Professional Documents

Culture Documents

The Design Is Adequate.: A W B L T (Weight P

Uploaded by

ZevanyaRolandTualakaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Design Is Adequate.: A W B L T (Weight P

Uploaded by

ZevanyaRolandTualakaCopyright:

Available Formats

PROJECT :

CLIENT :

JOB NO. :

DATE :

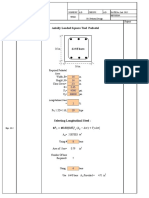

Steel Road Plate Design Based on AASHTO 17th Edition & AISC 360-10 using Finite Element Method

INPUT DATA & DESIGN SUMMARY

MAXIMUM TRENCH WIDTH

(A or B zero for one way trench.)

A=

B=

STEEL PLATE THICKNESS

t=

1.625

4

6

ft

ft

W=

L=

in

(Weight =

TRUCK CONCENTRATED LOAD

P=

(26 kips for H20-44, 19.5 kips for H15-44)

26

kips, (AASHTO Fig. 3.7.6B)

Fy =

50

ksi

STEEL YIELD STRESS

PAGE :

DESIGN BY :

REVIEW BY :

3185

6

8

ft

ft

lbs)

THE DESIGN IS ADEQUATE.

(The Minimum Plate Size: 6 ft x 8 ft x 1.625 in., Wt: 3185 lbs.)

ANALYSIS

IMPACT FACTOR (AASHTO 3.8.2)

I = 1+ Min[ 0.3 , 50/(L + 125) ] =

Where

L = Max(A , B) =

1.30

6.0

ft

JOINT DEFLECTIONS, REACTIONS, & PLATE SECTION FORCES

PI=

33.8

kips,( Truck point load at Joint 9.)

in

0

0.60

0.85

0.19

0.69

0.92

0.26

0.74

0.99

Joint

Number

1

2

3

4

5

6

7

8

9

R

kips

-9.246

d=

1.67

12.0

Z = d t2/ 4 =

My = Fy d t2/ 6 =

CHECK SHEAR CAPACITY (AISC 360-10, G2)

Vn / v =

2101.8

Where

ft-k/ft

Mn = Min( Fy Z , 1.6 My ) =

b =

Vn =0.6 Fy Aw Cv =

b =

M

ft-k/ft

8.63

10.54

16.55

18.26

Minimum W =

Minimum L =

E=

29000

CHECK BENDING CAPACITY (AISC 360-10, F11)

Mn / b =

19.8

Where

Bending

Section

7-8

8-9

3-6

6-9

1.67

>

M=

[Satisfactory]

33.0

ft, for FEM calculation

ft, for FEM calculation

ksi

17.4

ft-k/ft, (Max section average moment.)

ft-kips

, (AISC 360-10, F1)

in

7.9

in3

22.0

ft-kips

>

kips

3510.0

V=

kips

, (AISC 360-10, G1)

Cv =

1.00

Aw =Min (A + 2 , B +2, 8 ft) t =

6

8

117.0

in2

33.8

kips

[Satisfactory]

You might also like

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Cinnection-Bearing - Perhitungan Struktur Baja Dengan Ms ExcelDocument17 pagesCinnection-Bearing - Perhitungan Struktur Baja Dengan Ms ExcelAlzan Toch100% (19)

- Invoice TemplateDocument7 pagesInvoice TemplateZevanyaRolandTualaka100% (1)

- Steel Road Plate DesignDocument1 pageSteel Road Plate DesignAshraf KhanNo ratings yet

- Structural GlassDocument1 pageStructural Glasssamgivp2869100% (4)

- Minimum Steel Concrete Beam DesignDocument9 pagesMinimum Steel Concrete Beam DesignalshaijiNo ratings yet

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- HGPS User Manual (Bid Submission)Document21 pagesHGPS User Manual (Bid Submission)ZevanyaRolandTualaka0% (1)

- Clean Copy Metal Building Foundation Rev 2.1Document14 pagesClean Copy Metal Building Foundation Rev 2.1jh50000No ratings yet

- The Design Is Adequate.: A W B L T (Weight PDocument1 pageThe Design Is Adequate.: A W B L T (Weight PAhmed AjelNo ratings yet

- Angle CapacityDocument1 pageAngle CapacityAhmed Ben HmidaNo ratings yet

- Base Plate Hss2Document37 pagesBase Plate Hss2Sana UllahNo ratings yet

- Concrete Tunnel Design Based On AASHTO-17th & ACI 318-08: Input Data & Design SummaryDocument1 pageConcrete Tunnel Design Based On AASHTO-17th & ACI 318-08: Input Data & Design Summaryyanu13No ratings yet

- Pile Cap Design ExamplesDocument70 pagesPile Cap Design Examplest_solanki200160% (5)

- Shortcol141 DemoDocument19 pagesShortcol141 DemoterenvanzareNo ratings yet

- M M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10 Input Data & Design SummaryDocument1 pageM M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10 Input Data & Design SummarysushilkumarNo ratings yet

- HSS TorsionDocument1 pageHSS TorsionmohamedNo ratings yet

- Conc Short ColDocument13 pagesConc Short ColEngDbtNo ratings yet

- JRCP - Parking Yard Calc R1Document8 pagesJRCP - Parking Yard Calc R1Pieter HarryNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-08: Input Data & Design SummaryDocument1 pageBridge Column Design Based On AASHTO 17th & ACI 318-08: Input Data & Design Summaryyanu13No ratings yet

- Pilecap DesignDocument70 pagesPilecap DesignxavierlthNo ratings yet

- Flood WayDocument3 pagesFlood WayMario Sajulga Dela CuadraNo ratings yet

- Axial Capacity of 1 1/2" Type "B" Roof Deck Based On ICBO ER-2078PDocument1 pageAxial Capacity of 1 1/2" Type "B" Roof Deck Based On ICBO ER-2078PMarianne Aravilla Dela CruzNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryAhmed Ben HmidaNo ratings yet

- Scomposite-24.24Document87 pagesScomposite-24.24manish sharmaNo ratings yet

- BeamSplice DESIGNDocument1 pageBeamSplice DESIGNcecastaNo ratings yet

- Base Plate and Blot Design-UploadDocument6 pagesBase Plate and Blot Design-UploadygguptaNo ratings yet

- Steel BeamDocument37 pagesSteel BeamJeten C Rika100% (1)

- Steel Road PlateDocument1 pageSteel Road Platejklo12No ratings yet

- Axially Loaded Square Tied Pedastal: ReferenceDocument2 pagesAxially Loaded Square Tied Pedastal: ReferenceAddrien DanielNo ratings yet

- Circ BaseDocument9 pagesCirc Basejigarshah21No ratings yet

- Mini Caisson Design-CalculationsDocument6 pagesMini Caisson Design-CalculationsRobert SiqecaNo ratings yet

- Simpson Anchors 2008-03 by Jason Oakley PDFDocument31 pagesSimpson Anchors 2008-03 by Jason Oakley PDFaomareltayebNo ratings yet

- Ce591plategirders F13Document67 pagesCe591plategirders F13cocococo1100% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Pipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryDocument1 pagePipe Concrete Column Design Based On ACI 318-11: Input Data & Design SummaryYatsen Jepthe Maldonado SotoNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument5 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryPn EkanayakaNo ratings yet

- Copedwbeamseat - Xls (Revision 1.1)Document4 pagesCopedwbeamseat - Xls (Revision 1.1)sergiooiNo ratings yet

- Ocbf IbcDocument3 pagesOcbf IbcNikki RobertsNo ratings yet

- SignDocument16 pagesSignFakhrul AzmiNo ratings yet

- CalDocument19 pagesCalpandiangv100% (1)

- RCC31 One-Way Slabs (A&d)Document14 pagesRCC31 One-Way Slabs (A&d)Sovich82No ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Advanced AutoCAD® 2017: Exercise WorkbookFrom EverandAdvanced AutoCAD® 2017: Exercise WorkbookRating: 1 out of 5 stars1/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- DAPOT LAYOUT lt2 VASIN 2017 PDFDocument1 pageDAPOT LAYOUT lt2 VASIN 2017 PDFZevanyaRolandTualakaNo ratings yet

- 05 Overhead or Under Floor InstallationDocument22 pages05 Overhead or Under Floor InstallationZevanyaRolandTualaka100% (1)

- Coal Fired Power Plant (24 Apr 09)Document11 pagesCoal Fired Power Plant (24 Apr 09)ZevanyaRolandTualakaNo ratings yet

- Dartar Berat Besi BukuDocument29 pagesDartar Berat Besi BukuZevanyaRolandTualakaNo ratings yet

- Coal Fired Power Plant (24 Apr 09)Document11 pagesCoal Fired Power Plant (24 Apr 09)ZevanyaRolandTualakaNo ratings yet

- 2.column Base Plate (Fixed Type)Document15 pages2.column Base Plate (Fixed Type)ZevanyaRolandTualakaNo ratings yet

- Two Way Slab Design Excel SheetDocument11 pagesTwo Way Slab Design Excel SheetZevanyaRolandTualakaNo ratings yet

- Design of RCC SlabDocument8 pagesDesign of RCC Slabrajseema_n2180% (5)

- Column Base Plate (Hinge Type)Document11 pagesColumn Base Plate (Hinge Type)ZevanyaRolandTualakaNo ratings yet

- Elektrik - MS 10C A PDFDocument64 pagesElektrik - MS 10C A PDFZevanyaRolandTualaka100% (3)

- Bill of Quantities Rev.2 (IMEK-CP-151217)Document2 pagesBill of Quantities Rev.2 (IMEK-CP-151217)ZevanyaRolandTualakaNo ratings yet

- Parts List - SR-250SP PDFDocument570 pagesParts List - SR-250SP PDFZevanyaRolandTualaka100% (3)

- SR-250SP PDFDocument570 pagesSR-250SP PDFZevanyaRolandTualaka100% (1)

- Major Terms of Tender Rev.0 (IMEK-CP-151215)Document1 pageMajor Terms of Tender Rev.0 (IMEK-CP-151215)ZevanyaRolandTualakaNo ratings yet

- Basic (Arch) DrawingsDocument15 pagesBasic (Arch) DrawingsZevanyaRolandTualakaNo ratings yet

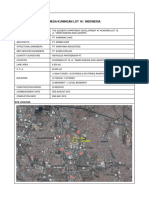

- Mega Kuningan Lot 16 / Indonesia: Project SynopsisDocument2 pagesMega Kuningan Lot 16 / Indonesia: Project SynopsisZevanyaRolandTualakaNo ratings yet

- Steel Beam BS 5950Document17 pagesSteel Beam BS 5950ZevanyaRolandTualakaNo ratings yet

- Prestressed Concrete Circular Hollow SectionDocument2 pagesPrestressed Concrete Circular Hollow SectionDipak Borsaikia100% (1)