Professional Documents

Culture Documents

Chapter 4 Shear Strength of Discontinuities

Chapter 4 Shear Strength of Discontinuities

Uploaded by

José Luis IllanesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4 Shear Strength of Discontinuities

Chapter 4 Shear Strength of Discontinuities

Uploaded by

José Luis IllanesCopyright:

Available Formats

4

Shear strength of discontinuities

4.1

Introduction

All rock masses contain discontinuities such as bedding planes, joints, shear zones and

faults. At shallow depth, where stresses are low, failure of the intact rock material is

minimal and the behaviour of the rock mass is controlled by sliding on the

discontinuities. In order to analyse the stability of this system of individual rock blocks,

it is necessary to understand the factors that control the shear strength of the

discontinuities which separate the blocks. These questions are addressed in the discussion

that follows.

4.2

Shear strength of planar surfaces

Suppose that a number of samples of a rock are obtained for shear testing. Each sample

contains a through-going bedding plane that is cemented; in other words, a tensile force

would have to be applied to the two halves of the specimen in order to separate them. The

bedding plane is absolutely planar, having no surface irregularities or undulations. As

illustrated in Figure 4.1, in a shear test each specimen is subjected to a stress n normal to

the bedding plane, and the shear stress , required to cause a displacement , is measured.

The shear stress will increase rapidly until the peak strength is reached. This

corresponds to the sum of the strength of the cementing material bonding the two halves

of the bedding plane together and the frictional resistance of the matching surfaces. As

the displacement continues, the shear stress will fall to some residual value that will then

remain constant, even for large shear displacements.

Plotting the peak and residual shear strengths for different normal stresses results in

the two lines illustrated in Figure 4.1. For planar discontinuity surfaces the experimental

points will generally fall along straight lines. The peak strength line has a slope of and

an intercept of c on the shear strength axis. The residual strength line has a slope of r.

The relationship between the peak shear strength p and the normal stress n can be

represented by the Mohr-Coulomb equation:

p = c + n tan

where

c is the cohesive strength of the cemented surface and

is the angle of friction.

(4.1)

Shear strength of planar surfaces

61

Figure 4.1: Shear testing of discontinuities

In the case of the residual strength, the cohesion c has dropped to zero and the

relationship between r and n can be represented by:

r = n tan r

where

(4.2)

r is the residual angle of friction.

This example has been discussed in order to illustrate the physical meaning of the term

cohesion, a soil mechanics term, which has been adopted by the rock mechanics

community. In shear tests on soils, the stress levels are generally an order of magnitude

lower than those involved in rock testing and the cohesive strength of a soil is a result of

the adhesion of the soil particles. In rock mechanics, true cohesion occurs when cemented

surfaces are sheared. However, in many practical applications, the term cohesion is used

for convenience and it refers to a mathematical quantity related to surface roughness, as

discussed in a later section. Cohesion is simply the intercept on the axis at zero normal

stress.

The basic friction angle b is a quantity that is fundamental to the understanding of the

shear strength of discontinuity surfaces. This is approximately equal to the residual

friction angle r but it is generally measured by testing sawn or ground rock surfaces.

These tests, which can be carried out on surfaces as small as 50 mm 50 mm, will

produce a straight line plot defined by the equation :

r = n tan b

(4.3)

62

Chapter 4: Shear strength of discontinuities

Figure 4.2: Diagrammatic section through shear machine used by Hencher and Richards (1982).

Figure 4.3: Shear machine of the type used by Hencher and Richards (1982) for

measurement of the shear strength of sheet joints in Hong Kong granite.

Shear strength of rough surfaces

63

A typical shear testing machine, which can be used to determine the basic friction angle

b is illustrated in Figures 4.2 and 4.3. This is a very simple machine and the use of a

mechanical lever arm ensures that the normal load on the specimen remains constant

throughout the test. This is an important practical consideration since it is difficult to

maintain a constant normal load in hydraulically or pneumatically controlled systems and

this makes it difficult to interpret test data.

Note that it is important that, in setting up the specimen, great care has to be taken to

ensure that the shear surface is aligned accurately in order to avoid the need for an

additional angle correction.

Most shear strength determinations today are carried out by determining the basic

friction angle, as described above, and then making corrections for surface roughness as

discussed in the following sections of this chapter. In the past there was more emphasis

on testing full scale discontinuity surfaces, either in the laboratory or in the field. There

are a significant number of papers in the literature of the 1960s and 1970s describing

large and elaborate in situ shear tests, many of which were carried out to determine the

shear strength of weak layers in dam foundations. However, the high cost of these tests

together with the difficulty of interpreting the results has resulted in a decline in the use

of these large scale tests and they are seldom seen today.

The authors opinion is that it makes both economical and practical sense to carry out

a number of small scale laboratory shear tests, using equipment such as that illustrated in

Figures 4.2 and 4.3, to determine the basic friction angle. The roughness component

which is then added to this basic friction angle to give the effective friction angle is a

number which is site specific and scale dependent and is best obtained by visual estimates

in the field. Practical techniques for making these roughness angle estimates are

described on the following pages.

4.3

Shear strength of rough surfaces

A natural discontinuity surface in hard rock is never as smooth as a sawn or ground

surface of the type used for determining the basic friction angle. The undulations and

asperities on a natural joint surface have a significant influence on its shear behaviour.

Generally, this surface roughness increases the shear strength of the surface, and this

strength increase is extremely important in terms of the stability of excavations in rock.

Patton (1966) demonstrated this influence by means of an experiment in which he

carried out shear tests on 'saw-tooth' specimens such as the one illustrated in Figure 4.4.

Shear displacement in these specimens occurs as a result of the surfaces moving up the

inclined faces, causing dilation (an increase in volume) of the specimen.

The shear strength of Patton's saw-tooth specimens can be represented by:

= n tan( b + i )

where

b is the basic friction angle of the surface and

i is the angle of the saw-tooth face.

(4.4)

Chapter 4: Shear strength of discontinuities

64

Figure 4.4: Pattons experiment on the shear strength of saw-tooth specimens.

4.4

Bartons estimate of shear strength

Equation (4.4) is valid at low normal stresses where shear displacement is due to sliding

along the inclined surfaces. At higher normal stresses, the strength of the intact material

will be exceeded and the teeth will tend to break off, resulting in a shear strength

behaviour which is more closely related to the intact material strength than to the

frictional characteristics of the surfaces.

While Pattons approach has the merit of being very simple, it does not reflect the

reality that changes in shear strength with increasing normal stress are gradual rather than

abrupt. Barton and his co-workers (1973, 1976, 1977, 1990) studied the behaviour of

natural rock joints and have proposed that equation (4.4) can be re-written as:

JCS

= n tan b + JRC log10

where

4.5

(4.5)

JRC is the joint roughness coefficient and

JCS is the joint wall compressive strength.

Field estimates of JRC

The joint roughness coefficient JRC is a number that can be estimated by comparing the

appearance of a discontinuity surface with standard profiles published by Barton and

others. One of the most useful of these profile sets was published by Barton and Choubey

(1977) and is reproduced in Figure 4.2.

The appearance of the discontinuity surface is compared visually with the profiles

shown and the JRC value corresponding to the profile which most closely matches that of

the discontinuity surface is chosen. In the case of small scale laboratory specimens, the

scale of the surface roughness will be approximately the same as that of the profiles

illustrated. However, in the field the length of the surface of interest may be several

metres or even tens of metres and the JRC value must be estimated for the full scale

surface.

Field estimates of JRC

65

Figure 4.2: Roughness profiles and corresponding JRC values (After Barton and Choubey 1977).

Chapter 4: Shear strength of discontinuities

66

Straight edge

Asperity amplitude - mm

20

16

12

10

8

6

5

4

3

400

300

200

Amplitude of asperities - mm

100

50

40

30

20

10

0.5

Joint Roughness Coefficient (JRC)

Length of profile - m

5

4

3

2

1

0.5

0.4

0.3

0.2

0.1

0.1

0.2 0.3

0.5

3 4 5

10

Length of profile - m

Figure 4.6: Alternative method for estimating JRC from measurements of surface

roughness amplitude from a straight edge (Barton 1982).

Field estimates of JCS

4.6

67

Field estimates of JCS

Suggested methods for estimating the joint wall compressive strength were published by

the ISRM (1978). The use of the Schmidt rebound hammer for estimating joint wall

compressive strength was proposed by Deere and Miller (1966), as illustrated in Figure

4.7.

3

28

300

26

24

200

22

150

20

100

90

80

70

60

50

40

Hammer orientation

Uniaxial compressive strength - MPa

250

Unit weight of rock - kN/m

30

32

250

200

150

400

350

100

50

Average dispersion of strength

for most rocks - MPa

30

20

10

10

20

10

0

0

0

10

10

30

30

20

10

40

30

20

20

20

40

40

40

30

30

40

60

50

50

60

50

60

50

50

60

60

Schmidt hardness - Type L hammer

Figure 4.7: Estimate of joint wall compressive strength from Schmidt hardness.

Chapter 4: Shear strength of discontinuities

68

4.7

Influence of scale on JRC and JCS

On the basis of extensive testing of joints, joint replicas, and a review of literature, Barton

and Bandis (1982) proposed the scale corrections for JRC defined by the following

relationship:

L

JRC n = JRCo n

Lo

0.02 JRCo

(4.6)

where JRCo, and Lo (length) refer to 100 mm laboratory scale samples and JRCn, and Ln

refer to in situ block sizes.

Because of the greater possibility of weaknesses in a large surface, it is likely that the

average joint wall compressive strength (JCS) decreases with increasing scale. Barton

and Bandis (1982) proposed the scale corrections for JCS defined by the following

relationship:

L

JCS n = JCS o n

Lo

0.03 JRCo

(4.7)

where JCSo and Lo (length) refer to 100 mm laboratory scale samples and JCSn and Ln

refer to in situ block sizes.

4.8

Shear strength of filled discontinuities

The discussion presented in the previous sections has dealt with the shear strength of

discontinuities in which rock wall contact occurs over the entire length of the surface

under consideration. This shear strength can be reduced drastically when part or all of the

surface is not in intimate contact, but covered by soft filling material such as clay gouge.

For planar surfaces, such as bedding planes in sedimentary rock, a thin clay coating will

result in a significant shear strength reduction. For a rough or undulating joint, the filling

thickness has to be greater than the amplitude of the undulations before the shear strength

is reduced to that of the filling material.

A comprehensive review of the shear strength of filled discontinuities was prepared by

Barton (1974) and a summary of the shear strengths of typical discontinuity fillings,

based on Barton's review, is given in Table 4.1.

Where a significant thickness of clay or gouge fillings occurs in rock masses and

where the shear strength of the filled discontinuities is likely to play an important role in

the stability of the rock mass, it is strongly recommended that samples of the filling be

sent to a soil mechanics laboratory for testing.

Shear strength of filled discontinuities

69

Table 4.1: Shear strength of filled discontinuities and filling materials (After Barton 1974)

Rock

Description

Peak

c' (MPa)

Peak

Basalt

Clayey basaltic breccia, wide variation

from clay to basalt content

0.24

42

Bentonite

Bentonite seam in chalk

Thin layers

Triaxial tests

0.015

0.09-0.12

0.06-0.1

7.5

12-17

9-13

Bentonitic shale

Triaxial tests

Direct shear tests

0-0.27

8.5-29

Clays

Over-consolidated, slips, joints and minor

shears

0-0.18

12-18.5

Clay shale

Triaxial tests

Stratification surfaces

0.06

32

Coal measure rocks

Clay mylonite seams, 10 to 25 mm

0.012

Dolomite

Altered shale bed, 150 mm thick

Diorite, granodiorite

and porphyry

Clay gouge (2% clay, PI = 17%)

Granite

Clay filled faults

Sandy loam fault filling

Tectonic shear zone, schistose and broken

granites, disintegrated rock and gouge

Greywacke

1-2 mm clay in bedding planes

Limestone

6 mm clay layer

10-20 mm clay fillings

<1 mm clay filling

Residual

c' (MPa)

Residual

0.03

8.5

0-0.003

10.5-16

19-25

16

11-11.5

0.04

14.5

0.02

17

26.5

0-0.1

0.05

24-45

40

0.24

42

0

21

13

15-24

0.08

11

0.1

0.05-0.2

13-14

17-21

0.08

0.1

38

10

Limestone, marl and

lignites

Interbedded lignite layers

Lignite/marl contact

Limestone

Marlaceous joints, 20 mm thick

25

Lignite

Layer between lignite and clay

0.014-.03

15-17.5

Montmorillonite

Bentonite clay

80 mm seams of bentonite (montmorillonite) clay in chalk

0.36

0.016-.02

14

7.5-11.5

Schists, quartzites

and siliceous schists

100-15- mm thick clay filling

Stratification with thin clay

Stratification with thick clay

0.03-0.08

0.61-0.74

0.38

32

41

31

Slates

Finely laminated and altered

0.05

33

Quartz / kaolin /

pyrolusite

Remoulded triaxial tests

0.042-.09

36-38

Chapter 4: Shear strength of discontinuities

70

4.9

Influence of water pressure

When water pressure is present in a rock mass, the surfaces of the discontinuities are

forced apart and the normal stress n is reduced. Under steady state conditions, where

there is sufficient time for the water pressures in the rock mass to reach equilibrium, the

reduced normal stress is defined by n' = (n - u), where u is the water pressure. The

reduced normal stress n' is usually called the effective normal stress, and it can be used

in place of the normal stress term n in all of the equations presented in previous sections

of this chapter.

4.10 Instantaneous cohesion and friction

shear stress

Due to the historical development of the subject of rock mechanics, many of the analyses,

used to calculate factors of safety against sliding, are expressed in terms of the MohrCoulomb cohesion (c) and friction angle (), defined in Equation 4.1. Since the 1970s it

has been recognised that the relationship between shear strength and normal stress is

more accurately represented by a non-linear relationship such as that proposed by Barton

(1973). However, because this relationship (e.g. Equation 4.5) is not expressed in terms

of c and , it is necessary to devise some means for estimating the equivalent cohesive

strengths and angles of friction from relationships such as those proposed by Barton.

Figure 4.8 gives definitions of the instantaneous cohesion ci and the instantaneous

friction angle i for a normal stress of n. These quantities are given by the intercept and

the inclination, respectively, of the tangent to the non-linear relationship between shear

strength and normal stress. These quantities may be used for stability analyses in which

the Mohr-Coulomb failure criterion (Equation 4.1) is applied, provided that the normal

stress n is reasonably close to the value used to define the tangent point.

In a typical practical application, a spreadsheet program can be used to solve Equation

4.5 and to calculate the instantaneous cohesion and friction values for a range of normal

stress values. A portion of such a spreadsheet is illustrated in Figure 4.9.

tangent

ci

n

normal stress

Figure 4.8: Definition of instantaneous cohesion c i and instantaneous friction angle i for a

non-linear failure criterion.

Instantaneous cohesion and friction

71

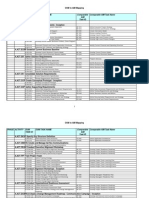

Barton shear failure criterion

Input parameters:

Basic friction angle (PHIB) - degrees

Joint roughness coefficient (JRC)

Joint compressive strength (JCS)

Minimum normal stress (SIGNMIN)

Normal

stress

(SIGN)

MPa

0.360

0.720

1.440

2.880

5.759

11.518

23.036

46.073

Shear

strength

(TAU)

MPa

0.989

1.538

2.476

4.073

6.779

11.344

18.973

31.533

dTAU

dSIGN

(DTDS)

1.652

1.423

1.213

1.030

0.872

0.733

0.609

0.496

Friction

angle

(PHI)

degrees

58.82

54.91

50.49

45.85

41.07

36.22

31.33

26.40

29

16.9

96

0.360

Cohesive

strength

(COH)

MPa

0.394

0.513

0.730

1.107

1.760

2.907

4.953

8.666

Cell formulae:

SIGNMIN = 10^(LOG(JCS)-((70-PHIB)/JRC))

TAU = SIGN*TAN((PHIB+JRC*LOG(JCS/SIGN))*PI()/180)

DTDS =

TAN((JRC*LOG(JCS/SIGN)+PHIB)*PI()/180)-(JRC/LN(10))

*(TAN((JRC*LOG(JCS/SIGN)+PHIB)*PI()/180)^2+1)*PI()/180

PHI =

ATAN(DTDS)*180/PI()

COH =

TAU-SIGN*DTDS

Figure 4.9 Printout of spreadsheet cells and formulae used to calculate shear strength,

instantaneous friction angle and instantaneous cohesion for a range of normal stresses.

Note that equation 4.5 is not valid for n = 0 and it ceases to have any practical

meaning for b + JRC log10 ( JCS / n ) > 70 . This limit can be used to determine a

minimum value for n. An upper limit for n is given by n = JCS.

In the spreadsheet shown in Figure 4.9, the instantaneous friction angle i, for a

normal stress of n, has been calculated from the relationship

i = arctan

n

(4.8)

Chapter 4: Shear strength of discontinuities

72

JCS

JRC 2

JCS

= tan JRC log10

+ b

+ b + 1

tan JRC log10

n

n

n

180 ln 10

(4.9)

The instantaneous cohesion c i is calculated from:

ci = n tan i

(4.10)

In choosing the values of ci and i for use in a particular application, the average normal

stress n acting on the discontinuity planes should be estimated and used to determine the

appropriate row in the spreadsheet. For many practical problems in the field, a single

average value of n will suffice but, where critical stability problems are being

considered, this selection should be made for each important discontinuity surface.

You might also like

- Oum Aim MappingDocument11 pagesOum Aim Mappingjoeb00gieNo ratings yet

- 103 YouTube Title Ab Tests 1Document122 pages103 YouTube Title Ab Tests 1kNo ratings yet

- Uninterruptible Power SuppliesDocument21 pagesUninterruptible Power SuppliesVer BautistaNo ratings yet

- Python Programming For Beginners and Hacking With Python 2 Bundle ManuscriptDocument136 pagesPython Programming For Beginners and Hacking With Python 2 Bundle ManuscriptStefano CastelliNo ratings yet

- Lal Kitab PredictionDocument4 pagesLal Kitab PredictionBrijesh MishraaNo ratings yet

- Algorithms For The Generation of Jazz Musical AccompanimentDocument114 pagesAlgorithms For The Generation of Jazz Musical Accompanimentshu2u100% (1)

- Bstem-5 4Document61 pagesBstem-5 4G-SamNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Shear Strength of Rock Joints in Theory and Practice - BartonDocument54 pagesShear Strength of Rock Joints in Theory and Practice - BartonCharlotte Woolley100% (1)

- Shear Strength of SoilDocument43 pagesShear Strength of SoilChristian Jude LegaspiNo ratings yet

- Lecture 3 Shear Strength of Soil Part 1Document32 pagesLecture 3 Shear Strength of Soil Part 1F.a.AlfredThomNo ratings yet

- Chapter 4 Results and DiscussionDocument47 pagesChapter 4 Results and DiscussionRamil Candido75% (4)

- Barton - Shear Strength Criteria For Rock, Rock Joints, Rockfill and Rock Masses - Problems and Some Solutions - 2012Document13 pagesBarton - Shear Strength Criteria For Rock, Rock Joints, Rockfill and Rock Masses - Problems and Some Solutions - 2012krainaoz2011No ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Shear Strength of Rockfill Interfaces and Rock JointsDocument17 pagesShear Strength of Rockfill Interfaces and Rock Jointsakhila sNo ratings yet

- Bolton 1986 - The Strength and Dilatancy of SandsDocument14 pagesBolton 1986 - The Strength and Dilatancy of SandsCristian SandovalNo ratings yet

- Ultimate Limit State Analysis and Design of Plated StructuresFrom EverandUltimate Limit State Analysis and Design of Plated StructuresNo ratings yet

- FerrisWheel 3 MuestraStudent SbookDocument12 pagesFerrisWheel 3 MuestraStudent SbookIleana IspizúaNo ratings yet

- Ch10 Slope Stability 2Document32 pagesCh10 Slope Stability 2rafiNo ratings yet

- 3 Shear Strength of DiscontinuitiesDocument27 pages3 Shear Strength of DiscontinuitiesSebastian Cristopher Hormazabal CortesNo ratings yet

- Shear Strength of Discontinuities - 2023 06 30 120608 - PBKXDocument14 pagesShear Strength of Discontinuities - 2023 06 30 120608 - PBKXThomas MarinkoNo ratings yet

- Practical Rock Engineering Chapter 4 Shear Strength of DiscontinuitiesDocument14 pagesPractical Rock Engineering Chapter 4 Shear Strength of DiscontinuitiesKaren MkNo ratings yet

- Shear Strength of Discontinuities: C Is The Cohesive Strength of The Cemented Surface andDocument6 pagesShear Strength of Discontinuities: C Is The Cohesive Strength of The Cemented Surface andZola1stNo ratings yet

- Lecture5 (ShearStrengthDiscontinuity)Document0 pagesLecture5 (ShearStrengthDiscontinuity)chouszeszeNo ratings yet

- Rock Mechanics PTR 339: Tishk International University Engineering Faculty Petroleum & Mining Eng. DepartmentDocument14 pagesRock Mechanics PTR 339: Tishk International University Engineering Faculty Petroleum & Mining Eng. DepartmentHassn LukakuNo ratings yet

- Session 3b - Shear Strength of Discontinuities - DR Louis WONGDocument45 pagesSession 3b - Shear Strength of Discontinuities - DR Louis WONGHinLapYuNo ratings yet

- Direct Shear Box and Ring Shear Test Comparison Why Does Internal Friction Angle VaryDocument17 pagesDirect Shear Box and Ring Shear Test Comparison Why Does Internal Friction Angle VaryBarry OcayNo ratings yet

- Shear StrengthDocument55 pagesShear StrengthDipendra Bahadur SinghNo ratings yet

- Rock Slope Engineering: 1 Compiled By: Sujan MakaDocument33 pagesRock Slope Engineering: 1 Compiled By: Sujan MakaKshitiz ShresthaNo ratings yet

- Chapter4-Slope StabilityDocument14 pagesChapter4-Slope StabilityjemalahmedusaayNo ratings yet

- Kawamoto Todd r-20-40Document21 pagesKawamoto Todd r-20-40pedro.moreiraNo ratings yet

- Basic PhiDocument16 pagesBasic PhiMuhammad Rahman YuliantoNo ratings yet

- 3 Constitutive Laws - FracturesDocument159 pages3 Constitutive Laws - Fracturesdorian.axel.ptNo ratings yet

- Chapter4 - Stress, Strain and Elastic Deformation of SoilsDocument20 pagesChapter4 - Stress, Strain and Elastic Deformation of SoilsBirhanuNo ratings yet

- Measurement of The Basic Friction Angle of Planar Rock Discontinuities With Three Rock CoresDocument11 pagesMeasurement of The Basic Friction Angle of Planar Rock Discontinuities With Three Rock CoresNguyen Viet HaNo ratings yet

- Mechanical Specific Energy Versus Depth of Cut in Rock Cutting and DrillingDocument37 pagesMechanical Specific Energy Versus Depth of Cut in Rock Cutting and Drillingcvlpla55No ratings yet

- Direct Shear Test On Sand ASTM D 3080Document6 pagesDirect Shear Test On Sand ASTM D 3080Muhammad ImranNo ratings yet

- Chapter 5 - Soil StrengthDocument47 pagesChapter 5 - Soil StrengthEstuardo Rosas BureloNo ratings yet

- Effect of The Back Rake Angle and Groove Geometry in Rock CuttingDocument10 pagesEffect of The Back Rake Angle and Groove Geometry in Rock CuttingChanchai WorrawngwannaNo ratings yet

- Strength Properties of Rock As An Index of BlastabilityDocument17 pagesStrength Properties of Rock As An Index of BlastabilityorazabilNo ratings yet

- Chapter - 4Document18 pagesChapter - 4BirhanuNo ratings yet

- C Attachment 76 673 PDFDocument17 pagesC Attachment 76 673 PDFStajic MilanNo ratings yet

- 58 - The Effect of Grading On Strength and Dilatancy Parameters of SandsDocument9 pages58 - The Effect of Grading On Strength and Dilatancy Parameters of SandsSeif EddineNo ratings yet

- Laboratory Investigations of Sand Smooth Steel Interface Under Monotonic and Cyclic LoadingsDocument9 pagesLaboratory Investigations of Sand Smooth Steel Interface Under Monotonic and Cyclic LoadingsSiham BelmelNo ratings yet

- In SituNormalStiffnessofRockMassDocument8 pagesIn SituNormalStiffnessofRockMassSonal GeotechNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument31 pagesWWW - MINEPORTAL.in: Online Test Series ForSheshu BabuNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument31 pagesWWW - MINEPORTAL.in: Online Test Series ForSusil SenapatiNo ratings yet

- Bank Stability and Toe Erosion Model: Static Version 5.4Document61 pagesBank Stability and Toe Erosion Model: Static Version 5.4Lim Yew KwangNo ratings yet

- Laboratory Exercise: Direct Shear Test: References and SourcesDocument7 pagesLaboratory Exercise: Direct Shear Test: References and SourcesFarid MarufNo ratings yet

- Ce 2010 - Experiment 04Document5 pagesCe 2010 - Experiment 04Minhajul IslamNo ratings yet

- Shear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignDocument15 pagesShear Strength of Rockfill, Interfaces and Rock Joints, and Their Points of Contact in Rock Dump DesignThomas LawsonNo ratings yet

- 7strength Properties of Rocks and Rock MassesDocument16 pages7strength Properties of Rocks and Rock MassesSheshu BabuNo ratings yet

- Failure Along Planes of Weakness: Can. Geotech. J. Vol. 12, 1975Document8 pagesFailure Along Planes of Weakness: Can. Geotech. J. Vol. 12, 1975Felipe PereiraNo ratings yet

- Alinia e Moosavi (2008) - A Parametric Study On The Longitudinal Stiffeners of Web PanelsDocument11 pagesAlinia e Moosavi (2008) - A Parametric Study On The Longitudinal Stiffeners of Web PanelsMaria FlorNo ratings yet

- Sismologia Mi ParteDocument13 pagesSismologia Mi ParteDiana Tapia CorreaNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiRodrigo De MeloNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument17 pagesShear Strength of Rockfill Interfaces and Rock JoiAlexandre RibeiroNo ratings yet

- Hencher - Interpretation of Direct Shear Tests On Rock JointsDocument8 pagesHencher - Interpretation of Direct Shear Tests On Rock JointsMark2123100% (1)

- Chapter4 Slope StabilityDocument14 pagesChapter4 Slope Stabilityismal sirajNo ratings yet

- Shear Strength of Rockfill Interfaces and Rock JoiDocument16 pagesShear Strength of Rockfill Interfaces and Rock JoiDaniel MoravanskýNo ratings yet

- Shear Strength and Triaxial TestsDocument18 pagesShear Strength and Triaxial Testsنور عليNo ratings yet

- Fang-Mikroudis1991 - Childs AnnuliDocument31 pagesFang-Mikroudis1991 - Childs AnnuliEric ChanNo ratings yet

- s10706 009 9295 7 PDFDocument11 pagess10706 009 9295 7 PDFjuan carlos molano toroNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Chapter 3 Active Fire PreventionDocument54 pagesChapter 3 Active Fire PreventionKan Fock-KuiNo ratings yet

- Stability of Clay MasksDocument7 pagesStability of Clay MasksGligorpaulaNo ratings yet

- PHC Conference Agenda 6-13Document5 pagesPHC Conference Agenda 6-13OSUMCNo ratings yet

- CH001Document23 pagesCH001Bo ZydarinNo ratings yet

- Engaging in The Concepts of SociologyDocument6 pagesEngaging in The Concepts of SociologylovellaNo ratings yet

- MPQ RankedDocument11 pagesMPQ Rankedblack jackNo ratings yet

- PR5203 Rev14 CP8L LCD ENGINEER ENDocument28 pagesPR5203 Rev14 CP8L LCD ENGINEER ENChrisNo ratings yet

- Gettin MaturaDocument12 pagesGettin MaturaMaciek BryńczakNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument2 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- Sharp Lc-60 Le 630 U-A - lc-60 Le 6300 U-A-b - lc-70 Le 735 U - PWB - Unit - EditionDocument38 pagesSharp Lc-60 Le 630 U-A - lc-60 Le 6300 U-A-b - lc-70 Le 735 U - PWB - Unit - EditionRabshaqa100% (1)

- Career Fact Sheet SummaryDocument2 pagesCareer Fact Sheet Summaryapi-240316748No ratings yet

- En Brochure ICE Zirkon 3D Stains WebDocument72 pagesEn Brochure ICE Zirkon 3D Stains WebOrxan TeymurluNo ratings yet

- Research Methodology Meaning of ResearchDocument2 pagesResearch Methodology Meaning of Researchsandesh28mayNo ratings yet

- Wastegate Turbocharger Operation DiagnosticDocument6 pagesWastegate Turbocharger Operation DiagnosticHamilton MirandaNo ratings yet

- Orientation Proposal LetterDocument6 pagesOrientation Proposal LetterMariel EstrellaNo ratings yet

- APP A Complete Guide To MSS SP 58Document20 pagesAPP A Complete Guide To MSS SP 58nicoNo ratings yet

- Tugas LK 1.1 - Jamaludin MalikDocument4 pagesTugas LK 1.1 - Jamaludin MalikDesa GunungaciNo ratings yet

- Computer Planner Class 4Document2 pagesComputer Planner Class 4rajni1970No ratings yet

- Liste SalariésDocument33 pagesListe SalariésIzabellaGonçalvesNo ratings yet

- Iso 5167 2Document54 pagesIso 5167 2Minh Hoàng Nguyễn100% (1)

- ElfDocument5 pagesElfkieraNo ratings yet

- Cmat Unit 1 4Document6 pagesCmat Unit 1 4Merle MañgaliNo ratings yet