noise. When

b lightly (to the point where

this happens, press lever F

it clicks); this causes the front derailleur to

move slightly towards the smaller

chainwheel, thereby eliminating

the noise.

Movement of the

front derailleur

5 mm Allen key

Lever F

b

Operate at least 2 - 3 times

2 mm Allen key

3. Disassemble as shown.

Lever stud set screw

Cable hook

Inner end

Click

screw until it is even with

the surface of the bracket.

Special tool (TL-ST01)

Push lever F

b at least

two - three times

before installing.

Make sure that the inner

end is firmly seated in the

cable hook.

Cable guide

complete stroke

Chain position

6. Tighten the lever stud set

bracket along the outer guide.

Lever F

b

One Holland Irvine CA 92618 U.S.A. Phone 949-951-5003

Industrieweg 24 NL-8071 CT Nunspeet Holland Phone 31-341-272222

The correct position is for

the round hollow on the

lever stud to be aligned

with the lever stud set

screw.

Inner cable

Bracket

Full gear shift stroke

For any questions regarding methods of installation, adjustment,

maintenance or operation, please contact a professional bicycle

dealer.

These service instructions

are printed on recycled paper

and can be recycled again

member in the bracket.

Note: Do not wipe the grease on the inner cable off.

Also, be careful that the inner cable does not pick

up dust and foreign matter.

Angled member of

outer guide

CS-HG70-9

Chain

Set the end of the spring in

the hole in the bearing

member. Note that the

spring has a right and left

side.

Inner cable

SLR outer casing

Click

Be sure leave some excess in the outer casing, even if

cutting it to the full length of the handlebars.

f 5 mm

Click

set the return spring.

SP40

Lever F

B

lever F

B

start position

SEALED

f 4 mm

Tightening torque:

6 - 8 Nm {50 - 70 in. lbs.}

Inner cable (stainless steel)

Lever F

A

1. Put the cable hook in to the bearing member, and

2. Pass the inner cable through, and set the outer casing.

f 4 mm

SP40 outer casing ()

Installation of the brake cable

Shimano Total Integration Features

Install the outer stopper for

the rear chainwheels with

the handle in the default

position.

Cable hook

SP40

installation nut

Handle default

position

f 1.2 mm

Inner cable (stainless steel)

5 mm Allen key

Cable used

The Shimano Total Integration ULTEGRA / 105 series features a

dual action control lever which actuates the brakes like a

conventional brake lever, and shifts the gears when moved inward

toward the center line of the bicycle. Gear shifting is now possible

without ever taking your hands off the brake hoods or drops.

Cable used

SP40 sealed outer casing ()

All levers return to the starting position when

released.

Operation of rear derailleur lever

WARNING

Installing the shifting cable

Gear shift

complete stroke

Pull the brake lever

(as when braking) to pass

the inner cable through the

shifting cable hole, and set

it in the outer casing.

Shifting cable hole

Tightening torque:

1 Nm {8 in. lbs.}

Do not disassemble any futher as reassembly

may not be possible.

Click

Click

5. Bring the outer casing along the front of the handlbar

and cover it with the outer guide. Now cut the outer

guide to the length of the handlebar, and tape it

temporarily in place.

Caution on operation

(FD-6500/FD-6503/FD-5500/FD-5503)

b will also move when lever F

a is operated,

Lever F

but be careful not to apply pressure to lever F

b.

Similarly be careful not to press lever F

a when

b . Gears will not shift when both

operating lever F

levers are pressed simultaneously.

Be sure to read these service instructions in conjunction with

the service instructions for the FD-6500 / FD-6503 /

FD-5500 / FD-5503 before use.

Inner cable

Outer stopper

1. Install the outer stopper to the down tube.

Outer guide

The tabs on the bracket cover each fit to a matching

slot on the bracket.

Use kerosene to wash the

lever index member as

shown below.

Outer casing

Do not smoke or use any

open flames when

cleaning with kerosene.

Direct mount seat (M5)

Replacing the bracket cover

Outer stopper

Installation bolt

Tape

Outer casing

3mm Allen key

6. Finally, wrap the handlebar with the finish tape.

Tightening torque:

1.5 - 2 Nm {13 - 18 in. lbs.}

Be sure to regrease

after cleaning.

Note the markings:

R : for right

L : for left

Grease

Wipe a little rubbing alcohol

inside the bracket cover to

make installation easier.

You might also like

- Shimano Tiagra 4600Document1 pageShimano Tiagra 4600Florian JurinNo ratings yet

- 6jr0a enDocument0 pages6jr0a enBilly GeorgiouNo ratings yet

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimNo ratings yet

- SI-5TK0D-En v1 m56577569830603908Document1 pageSI-5TK0D-En v1 m56577569830603908dcduquNo ratings yet

- Shimano Tourney Rear and Knob AdjustmentDocument1 pageShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetNo ratings yet

- SI 5VV0B en v1 m56577569830604982Document1 pageSI 5VV0B en v1 m56577569830604982iodinNo ratings yet

- DL RD m760 2 PDFDocument1 pageDL RD m760 2 PDFtudor-72No ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- SI F920A ShimanoDocument7 pagesSI F920A ShimanoolligesNo ratings yet

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouNo ratings yet

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Document1 pageAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16No ratings yet

- SH Cset m151 Front Chainwheel FC-M151Document2 pagesSH Cset m151 Front Chainwheel FC-M151Ingrid VantaNo ratings yet

- Giant Conduct SL User's ManualDocument10 pagesGiant Conduct SL User's ManualRicardo RegoNo ratings yet

- Si F570CDocument1 pageSi F570CmegclayNo ratings yet

- DM HB0003 06 EngDocument17 pagesDM HB0003 06 EngGaudencio LingamenNo ratings yet

- ShimanoDocument1 pageShimanoProto Popescu VictorNo ratings yet

- Technical ManualDocument0 pagesTechnical ManualSerban DraganNo ratings yet

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5No ratings yet

- SI 6PZRA 003 ENG - v1 - m56577569830677284Document1 pageSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5No ratings yet

- Shimano 105 5700 Rear Derailleur Installation ManualDocument2 pagesShimano 105 5700 Rear Derailleur Installation ManualjjjNo ratings yet

- SR Suntour XC Pro Forks Instructions ManualDocument8 pagesSR Suntour XC Pro Forks Instructions Manual110972ryanNo ratings yet

- MTB Technology: FRONT CHAINWHEEL: InstallationDocument4 pagesMTB Technology: FRONT CHAINWHEEL: InstallationRoy Chung Qi Huan100% (1)

- X FDD TechDocument2 pagesX FDD Techdag57No ratings yet

- Shimano XTR M980 Shift Lever Set ManualDocument4 pagesShimano XTR M980 Shift Lever Set ManualNick SpeisNo ratings yet

- CHEETAH E-SHIFT Pro Series Valve BodyDocument8 pagesCHEETAH E-SHIFT Pro Series Valve BodyhidraulicNo ratings yet

- 035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15Document6 pages035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15theteamofthedragonflyNo ratings yet

- Traxxas Revo Slipper RebuildDocument1 pageTraxxas Revo Slipper RebuildbernadysroseNo ratings yet

- Rear Derailleur: Dealer's ManualDocument20 pagesRear Derailleur: Dealer's Manualnadeem javedNo ratings yet

- Manual de Instalacion Angelus 60LDocument15 pagesManual de Instalacion Angelus 60LAnonymous WaC9PaQmr100% (1)

- Transcriptor Skeleton Turntable Owners ManualDocument20 pagesTranscriptor Skeleton Turntable Owners ManualMatt RichmondNo ratings yet

- Troubleshooting LawnmoversDocument6 pagesTroubleshooting LawnmoversnamkvalNo ratings yet

- DM CN0001 03 EngDocument9 pagesDM CN0001 03 EngXaver von TreyerNo ratings yet

- SI 6VJRA 001 00 Eng - v1 - m56577569830769083Document1 pageSI 6VJRA 001 00 Eng - v1 - m56577569830769083chandlerNo ratings yet

- GIANT WheelSystem Service Info - V01 PDFDocument32 pagesGIANT WheelSystem Service Info - V01 PDFcsrpirataNo ratings yet

- Dealer's Manual: (English)Document10 pagesDealer's Manual: (English)Rodney AtibulaNo ratings yet

- ST 6510Document9 pagesST 6510pacototo1No ratings yet

- Install Z1 Q50 Q60 Urethane Differential BushingDocument6 pagesInstall Z1 Q50 Q60 Urethane Differential BushingFer OrdazNo ratings yet

- Enfield Bullet Workshop Manual 2000 2 PDFDocument53 pagesEnfield Bullet Workshop Manual 2000 2 PDFsivakumar natarajanNo ratings yet

- Inst Man - Corsa - Eng2Document6 pagesInst Man - Corsa - Eng2Fernando Escobar HernandezNo ratings yet

- Instruction Manual: Internal Gear PumpDocument16 pagesInstruction Manual: Internal Gear PumpGrosu DanutNo ratings yet

- Instructions: 6 Speed Transmission Super KitDocument14 pagesInstructions: 6 Speed Transmission Super KitthailanNo ratings yet

- 2008 Hollow Gram SL Crank Owners Manual Supplement enDocument16 pages2008 Hollow Gram SL Crank Owners Manual Supplement engregclimbsNo ratings yet

- Revised Uzi Build TutorialDocument6 pagesRevised Uzi Build Tutorialphuk vokNo ratings yet

- DACRON HighlanderManualChapter4Document18 pagesDACRON HighlanderManualChapter4wordpower777No ratings yet

- Alpha Shift AdjustDocument15 pagesAlpha Shift Adjustsandie2121No ratings yet

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- Hercus 260 Lathe Maintenance ManualDocument24 pagesHercus 260 Lathe Maintenance ManualNewNo ratings yet

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- Dixon ZTR 428-429 Technical DataDocument10 pagesDixon ZTR 428-429 Technical DatatecsbrainNo ratings yet

- Kobalt - Lawn Mower GuideDocument21 pagesKobalt - Lawn Mower Guidessss23r5No ratings yet

- MAX1045 ManualDocument13 pagesMAX1045 Manualbrowar444100% (1)

- Richards Lock Up Kit For 2016+200Document7 pagesRichards Lock Up Kit For 2016+200chrisNo ratings yet

- RP2Document24 pagesRP2Vennia PapadipoulouNo ratings yet

- FH FW Skhd3836g En-De Ower ManualDocument19 pagesFH FW Skhd3836g En-De Ower ManualEnrico TondiniNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Archer C2 User Guide PDFDocument143 pagesArcher C2 User Guide PDFGA16DETNo ratings yet

- TL-WPS510U V5 User Guide 1910010986 PDFDocument73 pagesTL-WPS510U V5 User Guide 1910010986 PDFonggoimamNo ratings yet

- Принципиальная схема ИБП Back-UPS CS 350/500. CPU, датчики входного и выходного напряжения, EEPROM, схема включенияDocument4 pagesПринципиальная схема ИБП Back-UPS CS 350/500. CPU, датчики входного и выходного напряжения, EEPROM, схема включенияAndré BrunoNo ratings yet

- Archer C20i User Guide PDFDocument141 pagesArcher C20i User Guide PDFGA16DETNo ratings yet

- DH61WW Product Guide 02 EnglishDocument78 pagesDH61WW Product Guide 02 EnglishElio PereiraNo ratings yet

- Shift Register and Its TypesDocument22 pagesShift Register and Its TypeschoprahridyeshNo ratings yet

- Warranty PDFDocument23 pagesWarranty PDFGA16DETNo ratings yet

- Spring / Summer: WorkbookDocument142 pagesSpring / Summer: WorkbookGA16DETNo ratings yet

- RobotBASIC TutorialDocument7 pagesRobotBASIC Tutorialaloksahu1No ratings yet

- Simulator For ArduinoDocument26 pagesSimulator For ArduinoNinok Rizky AmaliaNo ratings yet

- HC SR501Document3 pagesHC SR501Đàm ThếNo ratings yet

- Energia Solar Con ArduinoDocument7 pagesEnergia Solar Con ArduinosalokaNo ratings yet

- RobotBASIC TutorialDocument7 pagesRobotBASIC Tutorialaloksahu1No ratings yet

- LM35 Temperature SensorDocument13 pagesLM35 Temperature Sensorapi-3799604100% (1)

- Datasheet Arduino Duemilanove ATMEG328Document448 pagesDatasheet Arduino Duemilanove ATMEG328Caio LoksNo ratings yet

- The LEGO MINDSTORMS EV3 Idea Book PDFDocument234 pagesThe LEGO MINDSTORMS EV3 Idea Book PDFGA16DETNo ratings yet

- Dell Service ManualDocument124 pagesDell Service Manual1224adhNo ratings yet

- BNET 50 Indispensable Word TipsDocument6 pagesBNET 50 Indispensable Word TipsarniesamNo ratings yet

- P3015 Partlist PDFDocument30 pagesP3015 Partlist PDFGA16DETNo ratings yet

- Informacion Tecnica Deka SolarDocument2 pagesInformacion Tecnica Deka SolarGA16DETNo ratings yet

- HC SR501Document3 pagesHC SR501Đàm ThếNo ratings yet

- 80+ Keyboard Shortcuts To Move Faster in Microsoft Outlook: Keystroke FunctionDocument4 pages80+ Keyboard Shortcuts To Move Faster in Microsoft Outlook: Keystroke FunctionUkeme OwohNo ratings yet

- Topics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsDocument20 pagesTopics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsGA16DETNo ratings yet

- Catalogo Tecnico Powerfit S300Document4 pagesCatalogo Tecnico Powerfit S300GA16DETNo ratings yet

- Shimano Anleitung ST5500 EN-SI6BS0E-EN PDFDocument1 pageShimano Anleitung ST5500 EN-SI6BS0E-EN PDFGA16DETNo ratings yet

- PhoenixDocument2 pagesPhoenixGA16DETNo ratings yet

- Sw4548e PDFDocument152 pagesSw4548e PDFGA16DET100% (1)

- EDOC - 001628 FusiblesDocument4 pagesEDOC - 001628 FusiblesGA16DETNo ratings yet

- EDOC - 001624 Technical SpecificationDocument12 pagesEDOC - 001624 Technical SpecificationGA16DETNo ratings yet

- Topics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsDocument20 pagesTopics Included: Introduction To Stepper Motors & Rotation Sequences Interfacing and Isolating Circuitry Industrial ApplicationsGA16DETNo ratings yet

- City of Kingston CMP Checklist 3 PDFDocument10 pagesCity of Kingston CMP Checklist 3 PDFTariq JamalNo ratings yet

- Request For Eligibility Review: Florida Department of Highway Safety & Motor Vehicle Bureau of Administrative ReviewsDocument1 pageRequest For Eligibility Review: Florida Department of Highway Safety & Motor Vehicle Bureau of Administrative Reviewsjack frostNo ratings yet

- Interlocking Concrete Block Pavement ICBDocument24 pagesInterlocking Concrete Block Pavement ICBAbhishek RanaNo ratings yet

- Nepal - Kathmandu Sustainable Urban Transport ProjectDocument63 pagesNepal - Kathmandu Sustainable Urban Transport ProjectSureshNo ratings yet

- Dec. 1997 Toyota MR2 - Original Beams Redtop' Engine - R671 TKVDocument1 pageDec. 1997 Toyota MR2 - Original Beams Redtop' Engine - R671 TKVCalum C CampbellNo ratings yet

- Traffic Volume Count SurveyDocument11 pagesTraffic Volume Count SurveyRudra Pratap SinghNo ratings yet

- Road To Solo Driving Introduction How To Use This Book English PDFDocument29 pagesRoad To Solo Driving Introduction How To Use This Book English PDFJoy HsiehNo ratings yet

- Flex-Beam Guardrail: Steel Guardrail For HighwaysDocument4 pagesFlex-Beam Guardrail: Steel Guardrail For HighwaysVictoria Berti SalazarNo ratings yet

- Passat 2016 PricessDocument22 pagesPassat 2016 PricessNicu MuțNo ratings yet

- London To Delhi by Bus PDFDocument28 pagesLondon To Delhi by Bus PDFMPA76 Ravindra Kumar SahNo ratings yet

- 3.4.3 Load Factors For Jacking and Post-Tensioning Forces 3.4.3.1 Jacking ForcesDocument10 pages3.4.3 Load Factors For Jacking and Post-Tensioning Forces 3.4.3.1 Jacking ForcesMin Min IINo ratings yet

- Catalogo EvergreenDocument34 pagesCatalogo EvergreenJesus RosalesNo ratings yet

- Ge - 14Document75 pagesGe - 14Binod Sharma100% (3)

- 4.4 Addis Ababa Spatial CompendiumDocument56 pages4.4 Addis Ababa Spatial CompendiumEdenNo ratings yet

- Car CretaDocument4 pagesCar Cretajsbibra6877100% (2)

- Roanoke Park Master PlanDocument61 pagesRoanoke Park Master PlanRoanokeParkNo ratings yet

- 5 - Superelevation & Transition CurvesDocument20 pages5 - Superelevation & Transition Curvesmochan31100% (3)

- Penentuan Kriteria Dalam Pemilihan Jenis Perkerasan Pada Dataran Tinggi Di Kabupaten TrenggalekDocument8 pagesPenentuan Kriteria Dalam Pemilihan Jenis Perkerasan Pada Dataran Tinggi Di Kabupaten TrenggalekDulsaNo ratings yet

- Where The Road Ends. A Guide To Trail Running PDFDocument240 pagesWhere The Road Ends. A Guide To Trail Running PDFYeboto Piratadelcaribe100% (1)

- Failures in PavementsDocument60 pagesFailures in Pavementsdeivarajeshkrishna100% (5)

- 03-27-24 Fatal Crash 101 at Humboldt HillDocument1 page03-27-24 Fatal Crash 101 at Humboldt HillRuth SchneiderNo ratings yet

- Form Na Walang Pamagat (Mga Tugon)Document1 pageForm Na Walang Pamagat (Mga Tugon)Jemark Abarico CenizaNo ratings yet

- Bahasa Inggris SoalDocument9 pagesBahasa Inggris SoalFitrani IsharNo ratings yet

- New Fournier BPDocument27 pagesNew Fournier BPdream_theater3No ratings yet

- Walchand College of Engg. Sangli. Seminar On Intelligent Transportation SystemDocument18 pagesWalchand College of Engg. Sangli. Seminar On Intelligent Transportation SystemShravan Nigade100% (2)

- Ch6test ApplofNewtonsLawsDocument3 pagesCh6test ApplofNewtonsLawsTill WangNo ratings yet

- Airport Pavement DesignDocument83 pagesAirport Pavement DesignMussa ElbarraniNo ratings yet

- Review Unit 4-5 BP - B1+Document5 pagesReview Unit 4-5 BP - B1+linhntm22401No ratings yet

- Citaro CNG (Tech Info)Document16 pagesCitaro CNG (Tech Info)Philippine Bus Enthusiasts SocietyNo ratings yet