Professional Documents

Culture Documents

HF4760 BL3 PDF

HF4760 BL3 PDF

Uploaded by

Niraj HattangdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HF4760 BL3 PDF

HF4760 BL3 PDF

Uploaded by

Niraj HattangdiCopyright:

Available Formats

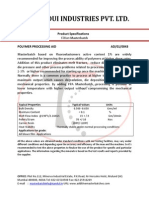

HDPE made via Hostalen Process

Product data sheet

HF-4760(BL3)

HDPE: HF-4760(BL3)

HF-4760(BL3) is a blow molding grade resin with high density polyethylene with

1-Butene as co monomer which is manufactured by the suspension polymerization of ethylene monomer. Stiffness, good ESCR are it's spetial properties. High

rigidity and good flowablity which made it proper for usage in bottles and small

blow molding goods.

Density: 0.954

MFI: 23

Features

Applications

Additives

High density and Stiffness, good

flowabilitty and impact Stvength

Small blow moulding

Bottles

Containers (up to 5 lit )

Packing of pharmaceuticals & sur-

Antioxidant/Process stabi-

and good Stvess Cvacking resistance.

lizer

Lubricant/ acid scavenger

factants

Material properties (This data are typical values and are not to be construed as product specifications.)

Resin Properes

Unit

Value

Test Method

Melt Index(21.6)

g/10 min

234

ISO 1133

Melt Index(5)

g/10 min

1.20.3

ISO 1133

FRR (21.6/5)

193

Density

g/cm

0.9540.002

ISO 1183

Molded Properes

Unit

Value

Test Method

Notched Impact @ 23 C

mJ/mm

ISO 179/ 1 eA

Handellling and Health Safty

sMolten polymers could be injured skin or eye so safty glasses and appropriate gloves are suggested to prevent possible

thermal injuries. Also appropriate ventilation is suggested in

working by melt polymer.

Accumulation of fines or dust particles that are in this grade

is not suitable because of explosion hazard probability. So

adequated filters and grounding exists at all time are recommended.

Storage

Polyethylen products (in pelletised or powder form) should

not be stored in direct sunshine and/or heat radiation.

Ultraviolet cause a change in the material properties.The

Storage area should be dry and preferably don't exceed 50

C. Under cool, dry, dark conditions Jam Polymers polyolefin

resins are expected to maintain the original material and

processing properties for at least 18 month. . JPC would not

ressponsible about quality diminishing such as color change,

bad smell or ets which caused by bad storage conditions. It

is better to process PE resin within 6 months after delivery.

- On compression molded according to ASTM D1928C

Processing Conditions

Recommended barrel tempratures range between 190 C

and 280 C.

Shear-Viscosity @ 190 C

pakaging

Jam Polymers Polyolefin resins are supplied in pllet form

packed in 25kg bags. Alternative packaging modes are avalable for selected grades.

The above values were

Calculated from data for 100 m

produced

on a 75mm Barrnage

extruder with 190C melt temperature using a 2:1 blow ratio

and a gap die of 3.0 mm.

You might also like

- HDPE For Blow Molding: Molded PropertiesDocument1 pageHDPE For Blow Molding: Molded Propertiesmohamad mostafaviNo ratings yet

- Biograde BL-FDocument3 pagesBiograde BL-FXuân Giang NguyễnNo ratings yet

- PLA NatureWorksDocument3 pagesPLA NatureWorkstblos100% (1)

- HF-4760 (BL) : Product Data SheetDocument2 pagesHF-4760 (BL) : Product Data SheetCarito LopezNo ratings yet

- Ergime Sıcaklığı 100 Derece Olan PolietilenDocument2 pagesErgime Sıcaklığı 100 Derece Olan PolietilenEngin ErbayrakNo ratings yet

- Product Data Sheet: HDPE Made Via Hostalen ProcessDocument2 pagesProduct Data Sheet: HDPE Made Via Hostalen ProcessvahidNo ratings yet

- Axalta Coathylene Masterbatch FlyerDocument3 pagesAxalta Coathylene Masterbatch FlyerdiamondicemxNo ratings yet

- Ester Gum EastmanDocument2 pagesEster Gum EastmanshishirchemNo ratings yet

- Biograde WS-50Document4 pagesBiograde WS-50Xuân Giang NguyễnNo ratings yet

- Master Reducer NH - 1024Document1 pageMaster Reducer NH - 1024AndyNo ratings yet

- RIL BoppDocument14 pagesRIL BoppSaurabh PariharNo ratings yet

- Fevicol Sa 73 Hot Melt AdhesiveDocument1 pageFevicol Sa 73 Hot Melt AdhesiveSaurabh GujarNo ratings yet

- SABIC DS 1965T 00900 Masterbatch Compounding EnglishDocument2 pagesSABIC DS 1965T 00900 Masterbatch Compounding EnglishpuipuiesperaNo ratings yet

- Tech - spec.CA SB66Document3 pagesTech - spec.CA SB66Sourabh ModiNo ratings yet

- Polypropylene (PP)Document8 pagesPolypropylene (PP)julioNo ratings yet

- TDS Chemflake Glass Flake SuggestedDocument5 pagesTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNo ratings yet

- Technical Information: Gecko Primer For Metalized FilmsDocument3 pagesTechnical Information: Gecko Primer For Metalized FilmsAtmaja SuryadiNo ratings yet

- Picco Tac 1095 N Hydrocarbon ResinDocument2 pagesPicco Tac 1095 N Hydrocarbon ResindevanandamqaNo ratings yet

- NCL Report - Chapter 4Document6 pagesNCL Report - Chapter 4Aparna YaduNo ratings yet

- Tds Tasnee LD 0222nDocument2 pagesTds Tasnee LD 0222nNoman Abu-FarhaNo ratings yet

- P750JDocument1 pageP750JTan Chen TatNo ratings yet

- PBT Polybutylene Terephthalate: WWW - Cjpsales.co - UkDocument3 pagesPBT Polybutylene Terephthalate: WWW - Cjpsales.co - UkAndy GilhamNo ratings yet

- Hdpe H355jaDocument2 pagesHdpe H355janimonh100% (1)

- 2310 Eng TM PDFDocument1 page2310 Eng TM PDFJordanNo ratings yet

- What Is Polypropylene?Document11 pagesWhat Is Polypropylene?Shivam KabirNo ratings yet

- Polystyrene Properties&UsesDocument5 pagesPolystyrene Properties&UsesChandrachood SBNo ratings yet

- MesamollDocument3 pagesMesamollKiên PhùngNo ratings yet

- Parti - General InformationDocument20 pagesParti - General InformationSantanu GhoshNo ratings yet

- Plastics Comparison Chart: Material Clarity MVTR O C0 Impact Strength Recycle CodeDocument2 pagesPlastics Comparison Chart: Material Clarity MVTR O C0 Impact Strength Recycle CodeCosmina RaduNo ratings yet

- Mplast NB-4 Tech enDocument1 pageMplast NB-4 Tech enSıdıka Sertkol KavuşNo ratings yet

- PEEK-OPTIMA Processing Guide SecuredDocument0 pagesPEEK-OPTIMA Processing Guide SecuredAngel LagrañaNo ratings yet

- Acrilem ST190: Product DescriptionDocument2 pagesAcrilem ST190: Product DescriptionMachidon OanaNo ratings yet

- Tds Kimacell HPMC E4000Document1 pageTds Kimacell HPMC E4000WANGYUSHENG Kima Chemical Co LtdNo ratings yet

- Innothane: Innotooling Ie-644-02Document2 pagesInnothane: Innotooling Ie-644-02Arieza PerdhanaNo ratings yet

- Polymer Processing Aid MB Ad0043Document1 pagePolymer Processing Aid MB Ad0043vb_scribd1234No ratings yet

- 4300 1000 Eng TM PDFDocument2 pages4300 1000 Eng TM PDFJordanNo ratings yet

- 2050 2000 Eng TM PDFDocument2 pages2050 2000 Eng TM PDFJordanNo ratings yet

- Ingeo 2003DDocument3 pagesIngeo 2003Djsk789No ratings yet

- TDS DR Bio 7200 Compostable F&V BagsDocument3 pagesTDS DR Bio 7200 Compostable F&V BagsMukul SareenNo ratings yet

- Pet Flake Conversion 2Document26 pagesPet Flake Conversion 2James NgNo ratings yet

- An Overview of Polyester and Polyester Dyeing Part-4: ..... Previous Part Next Part....Document5 pagesAn Overview of Polyester and Polyester Dyeing Part-4: ..... Previous Part Next Part....Ronak Joshi100% (1)

- Mpo TDSDocument4 pagesMpo TDSTrần Duy TânNo ratings yet

- Fixapret F-ECO TIDocument5 pagesFixapret F-ECO TISajida HafeezNo ratings yet

- Technical Data Sheet: Constab® Af 00240 PP (Former: AF 0240 PP) Antifog MasterbatchDocument1 pageTechnical Data Sheet: Constab® Af 00240 PP (Former: AF 0240 PP) Antifog MasterbatchmohammedNo ratings yet

- Phenoline 187 VOC: Selection & Specification DataDocument4 pagesPhenoline 187 VOC: Selection & Specification Datarajiv_quantumNo ratings yet

- Plastics and Their Uses Higher2Document18 pagesPlastics and Their Uses Higher2elsobkiNo ratings yet

- Anabond 7931 Aaf TdsDocument2 pagesAnabond 7931 Aaf TdsNanjappa K NuchumaniandaNo ratings yet

- TDS DR Bio 7211 Compostable Filler FilmsDocument3 pagesTDS DR Bio 7211 Compostable Filler FilmsMukul SareenNo ratings yet

- Hexa FlexiPackDocument38 pagesHexa FlexiPackBegenkzNo ratings yet

- Reprocessed Polypropylene CopolymerDocument2 pagesReprocessed Polypropylene Copolymernatuan74No ratings yet

- C Eagle (Va10 51) TDSDocument1 pageC Eagle (Va10 51) TDSzoranbr1No ratings yet

- TDS - MUKI EPS - English (Uk) - Issued.29.08.2005Document4 pagesTDS - MUKI EPS - English (Uk) - Issued.29.08.2005wey5316No ratings yet

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDocument2 pagesDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyNo ratings yet

- 2006-008 (NXPowerLite)Document2 pages2006-008 (NXPowerLite)vijayakumar_samyNo ratings yet

- Aktiplast PP en RCRDocument2 pagesAktiplast PP en RCRbelas728No ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Polyurethanes: Science, Technology, Markets, and TrendsFrom EverandPolyurethanes: Science, Technology, Markets, and TrendsRating: 1 out of 5 stars1/5 (1)

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet