Professional Documents

Culture Documents

Gas Purging Optimises Root Welds

Uploaded by

Deepu Chandran0 ratings0% found this document useful (0 votes)

57 views4 pageswelding

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwelding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

57 views4 pagesGas Purging Optimises Root Welds

Uploaded by

Deepu Chandranwelding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Gas Purging

Optimizes Root

Welds

In circumstances where welds have to

be designed to withstand stress in service,

special consideration needs to be given to

their metallurgy and profiles.

‘The mechanical properties of welds,

particularly their fatigue properties, ean

be influenced significantly by their shape

and composition. In particular at the weld

oot, a positive reinforcement combined

with smooth transition from weld to base

metal are prerequisites to achieve opti-

‘mum mechanical strength.

Good Practice

Joints of high quality between cylindri-

‘cal sections such as tubes and pipes can

only be made by ensuring that atmos-

ppheric gases are eliminated, and positive,

smooth weld reinforcement is provided.

‘The presence of oxygen, and to lesser

extent nitrogen, around the molten weld

can lead to wide-ranging defects. Discol-

ration is unsightly and in some instances

‘might reflect metallurgical imbalance, es-

pecially with some stainless steels. Gross

oxidation inevitably results in reduction

in mechanical properties and can cause

catastrophic loss of corrosion resistance.

Nitrogen contamination can result in brit-

teness. Gases in the weld may give rise to

cracking during or after cooling.

Itis clear that a reduction in weld sec-

tion at the root, as evidenced by a concave

geometry, will reduce the joint strength.

Perhaps not so evident, but in many ap-

plications of crucial importance is the

presence of notches or cracks, which tend

to appear at the weld/base metal inter-

face. These can propagate in service and

cause failure

Basic Principles

Weld root quality when making tubu-

lar joints can be ensured by applying ap-

propriate safeguards based on removal of

Air from the fusion zone by the provision

of inert gas. This is achieved by gas purg-

ing, and the general principles are shown

in Fig. 1

Purging Gases

‘The most commonly used purging gas

in Europe is commercial quality argon; in

the U.S., helium is in more general use,

being less expensive. For specialized ap-

plications, purging techniques. using

argon-hydrogen and helium-argon mix-

tures and nitrogen have been developed.

‘The materials being joined and the

welding process used are two main factors

in the selection of the optimum gas or gas

mixture. Purge gas flow rate and pressure

also need to be established, and once sé

lected, they should be included in the for-

‘mal welding procedure.

Variation in purge gas quality may arise

during welding, and it may be desirable 10

apply continuous gas monitoring, espe-

cially to control oxygen and moisture con-

tent. For this purpose, dedicated oxygen

analyzers and dewpoint meters are avail-

able commercially.

Purging Procedure

‘The first requirement is to provide gas

‘entry and exit points. Gas is fed through

‘one end seal with an exit hole atthe other

‘end to prevent an undesirable buildup of

pressure. Argon has a greater density than

air, and the gas inlet should be at a lower

clevation than the bleed end so that air is

expelled effectively from the pipe bore

Total Purging

On small pipes and tubes, where the

internal volume is small, the cost of cor

tinuous total purging may not be signif

Purging gas contaminants from the weld area

results in quality pipe welds

BY M. FLETCHER

cant. Under these circumstances wooden

‘or plastic dises simply taped to the tube

tends will be adequate. Plastic caps em-

ployed, for example, to protect pipe ends

and threads during transit are commonly

used. It is most important that potential

Jeak paths are eliminated and that any

branch pipes are vented to ensure com-

plete removal of air

‘When total purging is impractical, per-

hhaps because the pipe volume is large or

because access is difficult, alternative con-

tainment techniques are available.

Water Soluble Papers

and Pastes

A low-cost and effective solution to

providing gas coverage is to make dises

from water-soluble paper and tape them

inside the pipes to be joined. They should

not be placed in position until after any

preweld heat treatment and be far enough

part, typically 500 mm, to avoid thermal

damage during welding, Purge gas is in-

troduced into the area between the solu-

ble dams by means of a hypodermic tube

through the weld joint line.

On small-diameter pipes, an effective

-an be produced simply by erumpling

the paper and pushing it into the pipe

bore, Soluble pastes are also available and

cean be convenient for small diameters.

(On completion of the welding opera

tion, the paper or paste can be removed

by passing water into the pipe

ing time for it to dissolve the barrier

medium,

Thermally Disposable

Barriers

Water-soluble products are not always

acceptable, and an alternative method is

to.use cardboard discs. These are simply

M. FLETCHERis with Dela Consultants, Carmarthen, UK. Information available from Huntingdon Fusion (www.huntingdontusion.com),

Carmarthen, UK.

DE

IBER 2006

New Equipment, New

Successes

bility i

NASCAR fabs

Fig. 1— Schematic of a setup for purging.

Fig, 2— Purging a 9-deg bend.

ee

soo)

[REE won

eee) ee eee a

+

Fig. 3— Purging a shor elbow.

‘cut to fit the internal diameter of the pipe

‘and, if necessary, taped in position to pro-

vide a gas seal, The distance between discs

should be typically 500 mm to avoid ther-

‘mal damage during welding.

‘The thermally disposable dise solution

is convenient if welding is to be followed

by a postweld heat treatment cycle since

the card is removed effectively by incin-

eration. Otherwise, general heating by

torch isa sound method of removal.

‘The water-soluble and thermally dis-

posable barriers are expedient solutions

‘where access to the tube or pipe bore is

impractical after welding. If access can be

gained, several alternati

‘damming techniques, which

lapsible discs, rubber gasket discs, and in-

flatable bladders, can be considered.

‘These dams are normally placed in the

pipe at the time of joint assembly, the re-

covery cord or rod projecting down the

access route. A spacing of 150 to 200 mm_

will usualy prevent thermal damage dur-

ing welding, but it should be noted that

‘greater spacing is prudent if preweld heat

treatment is to be applied.

Collapsible Disc Barriers

Discs can be made from any rigid sheet

‘material; plywood is a good medium if in-

hhouse manufacture is planned. The discs

are split across the diameter and hinged

Fig. 4 — Purging a Tee piece.

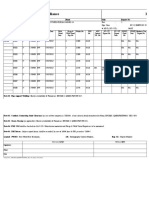

‘Table 1 — Purge Times for Various Pipe Diameters and Flow Rates

Purge Times for Gas Tungsten Are Welding of Steel Pipe

Pipe Diameter Flow Rate

in mm Limin

ape » 0

4 100 » 0

Bes, 2 0

6 130 ee)

6 aa gos aa

He 200 see cs Pe

2m »

AR as) 0) a

» oo 80) 7

Purge Time Vent Diameter

3 % 15,

3 a ot

5 Mas

6 x3

5 ee

B Me,

B ed

6 cu, Sp

3 ee

‘Nove: Purge ime and fow ates wore those required 10 reduce the onyen o 1% or om Based on caloure of

12. (900 mm) in length, When ensure exceed 12 in, length inrease flow tne proportional,

{Upon completion of parsing cee reduc fw rate o maintain sigh poste pressure during wok

and a sealing pad of synthetic foam

bonded to the periphery. Cords attached

to the discs are used to collapse the dam

after welding and to remove the discs from

ithe pipe.

Rubber Gasket Dam

A rubber disc can be sandwiched be-

‘tween a pair of wooden or metal dises and.

some adjustment to diameter can be ef-

fected by applying axial pressure. Ths gas-

ket technique is not collapsible, and after

‘welding the discs must be pulled out past

the weld root, an operation which may

‘cause difficulties.

Inflatable Bladder Dam

‘An efficient purge gas containment

method is to use inflatable dams such as,

the Argweld system. This has been devel-

‘oped specifically to provide a reusable so-

lution to gas purging. It is easy to use and

WELDING JOURNAL EE

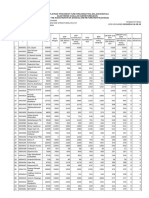

re purge time Ve pipe ciameter

eS ht ga 8 8

SSS CO ee ee aoa

Fig. 5 —Prepurge time vs. pipe diameter. Time is fora 12-in. Fig. 6 — Time to reduce oxygen content to below 1%.

pipe ata flow rate of 50 fh (23.5 Limin). To calculate the

‘prepurge time for any length of pipe, multiply the value ob-

tained from the chart by the length of pipe. For example, find

the time for prepurging 200 ft (60 m) of S-in. (127-mm) pipe.

From the char, it takes | min 1o purge 12 in. ofa Sin. pipe.

“Hence, it takes 200 min (3 h 20 min) to purge 200 ft of S-in.

Pipe.

economical when several similar joints

need to be produced,

‘The bladder, which has suficent length

to ensure sound sealing, is manufactured

from rubber with a protective canvas cover.

‘One is placed on each side of the joint and

inflated using either compressed airor the

purge gas itself. The latter is much pre-

ferredsinceit overcomes any problems that

tight arise from leakage of the bladder.

Figures 2-4 illustrate the bladder concept.

‘Variationson the basicequipment are com-

‘mercially available.

Purge inlet and outlet pipes can be in-

corporated in the bladder to allow the full

circumference to seal against the pipe wall.

High-temperature covers can be pro-

vided to afford protection during weld pre

Inca eyeles, and single bladders can be used

for closed end joints. Inflation and purging

{8 pressures can be separately controlled.

Longer or shorter spinal connecting

tubes are availabe, and provision can be

‘made for continuous alteration in gas flow

rate up to 20 Limin.

The Prepurge Process

A prepurge is used to displace air pres-

ent in the pipework system or dam vol-

‘ume. Numerous factors control the pre~

purge time such as pipe diameter, purge

‘volume, and maximum permitted oxygen

level. A common misconception is that

increasing the purge flow rate will reduce

FE peceneen 2006

the purge time. This is a fallacy. An in-

crease in flow rate increases turbulence

and results in unwanted mixing of purge

gas and air and can actually extend the

urge time.

‘As a general rule, the prepurge flow

rate and time should allow for about five

‘volume changes in the pipe system or dam

volume, but a typical gas flow rate will be

in the region of 20 L/min. Figure 5 is an

illustration of the relationship between

repurge time and pipe diameter based

on a pipe purge length of 300 mm. For

different purge lengths, itis reasonable

to use a prorata calculation. Table 1 pres-

cents examples of purge times for differ-

cent pipe diameters and flow rates.

‘Weld joints that require a root open-

ing or have poor fitup, both of which char-

acteristics provide an unwanted leak path

for the purge gas, can be sealed by taping.

Onygen and moisture levels in the

purge gas should be checked using appro-

priate equipment with checking taking

place at the outlet point. Where dam in-

serts are being used, the outlet point needs

tobe extended with a flexible pipe to acon-

venient access position. I this is impracti-

cal, a system that has the purge inlet and

‘outlet in the same dam unit should be used.

Figure 6 gives times to reduce the dam

‘volume oxygen content to below 1% using

inflatable bladders. While 1% residual

‘oxygen is a suitable working level for ma-

terials such as stainless steels, the level

needs to be as low as 20 ppm when weld-

ing the more sensitive alloys based on ti-

tanium and other reactive metals.

The Weld Purge Process

Once the quality of the gas in the

dammed volume has reached the required

level, gas flow can be reduced to about §

‘Limin for the welding operation. On a

‘more practical level, it should just be pos-

sible to feel the gas flow from the exit

point. Excessive flow can cause the inter-

nal pressure in the pipe to rise and create

concavity inthe weld root geometry and

‘nmore extreme cases can cause complete

ejection of the molten weld pool

‘To restrict leakage on joints not fully

sealed, a higher flow rate will be neces-

sary to avoid contamination. Toward the

‘end of the weld run, however, asthe joint

‘becomes permanently sealed, the gas flow

rate will need tobe reduced to avoid over-

pressurization.

Change of Address?

Moving?

Make sure delivery of your Welding

Journals not interrupted. Contact the

Membership Department with your

new address information — (800) 443-

9353, ext.217; smateo@ans.org.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Time and Work 30 QuestionsDocument5 pagesTime and Work 30 QuestionsDeepu ChandranNo ratings yet

- Mobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDocument1 pageMobile Crane, Hydra Planning & Risk Assessment Checklist: Plant/AreaDeepu ChandranNo ratings yet

- Ladder Inspection Check ListDocument4 pagesLadder Inspection Check ListDeepu ChandranNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- 300 Copy Gas Cutting Daily Check ListDocument3 pages300 Copy Gas Cutting Daily Check ListDeepu ChandranNo ratings yet

- Petal DevelopmentDocument2 pagesPetal DevelopmentDeepu ChandranNo ratings yet

- SyllogismDocument7 pagesSyllogismDeepu ChandranNo ratings yet

- RT OfferDocument12 pagesRT OfferDeepu ChandranNo ratings yet

- 100 Copy Scaffolding Erection Check ListDocument4 pages100 Copy Scaffolding Erection Check ListDeepu Chandran100% (1)

- STA Audit Format-EditableDocument1 pageSTA Audit Format-EditableDeepu ChandranNo ratings yet

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- Paint Type and DFT Requirements for TanksDocument2 pagesPaint Type and DFT Requirements for TanksDeepu ChandranNo ratings yet

- Sharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDocument3 pagesSharp Tanks & Structurals (P) LTD Drinking Water Tank - : J3 Project - ZRTFDeepu ChandranNo ratings yet

- Wled LengthDocument1 pageWled LengthDeepu ChandranNo ratings yet

- Imir 3156Document38 pagesImir 3156Deepu ChandranNo ratings yet

- Fabrication Yard LayoutDocument1 pageFabrication Yard LayoutDeepu ChandranNo ratings yet

- STS Ril 002Document1,127 pagesSTS Ril 002Deepu ChandranNo ratings yet

- SiteDocument9 pagesSiteDeepu ChandranNo ratings yet

- Too1 B LHSDocument347 pagesToo1 B LHSDeepu ChandranNo ratings yet

- Sharptank - PF ECR September-16Document11 pagesSharptank - PF ECR September-16Deepu ChandranNo ratings yet

- RT Summary Report for DWG NO MED-711Document130 pagesRT Summary Report for DWG NO MED-711Deepu ChandranNo ratings yet

- QC StickerDocument44 pagesQC StickerDeepu ChandranNo ratings yet

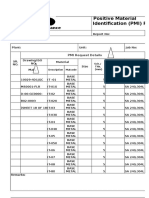

- Reliance: Positive Material Identification (PMI) ReportDocument16 pagesReliance: Positive Material Identification (PMI) ReportDeepu ChandranNo ratings yet

- 56 Requist Validation MTTDocument3 pages56 Requist Validation MTTDeepu ChandranNo ratings yet

- Safety Audit Report SampleDocument24 pagesSafety Audit Report Samplekanakarao187% (15)

- Pneumatic Test ProcedureDocument7 pagesPneumatic Test ProcedureDeepu ChandranNo ratings yet

- ASNT NDT Level III Certification GuideDocument8 pagesASNT NDT Level III Certification GuideIndigo Wave0% (2)

- Mastering Options StrategiesDocument40 pagesMastering Options Strategiesluong847180% (1)

- Sts-Sez HC Ra 2Document17 pagesSts-Sez HC Ra 2Deepu ChandranNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Technology of Machine Tools: Steady Rests, Follower Rests, and MandrelsDocument27 pagesTechnology of Machine Tools: Steady Rests, Follower Rests, and MandrelsAnibal DazaNo ratings yet

- Working at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2Document2 pagesWorking at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2ananthu.uNo ratings yet

- SDP SI Acetal Gear Mod 05 144 TeethDocument1 pageSDP SI Acetal Gear Mod 05 144 Teethgoooga299No ratings yet

- Cherry Bookcase - FH04DJDocument12 pagesCherry Bookcase - FH04DJjuliovargas100% (1)

- YedaiDocument4 pagesYedaiAbel SánchezNo ratings yet

- Welder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeDocument4 pagesWelder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeSpectex dubaiNo ratings yet

- SMP PPT No. 32 - Paint and Pigments - Vadivel RajaDocument11 pagesSMP PPT No. 32 - Paint and Pigments - Vadivel Rajaraja kundiiNo ratings yet

- Patchroc GP: Fast-Setting Emergency Patching Mortar For Concrete Pavements and FloorsDocument4 pagesPatchroc GP: Fast-Setting Emergency Patching Mortar For Concrete Pavements and FloorsAbdul Nazir - 11858 Hawiyah Branch - QCNo ratings yet

- Cost EconomicsDocument14 pagesCost Economicsamitvaze316No ratings yet

- INDEX_MS22-8_ENDocument16 pagesINDEX_MS22-8_ENRoberto LimaNo ratings yet

- EHS Guidance Notes - Bench GrinderDocument1 pageEHS Guidance Notes - Bench GrinderbesongNo ratings yet

- Rov Shank Hooks - GN - Hk5Document2 pagesRov Shank Hooks - GN - Hk5joosuasinagaNo ratings yet

- HT ManualDocument17 pagesHT ManualAkhilesh KumarNo ratings yet

- Printers' Marketplace October 5th 2010Document40 pagesPrinters' Marketplace October 5th 2010Christopher AllenNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- In-Situ MetallographyDocument7 pagesIn-Situ Metallographyhatem jafouraNo ratings yet

- Karakteristik Kimia Biomassa Untuk Energi (Chemical Characteristics of Biomass For Energy)Document8 pagesKarakteristik Kimia Biomassa Untuk Energi (Chemical Characteristics of Biomass For Energy)Yusuf UtgNo ratings yet

- Chemicals: Medium StrengthDocument128 pagesChemicals: Medium Strengthk mNo ratings yet

- Standard Operating Procedure of Blister Pack MachineDocument5 pagesStandard Operating Procedure of Blister Pack MachineSolomonNo ratings yet

- HUeLLER-HILLE NBH170-4 BJ1998 EN V1Document17 pagesHUeLLER-HILLE NBH170-4 BJ1998 EN V1aldacirjoe8360No ratings yet

- Comparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelDocument12 pagesComparative Study of Nylon and PVC Fluidized Bed Coating On Mild SteelWaqqas ChaudhryNo ratings yet

- Nanomaterials Synthesis by Sol-Gel and CVD MethodsDocument30 pagesNanomaterials Synthesis by Sol-Gel and CVD MethodsSk. Laila AyeshaNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Success Built On Experience: Ongoing Development of Radial Forging TechnologyDocument2 pagesSuccess Built On Experience: Ongoing Development of Radial Forging TechnologyemregnesNo ratings yet

- Fusealloy Fabrication Guidelines 2016Document25 pagesFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyNo ratings yet

- Paraloid Au 608xDocument7 pagesParaloid Au 608xCHIRE SARAYASI MANUELNo ratings yet

- AST100 Viscometer Ink 12Document2 pagesAST100 Viscometer Ink 12migueldemacrolabNo ratings yet

- Lamons Purely High Temperature GasketsDocument6 pagesLamons Purely High Temperature GasketsIjaz AhmedNo ratings yet

- 16 KL MS TANK-ModelDocument1 page16 KL MS TANK-ModelHardikNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet