Professional Documents

Culture Documents

General Description and Weldability of Ferrous Metals, Welding Positions, Welding Machines and Other Weliding Cutting Systems Plasma Weld

Uploaded by

ANILCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Description and Weldability of Ferrous Metals, Welding Positions, Welding Machines and Other Weliding Cutting Systems Plasma Weld

Uploaded by

ANILCopyright:

Available Formats

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

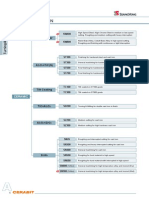

Welder Training & Certification

PlasmaCuttingMachines

PlasmaTransferredArcWelding(PTA)

WeldingAutomation

PlasmaWeldingEquipments

MicroPlasmaWeldingMachines

MicroTIGWeldingMachines

WeldingInverters

BoreWeldingCladding

WeldingData

Plasma Cutting Machines

GENERALDESCRIPTIONANDWELDABILITYOFFERROUS

METALS

WeldingData>>GENERALDESCRIPTIONANDWELDABILITYOFFERROUSMETALS

For precision cutting of

Stainless steel, Aluminium and

all other Ferrous and Non

ferrousmetals.

StainlessSteelcuttingupto150

mmthickplates.

BACK TO WELDING DATA

GENERAL DESCRIPTION AND WELDABILITY OF FERROUS METALS

PTA Hardfacing & Cladding

710.LOWCARBONSTEELS

(PTA)forHardfacing/Cladding

/ Reclamation & Protection of

Mechanicalparts.

a.General.Thelowcarbon(mild)steelsincludethosewithacarboncontentofupto0.30percent(fig.77).Inmostlowcarbon

steels,carbonrangesfrom0.10to0.25percent,manganesefrom0.25to0.50percent,phosphorous0.40percentmaximum,

andsulfur0.50percentmaximum.Steelsinthisrangearemostwidelyusedforindustrialfabricationandconstruction.These

lowcarbonsteelsdonothardenappreciablywhenwelded,andthereforedonotrequirepreheatingorpostheatingexceptin

specialcases,suchaswhenheavysectionsaretobewelded.Ingeneral,nodifficultiesareencounteredwhenweldinglow

carbonsteels.Properlymadelowcarbonsteelweldswillequalorexceedthebasemetalinstrength.Lowcarbonsteelsare

soft,ductile,canberolled,punched,sheared,andworkedwheneitherhotorcold.Theycanbemachinedandarereadily

welded.Caststeelhasarough,darkgraysurfaceexceptwheremachined.Rolledsteelhasfinesurfacelinesrunninginone

direction.Forgedsteelisusuallyrecognizablebyitsshape,hammermarks,orfins.Thefracturecolorisbrightcrystallinegray,

andthesparktestyieldssparkswithlong,yelloworangestreaksthathaveatendencytoburstintowhite,forkedsparklers.

Steelgivesoffsparkswhenmeltedandsolidifiesalmostinstantly.Lowcarbonsteelscanbeeasilyweldedwithanyofthearc,

gas,andresistanceweldingprocesses.

Welding Automation

IncreaseProductivityand

Capacity

Repeatablehighquality

welds

EnhanceQuality

Custommadesolutions

Plasma Welding

Lesssensitivitytochangesin

Arclength.

.

Micro Plasma Welding

Machines

Precisionweldingof

minature

parts

ControlledArcatlowcurrents

Automatedweldingatlow

currents.

WithbuiltinPilotarcing

system.

Micro TIG Welding

Machines

Precisionweldingof

minatureparts

Idealforsmallerrepairor

Assemblywork.

Builtinhighfrequency

ignition.

b.Coppercoatedlowcarbonrodsshouldbeusedforweldinglowcarbonsteel.Therodsizesforvariousplatethicknesses

areasfollows:

Platethickness

1/16to1/8in.(1.6to3.2mm)

1/8to3/8in.(3.2to9.5mm)

3/8to1/2in.(9.5to12.7mm)

1/2in.(12.7mm)andheavier

Welding Inverters

Roddiameter

1/16in.(1.6mm)

1/8in.(3.2mm)

3/16in.(4.8mm)

1/4in.(6.4mm)

Lightweight&compact:80%

lessweightcomparedto

conventionalmachines.

NOTE

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

1/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

Rodsfrom5/16to3/8in.(7.9to9.5mm)areavailableforheavywelding.However,heavyweldscanbemadewiththe3/16or

1/4in.(4.8or6.4mm)rodsbyproperlycontrollingthepuddleandmeltingrateoftherod.

c. The joints may be prepared by flame cutting or machining. The type of preparation (fig. 78) is determined by the plate

thicknessandtheweldingposition.

d.Theflameshouldbeadjustedtoneutral.Eithertheforehandorbackhandweldingmethodmaybeused,dependingonthe

thicknessoftheplatesbeingwelded.

e.Themoltenmetalshouldnotbeoverheated,becausethiswillcausethemetaltoboilandsparkexcessively.Theresultant

grainstructureoftheweldmetalwillbelarge,thestrengthlowered,andtheweldbadlyscarred.

f.Thelowcarbonsteelsdonothardeninthefusionzoneasaresultofwelding.

g.MetalArcWelding.

(1)Whenmetalarcweldinglowcarbonsteels,thebare,thincoatedorheavycoatedshieldedarctypesofelectrodes

maybeused.Theseelectrodesareoflowcarbontype(0.10to0.14percent).

(2)Lowcarbonsheetorplatematerialsthathavebeenexposedtolowtemperaturesshouldbepreheatedslightlyto

roomtemperaturebeforewelding.

(3)Inweldingsheetmetalupto1/8in.(3.2mm)inthickness,theplainsquarebuttjointtypeofedgepreparationmay

beused.Whenlongseamsaretobeweldedinthesematerials,theedgesshouldbespacedtoallowforshrinkage,

becausethedepositedmetaltendstopulltheplatestogether.Thisshrinkageislesssevereinarcweldingthaningas

welding,andspacingofapproximately1/8in.(3.2mm)willbesufficient.

(4)Thebackstep,orskip,weldingtechniqueshouldbeusedforshortseamsthatarefixedinplace.Thiswillprevent

warpageordistortion,andwillminimizeresidualstresses.

(5)Heavyplatesshouldbebeveledtoprovideanincludedangleofupto60degrees,dependingonthethickness.The

partsshouldbetackweldedinplaceatshortintervalsalongtheseam.Thefirst,orroot,beadshouldbemadewithan

electrodesmallenoughindiametertoobtaingoodpenetrationandfusionatthebaseofthejoint.A1/8or5/32in.(3.2

or4.0mm)electrodeissuitableforthispurpose.Thefirstbeadshouldbethoroughlycleanedbychippingandwire

brushingbeforeadditionallayersofweldmetalaredeposited.Additionalpassesofthefillermetalshouldbemade

witha5/32or3/16in.(4.0or4.8mm)electrode.Thepassesshouldbemadewithaweavingmotionforflat,horizontal,

orverticalpositions.Whenoverheadwelding,thebestresultsareobtainedbyusingstringbeadsthroughouttheweld.

(6) When welding heavy sections that have been beveled from both sides, the weave beads should be deposited

alternatelyononesideandthentheother.Thiswillreducetheamountofdistortionintheweldedstructure.Eachbead

shouldbecleanedthoroughlytoremoveallscale,oxides,andslagbeforeadditionalmetalisdeposited.Themotionof

the electrode should be controlled so as to make the bead uniform in thickness and to prevent undercutting and

overlap at the edges of the weld. All slag and oxides must be removed from the surface of the completed weld to

preventrusting.

h.CarbonArcWelding.Lowcarbonsheetandplateupto3/4in.(19.0mm)inthicknesscanbeweldedusingthecarbonarc

weldingprocess.Thearcisstruckagainsttheplateedges,whicharepreparedinamannersimilartothatrequiredformetal

arcwelding.Afluxshouldbeusedonthejointandfillermetalshouldbeaddedasinoxyacetylenewelding.Agaseousshield

shouldbeprovidedaroundthemoltenbase.Fillermetal,bymeansofafluxcoatedweldingrod,shouldalsobeprovided.

Weldingmustbedonewithoutoverheatingthemoltenmetal.Failuretoobservetheseprecautionscancausetheweldmetal

toabsorbanexcessiveamountofcarbonfromtheelectrodeandoxygenandnitrogenfromtheair,andcausebrittlenessinthe

weldedjoint.

711.MEDIUMCARBONSTEELS

a.General.Mediumcarbonsteelsarenonalloysteelswhichcontainfrom0.30to0.55percentcarbon.Thesesteelsmaybe

heat treated after fabrication and used for general machining and forging of parts which require surface hardness and

strength. They are manufactured in bar form and in the cold rolled or the normalized and annealed condition. When heat

treatedsteelsarewelded,theyshouldbepreheatedfrom300to500F(149to260C),dependingonthecarboncontent(0.25

to 0.45 percent) and the thickness of the steel. The preheating temperature may be checked by applying a stick of 5050

solder(meltingpoint450F(232C))totheplateatthejoint,andnotingwhenthesolderbeginstomelt.Duringwelding,the

weldzonewillbecomehardenedifcooledrapidly,andmustbestressrelievedafterwelding.Mediumcarbonsteelsmaybe

weldedwithanyofthearc,gas,andresistanceweldingprocesses.

b. With higher carbon and manganese content, the lowhydrogen type electrodes should be used, particularly in thicker

sections. Electrodes of the lowcarbon, heavy coated, straight or reverse polarity type, similar to those used for metalarc

weldingoflowcarbonsteels,aresatisfactoryforweldingmediumcarbonsteels.

c.Smallpartsshouldbeannealedtoinducesoftnessbeforewelding.Thepartsshouldbepreheatedatthejointandwelded

withafillerrodthatproducesheattreatablewelds.Afterwelding,theentirepieceshouldbeheattreatedtorestoreitsoriginal

properties.

d. Either a low carbon or high strength rod can be used for welding medium carbon steels. The welding flame should be

adjusted to slightly carburizing, and the puddle of metal kept as small as possible to make a sound joint. Welding with a

carburizingflamecausesthemetaltoheatquickly,becauseheatisgivenoffwhensteelabsorbscarbon.Thispermitswelding

athigherspeeds.

e.Careshouldbetakentoslowlycoolthepartsafterweldingtopreventcrackingoftheweld.Theentireweldedpartshouldbe

stressrelievedbyheatingtobetween1100and1250F(593and677C)foronehourperinch(25.4mm)ofthickness,and

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

2/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

thenslowlycooling.Coolingcanbeaccomplishedbycoveringthepartswithfireresistantmaterialorsand.

f.Mediumcarbonsteelscanbebrazedbyusingapreheatof200to400F(93to204C),agoodbronzerod,andabrazing

flux.However,thesesteelsarebetterweldedbythemetalarcprocesswithmildsteelshieldedarcelectrodes.

g.Whenweldingmildsteels,keepthefollowinggeneraltechniquesinmind:

(1)Theplatesshouldbepreparedforweldinginamannersimilartothatusedforweldinglowcarbonsteels.When

weldingwithlowcarbonsteelelectrodes,theweldingheatshouldbecarefullycontrolledtoavoidoverheatingtheweld

metalandexcessivepenetrationintothesidewallsofthejoint.Thiscontrolisaccomplishedbydirectingtheelectrode

moretowardthepreviouslydepositedfillermetaladjacenttothesidewallsthantowardthesidewallsdirectly.Byusing

this procedure, the weld metal is caused to wash up against the side of the joint and fuse with it without deep or

excessivepenetration.

(2)Highweldingheatswillcauselargeareasofthebasemetalinthefusionzoneadjacenttotheweldstobecome

hardandbrittle.Theareaofthesehardzonesinthebasemetalcanbekepttoaminimumbymakingtheweldwitha

seriesofsmallstringorweavebeads,whichwilllimittheheatinput.Eachbeadorlayerofweldmetalwillrefinethe

grainintheweldimmediatelybeneathit,andwillannealandlessenthehardnessproducedinthebasemetalbythe

previousbead.

(3) When possible, the finished joint should be heat treated after welding. Stress relieving is normally used when

joiningmildsteel,andhighcarbonalloysshouldbeannealed.

(4)Inweldingmediumcarbonsteelswithstainlesssteelelectrodes,themetalshouldbedepositedinstringbeadsin

ordertopreventcrackingoftheweldmetalinthefusionzone.Whendepositingweldmetalintheupperlayersofwelds

madeonheavysections,theweavingmotionoftheelectrodeshouldnotexceedthreeelectrodediameters.

(5)Eachsuccessivebeadofweldshouldbechipped,brushed,andcleanedpriortothelayingofanotherbead.

712.HIGHCARBONSTEELS

a.General.Highcarbonsteelsincludethosewithacarboncontentexceeding0.55percent.Theunfinishedsurfaceofhigh

carbonsteelsisdarkgrayandsimilartoothersteels.Highcarbonsteelsusuallyproduceaveryfinegrainedfracture,whiter

thanlowcarbonsteels.Toolsteelisharderandmorebrittlethanplatesteelorotherlowcarbonmaterial.Highcarbonsteel

canbehardenedbyheatingtoagoodredandquenchinginwater.Lowcarbonsteel,wroughtiron,andsteelcastingscannot

behardened.Moltenhighcarbonsteelisbrighterthanlowcarbonsteel,andthemeltingsurfacehasacellularappearance.It

sparksmorefreelythanlowcarbon(mild)steel,andthesparksarewhiter.Thesesteelsareusedtomanufacturetoolswhich

areheattreatedafterfabricationtodevelopthehardstructurenecessarytowithstandhighshearstressandwear.Theyare

manufacturedinbar,sheet,andwireforms,andintheannealedornormalizedandannealedconditioninordertobesuitable

formachiningbeforeheattreatment.Thehighcarbonsteelsaredifficulttoweldbecauseofthehardeningeffectofheatatthe

weldedjoint.Becauseofthehighcarboncontentandtheheattreatmentusuallygiventothesesteels,theirbasicproperties

areimpairedbyarcwelding.

b.Theweldingheatchangesthepropertiesofhighcarbonsteelinthevicinityoftheweld.Torestoretheoriginalproperties,

heattreatmentisnecessary.

c.Highcarbonsteelsshouldbepreheatedfrom500to800F(260to427C)beforewelding.Thepreheatingtemperaturecan

becheckedwithapinestick,whichwillcharatthesetemperatures.

d. Since high carbon steels melt at lower temperatures than low and medium carbon steels, care should be taken not to

overheat the weld or base metal. Overheating is indicated by excessive sparking of the molten metal. Welding should be

completedassoonaspossibleandtheamountofsparkingshouldbeusedasacheckontheweldingheat.Theflameshould

beadjustedtocarburizing.Thistypeofflametendstoproducesoundwelds.

e.Eitheramediumorhighcarbonweldingrodshouldbeusedtomaketheweld.Afterwelding,theentirepieceshouldbe

stressrelievedbyheatingtobetween1200and1450F(649and788C)foronehourperinch(25.4mm)ofthickness,and

thenslowlycooling.Ifthepartscaneasilybesoftenedbeforewelding,ahighcarbonweldingrodshouldbeusedtomakethe

joint.Theentirepieceshouldthenbeheattreatedtorestoretheoriginalpropertiesofthebasemetal.

f.Insomecases,minorrepairstothesesteelscanbemadebybrazing.Thisprocessdoesnotrequiretemperaturesashighas

thoseusedforwelding,sothepropertiesofthebasemetalarenotseriouslyaffected.Brazingshouldonlybeusedinspecial

cases,becausethestrengthofthejointisnotashighastheoriginalbasemetal.

g.Eithermildorstainlesssteelelectrodescanbeusedwithhighcarbonsteels.

h.Metalarcweldinginhighcarbonsteelsrequirescriticalcontroloftheweldheat.Thefollowingtechniquesshouldbekeptin

mind:

(1)Theweldingheatshouldbeadjustedtoprovidegoodfusionatthesidewallsandrootofthejointwithoutexcessive

penetration. Control of the welding heat can be accomplished by depositing the weld metal in small string beads.

Excessivepuddlingofthemetalshouldbeavoided,becausethiscancausecarbontobepickedupfromthebase

metal,whichinturnwillmaketheweldmetalhardandbrittle.Fusionbetweenthefillermetalandthesidewallsshould

beconfinedtoanarrowzone.Usethesurfacefusionprocedureprescribedformediumcarbonsteels(para711).

(2)Thesameprocedureforedgepreparation,cleaningofthewelds,andsequenceofweldingbeadsasprescribedfor

lowandmediumcarbonsteelsalsoappliestohighcarbonsteels.

(3)Small,highcarbonsteelpartsaresometimesrepairedbybuildingupwornsurfaces.Whenthisisdone,thepiece

shouldbeannealedorsoftenedbyheatingtoaredheatandcoolingslowly.Thepieceshouldthenbeweldedorbuilt

upwithmediumcarbonorhighstrengthelectrodes,andheattreatedafterweldingtorestoreitsoriginalproperties.

713.TOOLSTEELS

a.General.Steelsusedformakingtools,punches,anddiesareperhapsthehardest,strongest,andtougheststeelsusedin

industry. In general, tool steels are medium to high carbon steels with specific elements included in different amounts to

providespecialcharacteristics.Asparktestshowsamoderatelylargevolumeofwhitesparkshavingmanyfine,repeating

bursts.

b. Carbon is provided in tool steel to help harden the steel for cutting and wear resistance. Other elements are added to

providegreatertoughnessorstrength.Insomecases,elementsareaddedtoretainthesizeandshapeofthetoolduringits

heattreathardeningoperation,ortomakethehardeningoperationsaferandtoprovideredhardnesssothatthetoolretains

itshardnessandstrengthwhenitbecomesextremelyhot.Ironisthepredominantelementinthecompositionoftoolsteels.

Otherelementsaddedincludechromium,cobalt,manganese,molybdenum,nickel,tungsten,andvanadium.Thetoolordie

steelsaredesignedforspecialpurposesthataredependentuponcomposition.Certaintoolsteelsaremadeforproducingdie

blockssomearemadeforproducingmolds,othersforhotworking,andothersforhighspeedcuttingapplication.

c.Anotherwaytoclassifytoolsteelsisaccordingtothetypeofquenchrequiredtohardenthesteel.Themostseverequench

afterheatingisthewaterquench(waterhardeningsteels).Alessseverequenchistheoilquench,obtainedbycoolingthe

toolsteelinoilbaths(oilhardeningsteels).Theleastdrasticquenchiscoolinginair(airhardeningsteels).

d. Tool steels and dies can also be classified according to the work that is to be done by the tool. This is based on class

numbers.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

3/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

(1)ClassIsteelsareusedtomaketoolsthatworkbyashearingorcuttingactions,suchascutoffdies,shearingdies,

blankingdies,andtrimmingdies.

(2)ClassIIsteelsareusedtomaketoolsthatproducethedesiredshapeofthepartbycausingthematerialbeing

worked,eitherhotorcold,toflowundertension.Thisincludesdrawingdies,formingdies,reducingdies,forgingdies,

plasticmolds,anddiecastmoldingdies.

(3)ClassIIIsteelsareusedtomaketoolsthatactuponthematerialbeingworkedbypartiallyorwhollyreformingit

withoutchangingtheactualdimensions.Thisincludesbendingdies,foldingdies,andtwistingdies.

(4)ClassIVsteelsareusedtomakediesthatworkunderheavypressureandthatproduceaflowofmetalorother

materialcaressingitintothedesiredform.Thisincludescrimpingdies,embossingdies,headingdies,extrusiondies,

andstakingdies.

e. Steels in the tool steels group have a carbon content ranging from 0.83 to 1.55 percent. They are rarely welded by arc

weldingbecauseoftheexcessivehardnessproducedinthefusionzoneofthebasemetal.Ifarcweldingmustbedone,either

mildsteelorstainlesssteelelectrodescanbeused.

f.Uniformlyhighpreheatingtemperatures(upto1000F(583C))mustbeusedwhenweldingtoolsteels.

g. In general, the same precautions should be taken as those required for welding high carbon steels. The welding flare

should be adjusted to carburizing to prevent the burning out of carbon in the weld metal. The welding should be done as

quicklyaspossible,takingcarenottooverheatthemoltenmetal.Afterwelding,thesteelshouldbeheattreatedtorestoreits

originalproperties.

h.Drillrodscanbeusedasfillerrodsbecausetheirhighcarboncontentcomparescloselywiththatoftoolsteels.

i. A flux suitable for welding cast iron should be used in small quantities to protect the puddle of high carbon steel and to

removeoxidesintheweldmetal.

j.WeldingTechnique.Whenweldingtoolsteels,thefollowingtechniquesshouldbekeptinmind:

(1)Ifthepartstobeweldedaresmall,theyshouldbeannealedorsoftenedbeforewelding.Theedgesshouldthenbe

preheatedupto1000F(538C),dependingonthecarboncontentandthicknessoftheplate.Weldingshouldbedone

witheitheramildsteelorhighstrengthelectrode.

(2)Highcarbonelectrodesshouldnotbeusedforweldingtoolsteels.Thecarbonpickedupfromthebasemetalby

thefillermetalwillcausetheweldtobecomeglasshard,whereasthemildsteelweldmetalcanabsorbadditional

carbon without becoming excessively hard. The welded part should then be heat treated to restore its original

properties.

(3)Whenweldingwithstainlesssteelelectrodes,theedgeoftheplateshouldbepreheatedtopreventtheformationof

hardzonesinthebasemetal.Theweldmetalshouldbedepositedinsmallstringbeadstokeeptheheatinputtoa

minimum.Ingeneral,theapplicationprocedureisthesameasthatrequiredformediumandhighcarbonsteels.

k. There are four types of die steels that are weld repairable. These are waterhardening dies, oilhardening dies, air

hardeningdies,andhotworktools.Highspeedtoolscanalsoberepaired.

714.HIGHHARDNESSALLOYSTEELS

a.General.Alargenumberandvarietyofobtainhighstrength,highhardness,corrosionalloysteelshavebeendevelopedto

resistance,andotherspecialproperties.Mostofthesesteelsdependonaspecialheattreatmentprocessinordertodevelop

thedesiredcharacteristicinthefinishedstate.Alloysteelshavegreaterstrengthanddurabilitythanothercarbonsteels,anda

givenstrengthissecuredwithlessmaterialweight.

b.Highhardnessalloysteelsincludethefollowing:

(1) Chromium alloy steels. Chromium is used as an alloying element in carbon steels to increase hardenability,

corrosion resistance, and shock resistance, and gives high strength with little loss in ductility. Chromium in large

amountsshortensthesparkstreamtoonehalfthatofthesamesteelwithoutchromium,butdoesnotaffectthestream's

brightness.

(2) Nickel alloy steels. Nickel increases the toughness, strength, and ductility of steels, and lowers the hardening

temperaturesothatanoilquench,ratherthanawaterquench,isusedforhardening.Thenickelsparkhasashort,

sharplydefineddashofbrilliantlightjustbeforethefork.

(3)Highchromiumnickelalloy(stainless)steels.Thesehighalloysteelscoverawiderangeofcompositions.Their

stainless,corrosion,andheatresistantpropertiesvarywiththealloycontent,andareduetotheformationofaverythin

oxidefilmwhichformsonthesurfaceofthemetal.Sparksarestrawcolorednearthegrindingwheel,andwhitenear

theendofthestreak.Thereisamediumvolumeofstreakswhichhaveamoderatenumberofforkedbursts.

(4)Manganesealloysteels. Manganese is used in steel to produce greater toughness, wear resistance, easier hot

rolling, and forging. An increase in manganese content decreases the weldability of steel. Steels containing

manganeseproduceasparksimilartoacarbonspark.Amoderateincreaseinmanganeseincreasesthevolumeof

the spark stream and the intensity of the bursts. A steel containing more than a normal amount of manganese will

produceasparksimilartoahighcarbonsteelwithalowermanganesecontent.

(5)Molybdenumalloysteels.Molybdenumincreaseshardenability,whichisthedepthofhardeningpossiblethrough

heattreatment.Theimpactfatiguepropertyofthesteelisimprovedwithupto0.60percentmolybdenum.Above0.60

percentmolybdenum,theimpactfatigueproperisimpaired.Wearresistanceisimprovedwithmolybdenumcontent

above about 0.75 percent. Molybdenum is sometimes combined with chromium, tungsten, or vanadium to obtain

desiredproperties.Steelscontainingthiselementproduceacharacteristicsparkwithadetachedarrowheadsimilarto

thatofwroughtiron,whichcanbeseeneveninfairlystrongcarbonbursts.Molybdenumalloysteelscontaineither

nickeland/orchromium.

(6) Titanium and columbium (niobium) alloy steels. These elements are used as additional alloying agents in low

carbon content, corrosion resistant steels. They support resistance to intergranular corrosion after the metal is

subjectedtohightemperaturesforaprolongedperiodoftime.

(7)Tungstenalloysteels.Tungsten,asanalloyingelementintoolsteel,tendstoproduceafine,densegrainwhen

usedinrelativelysmallquantities.Whenusedinlargerquantities,from17to20percent,andincombinationwithother

alloys, tungsten produces a steel that retains its hardness at high temperatures. This element is usually used in

combinationwithchromiumorotheralloyingagents.Inasparktest,tungstenwillshowadullredcolorinthespark

streamnearthewheel.Italsoshortensthesparkstreamanddecreasesthesizeoforcompletelyeliminatesthecarbon

burst.Atungstensteelcontainingabout10percenttungstencausesshort,curved,orangespearpointsattheendof

thecarrierlines.Stilllowertungstencontentcausessmall,whiteburststoappearattheendofthespearpetit.Carrier

linesmaybefromdullredtoorange,dependingontheotherelementspresent,providingthetungstencontentisnot

toohigh.

(8)Vanadiumalloysteels.Vanadiumisusedtohelpcontrolgrainsize.Ittendstoincreasehardenabilityandcauses

markedsecondaryhardness,yetresiststempering.Itisaddedtosteelduringmanufacturetoremoveoxygen.Alloy

steelscontainingvanadiumproducesparkswithdetachedarrowheadsattheendofthecarrierlinesimilartothose

producedbymolybdenumsteels.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

4/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

(9)Siliconalloysteels.Siliconisaddedtosteeltoobtaingreaterhardenabilityandcorrosionresistance.Itisoftenused

withmanganesetoobtainastrong,toughsteel.

(10)Highspeedtoolsteels.Thesesteelsareusuallyspecialalloycompositionsdesignedforcuttingtools.Thecarbon

contentrangesfrom0.70to0.80percent.Theyaredifficulttoweld,exceptbythefurnaceinductionmethod.Aspark

testwillshowafewlong,forkedspadeswhicharerednearthewheel,andstrawcoloredneartheendofthespark

stream.

c.Manyofthesesteelscanbeweldedwithaheavycoatedelectrodeoftheshieldedarctype,whosecompositionissimilarto

that of the base metal. Low carbon electrodes can also be used with some steels. Stainless steel electrodes are effective

wherepreheatingisnotfeasibleordesirable.Heattreatedsteelsshouldbepreheated,ifpossible,inordertominimizethe

formationofhardzones,orlayers,inthebasemetaladjacenttotheweld.Themoltenmetalshouldnotbeoverheated,andthe

weldingheatshouldbecontrolledbydepositingthemetalinnarrowstringbeads.Inmanycases,theproceduresforwelding

mediumcarbonsteels(para711)andhighcarbonsteels(para712)canbeusedintheweldingofalloysteels.

715.HIGHYIELDSTRENGTH,LOWALLOYSTRUCTURALSTEELS

a.General.Highyieldstrength,lowalloystructuralsteels(constructionalalloysteels)arespecialsteelsthataretemperedto

obtainextremetoughnessanddurability.Thespecialalloysandgeneralmakeupofthesesteelsrequirespecialtreatmentto

obtain satisfactory weldments. These steels are special, lowcarbon steels containing specific, small amounts of alloying

elements.Theyarequenchedandtemperedtoobtainayieldstrengthof90,000to100,000psi(620,550to689,500kPa)and

atensilestrengthof100,000to140,000psi(689,500to965,300kPa),dependinguponsizeandshape.Structuralmembers

fabricatedfromthesehighstrengthsteelsmayhavesmallercrosssectionalareasthancommonstructuralsteelsandstillhave

equalstrength.Thesesteelsarealsomorecorrosionandabrasionresistantthanothersteels.Inasparktest,thesealloys

produceasparkverysimilartolowcarbonsteels.

b. Welding Technique. Reliable welding of high yield strength, low alloy structural steels can be performed by using the

followingguidelines:

CAUTION

Topreventunderbeadcracking,onlylowhydrogenelectrodesshouldbeusedwhenweldinghighyieldstrength,lowalloy

structuralsteels.

(1) Correct electrodes. Hydrogen is the number one enemy of sound welds in alloy steels therefore, use only low

hydrogen(MILE18038orMILE22200/1)electrodestopreventunderbeadcracking.Underbeadcrackingiscaused

byhydrogenpickedupintheelectrodecoating,releasedintothearc,andabsorbedbythemoltenmetal.

(2)Moisturecontrolofelectrodes.Iftheelectrodesareinanairtightcontainer,placethem,immediatelyuponopening

thecontainer,inaventilatedholdingovensetat250to300F(121to149C).Intheeventthattheelectrodesarenotin

anairtightcontainer,puttheminaventilatedbakingovenandbakefor11/4hoursat800F(427C).Bakedelectrodes

should,whilestillwarm,beplacedintheholdingovenuntilused.Electrodesmustbekeptdrytoeliminateabsorption

ofhydrogen.TestingformoistureshouldbeinaccordancewithMILE22200.

NOTE

MoisturestabilizerNSN3439004000090isanidealholdingovenforfielduse(MILM45558).

c. Low Hydrogen Electrode Selection. Electrodes are identified by classification numbers which are always marked on the

electrodecontainers.Forlowhydrogencoatings,thelasttwonunbersoftheclassificationshouldbe15,16,or18.Electrodes

of5/32and1/8in.(4.0and3.2mm)indiameterarethemostcommonlyused,sincetheyaremoreadaptabletoalltypesof

weldingofthistypesteel.Table714listselectrodesusedtoweldhighyieldstrength,lowalloystructuralsteels.Table715is

alistofelectrodescurrentlyestablishedintheArmysupplysystem.

d.SelectingWireFluxandWireGasCombinations.Wireelectrodesforsubmergedarcandgasshieldedarcweldingarenot

classifiedaccordingtostrength.Weldingwireandwirefluxcombinationsusedforsteelstobestressrelievedshouldcontain

nomorethan0.05recentvanadium.Weldmetalwithmorethan0.05percentvanadiummaybrittleifstressrelieved.When

usingeitherthesubmergedarcorgasmetalarcweldingprocessestoweldhighyieldstrength,lowalloystructuralsteelsto

lowerstrengthsteelsthewirefluxandwiregascombinationshouldbethesameasthatrecommendedforthelowerstrength

steels.

e.Preheating.Forweldingplatesunder1.0in.(25.4mm)thick,above50F(10C)isnotrequiredexcepttoremovesurface

moisturemetal.Table716containssuggestedpreheatingtemperatures.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

5/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

f.WeldingHeat.

(1)General.Itisimportanttoavoidexcessiveheatconcentrationinordertoallowtheweldareatocoolquickly.Either

theheatinputnomographortheheatinputcalculatorcanbeusedtodeterminetheheatinputintotheweld.

(2)Heatinputnomograph.Tousetheheatinputnomograph(fig.79),findthevoltsvalueincolumn1anddrawaline

totheampsvalueincolumn3.Fromthepointwherethislineintersectscolunm2,drawanotherlinetothein./minvalue

in column 5. Read the heat units at the point where this second line intersects column 4. The heat units represent

thousandsofjoulesperinch.Forexample,at20voltsand300amps,thelineintersectscolumn2atthevalue6.At12

in./min,theheatinputisdeterminedas30heatunits,or30,000joules/in.

(3)Heatinputcalculator.Theheatinputcalculatorcanbemadebycopyingthepatternprintedontheinsideofthe

back cover of this manual onto plastic, light cardboard, or other suitable material and cutting out the pieces. If no

suitablematerialisavailable,thecalculatormaybeassembledbycuttingthepatternoutofthebackcover.Afterthe

twopiecesarecutout,aholeispunchedinthecenterofeach.Theyarethenassembledusingapaperfastener,or

somesimilardevice,whichwillallowthepiecestorotate.Todetermineweldingheatinputusingthecalculator,rotate

untilthevalueonthevoltsscaleisaligneddirectlyoppositethevalueonthespeed(in./min)scale.Thevalueonthe

ampsscalewillthenbealigneddirectlyoppositethecalculatedvalueforheatunits.Aswiththenomograph,heatunits

representthousandsofjoulesperinch.

(4)Maximumheatinput.Checktheheatinputvalueobtainedfromthenomographorcalculatoragainstthesuggested

maximumsintables717and718.Ifthecalculatedvalueistoohigh,adjusttheamperes,travelspeed,orpreheat

temperatureuntilthecalculatedheatinputiswithintheproperrange.(Thetablesareapplicableonlytosinglearc,

shielded metalarc, submerged arc, gas tungstenarc, fluxcored arc, and gas metalarc processes. They are not

applicable to multiplearc or electroslag welding, or other high heat input verticalwelding processes, since welds

made by these in the "T1" steels should be heat treated by quenching and tempering.) For welding conditions

exceedingtherangeofthenomographorcalculator,theheatinputcanbecalculatedusingthefollowingformula:

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

6/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

g. Welding Process. Reliable welding of high yield strength, low alloy structural steel can be per formal by choosing an

electrodewithlowhydrogencontentorselectingtheproperwirefluxorwiregascombinationwhenusingthesubmergedarc

or gas metal arc processes. Use a straight stringer bead whenever possible. Avoid using the weave pattern however, if

needed,itmustberestrictedtoapartialweavepattern.Bestresultsareobtainedbyaslightcircularmotionoftheelectrode

withtheweaveareaneverexceedingtwoelectrodediameters.Neveruseafullweavepattern.Thepartialweavepattern

should not exceed twice the diameter of the electrode. Skip weld as practical. Peening of the weld is sometimes

recommendedtorelievestresseswhilecoolinglargerpieces.Filletweldsshouldbesmoothandcorrectlycontoured.Avoid

toecracksandundercutting.Electrodesusedforfilletweldsshouldbeoflowerstrengththanthoseusedforbuttwelding.Air

hammerpeeningoffilletweldscanhelptopreventcracks,especiallyiftheweldsaretobestressrelieved.Asoftsteelwire

pedestalcanhelptoabsorbshrinkageforces.Butterweldinginthetoeareabeforeactualfilletweldingstrengthsthearea

whereatoecrackmaystart.Abeadislaidinthetoearea,thengroundoffpriortotheactualfilletwelding.Thisbutterweld

beadmustbelocatedsothatthetoeofthefilletwillbelaiddirectlyoveritduringactualfilletwelding.Becauseoftheadditional

materialinvolvedinfilletwelding,thecoolingrateisincreasedandheatinputsmaybeextendedabout25percent.

716.CASTIRON

a.General.Acastironisanalloyofiron,carbon,andsilicon,inwhichtheamountofcarbonisusuallymorethan1.7percent

andlessthan4.5percent.

(1)Themostwidelyusedtypeofcastironisknownasgrayiron.Grayironhasavarietyofcompositions,butisusually

suchthatitisprimarilyperlitewithmanygraphiteflakesdispersedthroughout.

(2)Therearealsoalloycastironswhichcontainsmallamountsofchromium,nickel,molybdenum,copper,orother

elementsaddedtoprovidespecificproperties.

(3)Anotheralloyironisausteniticcastiron,whichismodifiedbyadditionsofnickelandotherelementstoreducethe

transformationtemperaturesothatthestructureisausteniticatroomornormaltemperatures.Austeniticcastironshave

ahighdegreeofcorrosionresistance.

(4)Inwhitecastiron,almostallthecarbonisinthecombinedform.Thisprovidesacastironwithhigherhardness,

whichisusedforabrasionresistance.

(5)Malleablecastironismadebygivingwhitecastironaspecialannealingheattreatmenttochangethestructureof

thecarbonintheiron.Thestructureischangedtoperliticorferritic,whichincreasesitsductility.

(6)Nodularironandductilecastironaremadebytheadditionofmagnesiumoraluminumwhichwilleithertieupthe

carbon in a combined state or will give the free carbon a spherical or nodular shape, rather than the normal flake

shapeingraycastiron.Thisstructureprovidesagreaterdegreeofductilityormalleabilityofthecasting.

(7)Castironsarewidelyusedinagriculturalequipmentonmachinetoolsasbases,brackets,andcoversforpipe

fittingsandcastironpipeandforautomobileengineblocks,heads,manifolds,andwaterpreps.Castironisrarely

usedinstructuralworkexceptforcompressionmembers.Itiswidelyusedinconstructionmachineryforcounterweights

andinotherapplicationsforwhichweightisrequired.

b. Gray cast iron has low ductility and therefore will not expand or stretch to any considerable extent before breaking or

cracking. Because of this characteristic, preheating is necessary when cast iron is welded by the oxyacetylene welding

process.Itcan,however,beweldedwiththemetalarcprocesswithoutpreheatingiftheweldingheatiscarefullycontrolled.

This can be accomplished by welding only short lengths of the joint at a time and allowing these sections to cool. By this

procedure,theheatofweldingisconfinedtoasmallarea,andthedangerofcrackingthecastingiseliminated.Largecastings

with complicated sections, such as motor blocks, can be welded without dismantling or preheating. Special electrodes

designedforthispurposeareusuallydesirable.Ductilecastirons,suchasmalleableiron,ductileiron,andnodulariron,can

besuccessfullywelded.Forbestresults,thesetypesofcastironsshouldbeweldedintheannealedcondition.

c.Weldingisusedtosalvagenewironcastings,torepaircastingsthathavefailedinservice,andtojoincastingstoeachother

or to steel parts in manufacturing operations. Table 719 shows the welding processes that can be used for welding cast,

malleable,andnodularirons.Theselectionoftheweldingprocessandtheweldingfillermetalsdependsonthetypeofweld

properties desired and the service life that is expected. For example, when using the shielded metal arc welding process,

differenttypesoffillermetalcanbeused.Thefillermetalwillhaveaneffectonthecolormatchoftheweldcomparedtothe

basematerial.Thecolormatchcanbeadeterminingfactor,specificallyinthesalvageorrepairofcastings,whereadifference

ofcolorwouldnotbeacceptable.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

7/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

d.Nomatterwhichoftheweldingprocessesisselected,certainpreparatorystepsshouldbemade.Itisimportanttodetermine

theexacttypeofcastirontobewelded,whetheritisgraycastironoramalleableorductiletype.Ifexactinformationisnot

known,itisbesttoassumethatitisgraycastironwithlittleornoductility.Ingeneral,itisnotrecommendedtoweldrepairgray

ironcastingsthataresubjecttoheatingandcoolinginnormalservice,especiallywhenheatingandcoolingvaryoverarange

oftemperaturesexceeding400F(204C).Unlesscastironisusedasthefillermaterial,theweldmetalandbasemetalmay

havedifferentcoefficientsofexpansionandcontraction.Thiswillcontributetointernalstresseswhichcannotbewithstoodby

graycastiron.Repairofthesetypesofcastingscanbemade,butthereliabilityandservicelifeonsuchrepairscannotbe

predictedwithaccuracy.

e.PreparationforWelding.

(1)Inpreparingthecastingforwelding,itisnecessarytoremoveallsurfacematerialstocompletelycleanthecasting

intheareaoftheweld.Thismeansremovingpaint,grease,oil,andotherforeignmaterialfromtheweldzone.Itis

desirabletoheattheweldareaforashorttimetoremoveentrappedgasfromtheweldzoneofthebasemetal.The

skin or high silicon surface should also be removed adjacent to the weld area on both the face and root side. The

edgesofajointshouldbechippedoutorgroundtoforma60angleorbevel.Wheregroovesareinvolved,aVgroove

froma6090includedangleshouldbeused.TheVshouldextendapproximately1/8in.(3.2mm)fromthebottomof

the crack. A small hole should be drilled at each end of the crack to keep it from spreading. Complete penetration

weldsshouldalwaysbeused,sinceacrackordefectnotcompletelyremovedmayquicklyreappearunderservice

conditions.

(2)Preheatingisdesirableforweldingcastironswithanyoftheweldingprocesses.Itcanbereducedwhenusing

extremelyductilefillermetal.Preheatingwillreducethethermalgradientbetweentheweldandtheremainderofthe

cast iron. Preheat temperatures should be related to the welding process, the filler metal type, the mass, and the

complexityofthecasting.Preheatingcanbedonebyanyofthenormalmethods.Torchheatingisnormallyusedfor

relativelysmallcastingsweighing30.0lb(13.6kg)orless.Largerpartsmaybefurnacepreheated,andinsomecases,

temporary furnaces are built around the part rather than taking the part to a furnace. In this way, the parts can be

maintainedatahighinterpasstemperatureinthetemporaryfurnaceduringwelding.Preheatingshouldbegeneral,

since it helps to improve the ductility of the material and will spread shrinkage stresses over a large area to avoid

criticalstressesatanyonepoint.Preheatingtendstohelpsoftentheareaadjacenttothewelditassistsindegassing

thecasting,andthisinturnreducesthepossibilityofporosityofthedepositedweldmetalanditincreaseswelding

speed.

(3)Slowcoolingorpostheatingimprovesthemachinabilityoftheheataffectedzoneinthecastironadjacenttothe

weld. The post cooling should be as slow as possible. This can be done by covering the casting with insulating

materialstokeeptheairorbreezesfromit.

f.WeldingTechnique.

(1)Electrodes.

(a)Castironcanbeweldedwithacoatedsteelelectrode,butthismethodshouldbeusedasanemergency

measureonly.Whenusingasteelelectrode,thecontractionofthesteelweldmetal,thecarbonpickedupfrom

the cast iron by the weld metal, and the hardness of the weld metal caused by rapid cooling must be

considered. Steel shrinks more than cast iron when ceded from a molten to a solid state. When a steel

electrodeisused,thisunevenshrinkagewillcausestrainsatthejointafterwelding.Whenalargequantityof

fillermetalisappliedtothejoint,thecastironmaycrackjustbackofthelineoffusionunlesspreventivesteps

aretaken.Toovercomethesedifficulties,thepreparedjointshouldbeweldedbydepositingtheweldmetalin

shortstringbeads,0.75to1.0in.long(19.0to25.4mm).Thesearemadeintermittentlyand,insomecases,by

thebackstepandskipprocedure.Toavoidhardspots,thearcshouldbestruckintheV,andnotonthesurface

ofthebasemetal.Eachshortlengthofweldmetalappliedtothejointshouldbelightlypeenedwhilehotwitha

small ball peen hammer, and allowed to cool before additional weld metal is applied. The peening action

forgesthemetalandrelievesthecoolingstrains.

(b) The electrodes used should be 1/8 in. (3.2 mm) in diameter to prevent excessive welding heat. Welding

shouldbedonewithreversepolarity.Weavingoftheelectrodeshouldbeheldtoaminimum.Eachweldmetal

depositshouldbethoroughlycleanedbeforeadditionalmetalisadded.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

8/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

(c)Castironelectrodesmustbeusedwheresubsequentmachiningoftheweldedjointisrequired.Stainless

steelelectrodesareusedwhenmachiningoftheweldisnotrequired.Theprocedureformakingweldswith

theseelectrodesisthesameasthatoutlinedforweldingwithmildsteelelectrodes.Stainlesssteelelectrodes

provideexcellentfusionbetweenthefillerandbasemetals.Greatcaremustbetakentoavoidcrackinginthe

weld,contractsapproximately50percentmorethanbecausestainlesssteelexpandsandmildsteelinequal

changesoftemperature.

(2)ArcWelding.

(a)Theshieldedmetalarcweldingprocesscanbeutilizedforweldingcastiron.Therearefourtypesoffiller

metalsthatmaybeused:castironcoveredelectrodescoveredcopperbasealloyelectrodescoverednickel

base alloy electrodes and mild steel covered electrodes. There are reasons for using each of the different

specifictypesofelectrodes,whichincludethemachinabilityofthedeposit,thecolormatchofthedeposit,the

strengthofthedeposit,andtheductilityofthefinalweld.

(b)Whenarcweldingwiththecastironelectrodes(ECI),preheattobetween250and800F(121and425C),

dependingonthesizeandcomplexityofthecastingandtheneedtomachinethedepositandadjacentareas.

The higher degree of heating, the easier it will be to machine the weld deposit. In general, it is best to use

smallsizeelectrodesandarelatively1owcurrentsetting.Amediumarclengthshouldbeused,and,ifatall

possible,weldingshouldbedoneintheflatposition.Wanderingorskipweldingprocedureshouldbeused,

andpeeningwillhelpreducestressesandwillminimizedistortion.Slowcoolingafterweldingisrecommended.

Theseelectrodesprovideanexcellentcolormatchcmgrayiron.Thestrengthoftheweldwillequalthestrength

ofthebasemetal.Therearetwotypesofcopperbaseelectrodes:thecoppertinalloyandthecopperaluminum

types.Thecopperzincalloyscannotbeusedforarcweldingelectrodesbecauseofthelowboilingtemperature

ofzinc.Zincwillvolatilizeinthearcandwillcauseweldmetalporosity.

(c)Whenthecopperbaseelectrodesareused,apreheatof250to400F(121to204C)isrecommended.

Smallelectrodesandlowcurrentshouldbeused.Thearcshouldbedirectedagainstthedepositedmetalor

puddletoavoidpenetrationandmixingthebasemetalwiththeweldmetal.Slowcoolingisrecommendedafter

welding.Thecopperbaseelectrodesdonotprovideagoodcolormatch.

(d)Therearethreetypesofnickelelectrodesusedforweldingcastiron.Theseelectrodescanbeusedwithout

preheat however, heating to 100F (38C) is recommended. These electrodes can be used in all positions

however,theflatpositionisrecommended.Theweldingslagshouldberemovedbetweenpasses.Thenickel

andnickelirondepositsareextremelyductileandwillnotbecomebrittlewiththecarbonpickup.Thehardness

of the heataffected zone can be minimized by reducing penetration into the cast iron base metal. The

techniquementionedabove,playingthearconthepuddleratherthanonthebasemetal,willhelpminimize

dilution.Slowcoolingand,ifnecessary,postheatingwillimprovemachinabilityoftheheataffectedzone.The

nickelbaseelectrodesdonotprovideaclosecolormatch.

(e) Copper nickel type electrodes cane in two grades. Either of these electrodes can be used in the same

mannerasthenickelornickelironelectrodewithaboutthesametechniqueandresults.Thedepositsofthese

electrodesdonotprovideacolormatch.

(f)Mildsteelelectrodesarenotrecommendedforweldingcastironifthedepositistobemachined.Themild

steel deposit will pick up sufficient carbon to make a highcarbon deposit, which is impossible to machine.

Additionally,themildsteeldepositwillhaveareducedlevelofductilityasaresultofincreasedcarboncontent.

This type of electrode should be used only for small repairs and should not be used when machining is

required.Minimumpreheatispossibleforsmallrepairjobs.Smallelectrodesatlowcurrentarerecommended

to minimize dilution and to avoid the concentration of shrinkage stresses. Short welds using a wandering

sequenceshouldbeused,andtheweldshouldbepeenedasquicklyaspossibleafterwelding.Themildsteel

electrodedepositprovidesafaircolormatch.

(3)Carbonarcweldingofcastiron.Ironcastingsmaybeweldedwithacarbonarc,acastironrod,andacastiron

weldingflux.Thejointshouldbepreheatedbymovingthecarbonelectrodesalongthesurface.Thispreventstoorapid

coolingafterwelding.Themoltenpuddleofmetalcanbeworkedwiththecarbonelectrodesoastomoveanyslagor

oxidesthatareformedtothesurface.Weldsmadewiththecarbonarccoolmoreslowlyandarenotashardasthose

madewiththemetalarcandacastironelectrode.Theweldsaremachinable.

(4)Oxyfuelgaswelding.Theoxyfuelgasprocessisoftenusedforweldingcastiron.Mostofthefuelgasescanbe

used.Theflameshouldbeneutraltoslightlyreducing.Fluxshouldbeused.Twotypesoffillermetalsareavailable:the

castironrodsandthecopperzincrods.Weldsmadewiththepropercastironelectrodewillbeasstrongasthebase

metal.Goodcolormatchisprovidedbyalloftheseweldingreds.Theoptimumweldingprocedureshouldbeusedwith

regard to joint preparation, preheat, and post heat. The copper zinc rods produce braze welds. There are two

classifications:amanganesebronzeandalowfumingbronze.Thedepositedbronzehasrelativelyhighductilitybut

willnotprovideacolormatch.

(5)Brazingandbrazewelding.

(a)Brazingisusedforjoiningcastirontocastironandsteels.Inthesecases,thejointdesignmustbeselected

for brazing so that capillary attraction causes the filler metal to flow between closely fitting parts. The torch

methodisnormallyused.Inaddition,thecarbonarc,thetwincarbonarc,thegastungstenarc,andtheplasma

arccanallbeusedassourcesofheat.Twobrazingfillermetalalloysarenormallyusedbotharecopperzinc

alloys.Brazeweldingcanalsobeusedtojoincastiron.Inbrazewelding,thefillermetalisnotdrawnintothe

joint by capillary attraction. This is sometimes called bronze welding. The filler material having a liquidous

above850F(454C)shouldbeused.Brazeweldingwillnotprovideacolormatch.

(b) Braze welding can also be accomplished by the shielded metal arc and the gas metal arc welding

processes.Hightemperaturepreheatingisnotusuallyrequiredforbrazeweldingunlessthepartisextremely

heavyorcomplexingeometry.Thebronzeweldmetaldeposithasextremelyhighductility,whichcompensates

forthelackofductilityofthecastiron.Theheatofthearcissufficienttobringthesurfaceofthecastironuptoa

temperatureatwhichthecopperbasefillermetalalloywillmakeabondtothecastiron.Sincethereislittleor

nointermixingofthematerials,thezoneadjacenttotheweldinthebasemetalisnotappreciablyhardened.

Theweldandadjacentareaaremachinableaftertheweldiscompleted.Ingeneral,a200F(93C)preheatis

sufficientformostapplication.Thecoolingrateisnotextremelycriticalandastressreliefheattreatmentisnot

usually required. This type of welding is commonly used for repair welding of automotive parts, agricultural

implementparts,andevenautomotiveengineblocksandheads.Itcanonlybeusedwhentheabsenceofcolor

matchisnotobjectionable.

(6)Gasmetalarcwelding.Thegasmetalarcweldingprocesscanbeusedformakingweldsbetweenmalleableiron

andcarbonsteels.Severaltypesofelectrodewirescanbeused,including:

(a)Mildsteelusing75%argon+25%CO2 forshielding.

(b)Nickelcopperusing100%argonforshielding.

(c)Siliconbronzeusing50%argon+50%heliumforshielding.

Inallcases,smalldiameterelectrodewireshouldbeusedatlowcurrent.Withthemildsteelelectrodewire,theArgon

CO2 shieldinggasmixtureissuedtominimizepenetration.InthecaseofthenickelbasefillermetalandtheCopper

base filler metal, the deposited filler metal is extremely ductile. The mild steel provides a fair color match. A higher

preheatisusuallyrequiredtoreduceresidualstressesandcrackingtendencies.

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

9/10

9/28/2016

generaldescriptionandweldabilityofferrousmetals,weldingpositions,weldingmachinesandotherwelidingcuttingsystemsPlasmaWelding

(7) Fluxcored arc welding. This process has recently been used for welding cast irons. The more successful

applicationhasbeenusinganickelbasefluxcoredwire.ThiselectrodewireisnormallyoperatedwithCO2 shielding

gas,butwhenlowermechanicalpropertiesarenotobjectionable,itcanbeoperatedwithoutexternalshieldinggas.

Theminimumpreheattemperaturescanbeused.Thetechniqueshouldminimizepenetrationintothecastironbase

metal.Postheatingisnormallynotrequired.Acolormatchisnotobtained.

(8)Studding.Cracksinlargecastingsaresometimesrepairedbystudding(fig.710).Inthisprocess,thefractureis

removedbygrindingaVgroove.Holesaredrilledandtappedatanangleoneachsideofthegroove,andstudsare

screwed into these holes for a distance equal to the diameter of the studs, with the upper ends projecting

approximately1/4in.(6.4mm)abovethecastironsurface.Thestudsshouldbesealweldedinplacebyoneortwo

beadsaroundeachstud,andthentiedtogetherbyweldmetalbeads.Weldsshouldbemadeinshortlengths,and

eachlengthpeenedwhilehottopreventhighstressesorcrackinguponcooling.Eachbeadshouldbeallowedtocool

andbethoroughlycleanedbeforeadditionalmetalisdeposited.Ifthestuddingmethodcannotbeapplied,theedges

ofthejointshouldbechippedoutormachinedwitharoundnosedtooltoformaUgrooveintowhichtheweldmetal

shouldbedeposited.

(9)Otherweldingprocessescanbeusedforcastiron.Thermitweldinghasbeenusedforrepairingcertaintypesof

castironmachinetoolparts.Solderingcanbeusedforjoiningcastiron,andissometimesusedforrepairingsmall

defectsinsmallcastings.Flashweldingcanalsobeusedforweldingcastiron.

AuthorizationLetter

BACK TO WELDING DATA

ArcraftPlasmaEquipments(India)Pvt.Ltd.ManufacturersSuppliersandExporterof

PlasmaWelding,PlasmaTransferredArcWelding(PTA),PlasmaCuttingMachine,MicroPlasmaWeldingMachine,MicroTigWeldingMachine,HardBander,weldinginverter,

weldingautomation,hardbandingmachine,weldingpositioners,weldingocillatorsmumbai,india.manufacturers,suppliersandExporterofACWeldingMachines,Migwelding

Machines,ShapeCuttingMachines,SpecialPurposeMachinesforhardfacingandcladding.mumbai.india.

Home|AboutUs|Download|Products|HardBander|Sitemap|Contacts|RelatedLinks

http://www.arcraftplasma.com/welding/weldingdata/ferrous.htm

WebsiteDevelopmentByWebsiteIntellect.com

10/10

You might also like

- Inconel 82 (Austral-Wright)Document1 pageInconel 82 (Austral-Wright)Claudia MmsNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTJhandu KumarNo ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Weldability of Stainless SteelDocument29 pagesWeldability of Stainless SteelEr Mishal GandhiNo ratings yet

- New Microsoft Office Word DocumentDocument16 pagesNew Microsoft Office Word DocumentsarathNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTAkshith SulliaNo ratings yet

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- Welding Related Points To RecallDocument3 pagesWelding Related Points To RecallThulasi RamNo ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Technical Data 3CR12Document15 pagesTechnical Data 3CR12rudiskw456No ratings yet

- BS 970 SteelsDocument8 pagesBS 970 SteelsTamal Guha100% (2)

- Quality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaDocument7 pagesQuality Oriented and ISO Approved Stainless Steel 316L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- ASTM A325: ScopeDocument2 pagesASTM A325: ScopetylerstearnsNo ratings yet

- UNS R30006 Steel GradesDocument3 pagesUNS R30006 Steel GradesRatnakar PatilNo ratings yet

- Astm A516Document11 pagesAstm A516Kokoh Aji LesmanaNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- BS 970Document5 pagesBS 970aezeadNo ratings yet

- Chapter 5Document3 pagesChapter 5Dufton MusiliNo ratings yet

- Lincoln Stainless Welding GuideDocument40 pagesLincoln Stainless Welding GuideAnonymous yQ7SQr100% (1)

- WS Hws Hss Asp CPMDocument12 pagesWS Hws Hss Asp CPMGross Meltiade AlexanderNo ratings yet

- RQT Technical Guide Loires TATA STEELDocument7 pagesRQT Technical Guide Loires TATA STEELEmad A.AhmadNo ratings yet

- Astm A335 A335m Grade p5Document1 pageAstm A335 A335m Grade p5estimationNo ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- RST 37Document8 pagesRST 3725091972No ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- 010 - AR200 Product Data Sheet 2012 04 01Document2 pages010 - AR200 Product Data Sheet 2012 04 01Baihaki StNo ratings yet

- ASTM A36/A36M Standard Specification For Carbon Structural SteelDocument4 pagesASTM A36/A36M Standard Specification For Carbon Structural SteeliuliamicutNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- T 6061Document5 pagesT 6061Zoran DanilovNo ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- Materials and HardwareDocument364 pagesMaterials and Hardwarekls070376100% (10)

- Welding of Ferritic/martensitic Stainless Steels: Job KnowledgeDocument2 pagesWelding of Ferritic/martensitic Stainless Steels: Job KnowledgeMuhammed SulfeekNo ratings yet

- Web Page Blocked: Home Matter IndexDocument5 pagesWeb Page Blocked: Home Matter Index4arunpandeyNo ratings yet

- Aisi 4140 Uk PDFDocument2 pagesAisi 4140 Uk PDFFikri SiplhoNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelAsril MaulanaNo ratings yet

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelAlineNo ratings yet

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelrekyNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Grossman HardenabilityDocument29 pagesGrossman HardenabilityIván VeltmanNo ratings yet

- Orm AssignmentDocument2 pagesOrm AssignmentDeepNo ratings yet

- Feritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelDocument8 pagesFeritscope FMP30 Measurement of The Ferrite Content in Austenitic and Duplex SteelBiju_PottayilNo ratings yet

- Arc Welding: CarbonDocument3 pagesArc Welding: CarbonmanandpatelNo ratings yet

- Arcelormittal Crane Rails enDocument6 pagesArcelormittal Crane Rails enjulius_xNo ratings yet

- DM Water Tank SpecificationDocument9 pagesDM Water Tank SpecificationManish PatelNo ratings yet

- TB Insert CCDocument44 pagesTB Insert CCMuh Syafiul UmamNo ratings yet

- Astm19 0101Document4 pagesAstm19 0101Aaron PerezNo ratings yet

- Cutter Wheel Chart 12 14Document4 pagesCutter Wheel Chart 12 14Pablo CoroNo ratings yet

- GP3.035.11.0.PR - Oil SeparatorDocument1 pageGP3.035.11.0.PR - Oil SeparatorsandipmhetreNo ratings yet

- A975-11 (Reapproved 2016)Document8 pagesA975-11 (Reapproved 2016)duongNo ratings yet

- CLA-VAL - Waste ConeDocument2 pagesCLA-VAL - Waste ConeVanja IvkovicNo ratings yet

- Breechlocks ImprovedDocument7 pagesBreechlocks ImprovedNenad TrkuljaNo ratings yet

- PW CAT Product Catalog enDocument116 pagesPW CAT Product Catalog enTymoteoNo ratings yet

- Welding Inspection Report NEWDocument2 pagesWelding Inspection Report NEWtrinhminhkhoa100% (1)

- Tunnel Support - Use of Lattice Girders in Sedimentary Rock PDFDocument94 pagesTunnel Support - Use of Lattice Girders in Sedimentary Rock PDFjulio1051No ratings yet

- General Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingDocument62 pagesGeneral Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingclaudiaNo ratings yet

- Railway Engineering MCQsDocument14 pagesRailway Engineering MCQstushark12127No ratings yet

- Welding HandbookDocument48 pagesWelding HandbookMohan Prasad.M93% (27)

- Is 14220-PumpDocument13 pagesIs 14220-PumpJignesh TrivediNo ratings yet

- Weld DefectsDocument48 pagesWeld DefectsStewart StevenNo ratings yet

- Heat Treatment of Carbon SteelDocument23 pagesHeat Treatment of Carbon SteelArielle Joyce de JesusNo ratings yet

- Aisi 1016 Carbon Steel (Uns g10160)Document2 pagesAisi 1016 Carbon Steel (Uns g10160)Naman TanejaNo ratings yet

- API 571 Damage MechanismsDocument42 pagesAPI 571 Damage MechanismsIsmail Jamaluddin100% (1)

- Ambit - Strategy - India's Best and Worst Capital AllocatorsDocument32 pagesAmbit - Strategy - India's Best and Worst Capital Allocatorsinvestmentcalls100% (1)

- Goodwin Check Valve Technical Catalogue PDFDocument68 pagesGoodwin Check Valve Technical Catalogue PDFAnonymous UcIPjRDWRNo ratings yet

- Pressure VesselsDocument42 pagesPressure VesselsIndra BRNo ratings yet

- Chapter 5 - Welding of High-Alloy Steels, Corrosion PDFDocument19 pagesChapter 5 - Welding of High-Alloy Steels, Corrosion PDFEmad A.AhmadNo ratings yet

- Praveen Audit Log SheetDocument59 pagesPraveen Audit Log SheetUnwanted Pyara PintuNo ratings yet

- SB410 (JIS) - Worldwide Equivalent Grades 11Document1 pageSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)