Professional Documents

Culture Documents

Chevrolet Blazer - Engine Performance Theory - Operation PDF

Uploaded by

Anonymous OrZIZ1BpgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chevrolet Blazer - Engine Performance Theory - Operation PDF

Uploaded by

Anonymous OrZIZ1BpgCopyright:

Available Formats

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

E - THEORY/OPERATION

1991 ENGINE PERFORMANCE General Motors Theory & Operation

INTRODUCTION

This article covers basic description and operation of engine performance-related systems and components.

Read this article before diagnosing vehicles or systems with which you are not completely familiar.

AIR INDUCTION SYSTEM

TURBOCHARGER (4.3L)

The turbocharger is basically an air compressor or air pump. Its major parts include a turbine wheel, shaft,

compressor wheel, turbine housing, compressor housing and center housing. The center housing contains a

turbine seal, compressor seal and bearings.

The internal combustion engine is an air-breathing machine. The amount of power produced by the engine is

determined not by the amount of fuel it uses, but by the amount of air it breathes in a certain period of time. Air

must mix with fuel to complete the combustion cycle. When the air/fuel ratio reaches a certain point, additional

fuel produces only black smoke, not more power; the denser the smoke, the more the engine is being

overfueled.

The turbocharger increases the quantity and density of air in the engine combustion chambers. The increased

volume of air allows more fuel to be used while maintaining the proper air/fuel ratio. The increased air and fuel

allows the engine to produce more horsepower than a non-turbocharged engine.

The turbocharger uses the normally wasted energy in the engine exhaust gas. As load on the engine is increased

and the throttle is opened wider, more air/fuel mixture flows into the combustion chambers. The increased flow

is burned and produces a larger volume of exhaust gas. The gas enters the exhaust manifolds, flows through the

turbocharger turbine housing and turns the turbine wheel and shaft. The shaft is coupled to the compressor

wheel. The compressor wheel compresses the air it receives and sends it to the intake manifold. The higher

pressure in the intake manifold allows a denser charge to enter the combustion chambers.

Intake manifold pressure, or "boost", is controlled by an exhaust by-pass valve, or wastegate. The wastegate is

operated by a spring-loaded diaphragm-type actuator which responds to boost pressure. The actuator, which is

controlled by the wastegate solenoid, opens the wastegate to allow exhaust gases to by-pass the turbine wheel,

thereby maintaining the correct boost level. The wastegate solenoid is controlled by the ECM through a turbo

boost relay.

CAUTION: On a turbocharged engine, any alteration to the air intake or exhaust

system which upsets the air flow balance may result in serious damage to

the engine.

The rotating assembly in the turbocharger can reach speeds of 130,000-140,000 RPM. An adequate supply of

clean engine oil is essential for cooling and lubrication. Whenever a basic engine bearing has been damaged or

ESYPRO

Martes, 22 de Septiembre de 2009 09:31:12

09:30:57 a.m.

Page 1

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

the turbocharger is replaced, the oil and oil filter should be changed and the turbocharger flushed with clean

engine oil.

CAUTION: Interruption or contamination of the oil supply to the turbocharger

bearings can result in major turbocharger damage.

CHARGE AIR COOLER

Before entering the combustion chambers, the air from the turbocharger is routed through an air-to-water charge

air cooler. As the turbocharger compresses air, the air's temperature rises. The heated, compressed air then flows

through the charge air cooler core, where it is cooled by coolant passing through the charge air cooler. The

cooler, denser air allows a denser air/fuel charge to enter the combustion chambers, producing significantly

more power.

The hot coolant is then routed through the charge air cooler radiator, where it releases the heat it absorbed at the

charge air cooler. An electric pump mounted to the charge air cooler radiator circulates coolant through the

system. Pump is controlled by the ECM through a charge air cooler air pump relay.

AIRFLOW SENSING

SPEED DENSITY

All gasoline vehicles are equipped with a MAP sensor, and use the speed density method to compute the airflow

rate. ECM uses manifold pressure to calculate the airflow rate. The MAP sensor responds to manifold vacuum

changes due to engine load and speed changes. The ECM sends a voltage signal to the MAP sensor. Manifold

pressure changes result in resistance changes in the MAP sensor. By monitoring MAP sensor signal voltage, the

ECM determines manifold pressure. If MAP sensor fails, the ECM supplies a fixed MAP value, and uses the

TPS to control fuel.

2.5L and 4.3L turbo models also use a Manifold Air Temperature (MAT) sensor. Sensor allows ECM to

determine intake air temperature. ECM uses signal to delay EGR until intake air temperature reaches about 40

F (5C). If intake air temperature becomes excessively high, ECM compensates by slightly retarding timing.

COMPUTERIZED ENGINE CONTROLS (GASOLINE)

The computerized engine control system monitors and controls a variety of engine/vehicle functions. The

computerized engine control system is primarily an emission control system designed to maintain a 14.7:1

air/fuel ratio under most operating conditions. When the ideal air/fuel ratio is maintained, the 3-way catalytic

converter can control oxides of nitrogen (NOx), hydrocarbon (HC) and carbon monoxide (CO) emissions.

The computerized engine control system consists of Electronic Control Module (ECM), input devices (sensor

and switch input signals) and output signals.

ELECTRONIC CONTROL MODULE (ECM)

NOTE:

Some models use a Powertrain Control Module (PCM). The difference between

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 2

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

an ECM and PCM is the PCM also controls electronic transmission internals and

cruise control system. Unless stated otherwise, references to ECM also apply to

PCM-equipped vehicles.

ECM is located in passenger compartment. For exact location of ECM, see ECM LOCATION in appropriate

article below:

G - TESTS W/CODES - DIESEL

G - TESTS W/CODES - GASOLINE

G - TESTS W/CODES - TRANSMISSION (If Trans. Codes Are Displayed)

Or under COMPONENT LOCATIONS in I - SYSTEM/COMPONENT TESTS article in this Section. The

ECM consists of the Arithmetic Logic Unit (ALU), Central Processing Unit (CPU), power supply and system

memories.

The ECM has a "learning" ability which allows it to make minor corrections for fuel system variations. If

battery power is interrupted, a vehicle performance change may be noticed. ECM corrects itself, and normal

performance returns if vehicle is allowed to "relearn" optimum control conditions. "Relearning" occurs when

vehicle is driven at normal operating temperature under part throttle, moderate acceleration and idle conditions.

ARITHMETIC LOGIC UNIT (ALU)

This internal component of the ECM converts electrical signals received from various engine sensors into

digital signals for use by the CPU.

CENTRAL PROCESSING UNIT (CPU)

CPU uses digital signals to perform all mathematical computations and logic functions necessary to deliver

proper air/fuel mixture. CPU also calculates spark timing and idle speed. The CPU controls operation of

emission control, "closed loop" fuel control and diagnostic system.

POWER SUPPLY

Power for ECM reference output signals (5 volts) and control devices (12 volts) is received from the battery

through ignition circuit when ignition switch is in ON position. Keep-alive memory power is received directly

from the battery.

MEMORIES

ECM uses 5 types of memory:

READ ONLY MEMORY (ROM) ROM is programmed information which only ECM can read. The

ROM program cannot be changed. If battery voltage is removed, ROM information is retained.

RANDOM ACCESS MEMORY (RAM) RAM is the scratch pad for the CPU. Data input, diagnostic

codes and results of calculations are constantly updated and temporarily stored in RAM. If battery voltage

is removed from ECM, all information stored in RAM is lost.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 3

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

PROGRAMMABLE READ ONLY MEMORY (PROM) PROM is factory programmed engine

calibration data which "tailors" ECM for specific transmission, engine, emission, vehicle weight and rear

axle ratio application. The PROM can be removed from ECM. If battery voltage is removed, PROM

information is retained.

CALIBRATION PACKAGE (CALPAC) Some models use a PROM and a CALPAC. CALPAC

provides fuel delivery back-up so engine runs in case of PROM or ECM failure. Any time ECM is

replaced, PROM and CALPAC must both be installed into replacement ECM. If battery voltage is

removed, CALPAC information is retained.

MEMORY CALIBRATION (MEM-CAL) Some vehicles may use a ECM containing a MEM-CAL

unit. This assembly contains functions of PROM and CALPAC. If power to ECM is removed, MEMCAL information is retained.

NOTE:

Components are grouped into 2 categories. The first category is INPUT

DEVICES, consisting of components which control or produce voltage signals

monitored by the control unit. The second category is OUTPUT SIGNALS,

consisting of components controlled by the control unit.

INPUT DEVICES

Vehicles are equipped with different combinations of input devices. Not all devices are used on all models. To

determine the input device usage on a specific model, see appropriate wiring diagram in L - WIRING

DIAGRAMS article in this section. The available input signals include:

A/C ON (A/C REQUEST) SIGNAL

The air conditioner "on" switch is mounted in instrument panel. This switch provides a simple "on" ("A/C

request") signal, which is monitored by the ECM. The ECM uses this signal to determine control of the A/C

clutch relay (if equipped) and to adjust idle speed when air conditioner compressor clutch is engaged. On some

models, ECM may also activate radiator cooling fan when this signal is present. If this signal is not present on

A/C equipped vehicles, vehicle may idle rough when A/C compressor cycles. To check function of the A/C

switch, perform functional check of switch. See I - SYSTEM/COMPONENT TESTS article in this section.

BATTERY VOLTAGE

Battery voltage is monitored by ECM. If battery voltage swings low, a weak spark or improper fuel control may

result. To compensate for low battery voltage, ECM may increase idle speed, advance ignition timing, increase

ignition dwell or enrichen the air/fuel mixture. If voltage swings high, ECM may set a charging system fault

code and turn on SERVICE ENGINE SOON light. If voltage signal swings excessively low (less than 9 volts)

or excessively high (16 volts, most models), ECM shuts down for as long as condition exists. If condition is

short-term, SERVICE ENGINE SOON light flickers and vehicle may stumble. Vehicle stalls if condition lasts

long enough.

BRAKE SWITCH FEEDBACK

On models equipped with cruise control systems, ECM may monitor the brake switch circuit to determine when

to engage and disengage cruise control. On vehicles equipped with a Torque Converter Clutch (TCC), one

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 4

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

circuit of brake switch is in series with the power supply for the TCC solenoid located in automatic

transmission.

COOLANT TEMPERATURE SENSOR (CTS)

The CTS is a thermistor (temperature sensitive resistor) located in an engine coolant passage. The ECM

supplies and monitors a 5-volt signal to CTS. This monitored 5-volt signal is then modified by resistance of the

CTS. When coolant temperatures are low, CTS resistance is high and the ECM sees a high monitored voltage

signal. When coolant temperatures are high, CTS resistance is low and the ECM sees a low monitored voltage.

When fully warmed, CTS should reflect a temperature of at least 185F (85C).

Coolant temperature input is used in the control of fuel delivery, ignition timing, idle speed, emission control

devices and converter clutch application. A CTS which is out of calibration will not set a trouble code, but can

cause fuel delivery and driveability problems. A coolant sensor circuit problem should set a related trouble

code.

CRANK SIGNAL

Crank signal is a 12-volt signal monitored by the ECM. Signal is present when ignition switch is in the START

position. The ECM uses signal to determine the need for starting enrichment. ECM also cancels diagnostics

until engine is running and 12-volt signal is no longer present.

DIGITAL RATIO ADAPTER CONTROLLER (DRAC)

DRAC compensates for various axle and tire ratios by monitoring the Vehicle Speed Sensor (VSS) signal and

modifying it before passing it on to the ECM and speedometer unit.

FUEL PUMP FEEDBACK

ECM monitors fuel pump circuit between fuel pump relay/oil pressure switch and fuel pump. This enables the

ECM to determine if fuel pump is being energized by fuel pump relay or back-up oil pressure switch. A failure

in this monitored circuit results in the setting of a related trouble code in ECM memory.

GEAR SWITCHES

Gear switches are located inside automatic transmission. Switches may be normally open or closed and change

status depending upon internal hydraulic pressures. ECM uses high gear switch information in controlling

emission components and engagement of Torque Converter Clutch (TCC).

KNOCK SENSOR

The knock sensor is a piezoelectric device which detects abnormal engine vibrations (spark knock) in the

engine. This vibration results in the production of a very low AC signal, which is sent from the knock sensor to

the ESC controller or the MEM-CAL portion of the ECM (on models equipped with 4L80-E transmission). The

ECM then retards ignition timing until the engine knock ceases.

For additional information on knock sensor operation, see ESC DETONATION RETARD OPERATION under

IGNITION TIMING CONTROL SYSTEMS (GASOLINE).

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 5

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

A fault in the ESC circuit may set a related trouble code. When a related trouble code is not present and the

ESC system is the suspected cause of a driveability problem, perform functional check of ESC system. See I SYSTEM/COMPONENT TESTS article in this section.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor measures changes in manifold pressure. Changes in manifold pressure result from engine load

and speed changes. The MAP sensor converts these changes in manifold pressure into a voltage output signal to

ECM (1.5 volts at idle to 4.5 volts at WOT). The ECM can monitor these signals and adjust air/fuel ratio and

ignition timing under various operating conditions.

If MAP sensor fails, the ECM substitutes a fixed MAP value, and uses the TPS to control fuel delivery. A fault

in the MAP circuit should set a related trouble code. If a related trouble code is not present and MAP sensor is

suspected of causing a driveability problem, perform functional check of MAP sensor. See I SYSTEM/COMPONENT TESTS article in this section.

MANIFOLD AIR TEMPERATURE (MAT) SENSOR (2.5L & 4.3L TURBO)

MAT sensor is a thermistor (temperature sensitive resistor) mounted in the intake manifold. Low intake air

temperature produces high internal sensor resistance, while high temperature causes low internal sensor

resistance. The ECM supplies and monitors a 5-volt signal to sensor through a pull-down resistor in ECM.

MAT sensor, also known as an intake air temperature sensor, allows ECM to determine intake air temperature.

ECM uses signal to delay EGR until intake air temperature reaches about 40F (5C). If intake air temperature

becomes excessively high, ECM compensates by slightly retarding timing. After a vehicle has sat overnight,

MAT and CTS signals (resistance and temperature) should be close to same reading. Failure in MAT sensor

circuit should set a related trouble code.

CAUTION: Measure O2 sensor voltage with a Digital Volt-Ohmmeter (10-megohm

impedance) only. Current drain of a conventional voltmeter could damage

sensor.

OXYGEN (O2) SENSOR

The O2 sensor is mounted in the exhaust system and monitors oxygen content of exhaust gases. The oxygen

content causes the Zirconia/Platinum-tipped O2 sensor to produce a voltage signal which is proportional to

exhaust gas oxygen concentration (0-3%) compared to outside oxygen (20-21%). This voltage signal is low

(about .1 volt) when a lean mixture is present and high (about 1.0 volt) when a rich mixture is present. As ECM

compensates for a lean or rich condition, this voltage signal constantly fluctuates between high and low,

crossing a .45-volt reference voltage supplied by ECM on the O2 sensor signal line. This is referred to as "cross

counts".

The O2 sensor does not function properly (produce voltage) until its temperature reaches 600F (316C). At

temperatures less than the normal operating range of the sensor, vehicle functions in "open loop" mode, and

ECM does not make air/fuel adjustments based upon O2 sensor signals, but uses TPS and MAP or MAF values

to determine air/fuel ratio from a table built into memory. When ECM reads a voltage signal greater than .45

volt from the O2 sensor, ECM begins to alter commands to injector to produce either a leaner or richer mixture.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 6

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Once vehicle has entered "closed loop", a fault in the O2 circuit (cooled-down sensor or open or shorted O2

sensor circuit) is the only thing which can return vehicle to open loop. A problem in the O2 sensor circuit

should set a related trouble code.

On the 4.3L turbocharged engine, O2 sensor uses an internal heating element. Heating element allows O2

sensor to warm more quickly, allowing fuel system to enter closed loop operation sooner. Heating element also

prevents fuel system from re-entering open loop operation, which would be a normal response to prolonged

idling.

PARK/NEUTRAL (P/N) SWITCH

This switch is connected to transmission gear selector and signals ECM when transmission is in Park or Neutral.

ECM uses this information for determining control of ignition timing, converter clutch and idle speed. To check

function of P/N switch, perform functional check of switch. See I - SYSTEM/COMPONENT TESTS article

in this section.

POWER STEERING (P/S) SWITCH (2.5L)

This switch informs ECM of engine load conditions which exist when steering wheel is turned from center to

full lock position. ECM uses this information to help control idle speed. To check function of P/S switch,

perform functional check of switch. See the article I - SYSTEM/COMPONENT TESTS in this section.

PRESSURE SWITCH MANIFOLD (PSM) (4L80-E TRANSMISSION)

The PSM is actually 5 pressure switches combined into a single unit mounted on the transmission valve body.

The PCM supplies battery voltage on 3 separate wires to PSM. By grounding one or more of the switches in

various combinations, PCM detects what gear range the vehicle operator has selected.

RPM REFERENCE SIGNAL

ECM monitors RPM through ignition module tach/pulse signals (on circuit No. 430) produced by the HEI

module (RPM reference line of 4-wire EST connector) or camshaft position sensor signal (Hall Effect signal on

2.5L). ECM uses signal to determine control of timing, fuel delivery, EGR function and idle speed. ECM also

uses signal to trigger fuel injectors.

THROTTLE POSITION SENSOR (TPS)

The TPS is a variable mechanical resistor connected directly to the throttle shaft linkage. The TPS has 3 wires

connected to it. One is connected to a 5-volt reference voltage supply from ECM, another is connected to ECM

ground and the third is the signal return which is monitored by ECM. The voltage signal from the TPS varies

from closed throttle (.5-1.0 volt) to wide open throttle (4.5-5 volts). ECM uses this signal to determine control

of fuel, idle speed, spark timing and converter clutch. A problem in the TPS circuit may set a related trouble

code.

TRANSMISSION TEMPERATURE SENSOR (TTS) (4L80-E TRANSMISSION)

TTS is a thermistor (temperature sensitive resistor) mounted to the transmission valve body. The PCM supplies

and monitors a 5-volt signal to TTS. This monitored 5-volt signal is then modified by resistance of TTS. When

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 7

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

transmission fluid temperatures are low, TTS resistance is high and PCM sees a high monitored voltage signal.

When transmission fluid temperatures are high, TTS resistance is low and PCM sees a low monitored voltage.

PCM uses transmission fluid temperature input in control of converter clutch application and shift quality.

Sensor circuit problem should set a related trouble code.

VEHICLE SPEED SENSOR (VSS)

VSS is a Permanent Magnet (PM) generator mounted in transmission or transfer case. The VSS sends a pulsing

signal to either the ECM or Digital Ratio Adapter Controller (DRAC), which passes the signal on to the ECM.

ECM then converts this signal into Miles Per Hour (MPH) by monitoring the time interval between pulses.

ECM uses this sensor input in controlling converter clutch engagement.

OUTPUT SIGNALS

NOTE:

Vehicles are equipped with different combinations of computer-controlled

components. Not all components listed below are used on every vehicle. For

theory and operation of components, refer to indicated system.

A/C CLUTCH RELAY refer to MISCELLANEOUS ECM CONTROLS .

AIR INJECTION CONTROL SOLENOID see EMISSION SYSTEMS (GAS) .

CHARGE AIR COOLER PUMP RELAY (4.3L TURBO) refer to TURBOCHARGER .

COOLING FAN RELAY (3.1L) refer to MISCELLANEOUS ECM CONTROLS .

SERVICE ENGINE SOON LIGHT refer to SELF-DIAGNOSTIC SYSTEM .

EGR CONTROL SOLENOID VALVE refer to EMISSION SYSTEMS (GAS) .

ESC TIMING RETARD refer to IGNITION SYSTEM .

EVRV SOLENOID refer to EMISSION SYSTEMS (GAS) .

FUEL INJECTORS refer to FUEL CONTROL (GAS) .

FUEL MODULE refer to FUEL DELIVERY (GAS) .

FUEL PUMP & FUEL PUMP RELAY refer to FUEL DELIVERY (GAS) .

HEI-EST IGNITION refer to IGNITION SYSTEM .

IDLE AIR CONTROL (IAC) VALVE refer to IDLE SPEED (GAS) .

SELF-DIAGNOSTICS refer to SELF-DIAGNOSTIC SYSTEM .

SERIAL DATA refer to SELF-DIAGNOSTIC SYSTEM .

SHIFT SOLENOIDS (4L80-E TRANSMISSION) refer to MISCELLANEOUS ECM CONTROLS .

TORQUE CONVERTER CLUTCH refer to MISCELLANEOUS ECM CONTROLS .

TRANSMISSION SHIFT LIGHT (MANUAL TRANSMISSION) refer to MISCELLANEOUS ECM

CONTROLS .

TURBO BOOST RELAY (4.3L TURBO) refer to TURBOCHARGER .

WASTEGATE SOLENOID (4.3L TURBO) refer to TURBOCHARGER .

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 8

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

COMPUTERIZED ENGINE CONTROLS (DIESEL)

6.2L Diesel engine with light duty emissions uses Diesel Electronic Control (DEC) system. DEC system

consists of Electronic Control Module (ECM), input devices and output signals. DEC system electronically

controls EGR system operation, Torque Converter Clutch (TCC) engagement, cold advance and glow plug

system.

ELECTRONIC CONTROL MODULE (ECM)

Electronic Control Module (ECM) is located in passenger compartment, behind glove box. It constantly

monitors information from various sensors to control EGR, TCC, cold advance and glow plug systems. ECM

processes input signals from sensors and then sends necessary electrical responses to control these systems.

The ECM performs the diagnostic function of the DEC system. It can recognize operational problems, alert

driver through the SERVICE ENGINE SOON light and store codes which identify problem areas to technicians

making system repairs.

MEMORIES

ECM uses 3 types of memory:

READ ONLY MEMORY (ROM) ROM is programmed information which only ECM can read. ROM

program cannot be changed. If battery voltage is removed, ROM information is retained.

RANDOM ACCESS MEMORY (RAM) RAM is the scratch pad for the CPU. Data input, diagnostic

codes and results of calculations are constantly updated and temporarily stored in RAM. If battery voltage

is removed from ECM, all information stored in RAM is lost.

PROGRAMMABLE READ ONLY MEMORY (PROM) PROM is factory programmed engine

calibration data which "tailors" ECM for specific transmission, engine, emission, vehicle weight and rear

axle ratio application. PROM can be removed from ECM. If battery voltage is removed, PROM

information is retained.

INPUT DEVICES

Each sensor or switch furnishes electronic (voltage) signals to ECM. The ECM uses these input signals to

control EGR, TCC, cold advance and glow plug systems. Various models are equipped with different

combinations of input devices. Not all devices are used on all models. To determine the input usage on a

specific model, refer to L - WIRING DIAGRAMS article in this section. The available input signals include:

COOLANT TEMPERATURE SENSOR (CTS)

CTS is a thermistor (temperature sensitive resistor). A coolant temperature of -40F (-40C) produces a high

resistance (100,000 ohms), while a coolant temperature of 266F (130C) produces a low resistance (70 ohms).

1 ECM supplies a 5-volt reference signal through an internal resistor 11to CTS and measures return voltage.

Voltage is high when coolant temperature is low, and low when coolant temperature is hot. By measuring

voltage, ECM knows engine coolant temperature. Engine coolant temperature affects cold advance and glow

plug systems.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 9

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

MAP sensor, mounted on left side of cowl, monitors vacuum in the EGR system. It senses the actual vacuum in

the EGR vacuum line and sends a signal to the ECM.

The signal is compared to the EGR duty cycle calculated by the ECM. If there is a minor difference in the

vacuum value sensed and the ECM command, the ECM corrects. When a major difference is sensed, the ECM

recognizes a fault and sends a full EGR signal.

THROTTLE POSITION SENSOR (TPS)

TPS, mounted on the injection pump, is a variable resistor monitoring throttle opening angle for the ECM. The

sensor is connected to a 5-volt reference signal and has a high resistance value when throttle is closed. At wide

open throttle, the TPS resistance value is low, and output to the ECM will be near 5 volts.

ENGINE SPEED SENSOR

The engine speed sensor is a camshaft driven pick-up and is mounted at center rear of engine. The sensor

receives a 5-volt reference signal and allows the ECM to measure engine RPM by the number of times

reference voltage is pulsed. The engine speed sensor pulses 4 times per revolution.

VEHICLE SPEED SENSOR (VSS)

Mounted on the transmission, VSS sends a pulsing signal to ECM for vehicle speed calculation. This

calculation is used to control TCC engagement.

OUTPUT SIGNALS

NOTE:

Output signals are regulated by the ECM to maintain correct driveability and

exhaust emissions. For theory and operation of components, refer to indicated

system.

ELECTRONIC CONTROLLER/GLOW PLUG RELAY refer to FUEL CONTROL (DIESEL) .

COLD ADVANCE CONTROL refer to FUEL CONTROL (DIESEL) .

TORQUE CONVERTER CLUTCH refer to MISCELLANEOUS ECM CONTROLS .

EXHAUST GAS RECIRCULATION SYSTEM refer to EMISSION SYSTEMS (DIESEL) .

FUEL SYSTEM (GASOLINE)

FUEL DELIVERY (GAS)

FUEL MODULE (7.4L, 5.7L G VAN & 5.7L OVER 8500 GVWR)

Fuel module overrides the ECM 2-second timer and fuel pump runs 20 seconds before shutting off when

vehicle is not started. This added circuit corrects hot restart problems which could cause vapor lock during high

ambient temperatures.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 10

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

FUEL PUMP

An in-tank electric fuel pump delivers fuel to injector(s) through an in-line fuel filter. The pump is designed to

supply fuel pressure in excess of vehicle requirements. The pressure relief valve in the fuel pump controls

maximum fuel pump pressure.

On TBI fuel systems, pressure regulator is mounted on throttle body. On Port Fuel Injection (PFI) systems,

pressure regulator is mounted on the fuel rail. Regulator keeps fuel available to injector(s) at a constant

pressure. Excess fuel is returned to fuel tank through pressure regulator return line.

When ignition switch is turned to ON position, ECM turns on electric fuel pump by energizing fuel pump relay.

ECM keeps pump on if engine is running or cranking (ECM is receiving reference pulses from ignition

module). If there are no reference pulses and vehicle is not equipped with a fuel module, ECM turns pump off

within 2 seconds after key is turned on. For additional information, see FUEL PUMP RELAY and FUEL

MODULE under FUEL DELIVERY (GAS) .

FUEL PRESSURE REGULATOR (TBI)

A constant fuel pressure of 9-13 psi (.6-9 kg/cm2 ) is maintained by a factory preset, nonadjustable, spring

loaded diaphragm contained within throttle body. Spring tension maintains a constant fuel pressure to injector

regardless of engine load.

FUEL PRESSURE REGULATOR (4.3L TURBO PFI)

Fuel pressure regulator is a diaphragm-operated relief valve with injector pressure on one side and manifold

pressure (vacuum) on the other. Pressure regulator compensates for engine load by increasing fuel pressure

when low manifold vacuum is experienced.

During periods of high manifold vacuum, regulator-to-fuel tank return orifice is fully open, keeping fuel

pressure on the low side of its regulated range. As throttle valve opens, vacuum to regulator diaphragm

decreases, allowing spring tension to gradually close off return passage. At wide open throttle (when vacuum is

at its lowest), return orifice is restricted, providing maximum fuel volume and maintaining constant fuel

pressure to injectors.

FUEL PUMP RELAY

When ignition switch is turned to ON position, ECM turns electric fuel pump on by energizing fuel pump relay.

ECM keeps relay energized if engine is running or cranking (ECM is receiving reference pulses from ignition

module). If there are no reference pulses, ECM turns pump off within 2 seconds after key on. See FUEL

MODULE under FUEL DELIVERY (GAS) .

As a back-up system to fuel pump relay, the oil pressure switch also activates fuel pump. The oil pressure

switch is normally open until oil pressure reaches approximately 4 psi (.28 kg/cm2 ). If fuel pump relay fails,

the oil pressure switch closes when oil pressure is obtained, and operates the fuel pump. An inoperative fuel

pump relay may result in extended cranking times due to the time required to build up oil pressure. Oil pressure

switch may be combined into a single unit with an oil pressure gauge sending unit or sensor.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 11

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

ECM monitors fuel pump circuit between fuel pump relay/oil pressure switch and fuel pump, enabling ECM to

determine if fuel pump is being energized by fuel pump relay or oil pressure switch. A failure in this monitored

circuit results in the setting of a related trouble code in ECM memory.

For additional information on fuel pump activation, refer to the following articles in this section:

F - BASIC TESTING

I - SYSTEM/COMPONENT TESTS

FUEL CONTROL (GAS)

The ECM, using input signals, determines adjustments to the air/fuel mixture to provide the optimum ratio for

proper combustion under all operating conditions. Throttle Body Injection (TBI) systems can operate in the

"open loop" or "closed loop" mode.

OPEN LOOP

When engine is cold and engine speed is greater than 400 RPM, ECM operates in open loop mode. In open

loop, ECM calculates air/fuel ratio based upon coolant temperature and Manifold Absolute Pressure (MAP)

sensor readings. Engine remains in open loop operation until O2 sensor reaches operating temperature, coolant

temperature reaches preset temperature and a specific period of time has elapsed after engine starts.

CLOSED LOOP

When O2 sensor reaches operating temperature, coolant temperature reaches a preset temperature and a specific

period of time has passed since engine start-up, ECM operates in closed loop. In closed loop, ECM controls

air/fuel ratio based upon O2 sensor signals (in addition to other input parameters) to maintain as close to a

14.7:1 air/fuel ratio as possible. If O2 sensor cools off (due to excessive idling) or a fault occurs in the O2

sensor circuit, vehicle once again enters open loop mode.

BATTERY VOLTAGE CORRECTION

ECM compensates for low battery voltage by increasing injector pulse width and increasing idle RPM. ECM is

able to perform these commands because of a built-in memory/learning function.

FUEL CUT-OFF

When ignition is turned off, injectors are de-energized to prevent dieseling. Injectors are not energized if RPM

reference pulses are not received by the ECM, even with ignition on. This prevents flooding before starting.

Fuel cut-off also occurs at high engine RPM to prevent internal damage to engine. Some models may also cut

off fuel injector signals during periods of sudden, closed throttle deceleration (when fuel is not needed).

THROTTLE BODY INJECTION

Injectors are located in throttle body unit. All models except 2.5L use 220 Series dual injector throttle body.

2.5L models use 700 Series single injector throttle body. Battery voltage is supplied to injector when ignition is

on. ECM energizes injector solenoid by providing a ground path through its internal circuitry. By regulating

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 12

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

injector ground circuit, ECM controls injector "on" time (pulse width) to provide proper amount of fuel to

engine.

Pressure regulator maintains pressure to injector at 9-13 psi (.6-.9 kg/cm2 ). Excess fuel passes through pressure

regulator and returns to fuel tank.

In the "run" mode, ECM uses tach (RPM) signal to determine when to pulse injector. Fuel injectors are pulsed

once for each engine revolution; each spray provides 1/2 the fuel required for the combustion process. Thus, 2

injections of fuel (2 rotations of crankshaft) are mixed with incoming air to produce the fuel charge for each

combustion cycle. On models equipped with dual injectors in the throttle body, injectors are pulsed alternately.

Internal ECM calibration controls fuel delivery during starting, clear flood mode, deceleration and heavy

acceleration.

STARTING During engine starts, ECM delivers one injector pulse for each distributor reference pulse

received (synchronized mode). Injector pulse width is based upon coolant temperature and throttle

position. ECM determines air/fuel ratio when throttle position is less than 80 percent open. Engine

starting air/fuel ratio ranges from 1.5:1 at -33F (-36C) to 14.7:1 at 201F (94C). At lower coolant

temperatures, injector pulse width is wider (richer air/fuel mixture ratio). When coolant temperature is

high, injector pulse width becomes narrower (leaner air/fuel ratio).

CLEAR FLOOD If engine is flooded, driver must depress accelerator pedal to Wide Open Throttle

(WOT) position. At this position, ECM adjusts injector pulse width equal to an air/fuel ratio of 20:1. This

air/fuel ratio is maintained as long as throttle remains in wide open position and engine speed is less than

600 RPM. If throttle position becomes less than 80 percent open and/or engine speed exceeds 600 RPM,

ECM changes injector pulse width to that used during engine starting (based upon coolant temperature

and manifold vacuum).

HEAVY ACCELERATION ECM provides fuel enrichment during heavy acceleration. Sudden opening

of throttle valve causes rapid increase in MAP signal. Pulse width is directly related to MAP, throttle

position and coolant temperature. Higher MAP and wider throttle angles give wider injector pulse width

(richer mixture). During enrichment, injector pulses are not in proportion to distributor reference signals

(non- synchronized). Any reduction in throttle angle cancels fuel enrichment.

DECELERATION During normal deceleration, fuel output is reduced. This reduction in available fuel

serves to remove residual fuel from intake manifold. During sudden deceleration, when MAP, throttle

position and engine speed are reduced to preset levels, fuel flow is cut off completely. This deceleration

fuel cut-off overrides normal deceleration mode. During either deceleration mode, injector pulses are not

in proportion to distributor reference signals.

PORT FUEL INJECTION (PFI)

Individual, electrically pulsed injectors (one per cylinder) are located in intake manifold fuel rails. These

injectors are next to intake valves in cylinder head.

PFI system features simultaneous double-fire injection. Fuel injectors are pulsed once for each engine

revolution; each spray provides 1/2 the fuel required for the combustion process. Thus, 2 injections of fuel (2

rotations of crankshaft) are mixed with incoming air to produce the fuel charge for each combustion cycle.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 13

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Constant fuel pressure to the injectors is maintained by the fuel pressure regulator. Air/fuel mixture is regulated

by the length of time injector stays open (pulse width). The ECM controls pulse width using information

provided by various sensors.

IDLE SPEED (GAS)

ECM controls engine idle speed depending upon engine operating conditions. The ECM senses engine

operating conditions and determines the best idle speed.

IDLE AIR CONTROL (IAC) VALVE

The IAC valve controls engine idle speed to prevent stalling during engine load changes. The IAC valve is

mounted on throttle body and controls the amount of air by-passed around the throttle plate. The IAC valve

controls engine idle speed by moving its pintle in and out in steps referred to as "counts" (0 counts, fully seated;

255 counts, fully retracted). Counts can be measured by plugging a Scan tester into the Assembly Line Data

Link (ALDL).

If engine RPM is too low, pintle is retracted and more air is by-passed around the throttle plate to increase

engine RPM. If engine RPM is too high, pintle is extended and less air is by-passed around the throttle plate to

decrease engine RPM. Normal counts on an idling engine should be 4-60. When engine is idling, ECM

determines proper positioning of IAC valve based on battery voltage, coolant temperature, engine load and

engine RPM.

If IAC valve is disconnected or reconnected with engine running, IAC loses its reference point and must be

reset. On some models, IAC is reset by turning ignition on and off. Other models require driving vehicle at

normal operating temperature over 35 MPH with circuit properly connected. Problems in IAC circuit should set

a related code.

The IAC valve affects only the idle system. If valve is stuck fully open, excessive airflow into the manifold

creates a high idle speed. Valve stuck closed allows insufficient airflow, resulting in low idle speed. For

calibration purposes, several different IAC valves are used. Ensure replacement valve is proper design.

FUEL SYSTEM (DIESEL)

FUEL DELIVERY (DIESEL)

A mechanical pump is mounted on the right side of engine block. Camshaft eccentric drives pump. Pump pulls

fuel from the fuel tank through a primary filter. The fuel is then pumped through a secondary filter, mounted on

firewall (pickups) or rear of air cleaner (vans), and to the injection pump.

The 6.2L diesel engine uses a mechanical, high pressure rotary diesel injection pump, which is gear-driven by

camshaft at camshaft speed. Pump injects a precisely metered amount of fuel to each cylinder at the proper

time.

High pressure fuel lines carry the fuel to an injection nozzle in each cylinder. All fuel lines are the same length

to ensure no variance in timing. A rotary fuel metering valve controls engine RPM. As the accelerator pedal is

depressed, throttle linkage opens fuel metering valve to allow increased fuel delivery.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 14

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

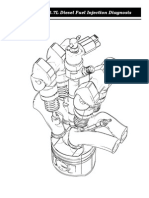

DIESEL INJECTION PUMP

The high pressure diesel injection pump is mounted at top of engine, below intake manifold. The pump is geardriven by camshaft. Pump precisely governs time and amount of fuel injection.

A built-in fuel pressure regulator and transfer pump picks up fuel at pump inlet, pushing it through a passage to

the pump head. The pump head distributes fuel at transfer pump pressure 8-12 psi (.5-.8 kg/cm2 ) to metering

valve, governor and automatic advance mechanisms. Fuel then passes to rotary fuel metering valve and into a

charging passage. As pump shaft rotates, fuel is directed at high pressure through each delivery pipe to an

injector.

Fig. 1: Identifying Diesel Injection Pump Components

Courtesy of GENERAL MOTORS CORP.

FUEL INJECTION LINES

Eight high pressure fuel injection lines are routed from the injection pump to an injector in each cylinder. The

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 15

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

lines are of equal length to prevent a difference in timing between cylinders. Lines are not interchangeable and

are pre-bent by the manufacturer.

FUEL CONTROL (DIESEL)

ELECTRONIC CONTROLLER/GLOW PLUG RELAY

The electronic controller/glow plug relay is mounted at rear of left cylinder head. It monitors and controls glow

plug operation. Controller uses four pins to determine glow plug operating requirements. Pin "B" senses voltage

at starter motor solenoid. Pin "C" senses glow plug voltage. Pin "D" supplies 12 volts, through cold advance

relay, to operate controller when coolant temperature is less than 80F (27C). Pin "E" is controller ground.

A normally operating system works as follows: at room temperature and with ignition on and engine off, the

glow plugs come on for 4-6 seconds and then go off for about 4.5 seconds. The glow plugs then cycle on for

about 1.5 seconds and off for about 4.5 seconds, for a total start sequence of about 20 seconds. If the engine is

cranked during or after start sequence, the glow plugs will cycle on and off for a total of 25 seconds after the

ignition switch is returned from the crank position, whether engine starts or not.

GLOW PLUGS

Glow plugs are small 6-volt heaters, powered by 12 volts to give rapid heating. Electronic controller operates

glow plugs, which cycle on when ignition switch is turned to the RUN position (prior to starting the engine).

The glow plugs remain pulsing a short time after engine starting, then automatically turn off.

The glow system for the LH6 (light duty emissions version) is different than the system for the LL4 (heavy duty

emissions version). The LH6 system has the same glow plugs, glow plug controller and WAIT light. However,

there is no temperature inhibit switch. Instead, the ECM, which receives temperature information from the

coolant temperature sensor located in the water crossover of the engine, controls glow plug temperature inhibit.

The computer transposes this temperature information into a voltage signal, which it sends to the cold advance

relay, ignition circuit and glow plug controller. The cold advance relay is located at the junction block in the

engine compartment on the right side of the cowl. For diagnostic information on computer controlled system,

see the article below

G - TESTS W/CODES - DIESEL

CAUTION: Using a jumper wire on by-pass relay causes glow plug failure.

GLOW PLUG INHIBIT SWITCH

The LL4 (heavy duty emissions version of 6.2L engine) is equipped with a glow plug inhibit switch. The inhibit

switch is calibrated to open above 125F (51.5C) to prevent glow plug operation above this temperature.

Two types of inhibit switches are used. Switches can be identified by their cap color. A switch with a Black cap

is a temperature-controlled switch. The other switch (with a non-Black cap) is an optional switch which is

always closed to allow for more frequent cycling of glow plugs.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 16

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

GLOW PLUG AFTER-START

Glow plug controller provides glow plug operation after starting a cold engine. This after-start operation is

initiated when ignition switch is returned to RUN from START position.

INJECTION NOZZLES

Each of the 8 combustion chambers is equipped with an injection nozzle. The injection nozzle has a single fuel

inlet fitting and 2 fuel return fittings (one on each side of fuel inlet fitting). The nozzle is threaded into the

cylinder head. Injection nozzles are spring loaded and calibrated to open at a specified fuel line pressure. The

combustion chamber end of the nozzle has a replaceable compression seal and carbon stop seal.

HOUSING PRESSURE COLD ADVANCE (HPCA)

The HPCA circuit is used to improve cold starting and aid in emission control. On light duty emissions (LH6

models), an ECM signal activates the HPCA circuit. On heavy duty emissions (LL4 models), a coolant

temperature switch located on rear of right cylinder head controls the HPCA circuit. The circuit advances

injection timing about 4 degrees when engine is cold.

When engine temperature is below 80F (27 C), the circuit decreases housing pressure from 10 psi (.7 kg/cm2 )

to zero. Meanwhile, the fast idle solenoid is activated. When the temperature switch opens, the HPCA circuit is

de-energized and housing pressure rises, retarding pump timing. The temperature switch closes again when

engine temperature falls below 85F (30C).

COLD ADVANCE CONTROL

The cold advance control circuit is designed to advance injection pump timing about 4 degrees during cold

engine operation. ECM activates this circuit through the cold advance relay to energize the cold advance

solenoid. The ECM opens the circuit when coolant temperature is above 95F (35C).

When coolant temperature is below the switching point and with ignition on, the cold advance solenoid is

continuously energized without the engine running. When coolant temperature is below the switching point and

with the engine running, injection pump housing pressure is decreased from 10 psi (.7 kg/cm2 ) to zero, which

advances injection pump timing by about 4 degrees. As engine warms, the cold advance solenoid is deenergized and the injection pump housing pressure is returned to 10 psi (.70 kg/cm2 ).

IDLE SPEED (DIESEL)

CURB IDLE SPEED

Curb idle is controlled by mechanical adjustment of the low idle speed screw. For idle speed adjustment

procedure, see CURB IDLE under IDLE SPEED (DIESEL) in D - ADJUSTMENTS article.

FAST IDLE SPEED

Fast idle solenoid controls fast idle. For adjustment of fast idle speed, see FAST IDLE under IDLE SPEED

(DIESEL) in D - ADJUSTMENTS article.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 17

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

IGNITION SYSTEM (GASOLINE)

WARNING: High Energy Ignition Electronic Spark Timing (HEI-EST) system can

produce more than 50,000 volts.

HIGH ENERGY IGNITION ELECTRONIC SPARK TIMING (HEI-EST) DISTRIBUTOR

The Delco-Remy HEI-EST system consists of distributor housing, rotor, cap, 7 or 8-terminal ignition module,

magnetic pick-up, pole piece, pick-up coil, connecting harness and the EST portion of the ECM. The distributor

is connected to the EST system by a 4-wire connector leading to Electronic Control Module (ECM).

No vacuum or centrifugal advance mechanisms are used. Based upon monitored input signals, ECM controls all

spark timing changes. Some models use an additional Electronic Spark Control (ESC) system, which retards

timing in case of engine detonation (knock). Most models are equipped with sealed ignition coil and ignition

module connectors.

When the external teeth on the timing core approach, align with and pass the pick-up coil windings, an

alternating current is produced in the pick-up coil windings. In the cranking mode, this alternating current

signals switching transistors in the HEI module to make or break the ignition coil primary ground circuit. Once

the engine starts, ECM takes control of primary ground circuit (EST mode).

When the primary ground circuit is removed, the magnetic field created by the flow of current in the primary

windings collapses across the primary and secondary windings of the coil. This induces a high-voltage surge in

the secondary windings of the coil. Secondary voltage is then discharged to the rotor, which distributes voltage

to the appropriate spark plug terminal. Depending on application, the distributor module may have either a 7terminal or an 8-terminal (sealed connector) ignition module.

The 2.5L HEI-EST system is also equipped with a Hall Effect switch located inside of the distributor. The Hall

Effect switch produces a camshaft signal which is used by the ECM to trigger injectors. Loss of the camshaft

signal results in a no-start condition.

IGNITION TIMING CONTROL SYSTEMS (GASOLINE)

IGNITION TIMING ADVANCE

At engine speeds less than 400 RPM, ignition module controls spark advance by triggering coil(s) at a

predetermined interval based on engine speed only. At engine speeds greater than 400 RPM (EST mode), ECM

controls ignition timing.

ECM controls ignition timing based upon input signals from engine RPM reference line (ignition module),

coolant temperature sensor, manifold air temperature sensor, throttle position sensor, knock sensor, vehicle

speed sensor, gear position switch and MAP sensor.

The PROM portion of the ECM has a programmed spark advance curve based on engine speed. ECM calculates

spark timing whenever an ignition pulse is present. Spark advance is controlled only when engine is running

(not during cranking). ECM uses input signal values to modify PROM information, increasing or decreasing

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 18

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

spark advance to achieve maximum performance with minimum emissions. To check ignition system operation,

see BASIC DIAGNOSTIC PROCEDURES or I - SYSTEM/COMPONENT TESTS article.

REFERENCE (RPM) Ignition module converts alternating current signals from pick-up coil to digital

signals which are used to trigger ignition coil. On models without Hall Effect sensor, the ignition module

passes signal to the ECM. On 2.5L models equipped with Hall Effect sensor, the Hall Effect switch

produces a separate signal for use by the ECM. The ignition module or Hall Effect signal supplies RPM

data and crankshaft position reference to the ECM. Since the signal on this circuit is used as an injector

trigger reference on fuel injected vehicles, engine will not run if circuit is open or grounded.

BY-PASS When the ECM receives an engine speed signal of approximately 400 RPM, it considers

engine to be running and applies 5 volts to the ignition module on the by-pass wire. This causes ignition

module to switch timing control over to the variable timing control circuit in the ECM. On some models,

this by-pass wire contains a connector located between the 4-wire connector and the ECM. This is

disconnected when adjusting base timing. On all models, an open or grounded by-pass circuit sets a

related trouble code in ECM memory. The engine runs at base timing plus a small amount of advance

built into the HEI module.

EST When 5 volts is present on by-pass circuit and ignition module has turned control of engine timing

over to ECM, ECM advances or retards spark on this circuit based on calculations involving reference

signal and other sensor input signals. If base timing is incorrectly set, entire advance curve will be

incorrect.

GROUND This is the reference ground circuit. It is grounded at distributor and ECM, ensuring there is

no voltage drop in the EST circuit which could affect ignition operation.

ESC DETONATION RETARD OPERATION

Some models use an Electronic Spark Control (ESC) retard system along with the HEI-EST system. System

consists of a knock (detonation) sensor, a high energy ignition system, an ESC controller (some models) and the

ECM. On some models, the function of the ESC controller is built into the Memory Calibration (MEM-CAL)

unit of the ECM.

When engine knock (detonation) occurs, knock sensor produces a low voltage AC signal. This signal goes to

the ESC controller or directly to the MEM-CAL unit inside the ECM, depending upon application.

On models using an ESC controller, controller supplies the ECM with a 12-volt signal. When detonation occurs,

controller grounds the 12-volt signal to the ECM, pulling the signal down to near zero volts. The ECM

interprets this as a signal to retard timing. The ECM then retards spark timing until the ESC controller returns

the 12-volt signal. If signal wire becomes open or grounded on models using ESC controller, ECM continuously

provides full ignition timing retard.

On vehicles using ECMs containing MEM-CAL units, the ECM supplies a 5-volt DC reference signal on the

knock sensor signal line. Internal circuitry of the knock sensor pulls this voltage down to about 2.5 volts. When

knock occurs, the knock sensor produces an AC voltage signal which rides on the 2.5-volt DC signal to the

ECM. The voltage and frequency of this signal depend upon knock signals received by the sensor. The ECM

retards spark timing until signals from detonation sensor cease.

A malfunction in the ESC circuit should set a related trouble code. If a code is not present and ESC system is

suspected cause of driveability problems, perform functional check of ESC system. See I ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 19

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

SYSTEM/COMPONENT TESTS article.

EMISSION SYSTEMS (GAS)

AIR INJECTION SYSTEM

Air Injection Reaction (AIR) system is used to reduce carbon monoxide (CO) and hydrocarbon (HC) emissions.

The AIR system provides additional oxygen to continue combustion process after exhaust gases leave the

combustion chamber. This added air also brings catalytic converter up to operating temperature more quickly

when engine is cold. The AIR system diverts air either to the exhaust manifold ports or to the air cleaner.

The system consists of an air pump, an Electric Air Control (EAC) valve (2.8L engine) or an electric air control

valve with relief tube (4.3L and V8 engines), solenoid, check valve(s) and plumbing.

NOTE:

On EAC valve, divert and signal tube locations are reversed from previous

model year.

ELECTRIC AIR CONTROL (EAC) VALVES WITH RELIEF TUBE

When engine is cold or at wide open throttle, ECM energizes solenoid on valve, and air is directed to exhaust

manifold ports. When coolant temperature increases, solenoid is de-energized and air goes into air cleaner. At

higher engine speeds, air is directed to air cleaner through pressure relief valve (if equipped), even though

solenoid may be energized. Air should not be entering exhaust manifold during closed loop mode. During

deceleration, the increased manifold vacuum signal directs air to air cleaner. Check valve on air injection pipe

prevents exhaust gases from entering air pump. Solenoid is de-energized under rich mixture condition or if

SERVICE ENGINE SOON light is on.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 20

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Fig. 2: Cross-Sectional View of EAC Valve

Courtesy of GENERAL MOTORS CORP.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 21

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Fig. 3: Cross-Sectional View of EAC Valve With Relief Tube

Courtesy of GENERAL MOTORS CORP.

AIR PUMP

The air pump is a belt-driven, positive displacement vane-type pump. A centrifugal filter mounted behind the

pulley purges air drawn into pump of dirt and contaminants. The air pump is permanently lubricated and

requires no periodic service.

CHECK VALVES

Check valves prevent the backflow of exhaust gases into the air injection system. Check valves close when

exhaust gas pressure in exhaust manifold exceeds pressure delivered by pump. This occurs when air pump bypasses at high speeds, when air delivery is switched to catalytic converter, when air is diverted to either

atmosphere or air cleaner or when air pump malfunctions.

AIR MANAGEMENT SYSTEM

When ECM energizes electronic air control solenoid on a cold vehicle, air is allowed to flow through control

valve to exhaust manifold. As coolant temperature increases or system enters closed loop, ECM opens solenoid

ground circuit, de-energizing control solenoid. Air is then routed to air cleaner.

CATALYTIC CONVERTER

A 3-way catalytic converter with dual bed is used to reduce exhaust emissions. This type of converter can

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 22

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

reduce hydrocarbons (HC), carbon monoxide (CO) and oxides of nitrogen (NOx).

The upstream section of the converter contains a reducing/oxidizing bed to reduce NOx while oxidizing HC and

CO. An air supply pipe from the AIR system injects air between the beds of the converter. Thus, the second

converter bed oxidizes any remaining HC and CO to efficiently reduce exhaust emissions.

EXHAUST GAS RECIRCULATION (EGR)

The Exhaust Gas Recirculation (EGR) system is designed to reduce oxides of nitrogen (NOx) emissions by

lowering combustion temperatures. A metered amount of exhaust gas is recirculated into the intake manifold

and mixed with the air/fuel mixture.

There are 2 types of EGR systems used. Port EGR is used on 2.8L, 3.1L, 4.3L ("S" and "T" Series), 7.4L and

5.7L (over 8500 GVWR). Negative backpressure EGR is used on 2.5L, 4.3L (except "S" and "T" Series), 5.0L

and 5.7L (under 8500 GVWR).

PORT EGR

Port EGR valve is controlled by manifold vacuum regulated by an ECM-controlled solenoid. Vehicles equipped

with 4L80-E transmissions use a pulse width-modulated EGR vacuum control solenoid, referred to as an

Electronic Vacuum Regulator Valve (EVRV).

NEGATIVE BACKPRESSURE EGR

Vacuum is applied to upper EGR diaphragm via a hose connected to intake manifold vacuum. Manifold

vacuum is also applied to lower EGR diaphragm (through intake port at base of EGR valve).

When manifold vacuum in lower chamber is insufficient to overcome spring tension on lower diaphragm, bleed

valve closes, allowing vacuum in upper chamber to open EGR valve. With engine at idle or under light load,

high manifold vacuum applied to lower chamber opens air bleed valve in lower diaphragm. This bleeds off

vacuum in upper chamber, keeping the EGR valve closed.

EVAPORATIVE EMISSION CONTROL

All vehicles use carbon canister storage for evaporative fuel control. Evaporative emission control system stores

gasoline fumes from fuel tank in a carbon canister until fumes can be drawn into engine for burning during

combustion process.

The 4 basic components which may be used in evaporative emission system are activated carbon canister (all

models, open at top or bottom for fresh air intake), vacuum operated canister control valve (4.3L and V8 high

altitude, mounted remotely), thermostatic vacuum switch (2.8L and 3.1L, mounted in coolant passage in intake

manifold) and tank pressure control valve (4.3L and V8 high altitude, mounted in hose between canister and

fuel tank). For specific component application and vacuum hose routing, see M - VACUUM DIAGRAMS

article.

CARBON CANISTER

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 23

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Evaporative fumes from fuel tank are vented through hose(s) into a canister containing activated carbon.

Activated carbon absorbs and holds fuel vapors when engine is not operating. When engine is started and

engine speed is greater than idle (purge at idle would cause too rich a mixture), engine vacuum draws fuel

vapors from canister into engine. A vacuum canister purge valve or thermostatic vacuum switch regulates

vapors through this purge line.

Carbon canisters are open in design. When the engine is started, engine vacuum draws outside air into canister

either through the top or bottom, and then through a filter in bottom of canister. This helps to purge vapors from

the activated carbon.

CANISTER CONTROL VALVE (CCV) (HIGH ALTITUDE 4.3L EXCEPT "S" & "T" SERIES & V8)

CCV is vacuum operated. When the engine is not running, vapor from the fuel tank is stored in the carbon

canister. When the vehicle is started, vacuum to the upper port draws in the internal vacuum diaphragm,

opening the port between the canister and purge valve. When engine is off, internal spring pressure closes valve

diaphragm, preventing vapor from venting to atmosphere.

The canister control valve acts as both vapor vent valve and purge valve. When engine is running, manifold

vacuum from PCV system pulls lower diaphragm upward. When engine is operating above idle speed, control

vacuum pulls upper diaphragm upward. This allows purging of canister through PCV system.

THERMOSTATIC VACUUM SWITCH (2.8L & 3.1L)

A wax pellet-type thermostatic vacuum switch is installed in the engine coolant passage in the intake manifold.

Two vacuum fittings on switch connect to charcoal canister and the TBI unit. When coolant temperature is less

than 115F (46C), switch closes, preventing purging of canister. When coolant temperature increases to greater

than 115F (46C), switch opens, allowing purging of canister.

FUEL TANK PRESSURE CONTROL VALVE (HIGH ALTITUDE 4.3L EXCEPT "S" & "T" SERIES & V8)

Fuel tank pressure control valve allows vapors to flow from the fuel tank into the EEC system. When fuel tank

pressure exceeds the spring pressure on the valve diaphragm, the valve opens and allows vapors to either enter

canister or, when purge is enabled, go directly to the engine.

The tank pressure control valve is located inside the gas cap on the 3.1L, in the engine compartment on "C" and

"K" Series and near the fuel tank on other models.

POSITIVE CRANKCASE VENTILATION (PCV)

The PCV system provides more effective elimination of crankcase vapors. Fresh air from the air filter housing

is supplied to the crankcase, where it is mixed with blow-by gases and passed through a PCV valve into the

intake manifold. This mixture is then passed into the combustion chamber and burned.

The PCV valve provides primary control in this system by metering the flow (according to manifold vacuum) of

the blow-by vapors. When manifold vacuum is high (at idle), the PCV restricts the flow to maintain a smooth

idle condition.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 24

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

Under conditions in which abnormal amounts of blow-by gases are produced (such as worn cylinders or rings),

system is designed to allow excess gases to flow back through crankcase vent hose into air inlet.

Spring pressure holds PCV valve closed when engine is not running. This prevents hydrocarbon fumes from

collecting in the intake manifold, a condition which could result in hard starting.

During engine operation, manifold vacuum pulls the valve open against spring pressure, permitting crankcase

fumes to enter the intake manifold. Should the engine backfire, the PCV valve closes to prevent ignition of

fumes in crankcase.

THERMOSTATIC AIR CLEANER (TAC)

Many models are equipped with a system for preheating the air entering the throttle body during cold engine

operation.

This system maintains incoming air temperature to a point where fuel injection system can maintain lean

air/fuel ratios to reduce hydrocarbon (HC) and carbon monoxide (CO) emissions. TAC systems are either

vacuum motor controlled or wax pellet controlled.

VACUUM MOTOR CONTROLLED (2.8L & 3.1L)

This system consists of an air cleaner assembly with integral air control door, vacuum control temperature

sensor, vacuum motor, heat shroud (on exhaust manifold), heated air tube and vacuum hoses.

- VACUUM CONTROL TEMPERATURE SENSOR The vacuum control temperature sensor controls

the operation of the air control door. During initial start-up situations, this valve directs engine vacuum to

the air control vacuum motor. The motor closes the air intake door, allowing the intake of heated

manifold air. When the intake air temperature reaches a pre-calibrated value, this valve opens, allowing

the intake of cooler outside air.

AIR CONTROL DOOR The air control door temperature sensor closes when the temperature of air

entering the air cleaner is less than the calibrated temperature of the temperature sensor. This allows

engine vacuum to operate the air control door vacuum motor, and warm manifold air to be routed to the

throttle body.

VACUUM MOTOR When engine vacuum is applied to the vacuum motor, the air control door stops the

intake of outside air. The air cleaner then draws in air from around the exhaust manifold. As air inside the

air cleaner warms, the temperature sensor begins to open, bleeding off vacuum to the vacuum motor. As

vacuum to vacuum motor decreases, the air control door begins to open. As air control door opens,

outside air is allowed to enter air cleaner assembly. When air entering air cleaner reaches a predetermined

temperature, the air control door opens completely and stops the intake of heated air.

WAX PELLET CONTROLLED (EXCEPT 2.8L & 3.1L)

A self-contained, wax pellet actuated assembly mounted in the air cleaner controls the air regulator damper

(hot/cold air delivery door). When incoming air is cold, wax material sealed in the actuator is in a solid

contracted state. As incoming air warms, wax material expands by changing to a liquid state. This forces piston

outward, repositioning air regulator damper and allowing air (either a mix of hot and cold or all cold) to enter

engine.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 25

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

EMISSION SYSTEMS (DIESEL)

EXHAUST GAS RECIRCULATION (EGR)

NOTE:

For additional information on 6.2L light duty emission EGR system, see G TESTS W/CODES - DIESEL article.

The Exhaust Gas Recirculation (EGR) system limits formation of oxides of nitrogen (NOx) emissions by

reducing peak combustion chamber temperatures in which NOx is formed. EGR system consists of EGR valve,

Exhaust Pressure Regulator (EPR) valve, EPR and EGR vent solenoids and EGR fault detection. A vacuum

pump is required to provide a vacuum source to operate the EGR system.

EGR VALVE

EGR valve reintroduces a small amount of exhaust gas into combustion chamber, diluting air/fuel mixture and

reducing combustion chamber peak temperatures, thereby reducing NOx formation.

EPR VALVE

The EPR valve is mounted between the exhaust manifold and the exhaust pipe. Valve increases exhaust

backpressure during idle, which increases exhaust flow through EGR system. EPR valve resembles the EFE or

heat riser type valves of earlier, carbureted vehicles. A vacuum diaphragm-type actuator opens and closes valve.

An ECM-controlled EGR/EPR solenoid regulates actuator.

EGR/EPR SOLENOIDS

EGR/EPR solenoids are mounted at rear of engine as a single assembly. Using input from engine speed sensor

and TPS, ECM controls EGR by controlling amount of "on" and "off" time of EGR solenoid. When EGR is not

needed, ECM energizes EGR vent solenoid to vent vacuum. Vacuum which controls EGR valve controls EPR

valve. ECM energizes EPR solenoid to close EPR valve at idle to increase exhaust backpressure.

EGR FAULT DETECTION

The ECM uses input from the MAP sensor to measure amount of absolute pressure in EGR vacuum line. If a

minor variation between calculated EGR and actual EGR is monitored by ECM, the ECM corrects. If variation

is too great for ECM to correct, an error is detected. The ECM then enters default mode and sets a related

trouble code in memory.

VACUUM PUMP

A vacuum pump is mounted on the engine and provides vacuum for operating emission controls (light duty

emissions), transmission modulator (heavy duty emissions with M40 automatic transmission), cruise control

and heater and A/C servos. The vacuum pump is either belt- or gear-driven.

The belt-driven vacuum pump, used on "G" and "P" Series, is bracket mounted to the right front of the engine.

Except for the pulley, the vacuum pump is replaced as an assembly.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 26

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer

E - THEORY/OPERATION' '1991 ENGINE PERFORMANCE General Motors Theory & Operation

The gear-driven pump, used on "R" and "V" Series, is mounted at the top rear of the engine and contains a

permanently-mounted speed sensor. Pump is driven by a cam inside the drive assembly to which it mounts. On

the lower end of the drive housing assembly is a drive gear which meshes with the camshaft gear in the engine.

The drive gear causes the cam in the drive housing to rotate.

CAUTION: The vacuum pump drives the engine oil pump. DO NOT run engine with

gear-driven vacuum pump removed.

CRANKCASE DEPRESSION REGULATOR (CDR)

The CDR valve, located on the right valve cover, is used on both light and heavy duty diesel engines. Valve

prevents crankcase pressure from accumulating during idle by regulating (metering) crankcase pressure back

into the engine. Intake manifold vacuum acts against a spring-loaded diaphragm to control flow of crankcase

gases. Higher intake manifold vacuum levels pull diaphragm closer to the top of the outlet tube, reducing

amount of gases drawn from crankcase. As intake manifold vacuum drops, spring pressure pushes diaphragm

away from top of outlet, allowing more gases to flow from crankcase into intake manifold.

Optimum pressure in crankcase is one inch of water (as measured with a manometer) at idle to 3-4 inches at full

load. Too little vacuum causes oil leaks; too much vacuum pulls oil into the air crossover.

SELF-DIAGNOSTIC SYSTEM

The ECM is equipped with a self-diagnostic system which detects system failures or abnormalities. When a

malfunction occurs, ECM illuminates the SERVICE ENGINE SOON light located on instrument panel. When

malfunction is detected and light is turned on, a corresponding trouble code is stored in ECM memory.

Malfunctions are designated as either "hard failures" or "intermittent failures". For procedures on retrieving

stored codes, see appropriate SELF-DIAGNOSTICS article below:

G - TESTS W/CODES - DIESEL

G - TESTS W/CODES - GASOLINE

G - TESTS W/CODES - TRANSMISSION (If Trans. Codes Are Displayed)

"HARD FAILURES"

Hard failures cause SERVICE ENGINE SOON light to glow and remain on until malfunction is repaired. If

light comes on and remains on during vehicle operation, cause of malfunction must be determined using

diagnostic charts located in appropriate SELF-DIAGNOSTICS article below:

G - TESTS W/CODES - DIESEL

G - TESTS W/CODES - GASOLINE

G - TESTS W/CODES - TRANSMISSION (If Trans. Codes Are Displayed)

If a sensor fails, ECM uses a substitute value in its calculations to continue engine operation. Although vehicle

is functional in this condition, driveability will probably be adversely affected.

ESYPRO

Martes, 22 de Septiembre de 2009 09:30:57 a.m.

Page 27

2005 Mitchell Repair Information Company, LLC.

1991 Chevrolet S10 Blazer