Professional Documents

Culture Documents

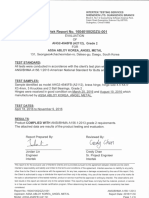

JIS Standard For Flange

JIS Standard For Flange

Uploaded by

Dương PhúcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JIS Standard For Flange

JIS Standard For Flange

Uploaded by

Dương PhúcCopyright:

Available Formats

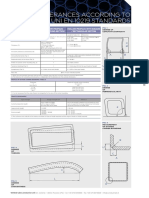

Pipi] ar [a [iasfiasp oo Pas ps apap]

3 |i6| is) 50 ss | 36 [igsfias| as] a fala} = | =

ao_|is| ie] oe pi eo ed ed

30 [16 | 18 | 69 73 [75 [135] tap Tao] a] a] a te

& |is|is) se a | a fiasfias}or}als fala} = | =

so_|is|is| a ios_| ios |r25|r2s} ols] s tals | = | =

so Pe | 18] = =| fisfizs} =| ae} 3] 7s] >]

io [1 | is | 27 wo | io |r2sjras| ae fas fs tats] = | =

izs_| 20 | 20 | 14 ir_| ise |i2s|ias] ol} e tals | = | =

18022] 22 182 183] ie [izs[izsy-ao espe Tay sp]

rs | 22| 22 |" ~ | ao fizsfias} Spas} 2] i]s] = | =

zo0_| 2 | 32 |= =| oe [iaslizs| = fee] s |=] | = | =

225 [2 [22] You might also like